epro Sailor User manual

Single Channel Pipettes

Instruction Manual

Table of Contents

1. Product Description ............................................................... 1

2. Packing......................................................................................... 1

3. Pipette Design...........................................................................2

4. Safety Recommendations ...................................................3

5. Specications ........................................................................... 4

6. Pipette Operation ....................................................................5

7. Operating Instructions ........................................................ 8

8. Aspiration and Dispensing Instructions........................ 9

9. Checking Pipetting Accuracy Parameters

and Pipette Recalibration................................................... 11

10. Pipette Maintenance ...........................................................14

11. Troubleshooting ....................................................................15

12. Spare Parts................................................................................17

13. Limited Warranty ...................................................................19

Instruction Manual – 1

1. Product Description

The EPRO® Sailor™ single channel pipette isavolumetric

instrument designed to measure and transfer liquids

precisely and safely. It is available in volumes from 0.1μL to

1,000 μL in ve volume ranges: 0.1-2 µL, 0.5-10 µL, 2-20µL,

20-200µL, and 100-1,000 µL.

The EPRO® Sailor™ pipettes are available in three versions

which dier in the color of the ejector bush, pushbutton,

and shaft (red, yellow, and blue), depending on the volume

range of the pipettes and corresponding tip size.

Nominal

Volume (µL) Cat. No.

Range of Pipette

Volumes (µL)

Color

Code

2 EPS2 0.1 - 2 Red

10 EPS10 0.5 - 10

20 EPS20 2 - 20 Yellow

200 EPS200 20 - 200

1,000 EPS1000 100 - 1,000 Blue

The EPRO® Sailor™ pipettes operate using an air-cushion

(i.e.,theaspirated liquid does not come into contact with

the shaft or plunger of the pipette). The liquid is drawn into

thedisposable tip attached to the pipette.

2. Packing

The pipettes are delivered with the following:

Description Qty/Pk

Instruction manual (QR code) 1

Quality Control certicate 1

Calibration key 1

Wall mount 1

Lubricant (for single channel pipettes) 1

Ejector cap (for pipette models EPS2 and EPS10) 1

Color identication rings 6

Starter Kit

The EPRO® Sailor™ Pack (Cat. No. EPS2.20.200.1000) comes

with four individually boxed pipettes (EPS2, EPS20, EPS200,

and EPS1000) containing the packing items listed above,

a4-position plexi stand, and EPROTIPS™.

