EPS IPES-IR3 User manual

IPES-IR3 Flame Detector

Operating Manual

820-0003

820-0003

IPES IR3 Flame Detector

Operating Manual

Page 2of 37

IPES-IR3 Flame Detector

Operating Manual

820-0003

ESP Safety, Inc.

555 North First Street San Jose,

CA 95112 USA 408‐886‐9746

May 2020

Revision History: 820‐0003

Date

Revision

Description

Approved

3/14/13

02

Addition; Appendix C Warranty &

Return Policy

Burgos

3/25/13

03

Reformat

Burgos

2/28/14

04

Updated Functional TestProcedure

Burgos

10/31/14

A

Update FM references; change PN from

80010‐001; steel enclosure only

ECO 141103

\

10/19/2016

B

New Terminal Board Connections

FOV Diagram. Self Test Output

Martinez

05/01/2020

C

HART Communication

Wong

820-0003

IPES IR3 Flame Detector

Operating Manual

Page 3of 37

Table of Contents5

1.0 Introduction....................................................................................................................................................................5

Introduction.................................................................................................................................................................5

Our Mission ................................................................................................................................................................5

ESP Safety, Inc. Contact Information ........................................................................................................................5

2.0 Description......................................................................................................................................................................6

Application..................................................................................................................................................................6

Specifications.............................................................................................................................................................6

3.0 Safety Considerations .....................................................................................................................................................8

Guidelines ..................................................................................................................................................................8

Explosion Protection Means.......................................................................................................................................8

4.0 FM Compliance ...............................................................................................................................................................9

IPES-IR3 ....................................................................................................................................................................9

Standards...................................................................................................................................................................9

Flame Response Sensitivity.......................................................................................................................................9

False Stimuli Exposure ............................................................................................................................................10

Field of View.............................................................................................................................................................10

5.0 PerformanceCharacteristics .........................................................................................................................................11

Appearance

...............................................................................................................................................................11

Response Time

.........................................................................................................................................................11

Generation of Alarm Signals

......................................................................................................................................11

Elimination of False Alarms

........................................................................................................................................12

Serviceability............................................................................................................................................................12

LED ..........................................................................................................................................................................12

Optical Integrity ........................................................................................................................................................12

Analog Signal ...........................................................................................................................................................14

Digital Signal ............................................................................................................................................................14

Relay Dry Contact Signal.........................................................................................................................................14

Operating Modes......................................................................................................................................................14

6.0 Installation ....................................................................................................................................................................15

Component Parts and Delivery Set..........................................................................................................................15

Visual Examination...................................................................................................................................................15

Pre‐Installation Steps...............................................................................................................................................15

Installation................................................................................................................................................................15

Moisture Damage Protection....................................................................................................................................16

General Wiring Requirements..................................................................................................................................16

24VDC Requirements ..............................................................................................................................................16

Earth Grounding.......................................................................................................................................................17

Power Cable Conductor Size affects CableLength.................................................................................................17

IPES‐IR3 Terminal Block .........................................................................................................................................18

Setting the Modbus Address and Baud Rate...........................................................................................................18

Completing the Installation.......................................................................................................................................19

IPES‐IR3 3 Wire +4 to 20 mA Current Loop WiringDiagram ..................................................................................20

Connection to Digital RS‐485Circuit........................................................................................................................20

7.0 Startup and Operation ..................................................................................................................................................21

Installation Review Prior to Startup..........................................................................................................................21

Performance Test.....................................................................................................................................................21

Test Equipment........................................................................................................................................................21

Power‐On Self‐Test..................................................................................................................................................21

IPES‐IR3 in Self‐Test Mode.....................................................................................................................................22

Fire Detection Test...................................................................................................................................................22

Photonic Detector Locations....................................................................................................................................23

Dust/ Obstruction Fault Test ....................................................................................................................................23

820-0003

IPES IR3 Flame Detector

Operating Manual

Page 4of 37

8.0 Troubleshooting............................................................................................................................................................24

Troubleshooting Table .............................................................................................................................................24

9.0 Maintenance.................................................................................................................................................................25

Maintenance Activities .............................................................................................................................................25

Daily Maintenance....................................................................................................................................................25

Every Six Months .....................................................................................................................................................25

Automatic Testing ....................................................................................................................................................26

10.0 Transportation and Storage ........................................................................................................................................26

11.0 Warranties ..................................................................................................................................................................27

12.0 Repair and Return .......................................................................................................................................................28

Field Repair..............................................................................................................................................................28

Return Material Authorization (RMA) Number.........................................................................................................28

13.0 Parts Ordering Information.........................................................................................................................................28

14.0 Certifications...............................................................................................................................................................29

Appendix A: IPES-IR3 Explosion Protection Means.............................................................................................................31

Appendix B: IPES Digital Communications Protocol ...........................................................................................................32

Appendix C: HART Communication Protocol......................................................................................................................34

It is important that this entire manual be thoroughly read and

understood prior to installing or operating the IPES‐IR3. Any

deviation from the recommendations in this manual may impair

system performance and compromise safety.

