EPS MULTIBOOST 350L Simplicity Slimline Fixed Speed... User manual

MULTIBOOST

O & M Manual Rev 4

Integrated Sanic

UV System

Multiboost Installation

& Dos & Donts

2

Contents

Declaration of Conformity 3

Directives & National Implementation Provisions

4

Multiboost Range 5

Delivering, Handling and Storing 7

Installation Guide & Schematics 8

Key Features 13

Drip Trays 14

Electrical 15

Pump Type & Control Information 16

Fixed Speed - Preso Multi Controls 17

Preso Multi 18

Preso Vario 19

Steadypres 20

Anti Vibration Mat 22

Insulation Jacket - Foil back 23

Insulation Jacket - Black 24

Dimensions 25

Components 26

Errors and omissions excepted

3

We, EPS Group

of Mallow Business and Technology Park

Quartertown

Mallow

Co Cork P51 AC94

Telephone: +353 (22) 31200

Fax: +353 (22) 31250

Email: info@epswater.com

in accordance with the following Directives:

Refer to page 2 for list of directives

Hereby declare that:

Equipment: Multiboost Range

Model : Refer to page 5 for complete range of models & product codes

is in conformity with the applicable requirements of the following documents:

Refer to page 4 for list of national implementation provisions

I hereby declare that the equipment above has been designed and assembled to comply with

the relevant section of the above referenced specications. The unit complies with all applicable

Essential Requirement of the Directives.

The Technical Construction File is maintained at:

EPS Group

Mallow Business and Technology Park

Quartertown

Mallow

Co Cork P51 AC94

Telephone: +353 (22) 31200

Email: info@epswater.ie

DECLARATION OF CONFORMITY

PLEASE KEEP THIS DOCUMENT IN A SAFE PLACE

Signed:

Managing Director, EPS

Date:

Declaration of Conrmity

March 2019

4

4

Pump Range Provisions

EN 60335-1

Top Multi EN60034-1

Top Multi-Tech IEC 60335-1

NK IEC 60334-1

UP CIE 61-150

CIE 2-3

Fitting Type Provisions

Nylon Fittings

EN 60335-1

Pipe Type Provisions

MDPE Blue Pipe

AS/NZS 4020

BS EN 12201-2

BS EN 1717:2000

BS EN 12201

Valve Type Provisions

Check Valve EN 1717:2000

Flow Valve BS 1212/1

Fill Valve

WRAS Approved 1203001

Tank Type Provisions

Holding Tank BS 6920-1:2000

Controllers Directives

Steadypres

2006/95/CEE Low Voltage Directive

2002/95/CEE Dangerous substances in electromagnetic compliances (RoHS)

2002/96/CEE e 2003/108/CEE Dangerous substances in electronic appliances (WEEE)

2004/108/CE Electromagnetic Compatibility Directive(EMC)

EN 5501-1 (emissions)

Provisions

EN 61000-3-2 (emissions)

EN 61000-3-3 (emissions)

EN 55014-2 (immunity)

EN 61000-4 (immunity)

Preso Multi

Directives

2006/95/CEE Low Voltage Directive

2002/95/CEE Dangerous substances in electomagnetis compliances (RoHS)

2002/96/CEE e 2003/108/CEE Dangerous substances in electronic appliances (WEEE)

2004/108/CE Electromagnetic Compatibility Directive(EMC)