2 – EPRO® SAILOR™ PIPETTES

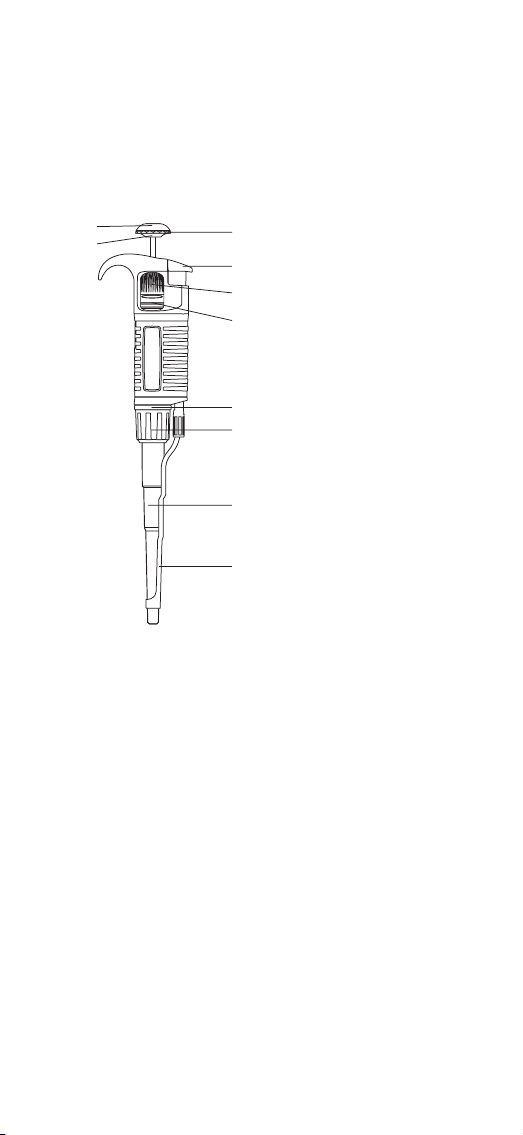

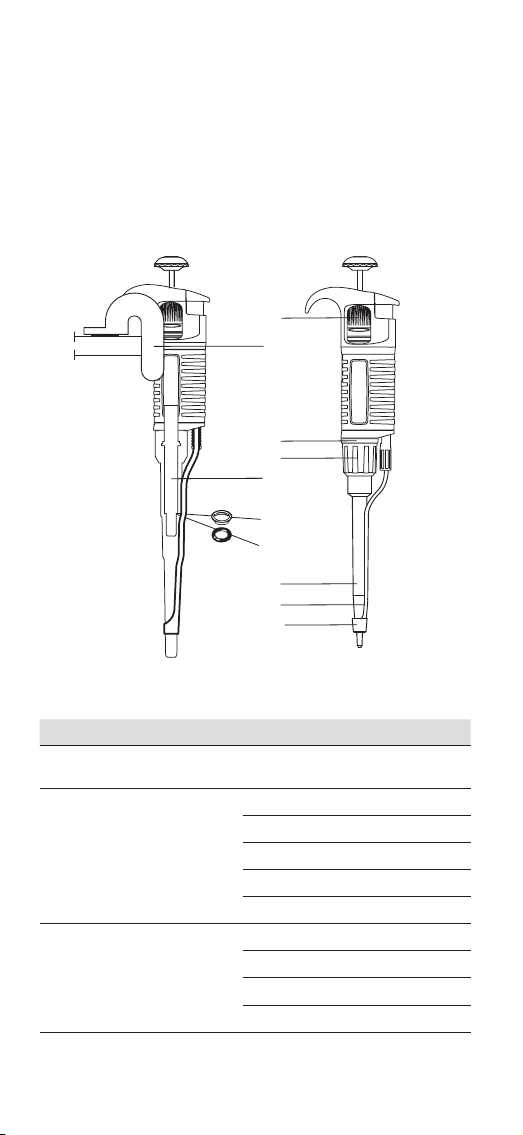

3. Pipette Design

Model Identication

The pipette shaft comes in red, yellow, and blue depending

on the volume range of the pipette. The volume range of

the pipette is also displayed on the pushbutton.

Pipetting pushbutton (A)

Ejector pushbutton (N)

Volume adjustment knob (B1)

Locking ring (B2)

Color identification ring (P)

Shaft (C)

Tip ejector (D)

Shaft nut (F)

A1

A2

A. Pipetting pushbutton: Consists of 2 parts:

thepushbutton (A1) and the knob (A2).

B1. Volume adjustment knob: Used to set thevolume.

B2. Locking ring: Allows the volume setting to be locked by

pushing the ring upwards.

C. Shaft: Manufactured using high quality plastic,

ensuring high chemical and mechanical strength.

D. Tip ejector

F. Shaft nut

N. Ejector pushbutton

P. Color identication ring

Instruction Manual – 3

4. Safety Recommendations

Long-term use of the pipette relies on correct method of use.

Please read and follow the instructions for use carefully.

Symbols used:

Danger, risk of injury.

NOTE Risk of damage to the pipette or errors in pipetting.

NOTE:

• The pipette is designed for the transfer of liquids only

using the tip. Do not aspirate liquids without the tip

attached. The aspirated liquid should not enter the

pipette, asit may cause damage.

• Single-use tips reduce the risk of contamination of

samples.

• Keep the pipette clean, avoiding the use of abrasive or

corrosive cleaning agents (e.g., acetone).

• Keep the pipette upright when there is liquid in the tip.

• Only using the pipette in accordance with the

manufacturer’s instructions ensures the correct pipette

parameters are maintained.

• After replacing the plunger or the shaft, the pipette

should be calibrated.

• In the case of incorrect operation, the device should

be cleaned in accordance with the Instructions for use

ortransferred to a service point.

• Ambient operating temperature is +5°C to 45°C.