820-0003

IPES IR3 Flame Detector

Operating Manual

Page 5of 37

1.0 Introduction

Introduction

The IPES‐IR3 flame detector’s advanced microprocessor based technology ensures rapid flame recognition and alarm

signaling. In addition, the IPES‐IR3’s selective, multiple spectrum technology virtually eliminates false alarms from a

variety of sources including:

●Direct or indirect sunlight

●Arc welder flash, resistive heaters

●Fluorescent, halogen

●Incandescent light

●Nuclear radiation

The IPES‐IR3 generates an alarm signal only when detection from three different IR wavelengths agree that a flame or

fire is present in the field of view. Upon confirmation of flame or fire, the IPES‐IR3 triggers alarm relays and provides

alarm signals via RS‐485 Modbus and industry standard +4 to 20mA current loop to the users’ receiving devices and

alarm systems.

For ease of operation status and alarm condition the IPES‐IR3 provides an easily visible high illumination Tri State LED

that follows an Industry Standard protocol:

●Green for normal operation

●Yellow for fault condition

●Red for alarm Conditions

The IPES‐IR3 provides superior false alarm processing making it the detector of choice. Alarms occur instantly after our

proprietary False‐Positive Algorithm determines possible alarm states. This makes IPES‐IR3 the industry standard for

several industrial applications:

Our Mission

ESP Safety, Inc.’s mission is to provide complete turn‐key protection solutions beginning with the design stage, through

system installation and commissioning, and on‐going field service in hazardous environments. Our line of

industry‐leading products, services, and systems benefits society, saves lives, and preserves capital resources.

ESP Safety, Inc.

Contact Information

Telephone: 408‐886‐9746

FAX: 408‐886‐9757

Address: 555 North First Street, San Jose, CA 95112 USA

820-0003

IPES IR3 Flame Detector

Operating Manual

Page 6of 37

2.0 Description

Application

The IPES‐IR3 design and explosion‐proof ratings make it an excellent choice for indoor and outdoor applications,

including:

Drilling andproduction

Paintproduction

Automated and manned ocean

Power Plants‐ Nuclear, Coal, Oil,

based platforms.

Natural Gas, Solar Process, MHD

Fuel loading and transfer facilities

Shipping Tankers,Freighters.

Refineries

Virtually any vessels that may

havea

Bulk terminals

potential firehazard.

Tank farms and storage facilities

Laboratory and Plasma

LNG/LPG processing and storage

Study/Process

Compressor stations

Transportation facilities,Airports,

Pipelines and pump stations

Petrochemical processing

facilities

Subways, Aircraft hangers

Oil and Gas Boilers

Fertilizerproduction

Stage and entertainment

special effects

Specifications

The IPES‐IR3 meets industry certifications and requirements for Hazardous Locations.

Detection Type: Optical

Detection Method: Multiple Spectrum Infrared Radiation Source Spectral Range: Three points in a range of 4.0 to 5.0 m

Detection Process Time:

4.5 to 7 Seconds

(Complies with FM Standard 3260)

Refer to Section 4.0

Detection Distance: Minimum 211 feet (64meters) depending on detected fuel.

Detection Cone of Vision: Up to 90° (45° Left/Right of center)

Sensitivity: User Selectable for distance and False/Positive process time

Power requirements: 24VDC nominal (18‐32VDC range)

Power Consumption: 3 VA (3 Watt) Max

Outputs:

●Industry Standard +4 to 20mA

●1 Alarm Relays (SPDT/Form‐C latching)

●1 Fault condition (NO/Form‐A)

*All Relays Contact Rating 1 Amp@125VAC/30VDC

●Digital RS‐485 Modbus

●HART Communication Protocol

Cable Distance: 6200ft (1900m) 18 AWG

Ingress Protection: IP66

Vibration: Meets FM 3260: 2000

Impact Resistance: 1.9 Joules

Test Method: ITES Test Lamp

RFI‐resistant to interference by EMI and RFI: EMC Directive compliant with CE mark. Not susceptible to keying 5 watt

walkie‐talkie at distances greater than 1 foot.

820-0003

IPES IR3 Flame Detector

Operating Manual

Page 7of 37

Optical Integrity: IPES‐IR3 performs an automatic calibrated performance test once per minute to verify complete

detector operation capabilities.

Operating Temperature: ‐40°F to +185°F (‐40°C to 85°C)

Storage Temperature: ‐76°F to +185°F (‐60°C to 85°C)

Humidity Range: 0 to 95% relative humidity

(can withstand 100% condensing humidity for short periods of time)

Conduit Entry: ¾” NPT

Enclosure Material: Stainless Steel Grade 316

Weight: Stainless Steel 11lbs (5.0kg)

820-0003

IPES IR3 Flame Detector

Operating Manual

Page 8of 37

3.0 Safety Considerations

Guidelines

For maximum safety:

•Only persons who have thoroughly read and understood this manual, are trained in safety techniques, and have

electric-safety certificates are permitted to install and operate the IPES-IR3.