Provisions

EN 60730-2-6

EN 61000 6-3

Sealant Type Provisions

Thread Sealant

WRAS Approved

Certied NSF P1. sealant paste“green”, no risk phrases, blank MSDS

Directives & National Implementation Provisions

5

5

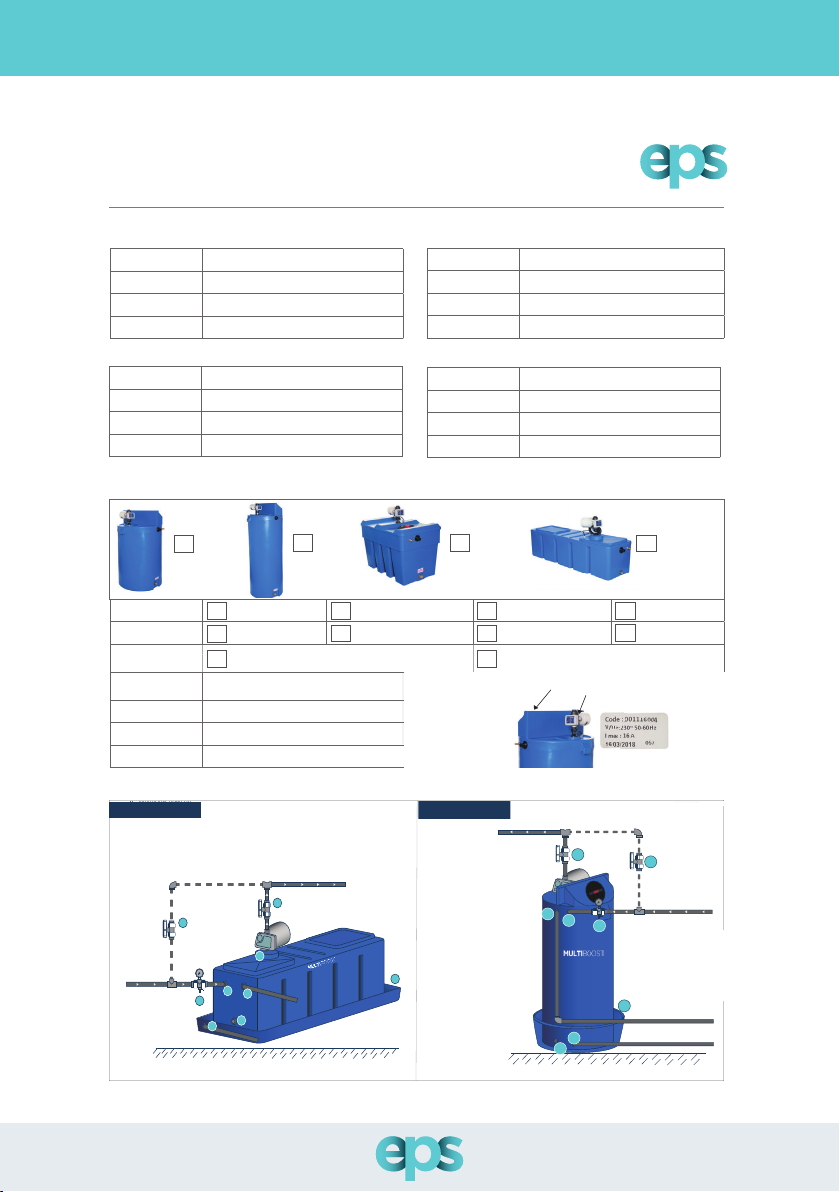

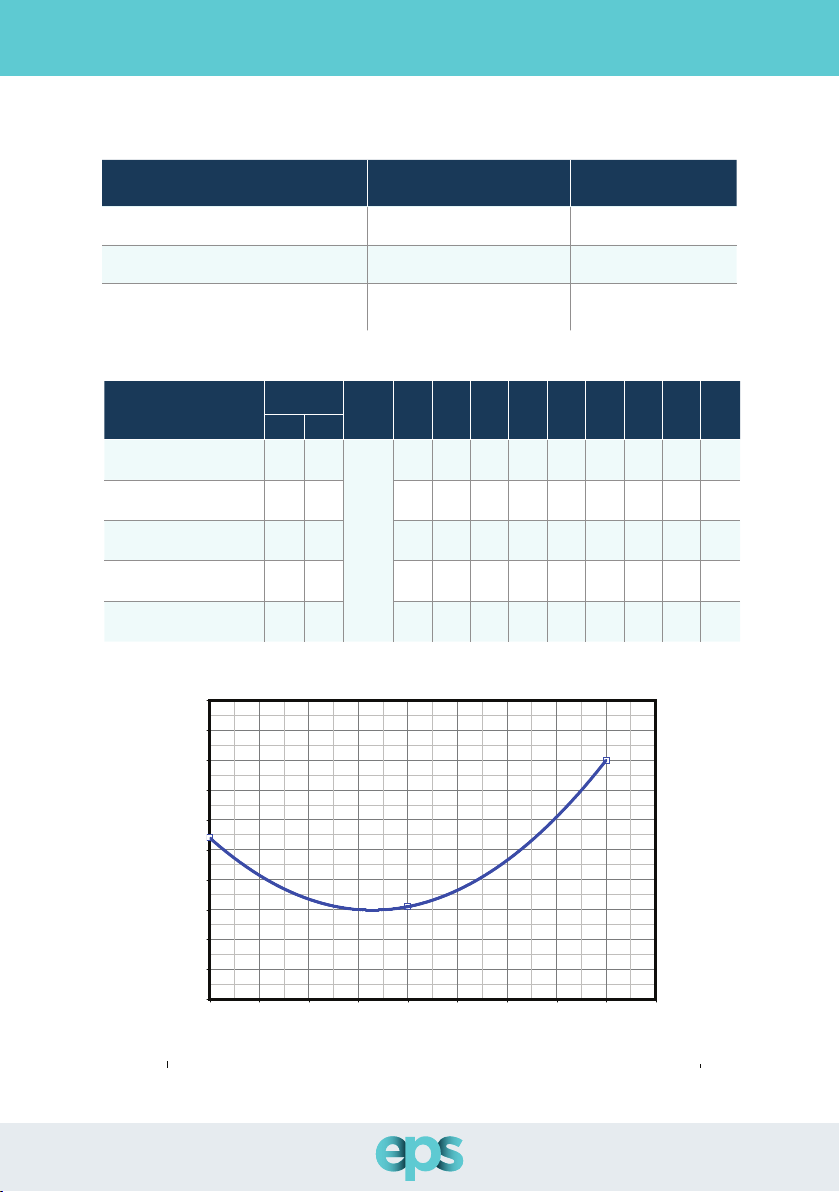

Product

Code Model Type Volume

[L]

Length

[MM]

Width

[MM]

Height

[MM]

Inlet

[Inch]

Outlet

[Inch]

Over-

o w

[Inch]

Drain

o ff

[Inch]

Weight

(Empty

Tank)

(kg)

