Martin Engineering M4097-05/18 1Martin®Air Cannon Controller - multiple circuit

Introduction

General The Martin®Air Cannon Controller is a reliable, practical system for firing

Martin®Air Cannons at predetermined intervals. The controller uses

programmable logic to energize the air cannons’ solenoids. It reduces the

chance for human error and is expandable to control multiple air cannons in

several structures where material flow problems exist.

The controller is used to fire cannons in a timed sequence. It is available with

up to 10 outputs.

Each controller has a factory-set on-time of 1 second and an adjustable off-

time of 1 to 65,000 seconds. Manual override selector knobs are mounted on

the outside of the enclosure.

Overview of

controller

operation

The controller can be used to fire air cannons in three ways:

• Manually fire individual cannons using the manual override selector knobs.

• Automatically fire all cannons in a timed sequence.

• Automatically fire all cannons in a timed sequence when activated by an

external switch.

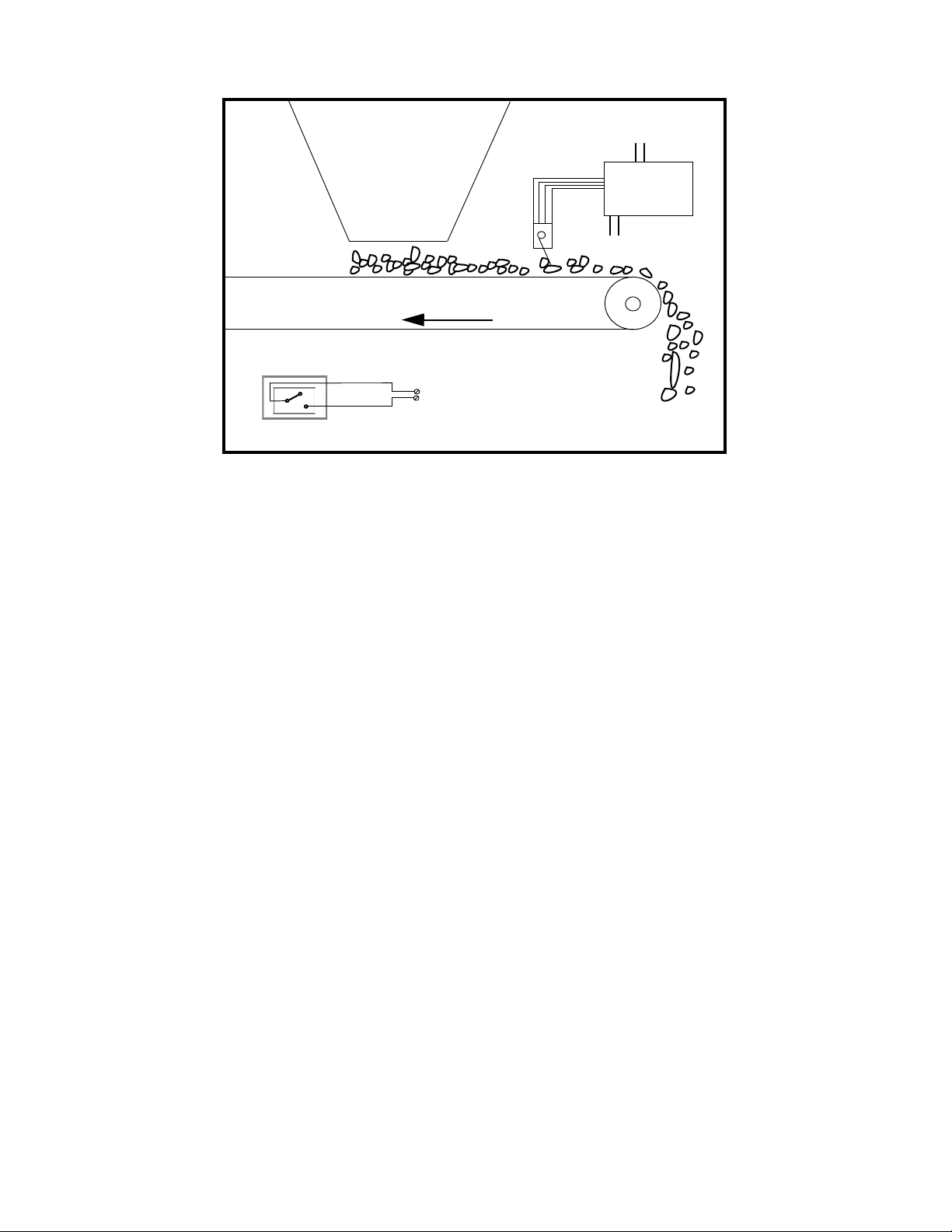

(An example of an external switch is a paddle-type flow switch that

monitors flow of material as shown in Figure 1. When material stops

flowing from the hopper, the flow switch inputs are closed and the controller

is enabled to begin the firing sequence. Whenever material is flowing from

the hopper, the flow switch inputs are opened and the controller is disabled;

the firing sequence is deactivated.)