•Never operate the IPES-IR3 if the casing is damaged.

•Do not open, separate or disassemble the IPES-IR3 when energized.

•Refer to the Appendices and diagrams in this manual to ensure that the wiring is in compliance with local

ordinances and the NEC.

•Perform regular testing and maintenance as outlined in the Maintenance section.

•Ensure that fire-alarm and fire-extinguishing systems and controls are switched off before any testing or

maintenance to avoid unwanted operation of alarms and fire-extinguishing equipment.

Also see the individual sections in this manual for relevant specific safety guidelines.

Explosion Protection

Means

The table below describes design features that protect the IPES-IR3 against explosions:

Feature

Protection Means

Enclosure of

Current Carrying

Parts

The casing includes spigot joints with controlled gaps

to meet explosion‐proof requirements for installation

in Class I, Division I, Group B, C and D, and T4 locations.

Case Mechanical Strength

The high mechanical strength of the case is able to

withstand high explosive pressures without rupture or

failures of mechanical parts. The case design is in

accordance with FM 3600 and FM3615.

Manufacturing Control

Of Casing

Important parametersinclude:

●

Maximum width and minimum length of spigot joints

●

Surface roughness of the joinedparts

●

The number of complete intact threads at the

conduit entry point

Ignition Temperature

The ignition temperature of the surrounding

environment is limited by the outside surface

temperature of the housing, which does not exceed

275°F (135°C).

Securing of Bolts,

Joints and Grounding

Spring washers, lock washers, and lock nuts maintain the

integrity of the bolted connections by preventing

loosening of the bolts.

Joined Parts Protection

Anti‐seize lubricant is applied on the critical joints as

described on Appendix A.

Casing Ingress Protection

The design of the casing is protection class IP 66 in

accordance with IEC 60529‐004.

Sealing Cables at

Conduit Entry

Use approved hazardous location sealed conduit fittings.

Foroutdoor installations, ensure sealing meets IP66

requirements.

Before installing and operating the IPES‐IR3, be sure to read this

entire manual. Failure to follow these guidelines could result in

impaired product performance and safety hazards.

820-0003

IPES IR3 Flame Detector

Operating Manual

Page 9of 37

4.0 FM Compliance

IPES-IR3

Meets FM (US and Canada) certifications and requirements for Hazardous Location classification: Class I, Division I,

Group B, C and D and T4 Case design accords with FM 3600 and FM 3615. Ta = ‐40°C to +85°C (‐40°F to +185°F) IP66

Standards

TITLE

AUTHOR‐NUMBER

DATE

National Fire Alarm Code

ANSI/NFPA 72

2002

Radiant Energy‐Sensing Fire

Detectors for Automatic Fire

Alarm Signaling

ANSI/FM –3260

2004

Radiant Energy‐Sensing Fire

Detectors for Automatic Fire

Alarm Signaling

FM Approvals ‐ 3260

2000

Electrical Equipment For Use In

Hazardous (Classified) Locations–

General Requirements

FM Approvals –3600

1998

Explosion proofElectrical

Equipment –General

Requirements

FM Approvals –3615

2006

Flame Detectors

ULC/ORD ‐ C386

1990

Standard for Smoke Detectorsfor

Fire Alarm Systems

CAN/ULC ‐ S529

2002

Threaded Conduit Entries

CSA C22.2 No. 0.5

1982

(Reaffirmed)

(1999)

Explosion‐Proof Enclosuresfor

CSA C22.2 No. 30

1986

Use in Class I Hazardous Locations

(Reaffirmed)

(2003)

Degrees of Protection Provided by

ANSI/IEC 60529

2004

Enclosures (IP Code)

CSA‐C22.2 No. 60529

2005

Explosive Atmospheres, General

Requirements

ANSI/ISA 60079‐0

2009

Explosive Atmospheres,

Equipment protection by

flameproof “d” enclosures

ANSI/ISA 60079‐1

2009

Flame Response

Sensitivity

When an IPES‐IR3 detector is exposed to a series of test fires along the center line of the sensor as described in the table

below, the alarm response of the IPES‐IR3 is below the 30‐ second response time required under FM Standard 3260.

Fuel

Distance

Fire Size

Average Time

n‐Heptane

211 ft. (64 m.)

1 ft. x 1 ft. (32.5 cm.) pan

9 sec.

Denatured ethyl

alcohol (85.4%)

151 ft. (46 m.)

1 ft. x 1 ft. (32.5 cm.)

11 sec.

JP4

206 ft. (63 m.)

2 ft. x 2 ft. (60 cm.) pan

10 sec.

820-0003

IPES IR3 Flame Detector

Operating Manual

Page 10 of 37

False Stimuli

Exposure

When the IPES‐IR3 is exposed to the fires specified above, and are in the presence of the following false stimuli sources –

modulated at approximately 1.5 Hz, and un‐modulated – no false alarm activation or instability occurs at the minimum

distances listed below.