1019648 MULTIBOOST 125L Compact

Fixed Speed 125 560 490 850 3/4" BSP 1" BSP 1¼" BSP 1" BSP 30

1028178 MULTIBOOST 125L Compact

-Fixed Speed 125 560 490 850 3/4" BSP 1" BSP 1¼" BSP 1" BSP 30

1012150 MULTIBOOST 200L Slimline

-Fixed Speed 200 584 584 1190 1/2" BSP 1" BSP 1" BSP 1" BSP 26

1001906 MULTIBOOST 350L Slimline

-Fixed Speed 350 584 584 1580 1/2" BSP 1" BSP 1" BSP 1" BSP 29

1001909 MULTIBOOST 250L Utility

Fixed Speed 250 760 760 1033 1/2" BSP 1" BSP 1" BSP 1" BSP 28

1012151 MULTIBOOST 250L Utility

Variable Speed 250 760 760 1033 1/2" BSP 1" BSP 1" BSP 1" BSP 35

1001911 MULTIBOOST 450L Utility

Fixed Speed 450 760 760 1393 1/2" BSP 1" BSP 1" BSP 1" BSP 35

1001916 MULTIBOOST 750L Utility

Fixed Speed 750 760 760 2113 1/2" BSP 1" BSP 1" BSP 1" BSP 46

1012152 MULTIBOOST 750L Utility

Variable Speed 750 760 760 2113 1/2" BSP 1" BSP 1" BSP 1" BSP 53

Multiboost Range

Product

Code Model Type Volume

[L]

Length

[MM]

Width

[MM]

Height

[MM]

Inlet

[Inch]

Outlet

[Inch]

Over-

o w

[Inch]

Drain

o ff

[Inch]

Weight

(Empty

Tank)

(kg)

1031919 MULTIBOOST 350L Simplicity

Slimline

Fixed Speed (Vario) 350 584 584 1260 ½”BSP 1” BSP 1” BSP 1” BSP 29

1033476 MULTIBOOST 450L Simplicity

Utility - Fixed Speed (Vario) 450 760 760 1300 ½” BSP 1”BSP 1”BSP 1” BSP 35

1036386 MULTIBOOST 200L Simplicity

Rectangular - Fixed Speed

(Vario) 200 1106 475 540 ½”BSP 1” BSP 1” BSP 1” BSP 20

1033898 MULTIBOOST 270L Simplicity

Rectangular - Fixed Speed

(Vario) 270 1571 475 521 ½”BSP 1” BSP 1” BSP 1” BSP 29

1033899 MULTIBOOST 300L Simplicity

Rectangular - Fixed Speed

(Vario) 300 1029 664 710 ½”BSP 1” BSP 1” BSP 1” BSP 29

1033900 MULTIBOOST 500L Simplicity

Rectangular - Fixed Speed

(Vario) 500 1190 720 720 ½”BSP 1” BSP 1” BSP 1” BSP 34

1081647 MULTIBOOST 345L Simplicity

Rectangular - Fixed Speed

(Vario) 345 1571 475 632 ½”BSP 1” BSP 1” BSP 1” BSP 34

1070476 MULTIBOOST 455L Simplicity

Rectangular - Fixed Speed

(Vario) 455 1765 580 616 ½”BSP 1” BSP 1” BSP 1” BSP 34

Pres o Vario System

Pres o Multi System

• Please ensure that Multiboost Vario is tted with the correct rated RCBO on incoming electrical supply

• Please ensure that the Preso Multi system is tted with the correct rated RCBO on incoming electrical supply

6

6

Product

Code Model Type Volume

[LTR]

Length

[MM]

Width

[MM]

Height

[MM]

Inlet

[Inch]

Outlet

[Inch]

Over-

o w

[Inch]

Drain

o ff

[Inch]

Weight

(Empty

Tank)

(kg)

1028679 MULTIBOOST 650L Utility

Fixed Speed 650 1083 669 1083 ½" BSP 1" BSP 1" BSP 1" BSP 63

1001925 MULTIBOOST 1000L Utility

Fixed Speed 1000 1688 563 1444 ½" BSP 1" BSP 1" BSP 1" BSP 63

1019276 MULTIBOOST 250L Bunded

Fixed Speed (Auto) 250 760 760 1478 ½" BSP 1" BSP 1" BSP 1" BSP 45

1028680 MULTIBOOST 650L Bunded

Fixed Speed (Auto) 650 752 1200 1174 ½" BSP 1" BSP 1" BSP 1" BSP 45

1021452 MULTIBOOST 270L

Rectangular Utility

Fixed Speed (Auto Tech) 270 1574 475 520 ½" BSP 1" BSP 1" BSP 1" BSP 29

1036388 MULTIBOOST 200L

Rectangular Utility

Fixed Speed (Preso) 200 1106 475 540 ½" BSP 1" BSP 1" BSP 1" BSP 20

1036439 MULTIBOOST 270L

Rectangular Utility

Fixed Speed (Preso) 270 1571 475 520 ½" BSP 1" BSP 1" BSP 1" BSP 29

1017488 MULTIBOOST 300L

Rectangular Utility

Fixed Speed 300 1045 665 710 ½" BSP 1" BSP 1" BSP 1" BSP 29

1017490 MULTIBOOST 500L

Rectangular Utility

Fixed Speed 500 1190 720 800 ½" BSP 1" BSP 1" BSP 1" BSP 34

1017488 MULTIBOOST 300L

Rectangular Multi Fixed

Speed (Preso) 300 1045 665 710 ½” BSP 1” BSP 1”BSP 1” BSP 29

1070476 MULTIBOOST 455L

Rectangular Multi Fixed

Speed (Preso) 455 1765 616 580 ½” BSP 1” BSP 1”BSP 1” BSP 34

Multiboost Range

Product

Code Model Type Volume

[LTR]

Length

[MM]

Width

[MM]

Height

[MM]

Inlet

[Inch]

Outlet

[Inch]

Over-

o w

[Inch]

Drain

o ff

[Inch]

Weight

(Empty

Tank)

(kg)