• Ambient storage conditions (in the original packaging

during transport and short storage) is -25°C to 55°C.

When working with the pipette:

• Follow general work safety regulations regarding

hazards related to work in the laboratory.

• Take special care when pipetting aggressive substances.

• Use appropriate protective attire (e.g., clothing, goggles,

and gloves).

• Avoid pointing the pipette at yourself or others during use.

• Only use parts and accessories recommended by the

manufacturer.

4 – EPRO® SAILOR™ PIPETTES

5. Specications

The pipette is a high quality instrument which oers

excellent accuracy and precision. The accuracy and

precision (repeatability) of the liquid volume depends on

the quality of pipette tips used. The values for accuracy

and precision shown in the table below were obtained

using manufacturer non-lter pipette tips. Those tips

are recommended for use to ensure compatibility,

accuracy and precision when pipetting. The manufacturer

recommends using EPRO® tips.

Nominal

Volume

(μL)

Volume

(μL)

Accuracy

(%)

Precision

(%)

Non-lter

Tips (μL)

2

Min. 0.1 ±40.0 ≤12.0

10

0.2 ±12.0 ≤6.0

1 ±2.7 ≤1.3

Max. 2 ±1.5 ≤0.7

10

Min. 0.5 ±4.0 ≤2.8

10

1.0 ±2.5 ≤1.8

5.0 ±1.0 ≤0.6

Max. 10.0 ±0.5 ≤0.4

20

Min. 2 ±3.0 ≤1.5

20010 ±1.0 ≤0.5

Max. 20 ±0.8 ≤0.3

200

Min. 20 ±1.2 ≤0.60

200100 ±0.8 ≤0.25

Max. 200 ±0.6 ≤0.20

1,000

Min. 100 ±1.6 ≤0.40

1,000500 ±0.7 ≤0.20

Max. 1,000 ±0.6 ≤0.15

The accuracy and precision were obtained gravimetrically

using manufacturer tips performing at least 10measurements

ofdistilled water at a temperature of 20°C ± 1°C according to

ENISO 8655 standards.

The use of tips from other manufacturers or lter tips may

result in incorrect liquid aspiration and require pipette

recalibration.

The design of the pipette enables the user to recalibrate it

according to the information presented in Section 9.

Instruction Manual – 5

6. Pipette Operation

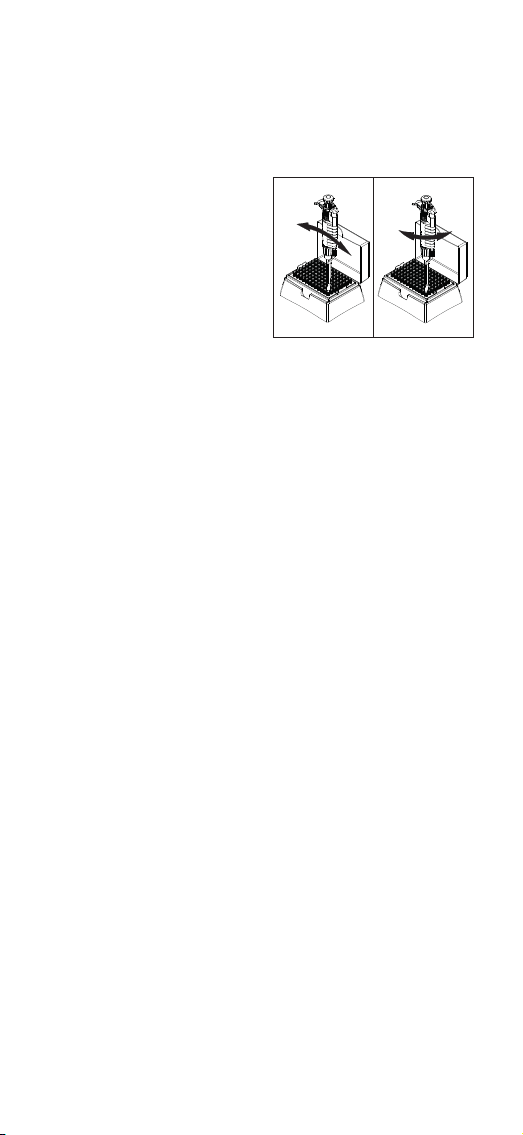

Attaching the Tips

• Attach the correct tip corresponding to the model number

displayed on the pipette pushbutton (Section5).