Source

Distance

1.5 kW Heater

36 inches (0.9 m)

Arc welder, 200A, 3/16” – 7018

electrode

9.0 feet (3.7 m)

Fluorescent, (2) 20W (6000 Lux)

0 inches (0 m)

Halogen, 500W

36 inches (0.9 m)

Incandescent, 100W (2000 Lux)

12 inches (0.3 m)

Direct sunlight

Detectors not affected by frequency

range of visible light

Indirect sunlight

Detectors not affected by frequency

range of visible light

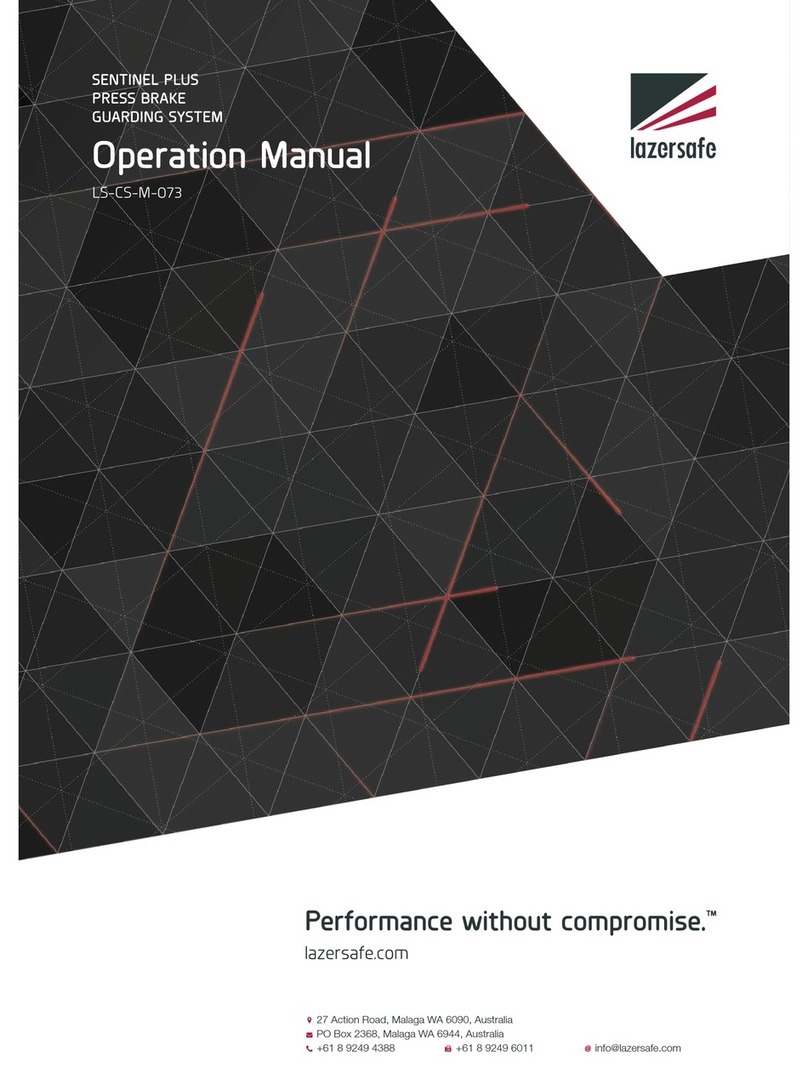

Field of View

The IPES‐IR3 has a 90° cone of vision (horizontal) with the highest sensitivity lying along the central axis

X= Distance in Ft Y= Angle of Vision

Refer to Section 7.0 for testing method

820-0003

IPES IR3 Flame Detector

Operating Manual

Page 11 of 37

5.0 PerformanceCharacteristics

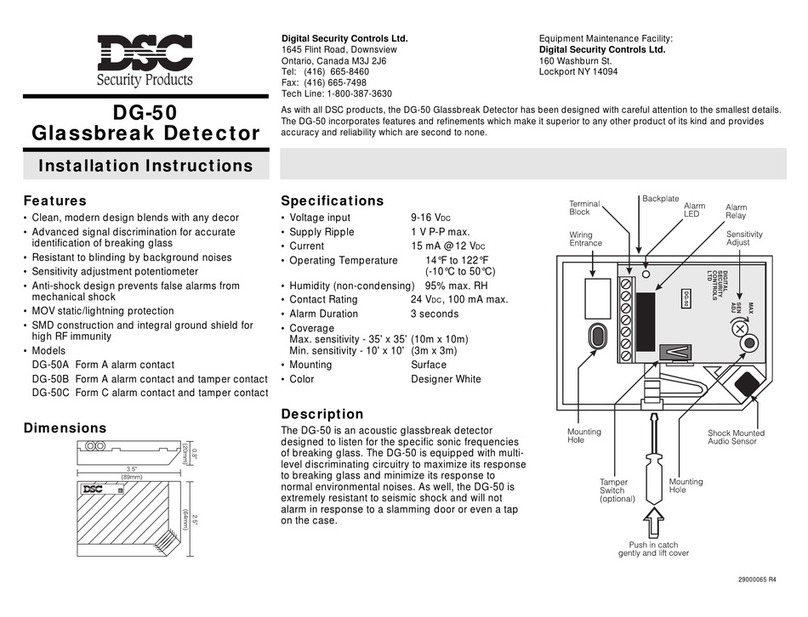

Figure 5-1: IPES-IR3 Components

Appearance

The IPES‐IR3 consists of an explosion‐proof casing with sensors to detect electromagnetic radiation from flames at three points