1019649 MULTIBOOST 125L Compact

Variable Speed 125 560 490 850 3/4" BSP 1" BSP 1¼" BSP 1" BSP 34

1001905 MULTIBOOST 300L Slimline

Variable Speed 300 584 584 1580 1/2" BSP 1" BSP 1" BSP 1" BSP 36

1001912 MULTIBOOST 500L Utility

Variable Speed 500 760 760 1393 1/2" BSP 1" BSP 1" BSP 1" BSP 42

1012153 MULTIBOOST 1000L Utility

Variable speed 1000 1688 563 1444 ½" BSP 1" BSP 1" BSP 1" BSP 70

1019650 MULTIBOOST 250L Bunded

Variable Speed 250 760 760 1478 ½" BSP 1" BSP 1" BSP 1" BSP 53

Steadypres VSD System

Pres o Multi System

Weight

• Please ensure that Preso Multi system is tted with the correct rated RCBO on incoming electrical supply

• Please ensure that the Steadypres is tted with the correct rated MCB on incoming electrical supply

7

7

Delivery and Handling

The Multiboost system is supplied from the factory, as an all-in-one packaged water boosting

system. The weight and size of the Multiboost (depending on model chosen) may require

the aid of lifting equipment and if so, must be handled in a safe and proper manner to

avoid causing unnecessary damage to the unit and/or individual/s. In the event that lifting

equipment is used, please follow widely accepted safe lifting procedures.

Inspection

On delivery, the Multiboost should be inspected thoroughly and any damage must be

reported to the supplier in writing within 24/48 hours. Always ensure the Multiboost

inspection takes place prior to installation.

Applications

The Multiboost set is designed to be compact, with ease of installation, and to provide many

years of service for domestic pressure boosting and light commercial pressure boosting.

The Multiboost set should not be installed in areas that are classied as hazardous, where

an explosion could occur or people could be harmed or in an area of any potential leaks that

could cause damage to any person or property. The use of bunded tanks and/or a drip tray are

essential to any Multiboost being installed above ceiling level.

EPS accepts zero responsibility if the Multiboost is used to pump liquids that are considered

hazardous by touch, ingestion or inhalation of fumes or gases given o by the liquid, or any

damage caused to property where the recommended protection of a drip tray or use of

bunded tank was not adhered to.

Warranty

Your Multiboost system is covered by a 12 month warranty from the date of purchase. This

warranty covers all parts or material defects and will be replaced free of charge. Labour call

outs for warranty / repair will require a call out fee of €150 incl. VAT. This fee must be paid

up front to secure call out. If there is a warranty defect with the unit, it will be repaired /

replaced and your €150 will be refunded. If there is a defect outside EPS’ control (i.e. incorrect

installation) the €150 fee will not be refunded. The additional cost of replacement parts will be

administered in this situation also. EPS cannot carry out any tests, servicing or repairs on a unit

if the drip tray has not been tted as part of the unit being installed in the property.

Site Storage

Once a Multiboost has arrived on site and has been inspected, it is recommended that it is

stored away from sharp objects, in a safe place, on an even surface, free from moisture, dust,

sunlight and frost.

Pre Installation Checks

Please ensure the unit is tted and supported in the right manner. Check the unit for any visual

defects.

In accordance with the latest IEE regulation, all electrical connections should be carried out

by a qualied electrician. The Multiboost must be earthed. EPS strongly recommend that

a correctly sized RCBO for xed speed and MCB for variable speed units are tted on the

incoming electrical supply. If the installer is tting a plug, please ensure the correct fuse is

selected in relation to the pump selection ampage. Please see page 13 for more information.

Delivering, Handling and Storing

Multiboost Range

• Please ensure that Preso Multi system is tted with the correct rated RCBO on incoming electrical supply

• Please ensure that the Steadypres is tted with the correct rated MCB on incoming electrical supply

8

8

Installation Guide

Fill the storage tank with water through the ball cock. Please ensure the right ball cock is tted

for the corresponding pressure rating. High pressure and low pressure ball cocks available.

Installer to ensure and test the correct option is being used, as pressure diers between areas.

Make sure the electrical supply is fully isolated and cannot be turned on before working on

the pump, motor controller or any part of the unit.

Do not turn on electrical supply to the Multiboost without ensuring all electrical ttings and

all covers are intact and fully isolated from human touch during operation.

General Information

1. The discharge pipe from the controller must be, at minimum, the same size as the

Multiboost inlet supply; if it is smaller, it may result in reduced pressure and ow to the

outlets

2. The overow pipe that is tted should be twice the size of the inlet supply and should be

piped away to safe drainage zone. (It’s recommended that a full test is carried out by the

installer)

3. When being installed, the tank’s overow connection must be at least twice the internal

size of the supply pipe, taking into account the incoming pressure and ow. The

overow pipe must not be obstructed or restricted (no sharp elbows), factoring in the

distance being piped away to the drainage zone. The pipe should have an even, gradual,

straight slope to cope with the incoming pressure and ow. This pipe may have to be

further increased in size and EPS recommends the installer fully tests this system to

ensure that the overow pipe is capable and adequate to cope with the unlikely event of

a failure. The pipe size should be increased in proportion with the distance from the unit

to the drainage zone

4. The discharge pipe work must be properly secured so once the Multiboost is tted,

there is no stressed internal pipe work

5. Pipework installations should meet local water authority regulations

6. Electrical installation should meet the most recent issue of the IEE regulations and is

tted by a qualied person

7. Check that the cold water storage tank capacity is designed to meet your water

consumption demands and is suitable for the installation location

8. Drip tray or bunded tank must be included on every installation with correct overow

9. Please refer to Multiboost Commissioning Checklist as a guide

Recommendations

• Isolation valves tted before and after unit.

