Operating and Maintenance Instructions

210-OMI13277_Iss1.doc ORIGINAL INSTRUCTIONS Page 9 of 15

ebm-papst UK Ltd, 2012

Chelmsford Business Park Chelmsford Essex CM2 5EZ

Telephone: +44(0)1245468555 Fax: +44(0)1245466336

Constant Pressure Control, Operation

For use with ebm-papst EC products with 0-10V control input in HVAC constant pressure systems. Can also be

used with a pressure tapped inlet ring to provide a constant air volume system

The controller uses an external pressure sensor. The controller is suitable for use with the DS85 Series

Differential Pressure Sensor, or compatible 0-10V output pressure sensor.

The user should select a pressure sensor which covers the pressure range required (0-500Pa is typical).

The controller uses a PID control program to vary the fan speed as required to maintain the pressure at the set

value.

The pressure set-point(s) are set by rotary DIP switch(es) or by a second 0-10V input which allows the Set-point

to be adjusted by an external Potentiometer or 0-10V BMS signal. Selection between the Set-points is by means

of Switched Live or Volt Free select inputs, see table below.

The maximum fan speed can be limited if desired, see below.

Constant Pressure Control, Commissioning

Low / Single Pressure Set-point (Default setting if SL1 and Volt Free Select Inputs not connected

Refer to the datasheet for the pressure sensor used, to determine the sensor output voltage at the required

pressure set-point, then adjust rotary switch S2 to select the value closest to the required point, see table below.

High / Second Pressure Set-point, if used (See table for select input use

Refer to the datasheet for the pressure sensor used, to determine the sensor output voltage at the required

pressure set-point, then adjust rotary switch S3 to select the value closest to the required point, see table below.

BMS / External Potentiometer Set-point, if used (See table for select input use

If selected, the Set-point voltage will be the voltage present on 0-10V Input 2 (min/max not limited by S2/S3).

For local manual control an ebm-papst RM-ECv is recommended. This can provide min/max limits if required.

Set the Maximum Fan Speed:

Set the Maximum Fan Speed control voltage using variable resistor R2. Normally the setting will be fully

clockwise to allow full fan speed. If reduced maximum fan speed is required, adjust R2 for the required maximum

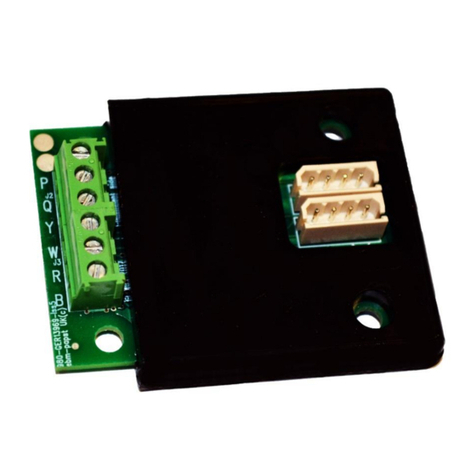

fan speed control voltage which will be three times the voltage measured on test point R2, see “PCB Component

Location” below.

Note: There is no minimum fan speed setting for Constant Pressure operation.

Constant Pressure Control PID Program Response Speed

Set R1 to mid position and monitor the operation of the system.

If the fan speed repeatedly overshoots (hunts), adjust R1 anti-clockwise.

If the fan speed is too slow to vary in response to changes in airflow demand, adjust R1 clockwise.

Constant Volume Operation (single fan operation only

By measuring the difference between the ambient inlet pressure and the pressure at a fan inlet ring, it is possible

to calculate air flow volume. If the pressure difference is kept constant, a constant volume system is established.

Inlet Rings: A special inlet ring is required which has hose connections to measure the pressure inside the inlet

ring. They also have a known K-factor, a constant relative to the airflow through the inlet ring, which is needed to

calculate the air volume. Contact ebm-papst for further information.