within a spectral window of 4.0 to 5.0μm. Detection is performed using Infrared Sensors that capture heat and radiating gas

signatures emitted by fire. Significantly, the IPES‐IR3 can detect fires fueled by hydrocarbon‐based liquids and gases that may

not be visible to the human eye.

The basic technology is well tested and used for many devices designed for human interaction. These include night vision

equipment, FLIR navigation assist, and Spectral Telescopes used in astronomy.

The IPES‐IR3 uses microprocessors with proprietary algorithms that transform the detected signal into industry standard analog

and digital communication signals, alarms indicators.

Response Time

The IPES‐IR3 response time detecting radiation emitted by test sources of n‐Heptane combustion in a 12” x 12” (0.3m by

0.3m) pan, and ethyl alcohol combustion in a 12” x 12” (0.3m by 0.3m) pan, at a distance of 150 feet (46 meters) does not

exceed 30 seconds.

The sensitivity and response time can be varied in order to reduce unwanted “noise” when the IPES‐IR3 identifies a fire, or

the distance to the probable place of fire is short (“near/far” and “slow/fast” modes).

Generation of Alarm

Signals

The IPES‐IR3 takes the following parameters into consideration when generating an alarm signal:

•

Magnitude of signals from different optical channels

•

Ratios between the signal amplitudes of different channels

•

Signal modulation frequency

•

Phase relationships among the channels

820-0003

IPES IR3 Flame Detector

Operating Manual

Page 12 of 37

Elimination of False

Alarms

False alarms from detectors used for industrial applications can cost productivity in down time. This is especially noted for

automated systems and processes.

Conversely, failure to generate an alarm can have catastrophic results.

The combination of microprocessor, algorithms, multiple sensors and wavelength range settings makes the IPES‐IR3 an

excellent choice for elimination of false positive indicators caused by non‐flame sources of radiation such as artificial

lighting, direct and indirect sunlight, lightning, electrical arcs, radiation (nuclear), arc welding and metal grinding.

An Alarm condition will normally override a Fault condition unless a loss of operating power impairs the detector’s ability to

generate or maintain an alarm. The IPES‐IR3 reports both Fault and Alarm conditions exclusive of each other. This means

both a Fire and Fault can be reported at the same time if they occur simultaneously.

Serviceability

The IPES‐IR3 remains serviceable in non‐heated rooms or under sheds at temperatures from –40°F to +185°F (–40° to

+85°C).

LED

Normal, Fire and Fault conditions are indicated by status LEDs located on the cover. Refer to

Table 5‐1: Determining

LED Conditions.

Optical Integrity

To maintain reliability of the IPES‐IR3, the optical devices are automatically self‐tested for

radiation transmission

every 25 to 45 minutes. This routine test does not require the use of a test lamp. This test determines whether any

dust or other contamination has formed on the detecting windows which would scatter the infrared radiation.

820-0003

IPES IR3 Flame Detector

Operating Manual

Page 13 of 37

Table 5‐1: Determining LED Conditions

After completing all installation steps, refer to the illustration and LED indicator table below to determine LED conditions.

State

IPES‐IR3 status

Fire

Relay State

Fault

Relay Status

Output

signal,

am

Normally open

when energized

Normally closed

when energized

LED Status Condition

1

No power

supply voltage

Open

Open

0mA

Off

2

After switching

on during 45

sec.

Open

Open

2mA

Continuous green LED light for the first

10 sec. and then the green LED will begin

flashing.

3

Fault or optical

interference

(dust)

Open

Open

2mA

Alternate flashing of the yellow and

green LED lights.

4

Normal

(no faults or

fires during

operation)

Open

Closed

4mA

Continuous lighting of the green LED

light.

5

Fire

Closed

Closed

18mA

Continuous lighting of the red LED light.

6

Fire & Fault

Closed

Open

8mA

Alternate flashing of the yellow and

green LED light.

7

Test mode

(magnetic collar

is on)

Open

Open

2mA

Magnetic collar is on. fire relay isblocked.