• Overow valve twice the size of the inlet supply valve.

• Pipe work easy to disassemble.

• Bunded tank/drip tray used for dwelling installations.

Water Quality

In the event that the water remains unused inside the tank for an extended period, it should

be drained and ushed to maintain water quality. This is recommended to ensure water

remains t for use year on year. There should be a drain o point at the end of each tank.

As required by any stored water arrangement, it is recommended that you disinfect and clean

the tank annually. Regular water samples should be taken periodically to check bacteria levels

(Recommended 2 tests per year).

9

9

We do not recommend installations in loft areas due to the weight of the tank and the increased

potential for damage in the event of a water leak or spillage. If the system must be installed

above ceiling level, it is highly recommended to use drip trays/bunded tank with the added

protection of an insulated jacket. Sound also travels very well through rafters and it is likely

that such an installation will be noisy compared to an installation on solid ground. Installations

higher than the mains water stop tap will reduce the rell rate of the tank.

1.

The Multiboost should be installed in a dry, well ventilated and frost free area where it is not

exposed to extreme temps. An ambient temperature of <20 °C is required to limit or reduce

bacteria growth. Multiboost may be located outdoors if in a weatherproof, frost and rodent

proof enclosure with adequate ventilation especially during warm weather

2. All pipe work that is exposed to freezing condition should be fully protected

3. Multiboost installation must be positioned properly for ease of access for examination and

service for compliance with health and safety practice

4.

EPS oer adequate facilities (Bunded Tank/Drip Tray) and protection from water damage in

the immediate location of the Multiboost

5.

1L of water = 1kg weight and the weight of the storage tank also. Please check load bearing

supports

6. There should be adequate lighting for service to be carried out safely

7. Where a Multiboost product is installed, it should be signed o by an approved engineer

and/or plumber/installer ensuring that the unit is installed in an appropriate location and

has all appropriate and required overows and protections in place and all of our guidelines

and recommendations have been considered. Please refer to Commissioning Checklist.

Foundation & Mounting

Multiboost must be mounted on a solid foundation to support the weight of the unit. Surfaces

must be at and level to spread weight load evenly. The recommended surface for Multiboost

is concrete plinth or oor. As previously stressed, EPS does not recommend installation of

Multiboost on wooden structures due the natural noise and vibration levels that travel along

it. When a pump is submerged in liquid, you are no longer dealing with decibel levels, but with

vibration levels. Please take the positioning of your Multiboost and the surrounding environment

into account.

Storage Tank

Multiboost is a cold water storage tank and must be installed in accordance with current

regulations. The quality of water in the storage tank should be potable and suitable for drinking.

However, it should be noted that the quality of stored water deteriorates over time if ambient

temperature is greater than 20 degrees Celsius (>20 °C). If the tank has been left idle for a length

of time, it is recommended that it is completely drained. At temperatures above 20 °C, the use of

a disinfection system (such as UV) is highly recommended.

Slave Tank & Bypass

EPS can provide an additional slave tank to cater for additional cold water storage demand and

they can be linked together. This allows for an increase in storage tank capacity for extra demand

that may occur. In the unlikely event of a Multiboost failure, it is recommended to install cold

water mains bypass to allow the water supply continue, at a reduced pressure, to the property.

This ensures a low pressure supply is available at all times while the unit is being repaired. The

bypass must be installed in accordance with the water bylaw regulations. The bypass should be

drained to prevent water stagnation if it is not being used.

Installation Guide

Installation Best Practice

10

10

Installation Guide

Information Label on each tank

Use of drip trays for installations over ceiling height is HIGHLY recommended

›Customer/installer to check unit for any

damage or leaks on delivery prior to

installation of unit

›Bunded tank or tank with drip tray

should be used for in-house installations

(depending on tank application & location)

›Tank installation above ceiling level is not

recommended. Unit’s ideal support base

is concrete due to weight. (i.e. 1L of water

= 1 kg)

›Unit to be fi tted in a safe place away from

any potential hazards & kept out of direct

sunlight

›Protective lid of tank to be installed over

control unit

›EPS is unable to service any unit installed

above ceiling level unless in accordance

with H&S regulations

›Unit to be installed by qualifi ed persons

only

›EPS recommends a by-pass valve be fi tted

on both the inlet & outlet in the unlikely

event of a pump failure

›Isolation shut-o valve to be fi tted

on supply & delivery side of tank (for

maintenance purposes

DO NOT REMOVE THIS LABEL

(Removal of this label will void warranty)

Inlet

Overfl ow

By-Pass Line

Typical example of installation

Rethinking Water

›The overfl ow pipe that is fi tted should be

twice the size of the inlet supply minimum (it

may have to be enlarged further, depending

on incoming pressure and fl ow) and should

be piped away to safe drainage zone. (It’s

recommended that a full test is carried out by

the installer).

›Overfl ow test to be completed after every

installation. This is to ensure the capacity of the

overfl ow pipe is able to handle any ballcock

failure, blockage or restriction. Ensure pipe is

not restricted & is laid straight with a su cient

fall without lags.

›The overfl ow pipe must not be obstructed or

restricted (no sharp elbows), factoring in the

distance being piped away to the drainage zone.

›Overfl ow/vermin screen needs to be cleaned

regularly to ensure removal of any impurities

present in the water.