• Position the pipette

verticallywhen

attachingtips.

• Push the pipette tip

on rmlyusing a slight

twistingmotion to

ensureanairtight seal.

NOTE:

• Do not attach the tips with a rocking movement,

as this may damage the shaft or plunger. Observe this

rule particularly with single channel pipettes of low

volume range.

• Never draw liquids directly into the pipette without

thetip attached.

Adjusting the tip ejector

The tip ejector can be adjusted by the user and can

accommodate most types of tips available on the market.

When using narrow tubes, it may be necessary to remove

the tip ejector.

✓✕

6 – EPRO® SAILOR™ PIPETTES

1. Tip ejector disassembly

• Press the tip ejector pushbutton.

• Turn the metal tip ejector 1/3 turn counter-clockwise.

• Slide the ejector from the plastic arbor.

2. Tip ejector assembly

• Press the tip ejector pushbutton.

• Line the metal tip ejector up with the plastic arbor.

• Turn the metal tip ejector clockwise until it has fully

latched.

3. Tip ejector adjustment

• Remove the tip ejector pushbutton.

• To increase the ejector length turn the plastic bush

counter-clockwise.

• To decrease the ejector length turn the plastic bush

clockwise.

Instruction Manual – 7

If the tip ejector cannot be adjusted

suciently, or if the diameter of the

ejector is insucient to eject the tip, it

may be necessary to attach the ejector

cap “M” to the ejector.

For 2 and 10 μL pipettes place the cap,

supplied with the pipette, on the bottom

of the pipette shaft and slide thecap

upwards to the bottom of the tip ejector.

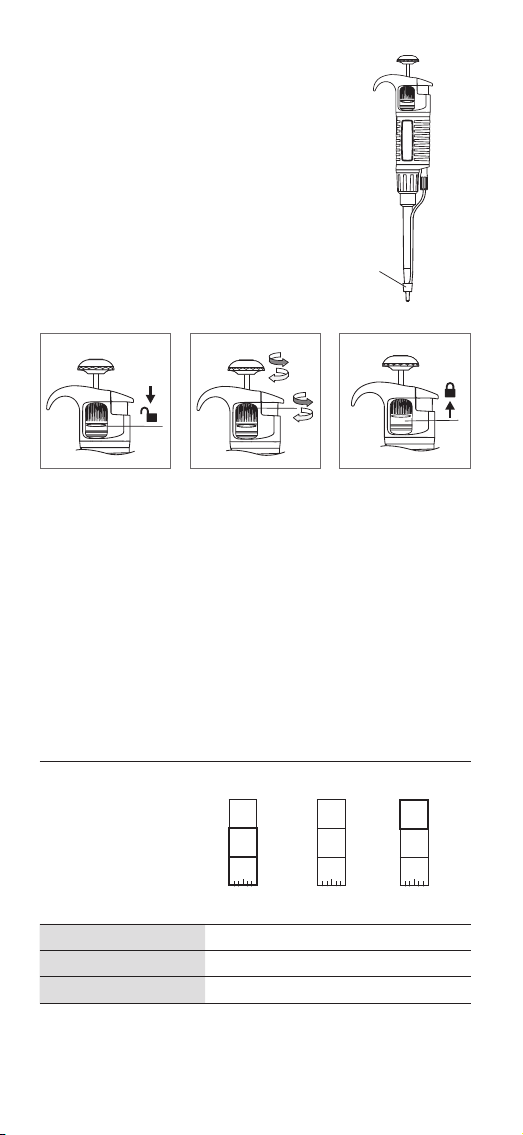

Volume Setting

1. 2. 3.

1. To enable volume selection, set the locking ring to the

lower position.

2. Aspiration volume can be set by either turning the

pipetting pushbutton knob, or the adjustment knob.

The volume setting is displayed as a three digit counter,

which should be read from top to bottom. The smallest

volume increment is printed on the bottom counter drum.