820-0003

IPES IR3 Flame Detector

Operating Manual

Page 14 of 37

Analog Signal

Analog signal (4‐20 mA)

Signal level

Detector State

(±0.1) mA

Circuit opening

(2 ± 0.1) mA

Fault

(4 ± 0.1) mA

Normal

(18 ± 0.1) mA

Fire

(2 ± 0.1) mA

Magnetic Collar Test

(4.1 ± 0.1) mA

Self-Test-Every 35 minutes

Digital Signal

Informational digital signals are standard RS‐485 communication with Modbus:

●Hardware self‐test Fault

●Optical interference Fault

●Fire detected

(The digital channel protocol Modbus RTU is described in Appendix B.)

Relay Dry Contact

Signal

Relay dry contact signal:

•Operation of the normally open Fire relay dry contacts*

oFIRE relay –two‐directional single‐pole contact, which allows the state to be changed at the output to normally

closed or normally open. Relay state is set at the factory. Default setting is Normally Open (Closes when in Fire

Alarm mode). The contact relay is rated for currents ranging from 10 mA to 5 A at DC voltage of 30 V.

The output signal “Fire” can be cleared after eliminating the source of the alarm signal.

* A normally closed condition of the Fire relay contacts does not comply with the requirements of NFPA 72 or

ULC/ORD –C386 and is not approved by FM approvals.

•Operation of the normally open Fault relay dry contacts

oFAULT relay –single‐direction pole contact which is normally open. The relay is designed to handle currents of

10 mA to 5 A at DC voltage of 30 V.

Refer to Table 5‐1: Determining LED Conditions above.

Operating Modes

Possible detector configurations using ESP Commander

The IPES–IR3 has the following detector operating modes:

•“Near/far” and “slow/fast” modes – To provide maximum sensitivity.

•“Latching/non‐latching mode”– To select either latching or non‐latching functionality of the fire relay, which

provides latching alarm state for the fire‐alarm relay in compliance with NFPA 72 and ULC/ORD – C386.

The manufacturer’s default settings correspond to far and fast. To change the manufacturer’s settings, connect the

flame detector to the computer and use the ESP Commander program.

HART Protocol

Communication

The HART communication is used to monitor status of the flame detectors and provides the flexibility to make

configuration changes in the field. The important status monitored are the process value (value to determine fault, or

alarm conditions). In addition, the user can test the built-in test, which occurs automatically every 35 mins. For more

details, HART menu tree and connection diagram, please refer to the Appendix C.

820-0003

IPES IR3 Flame Detector

Operating Manual

Page 15 of 37

6.0 Installation

Component Parts

and Delivery Set

The IPES‐IR3 detector component parts and delivery set consists of the following:

•One IPES‐IR3 Fire Detector

•One Adjustable Mounting Bracket

•One Operating Manual

•IPES Mounting Hardware (bolts, nuts, washers, etc.).

•One Sunshade Hood

•Optional magnetic collar (delivered only by special request).

Compare the contents of the set to the packing list to be sure all items were received. If any items are missing, contact

ESP Safety Inc.

Visual Examination

•The nameplates and warning labels are in place.

•The external surfaces of the elements and joined surfaces of the casing are free of dents or damage.

•The tamper‐proof screw is intact on the front cover

Pre‐Installation

Steps

Make sure all removable parts are joined to the casing as tightly as possible.

Installation

Positioning the Detector

1. Position the detector to provide an unobstructed view of the area to be protected. The detector’s 90° viewing angle

is most sensitive along the central axis; therefore, position the central axis so that it has the best unobstructed view

of the place of probable fire. Use line of sight or laser level for more precise targeting.

2. Identify all high-risk fire sources, to determine the number of detectors needed for adequate coverage.

3. Locate the detector(s) for ease of cleaning and servicing. Ensure that probable fire sources are within the

detector(s) field of view and detection range.

4. When installing multiple detectors in the same area, be aware of overlapping fields of view and detector hierarchy.

Overlapping fields of view can be used to provide additional protection against false positives or false negatives,

depending on the control system logic connected to the detectors.

Note: To mitigate false positives, position the detector so that its field of view does not cover any areas outside the

hazardous area.

5. Mount the detector on a rigid surface which minimizes vibrations. Use the mounting hardware provided along with

the rubber bushings to further isolate the detector from vibrations

Note: ESP Safety Inc. recommends bolting the mounting base plate to the mounting surface. If bolting is not

possible, the mounting plate can be welded to the mounting surface if it is a similar metal (either 316 Stainless Steel

or 6061 aluminum). Before welding, be sure to remove the detector from the base plate before attempting any

weld operation.

Warning: Do not open, separate or disassemble casing when

energized! Separating the casing can result in serious damageto

the detector which could go undetected, resulting in failure to

detect fires.

820-0003

IPES IR3 Flame Detector

Operating Manual

Page 16 of 37

Moisture Damage Protection

•It is the responsibility of the installer to take proper precautions during installation to protect the

electrical connections and components frommoisture.

•Anti‐seize lubricant is provided for easy assembly and corrosion protection of the joints between the

enclosure/cover and enclosure/base. After disassembly, wipe these surfaces clean with a soft cotton

or wool cloth and then re‐apply a thin layer of lubricant prior to assembly.