›Pressure vessel air pre-charge to be checked

every 6 months (set 2lbs below cut-in pressure)

›High pressure ballcock fi tted as standard. (Low

range available on request)

›EPS recommends testing water for any

impurities or any water treatment required

›EPS accept no responsibility whatsoever for leaks

inside /outside of tank which are outside of our

control

ASSEMBLED BY: DATE:

INSTALLED BY: DATE: TEL:

MULTIBOOST

Scan for O&M Manual

or download on

Multiboost.ie

Scan for Multiboost O&M Manual

or download at Multiboost.ie

Fitting of a bypass unit & drip tray

with correct overflow capability is

highly recommended

Full overflow test is necessary on

every installation

Use of sharp elbows that may cause

flow restrictions is not recommended

The

MULTIBOOST

Range

C

M

Y

CM

MY

CY

CMY

K

Multiboost Stickers 4.pdf 1 08/02/2019 16:36:01

Water

Supply

Water

Delivery

11

11

Installation Guide

Use of drip trays for installations over ceiling height is HIGHLY recommended

Installation Schematic

Bypass

Mains

Water Supply

Outlet Supply

2

3

7

3

8

56

4

1

1. Ball cock

Isolation valve with

pressure gauge

Bypass isolation valve

Separate Multiboost overflow

Separate drip tray over flow

Multiboost drain off

Drip tray

2.

3.

4.

5.

6.

7.

Removable lid with pump

8.

& controller inbuilt

Multiboost

200L, 270L, 345L and 455L

*EPS recommends the use of a drip tray and insulation jacket with every installation

Scan for Ball Cock

Performance Selection

Please note - Ball cock entry location (1) and tank overow connection (4) can be modied

to suit diering applications if required.

12

12

Installation Schematic

Bypass

Mains

Water Supply

Overflow to drain from tank

Overflow to drain from drip tray

Outlet

3

3

6

7

5

2

1

4

*EPS recommends the use of a drip tray and insulation jacket with every installation

1. Ball cock

Isolation valve with

pressure gauge

Bypass isolation valve

Multiboost overflow

Multiboost drain off

Drip tray

2.

3.

4.

5.

6.

Drip tray overflow7.

Multiboost

200L, 350L, 450L, 750L

Scan for Ball Cock

Performance Selection

13

13

Key Features

1

2

1

Pressure Vessel (Preso Multi Version Only)

2

Removal union to access ow valve

3

Split union for easy maintainance

4

Drip tray built in to mould

(Selected models only)

4

3

5

Easy adjustable cut in pressure function

6

Variable speed option available

5

7

Vermin screen

7

8

Ball cock unit & oat

8

9

Drain o facility to clean tank

9

10

Overow

11

Inlet water supply

10 11

6

12

Total Removal Design of Pump and

Controller System (2018Version)