To manually fire individual cannons, it is not necessary to program the

controller. The selected cannon fires when activated by the selector knobs on

the outside of the controller.

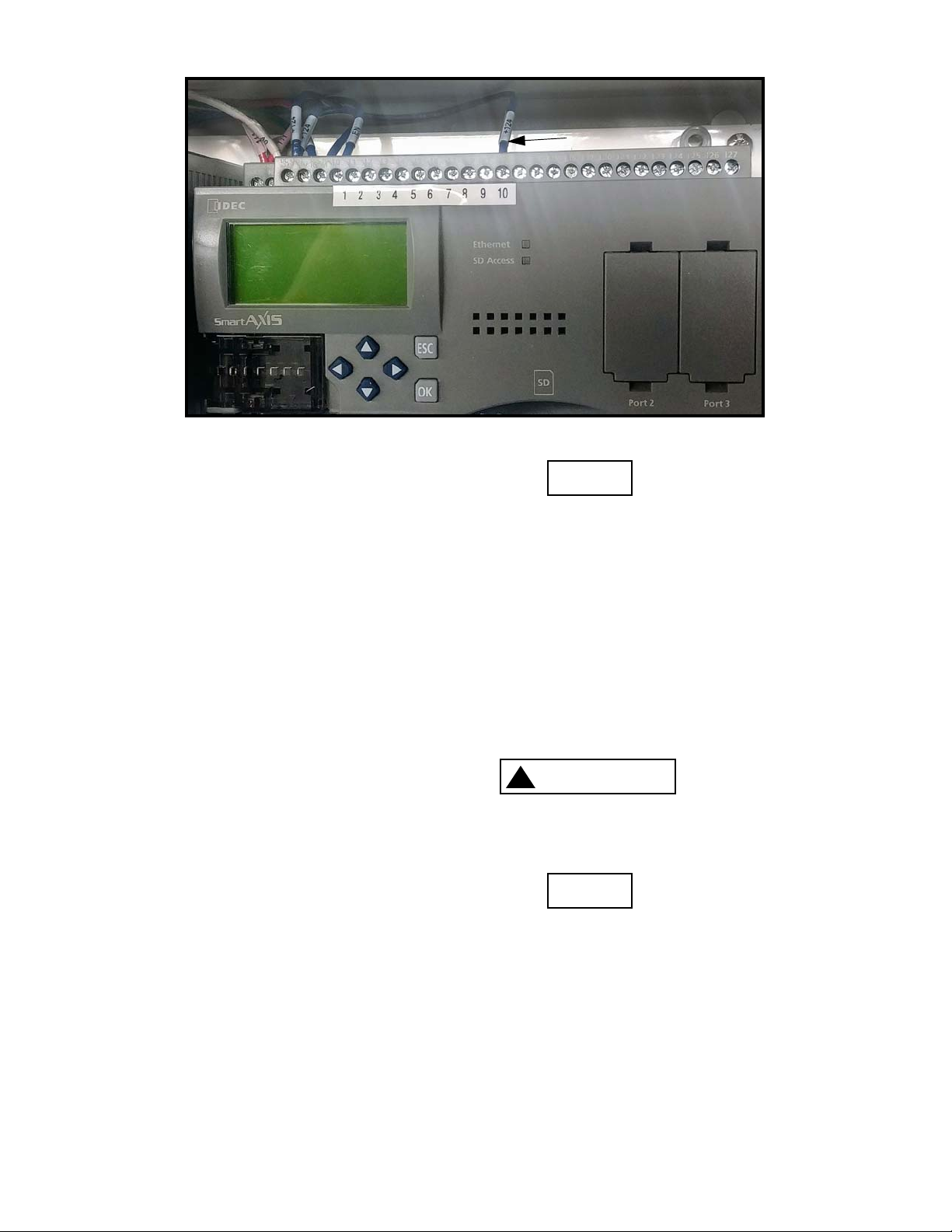

To automatically fire all cannons in a timed sequence, the controller must be

programmed for the desired number of air cannons to sequence (from 1 up to

10 air cannons) and the desired off-time (the length of time between each

cannon firing).