•If installing wiring cable in conduit, do not use conduit for wiring to other equipment.

•Care should be taken to not install the detector where heavy condensate, rain, or fog can cover the

lens and reduce the sensitivity of thedetector.

General Wiring Requirements

Cabling Guidelines

If installing connection cables in an explosion proof conduit, do not use the same conduit tocarry wiring for

any other purpose or equipment.

Minimum 14 AWG (2.08 mm2) shielded cable conductors are required for optimal performance. The gauge of the

wire used determines the maximum distance between the 24VDC power sources.

When using Modbus, power and signal must be separate shielded twisted pair conductors

24VDC Requirements

The IPES‐IR3 detector has a maximum power draw of 3VA/Watt in an active alarm state with all relays and optics

heater active. (Fault, Alarm1) Select a power supply with adequate capability for the calculated load. Ensure that

the 24VDC (+/‐8VDC) power positive and common connections are from the same source

Warning: System ground must be provided at the point of

origination for 24VDC. Failure to do this may result in loss of range

and/or signal integrity.

Avoid low frequency, high voltage, and non‐signaling conductors to

prevent potential EMI problems.

Caution: All cable/conduit entries must be sealed with an

appropriate and certified sealing plug and cable gland. The use of

industrial grade, armored field cable is recommended.

820-0003

IPES IR3 Flame Detector

Operating Manual

Page 17 of 37

Earth Grounding

The enclosure of the IPES‐IR3 must be earthed/grounded for electrical safety and to limit the effects of radio

frequency interference. An earth/ground point is provided on the outside of the IPES‐IR3 Explosion Proof

enclosure.

Use 14 AWG copper (Stranded, or Solid),wire.

Loosen the nut sufficiently to enable wrapping of the wire or wire terminated with a crimped lug around the

thread in a “U” shape. Raise the flat and lock washers and position the wire between the 2 flat washers and

ground base.

*Note: Earth and System Grounds are separated to prevent ground loop potential plus maintain signal and

current output integrity

Power Cable Conductor Size affects CableLength

The IPES‐IR3 detector must receive a nominal voltage of 24 VDC (+/‐ 8VDC) to operateproperly. Wire size

requirements are dependent upon power supply voltage and wire length.

There are several possible methods to electrically connect an IPES‐IR3 that are determined by each user’s

application.

These can run from a single IPES‐IR3 running on 24VDC that is operating as an isolated device and is connected

directly to a warning system of alarms and/or lights to a network of devices that are connected in series that can

provide any mix of RS‐485 Modbus, +4 to 20 am, and relays to separate devices.

22 AWG 0.326mm2)

40.5Ω

750

2460

20 AWG 0.518mm2)

40.8

1200

3936

18 AWG 0.823mm2)

40.7Ω

1900

6232

16 AWG (1.31mm2)

40.2Ω

3000

9840

820-0003

IPES IR3 Flame Detector

Operating Manual

Page 18 of 37

IPES‐IR3 Terminal Block

Table 6‐1: Arrangement of Electrical Connections

Terminal Block

Pin

Function

X3

+24V

24VDC from system power source (External User Provided)

GND

System Ground from system power source (External User Provided)