200L & 270L Rectangular Versions Only

12

Presflo Multi

Vario

Steadypres VSD

Key Features

Installation Schematic

14

14

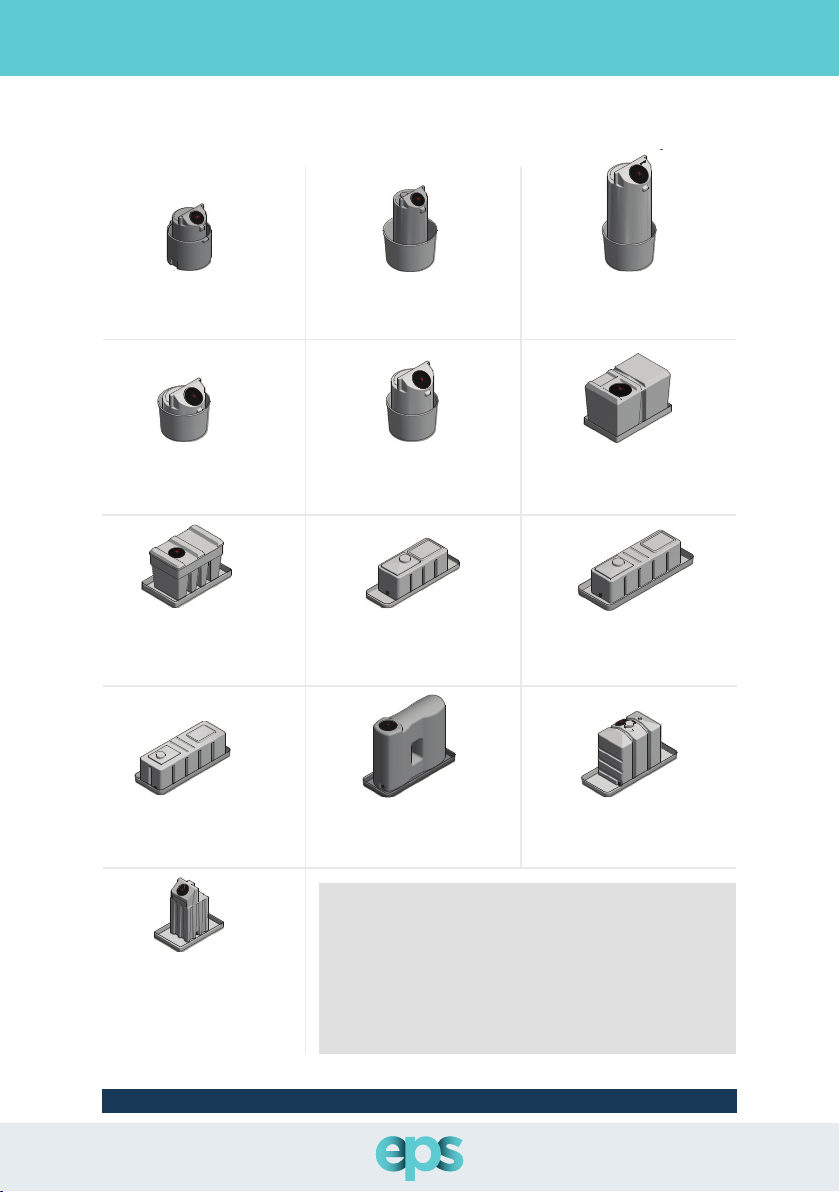

Drip Trays

Multiboost Rectangular Tray: 200L

›Height: 80mm

›Width: 515mm

›Length: 1648mm

›Product Code: 1033640

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

E E

F F

STBL00300V

190mm Lid + 1" Connection

Height: 1422mm

STBL00450V

285mm Lid + 1" Connection

Height: 1285mm

STBL00250V

285mm Lid + 1" Connection

Height: 925mm

STBL00750V

285mm Lid + 1" Connection

Height: 2005mm

STBL00200V

190mm Lid + 1" Connection

Height: 1035mm

EPS - Tanks & Drip Trays

Rev N o: R1.0

Rev D ate : 0 8-0 2-2 019

Appr ove d By : J S - SW

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

E E

F F

STBL00300V

190mm Lid + 1" Connection

Height: 1422mm

STBL00450V

285mm Lid + 1" Connection

Height: 1285mm

STBL00250V

285mm Lid + 1" Connection

Height: 925mm

STBL00750V

285mm Lid + 1" Connection

Height: 2005mm

STBL00200V

190mm Lid + 1" Connection

Height: 1035mm

EPS - Tanks & Drip Trays

Rev N o: R1.0

Rev D ate : 0 8-0 2-2 019

Appr ove d By : J S - SW

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

E E

F F

STBL00300V

190mm Lid + 1" Connection

Height: 1422mm

STBL00450V

285mm Lid + 1" Connection

Height: 1285mm

STBL00250V

285mm Lid + 1" Connection

Height: 925mm

STBL00750V

285mm Lid + 1" Connection

Height: 2005mm

STBL00200V

190mm Lid + 1" Connection

Height: 1035mm

EPS - Tanks & Drip Trays

Rev N o: R1.0

Rev D ate : 0 8-0 2-2 019

Appr ove d By : J S - SW

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

E E

F F

STBL00300V

190mm Lid + 1" Connection

Height: 1422mm

STBL00450V

285mm Lid + 1" Connection

Height: 1285mm

STBL00250V

285mm Lid + 1" Connection

Height: 925mm

STBL00750V

285mm Lid + 1" Connection

Height: 2005mm

STBL00200V

190mm Lid + 1" Connection

Height: 1035mm

EPS - Tanks & Drip Trays

Rev N o: R1.0

Rev D ate: 08-0 2-2 019

Appr ove d By : JS - SW

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

E E

F F

STBL00300V

190mm Lid + 1" Connection

Height: 1422mm

STBL00450V

285mm Lid + 1" Connection

Height: 1285mm

STBL00250V

285mm Lid + 1" Connection

Height: 925mm

STBL00750V

285mm Lid + 1" Connection

Height: 2005mm

STBL00200V

190mm Lid + 1" Connection

Height: 1035mm

EPS - Tanks & Drip Trays

Rev N o: R1.0

Rev D ate: 08-0 2-2 019

Appr ove d By : JS - SW

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

E E

F F

STBL00500R

285mm Lid + 1" Connection

STBL00300R

190mm Lid + 1" Connection

STBL00200R

One Lid Only + 1" Connection

STBL00270R

One Lid Only + 1" Connection

EPS - Tanks & Drip Trays

Rev N o: R1.0

Rev D ate: 08-0 2-2 019

Appr ove d By: JS - S W

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

E E

F F

STBL00500R

285mm Lid + 1" Connection

STBL00300R

190mm Lid + 1" Connection

STBL00200R

One Lid Only + 1" Connection

STBL00270R

One Lid Only + 1" Connection

EPS - Tanks & Drip Trays

Rev N o: R1 .0

Rev D ate : 08 -02 -20 19

Appr ove d By : J S - SW

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

E E

F F

STBL00500R

285mm Lid + 1" Connection

STBL00300R

190mm Lid + 1" Connection

STBL00200R

One Lid Only + 1" Connection

STBL00270R

One Lid Only + 1" Connection

EPS - Tanks & Drip Trays

Rev N o: R1 .0

Rev D ate : 08 -02 -20 19

Appr ove d By : J S - SW

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

E E

F F

STBL00500R

285mm Lid + 1" Connection

STBL00300R

190mm Lid + 1" Connection

STBL00200R

One Lid Only + 1" Connection

STBL00270R

One Lid Only + 1" Connection

EPS - Tanks & Drip Trays

Rev N o: R1 .0

Rev D ate: 08-0 2-2 01 9

Appr ove d By : JS - SW

Multiboost Slimline Tray: 200L

›Height: 603mm

›Width: 760mm

›Product Code: 1019180

Multiboost Slimline Tray: 300/350L

›Height: 603mm

›Width: 936mm

›Product Code: 1019180

Multiboost Utility Tray: 750L

›Height: 603mm

›Width: 936mm

›Product Code: 1028827

Multiboost Utility Tray: 250L

›Height: 603mm

›Width: 936mm

›Product Code: 1028827

Multiboost Utility Tray: 450L

›Height: 603mm

›Width: 936mm

›Product Code: 1028827

Multiboost Rectangular Tray: 500L

›Height: 80mm

›Width: 760mm

›Length: 1250mm

›Product Code: 1061457

Multiboost Rectangular Tray: 300L

›Height:80mm

›Width: 760mm

›Length: 1250mm

›Product Code: 1061457

Multiboost Rectangular Tray: 270L

›Height: 115mm

›Width: 745mm

›Length: 1935mm

›Product Code: 1079554

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

E E

F F

Rev N o: R1.0

Rev Da te: 0 8-0 2-2 019

Appr ove d By : J S - SW

STBL00455R

One Lid Only + 1" Connection

STBL00650R

190mm Lid + 1" Connection

STBL01000R