3. After the volume has been set, set the locking ring to the

upper position to avoid inadvertent changing of volume.

Examples of counter indications

The decimal point in the

volume of aspirated liquid

(µL or mL) is indicated by

change in colour of digits.

Black digits represent

integer numbers, and red

digits represent decimal

fractions (pipettes up to

20 μL).

1

2

5

red

red

0

3

5

0

7

5

red

Volume Ranges 0.1-2 µL 20-200 µL 100-1,000 µL

Set Volume 1.25 µL 35 µL 750 µL (0.75 mL)

Increment 0.002 μL 0.2 μL 2.0 μL

M

8 – EPRO® SAILOR™ PIPETTES

For maximum accuracy, the set volume must be approached

from a higher value by decreasing counter readings. Before

reaching the desired value, reduce the speed of turning

the adjustment knob to avoid inadvertently exceeding the

desired value.

7. Operating Instructions

Observing the following recommendations will ensure

maximum possible accuracy and precision of liquid sampling.

• During operation, the volume setting should be locked,

with black adjustment knob in the lower position.

• Ensure smooth and slow operation of the pipette.

• Immersion of the tip into the sample liquid should

be kept to a minimum depth, which should remain

constant during aspiration. The recommended

immersion depths are given in the table below:

Model Volume Range (µL) Immersion Depth (mm)

0.1-1 ≤1

1-100 2-3

101-1,000 2-4

• The pipette should be held in a vertical position.

• The pipette tip should be changed whenever the volume

setting is altered, and when a dierent liquid is to be

aspirated.

• The pipette tip should be changed if a droplet remains

on the end ofthe tip from the previous pipetting

operation.

• Each new pipette tip should be pre-rinsed with the

liquid to be pipetted.

• Liquid should never enter the pipette shaft. To prevent this:

– Press and release the pushbutton slowly and

smoothly.

– Never turn the pipette upside down.

– Never lay the pipette on its side when there is liquid in

the tip.

• Never force the volume setting beyond

therecommended limits.

Instruction Manual – 9

• When pipetting liquids with a dierent temperature

from the ambient temperature, it is recommended to

pre-rinse the tip several times prior to use.

• Do not pipette liquids with temperatures above 70°C.

NOTE: When pipetting acids or corrosive solutions which

emit vapors, it is recommended to disassemble the shaft

and rinse the plunger and O-ring with distilled water after

nishing the pipetting operation.

8. Aspiration and Dispensing Instructions

1. 2. 3. 5.4. 6.

Aspirating Liquid

1. Press the pushbutton to the rst stop point.

Holdingthe pipette vertically, immerse the pipette tip

into the sample liquid to the recommended depth (for

recommended values see Section 7). Ifthepipette tip

is not immersed to the recommended depth or if the

pipetting pushbutton is rapidly released, air may enter

the pipette tip.

2. Release the pipetting pushbutton slowly and smoothly

to aspirate the sample. Wait one second and then

withdraw the pipette tip from the liquid.

CAUTION: Do not touch the used tip.

10 – EPRO® SAILOR™ PIPETTES

Dispensing Liquid

3. Place the end of the pipette tip against the inside wall of

the vessel at an angle of 10° to 40°. Press the pushbutton

smoothly to the rst stop. Wait one second.

4. Press the pushbutton to the second stop to expel

any remaining liquid. While keeping the pushbutton

depressed, remove the pipette from the vessel by

drawing the pipette tip against the inside surface of

thevessel.

5. Release the pushbutton to its starting position.

6. Eject the pipette tip by pressing the tip ejector

pushbutton.

Remember to change the pipette tip whenever a

dierent type of liquid is to be sampled.

Aspirating High-density Liquids

When pipetting liquids of higher viscosity or lower surface

tension than water (e.g., sera or organic solvents), a lm

of liquid may be formed on the inside of the pipette tip

which may produce erroneous results. As the lm remains

relatively constant in successive pipetting operations with

the same tip, this error can be eliminated by pre-rinsing

the tip and allowing a lm to form before transferring the

rst sample. This is achieved by aspirating asample and

dispensing it back into the same vessel. Allowing a lm

to form prior to sampling ensures optimal accuracy and

repeatability.