To automatically fire all cannons in a timed sequence when activated by an

external (flow) switch, the controller must be programmed as described

above, and the switch must be connected to the controller as follows:

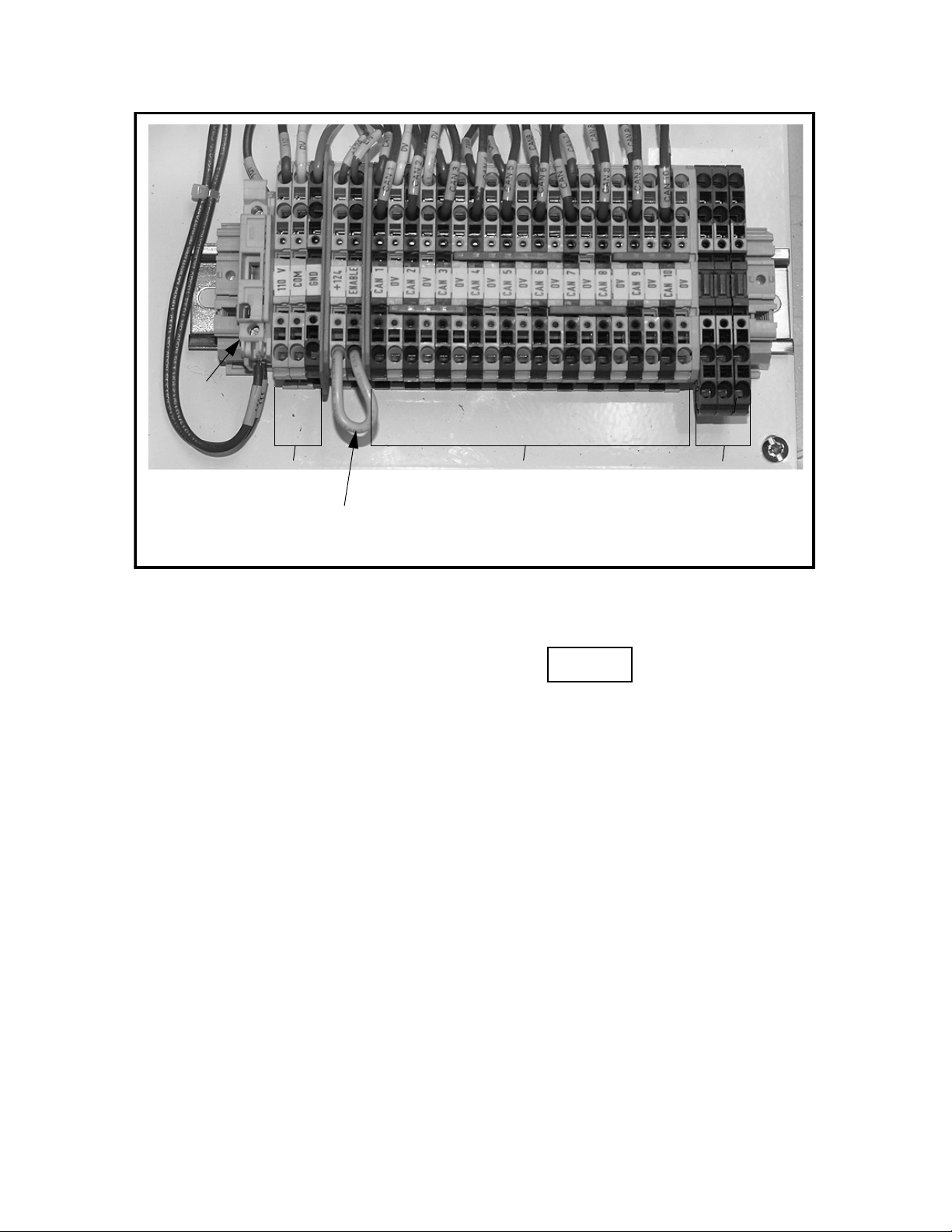

• When connected to the controller’s ENABLE terminal block, the cannons

will fire in the programmed sequence (e.g., cannons 1 through 10 fire in

sequence) until the switch disables the controller and deactivates the firing

sequence. When the switch enables the controller again (activates firing),

the controller resets the sequence to begin with cannon 1 (e.g., if the switch

disabled the controller after firing cannon 3, the sequence will start by firing

cannon 1 the next time it is activated).

Introduction