+4/20

Industry Standard +4-20mA current loop output

RS485A

RS-485 MODBUS

RS485B

RS-485 MODBUS

R_WORK

R_WORK

Fault / Obstruction Relay Normally Closed (NC Type B) When Energized

X4

+24V

Output to next device if required

GND

Output to next device if required

-4/20

Industry Standard +4-20mA current loop output

RS485A

Output to next device if required

RS485B

Output to next device if required

R_FIRE

R_FIRE

Alarm Relay Normally Open (NO Type A) When Energized

X5

Factory Use

X6

Factory Use

Arrangement of

Electrical Connections

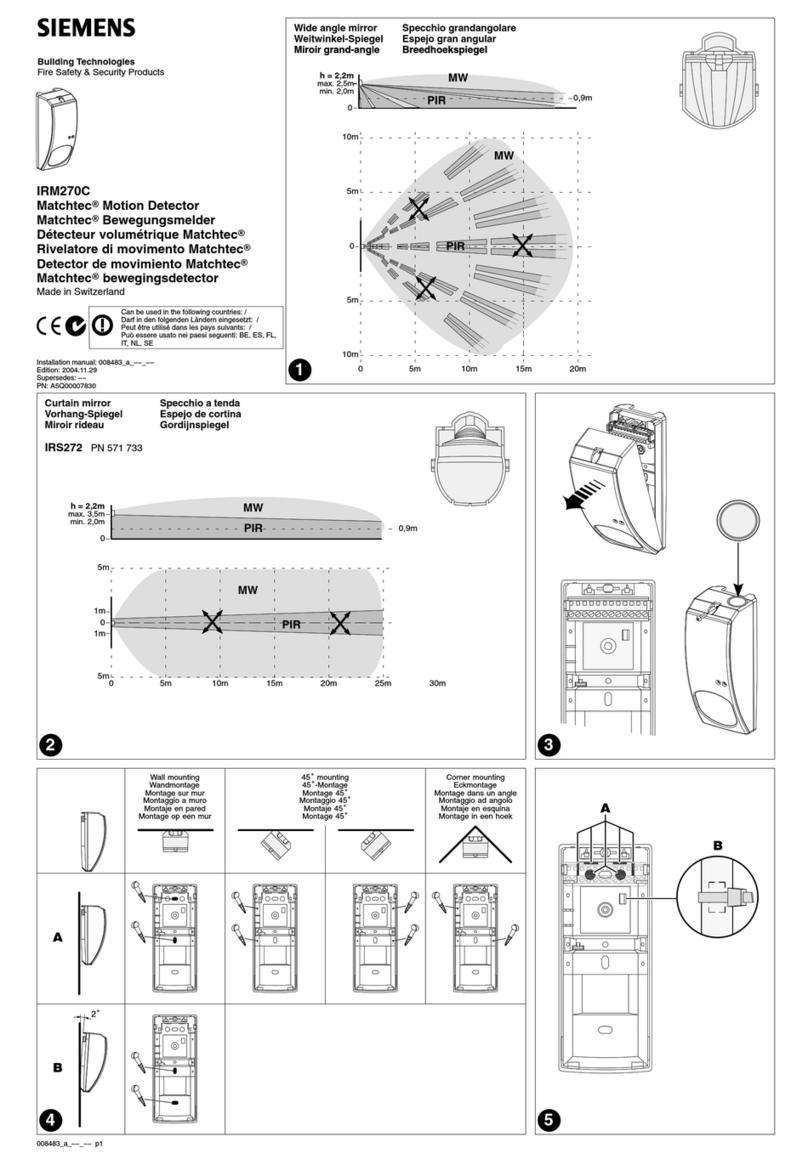

Arrange the electrical connections as described in Table 6‐1, Table 6‐2 and Figure 6‐3below.

To connect the IPES‐IR3 to external devices, use armored control cables 4 x 1.5, which are used in

all classes of explosive zones including indoor and outdoor sites, channels, tunnels, ground

(trenches) with corrosive medium, and in zones containing roamingcurrents.

Setting the Modbus

Address and Baud Rate

To ensure proper communications, a unique address must be assigned to each device, as duplicate

addresses are not automatically detected. Modules with duplicate addresses will report with the

same address, confusing latest updates. Record all addresses and device types after completing the

installation.

Refer to Appendix B for setting the Modbus address and baud rate.

When using an RS‐485 bus connection, it is advisable to connect the IPES‐IR3 to the bus via the

terminal box. To connect the detector to the terminal box, use a cable not longer than

1.64

feet (0.5 m). The cable characteristics should meet the requirement of the cable entries

mounted on the IPES‐IR3 casing and those of the terminalbox.

820-0003

IPES IR3 Flame Detector

Operating Manual

Page 19 of 37

Completing the Installation For the following,

1. Unscrew the M5 Socket Head Cap screws from the base. Remove the detector from the

base.

2. Detach NPT conduit bushing from base.

3. Install the base on a suitable work platform and secure using the 4 mounting screws,

washers, nuts, and rubber grommets.

4. Run the power, control, and ground wires from the conduit into the conduit bushing and

connect to the wiring terminals in the base. Follow Figure 6‐2, Arrangement and Functions

of Mounting Connection Terminals, for details.

5. Tighten the conduit bushing to 4‐1/2 +‐ 1 turns of engagement. Seal the conduit entry

with an approved hazardous location conduitsealant.

6. Run the earth ground wire to the external ground stud on thebase.

7. After completing all wiring, refer to Table 6‐1 to verify the functionality of the front cover

LEDs.

8. Inspect base and re‐apply a thin film of anti‐seize compound if required; re‐install the

detector on the base and evenly tighten the M5 screws to40 in‐lbs.

9. Upon completing the installation, check the resistance of the earth ground lug to ground

which should not exceed 1 ohm.

10. Arrange the power‐supply system so that the power‐supply voltage across the device

terminals ranges from 18 to 32 V (taking into account the IPES‐IR3 consumption).

820-0003

IPES IR3 Flame Detector

Operating Manual

Page 20 of 37

IPES‐IR3 3 Wire +4 to 20 mA Current Loop WiringDiagram

When using the current loop method of connection the circuit is a point‐ to‐point

connection between a single IPES‐IR3 and a threshold detection device. In most cases the

threshold device will provide the 24VDC power and will operate in a closed loop. Refer to

Appendix C for interpretation of

+4 to 20ma indications.

If 24VDC is from a common source, use of a connection bus‐block is recommended

to provide connect/disconnect capability without disruption to any other devices

using the same powersource.

Figure 6-3: IPES-IR3 Connection to Analog +4 to 20 mA Current Loop

Connection to Digital RS‐485Circuit

Figure 6-4: IPES-IR3 Connection to Digital RS-485 Circuit

Table of contents