This pre-rinsing operation should be repeated when

thevolume to be aspirated is changed or when a new

pipette tip is used.

NOTE: Normally the degree of error resulting from viscous

liquids is negligible if pipetting is performed slowly and

carefully, however can be minimized further by holding

the pipette tip in position for at least 2 seconds after

aspiration to allow the liquid time to react to the change

in pressure before it is dispensed.

If the above method does not result in accurate values,

recalibrate the pipette in accordance with Section 9.

It is recommended to record recalibration and correction

values, in order to facilitate reverse calibration to astandard

liquid.

Instruction Manual – 11

9. Checking Pipetting Accuracy Parameters

and Pipette Recalibration

The EPRO® Sailor™ pipettes have been factory-calibrated

using gravimetric methods with manufacturer pipette tips

and distilled water, in accordance with ISO 8655 guidelines

for the maximum (nominal) liquid volume drawn by the

pipette and for 10% of the maximum or minimum liquid

volume according to the values given (Section 5).

The EPRO® Sailor™ pipettes are designed to enable

recalibration and adaptation to dierent pipetting

techniques and liquid properties (e.g., temperature,

density, and viscosity).

Periodic checks of the operation of the pipette are

recommended at least once per year. Frequency of checks

should be increased depending on workload, sterilization

or autoclave processes, and frequency of replacement of

component parts.

If during pipette operation the accuracy error (the

dierence between the real aspirated volume and the

preset volume) exceeds the permissible value given

inthetable in Section 5, pipette recalibration should be

carried out.

Recalibration of the pipette involves volume adjustment

based on the value obtained by weighing. Recalibration of

the pipette is performed only for one liquid volume drawn

by the pipette.

The recommended volume for recalibration is 10% of the

maximum (nominal) value or minimum volume depending

on which of these values is greater. See table onpage 13 for

more details.

12 – EPRO® SAILOR™ PIPETTES

Parameters for Checking the Pipetting Accuracy

The pipetting accuracy is inuenced by factors such as:

tips used, characteristics of the pipetted liquid (density,

viscosity), and operating conditions (ambient temperature,

pressure).

To determine the accuracy error of the pipette, the following

conditions should be met:

• Ambient temperature and temperature of the pipette,

pipette tips, and liquid should be within the range of

20°C to 25°C and stabilized during weighing within

±0.5°C.

• Measurements should be conducted using distilled water.

• Balance sensitivity should be suitable for the volume “V”

to be measured.

Volume Checked (V, μL) Balance Sensitivity (mg)

0.1≤V≤10 0.001

10≤V≤100 0.01

100≤V≤1,000 0.1

• When calculating the liquid volume aspirated by

thepipette, the conversion factor (Z) [μL/mg] for

distilled water or a liquid with comparable density

should be taken into account. Sample values of

conversion factors are given in the following table.

Temperature

(°C)

Pressure (kPa)

95.0 101.3 105.0

20 1.0028 1.0029 1.0029

21 1.0030 1.0031 1.0031

22 1.0032 1.0033 1.0033

23 1.0034 1.0035 1.0036

24 1.0037 1.0038 1.0038

25 1.0039 1.0040 1.0040

See ISO 8655 for the full table of conversion factors (Z).

NOTE: Pipetting should be performed in accordance with

guidance described in Sections 7 and 8.

Checking the Pipetting Accuracy Parameters

• Set the preset volume depending on the pipette volume

according to the following table.

Instruction Manual – 13

Nominal

volume

(µL)

Preset

volume

(μL)

Permissible

values (μL)

Volume Change ΔV (μL) for a

Turn of a Calibration Key by

1 Turn 1 Increment

20.2 0.176 - 0.224 0.06 0.0025

10 1 0.975 - 1.025 0.33 0.0137

20 2 1.94 - 2.06 0.63 0.0262

200 20 19.76 - 20.24 6.30 0.262

1,000 100 98.4 - 101.6 25.00 1.04

• Perform 10 aspirations, and calculate the average value

in [mg].

• Calculate the volume in [μL] by multiplying the value

in[mg] by the conversion factor Z [μL/mg].

If the average aspirated volume exceeds the permissible

values of the range, the pipette should be recalibrated.

Pipette Recalibration

K

1. Remove the pipetting pushbutton.

CAUTION: The pipetting pushbutton consists of 2 parts:

the knob and the pushbutton. After removal of the

pushbutton, both parts are separated.

2. Holding the volume setting knob to prevent rotation,

insert the calibration key into the calibration screw.

3. Turn the key clockwise to reduce the aspirated volume,

or counter-clockwise to increase the aspirated volume.

Use the values given in the above table to precisely

adjust the volume.

K

1. K

K

K

2. 3. 4.

14 – EPRO® SAILOR™ PIPETTES

4. Remove the key and replace the pipetting pushbutton by

rst replacing the knob, then the pushbutton.

Determine the average aspirated volume. The average

volume should be within the permissible range given in

the table. If the volume exceeds the values stated, the

recalibration procedure should be repeated.

When pipetting liquids with physical properties

considerably dierent from those of water, follow

theguidance given in Section 5.

More information on the calibration procedure can be

found at www.eproscience.com and

https://shop.eproscience.com.

10. Pipette Maintenance

Depending on the applications and intensity of use, the

EPRO® Sailor™ pipette requires periodic maintenance.

Thecomponents exposed to corrosive vapors, such as

shaftelements, should be regularly checked and cleaned.

Do not use sharp tools for pipette maintenance. Itmay

cause damage to the device and aect the user’s safety.

Cleaning

External surfaces of the pipette such as the pushbutton,

ejector pushbutton, handgrip, shaft nut, and adjustment

knob may be cleaned using a cloth dampened in isopropyl

alcohol. The remaining parts removed from the pipette

during pipette disassembly may be washed with distilled

water or isopropyl alcohol.

NOTE: Before using cleaning agents other than those

recommended by the manufacturer, check the compatibility

charts and consider chemical resistance of the following

plastics which form components of the pipette: PP, PC,

POM, PA, PPS, PVDF.

Sterilization

Sterilization using an autoclave

The EPRO® Sailor™ pipettes can be sterilized in an

autoclave at 121°C for 20 minutes. Sterilization under

other conditions may cause damage to the pipette. It is

recommended to:

• Unscrew the shaft nut slightly. Prior to autoclaving, and

once autoclaving is nished, the nut should be screwed

tight again.

Instruction Manual – 15

• Set the locking ring to the lower (unlocked) position

prior tosterilization.

• Sterilize the pipettes using an autoclave with an initial

vacuum and drying cycle.

• After sterilization, the pipette should be dried and

cooled to room temperature.

Precision and accuracy should not alter if the pipetting

processes including autoclaving are carried out as

described in this manual. If a change in accuracy occurs,

itis recommended to:

• Check the calibration of the pipette after the rst,

third, and fth autoclaving cycles and then after every

10autoclaving cycles.

Ultra Violet (UV) Sterilization

The EPRO® Sailor™ pipettes are UV resistant. The distance

from the radiation source to the exposed element of the

pipette should be at least 50 cm. Prolonged or intense UV

exposure can cause discoloration of pipette parts but does

not aect its performance.

11. Troubleshooting

If a problem is encountered during pipette operation, use

the following table to identify and eliminate the fault

following the instructions provided. Replacement of parts

should be required only occasionally and should not be

required with normal pipette use.

Problem Cause Solution

Droplets of

liquid remain

in the pipette

tip.

The pipette tip is emptied

too fast.

Decrease the speed

of pressing the pipette

pushbutton.

The pipette tip wettability

has increased due to

extensive use.

Replace the tip with

a new one.

Droplets

of air appear

in the liquid

aspirated

into the

pipette tip.

The pipette tip immersion

depth is too shallow.

Immerse the tip

to the recommended

depth according to the

instructions.

The pipette tip is

incorrectly pressed onto

the pipette shaft.

Press the pipette

tip rmly onto the

pipette.

The tip is damaged or

worn out due to extensive

use.

Replace the tip with

a new one.

16 – EPRO® SAILOR™ PIPETTES

Problem Cause Solution

The pipette

incorrectly

aspirates

the liquid

or the liquid

drops out

from the tip.

The pipette tip is

incorrectly pressed onto

the pipette shaft.

Press the pipette

tip rmly onto the

pipette.

The shaft surface is

damaged or contaminated

at the sealing site.

Clean the shaft or

replace it with a new

one.

The plunger or the

O-ring is damaged due

toprolonged aspiration

ofcorrosive liquids.

Disassemble the

shaft set; wash the

shaft, the plunger and

the seal (Section 10:

Cleaning). Replace the

elements with new

ones if necessary.

Apply a small amount

of lubricant onto

the plunger and

reassemble the set

inthe correct order.

The inside of the pipette is

contaminated.

The sealing elements are

not suciently lubricated.

Uneven

work of the

pipetting set,

the pipetting

pushbutton

gets blocked.

The inside of the pipette

is contaminated due to

aspiration of corrosive

substances.

Unscrew the shaft

set, wash the parts.

Replace the elements

with new ones if

necessary. Apply

a small amount

of lubricant on

the plunger and

reassemble the set

inthe correct order.

The inside of the pipette is

contaminated due to the

liquid entering the pipette.

The sealing elements are

not suciently lubricated,

e.g. after repeated

autoclaving procedures.

Incorrect

aspiration.

Liquid with properties

other than water (density,

viscosity).

Calibrate the pipette

using the liquid which

is to be pipetted.

Tips with a lter with

increased ow resistance.

Calibrate the pipette

using the tips which

are to be used for

pipetting.

If the problem persists after carrying out the above steps,

contact our regional representative.

Before returning the pipette, please ensure the pipette

is completely free of any chemical, radioactive, or

microbiological contamination which could pose athreat

during transport and repair.

Instruction Manual – 17

12. Spare Parts

Contact our Customer Service to inquire about the

availability of spare parts. Pipette model and name of the

part required should be specied. The most common parts

are depicted below.

NOTE: The replacement of the plunger requires conducting

the calibration procedure according to Section 9.

I

J*

GG

B

F

P

C

D

M

S

Item Description Model Cat. No. Qty/Pk

BVolume adjustment

knob set

All ESP20221 1

C, I,

J*

Shaft with O-ring and

seal

2 ESP20222 1

10 ESP20223 1

20 ESP20224 1

200 ESP20225 1

1,000 ESP20226 1

D Tip ejector 2, 10 ESP20211 1

20 ESP20212 1

200 ESP20213 1

1,000 ESP20214 1

*Seal (J) used only in 2 µL model

18 – EPRO® SAILOR™ PIPETTES

Item Description Model Cat. No. Qty/Pk

F Shaft nut All ESP20210 1

G Plunger assembly 2 ESP20215 1

10 ESP20216 1

20 ESP20217 1

200 ESP20218 1

1,000 ESP20219 1

I, J* O-ring (and seal) 2 ESP20227 10

10 ESP20228 10

20 ESP20229 10

200 ESP20220 10

1,000 ESP20230 10

K Calibration key All ESP20231 1

M Tip ejector cap 2, 10 ESP20232 3

PColor indentication

rings

All ESP20233 6

S Wall mount All ESP20234 1

*Seal (J) used only in 2 µL model

Table of contents

Other epro Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Hydrotech

Hydrotech HSF2200 Series Operation & maintenance manual

Bungard

Bungard EXP3040LED instructions

Eaton

Eaton Airflex CB Installation & operation

Dustcontrol

Dustcontrol TPR 50 Original instructions

DUSTLESS BLASTING

DUSTLESS BLASTING DB150 user manual

KINSHOFER

KINSHOFER KM 506 HD operating instructions

TAAG

TAAG TIN KNOCKER MWETK-RFBL20 INSTRUCTIONS & PARTS DIAGRAM

Bosch

Bosch Rexroth BS 2/C Series Assembly instructions

Altronic

Altronic GTI Bi-Fuel Installation & operating manual

ABB

ABB Orion1 Base Original instructions

Emerson

Emerson Fisher ENVIRO-SEAL instruction manual

Eaton

Eaton PowerPass 9PXTFMR5 user guide