285mm Lid + 1" Connection

EPS - Tanks & Drip Trays

STBL00210UP

190mm Lid + 1" Connection

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

E E

F F

Rev N o: R1.0

Rev Da te: 0 8-0 2-2 019

Appr ove d By : J S - SW

STBL00455R

One Lid Only + 1" Connection

STBL00650R

190mm Lid + 1" Connection

STBL01000R

285mm Lid + 1" Connection

EPS - Tanks & Drip Trays

STBL00210UP

190mm Lid + 1" Connection

Multiboost Rectangular Tray: 455L

›Height: 115mm

›Width: 745mm

›Length: 1935mm

›Product Code: 1079554

Multiboost Rectangular Tray: 1000L

›Height: 115mm

›Width: 745mm

›Length: 1935mm

›Product Code: 1079554

Multiboost Rectangular Tray: 650L

›Height: 115mm

›Width: 745mm

›Length: 1935mm

›Product Code: 1079554

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

E E

F F

Rev No : R1.0

Rev Da te: 08 -02 -20 19

Appr ove d By: JS - SW

STBL00455R

One Lid Only + 1" Connection

STBL00650R

190mm Lid + 1" Connection

STBL01000R

285mm Lid + 1" Connection

EPS - Tanks & Drip Trays

STBL00210UP

190mm Lid + 1" Connection

Multiboost Xilent Tray: 210L

›Height: 80mm

›Width: 760mm

›Length: 1250mm

›Product Code: 1061457

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

E E

F F

Rev N o: R1 .0

Rev Da te: 08- 02-2 01 9

Appr ove d By : JS - S W

STBL00455R

One Lid Only + 1" Connection

STBL00650R

190mm Lid + 1" Connection

STBL01000R

285mm Lid + 1" Connection

EPS - Tanks & Drip Trays

STBL00210UP

190mm Lid + 1" Connection

*All dimensions are for drip trays only. Tank not included.

NOTE: These drip trays will arrive with a separate overflow

connection. The overflow connection must be installed on

site by a qualified fitter to determine the correct positioning.

Please ensure correct overflow pipe size is calculated, taking

into account the overflow pipe distance, the incoming flow rate

and the pressure of the inlet valve. A full test is recommended

once installation is complete to ensure the overflow pipework

has the capacity to handle an excess volume of water in the

unlikely event of an overflow occuring.

EPS recommends the use of a drip tray for each installation

15

15

All electrical work should be conducted by a fully qualied and competent electrician.

Electrical supply must be isolated and cannot be switched on before removing any electrical

covers. In accordance with the latest IEE regulation, all electrical connections should be carried

out by a qualied electrician. The Multiboost must be earthed. EPS strongly recommends that

an earth leakage circuit breaker (ELCB) is tted on the incoming electrical supply.

As electrical regulations can change, please ensure correct regulations are adhered to at the

time of installation.

Multiboost is suitable for single phase voltage supply 230v+-10%. See below for the full load

current of our dierent Multiboost pump options.

• All Steadypres variable speed units must be tted with correct size MCB - (C rated)

• All Vario & Preso units must be tted with correct size RCBO breaker

Multiboost Pump Option 230V

Pedrollo Top Multi 2 (230V) 3.4 Amps

Pedrollo Top Multi Tech 2 (230V) 3.4 Amps

NKm 2/3 & UPm 2/3 Pump (230V) 5.4 Amps

NKm 2/4 & UPm 2/4 Pump (230V) 6.2 Amps

Commissioning

Carry out a visual check to make sure all pipe work and electrical connections are connected in

a safe manner.

Fill the storage tank through the ll valve and ensure the overow connection and bypass are

connected. Ensure all of the below are completed before carrying out further commissioning

checks using the Multiboost Commissioning Checklist as a guide.

1. Discharge connection is connected to the system pipe work and overow.

2. The electrical supply cables are correctly connected to the mains isolator switch.

3. Check that the pre-charge pressure in the pressure tank is set 2LBs below the cut in

pressure.

4. Check all isolation valves are open on the Multiboost.

5. Check all pipe work for leaks.

6. Please ensure all current electrical regulations are adhered to on installation

7. Ensure correct model of Multiboost is selected for each application

8. Ensure drip trays/bunded tanks and insulation jackets are installed where required

9. Ensure a full mechanical and electrical test is carried out after installation has been

completed by a qualied registered installer

Electrical

Drip Trays

16

16

Commissioning Checklist

Installer Name:

Address:

Email:

Mobile No:

Multiboost Commissioning Checklist

INSTALLER DETAILS

TANK DETAILS

SCHEMATICS

Size of Tank (L): 200L 250L 350L 345L

450L 500L 750L 1000L

Bunded Option: 2

50L

650L

Tank Serial Number*:

Control Unit Date**:

Date Installed:

Commission Date:

Rectangular Rectangular

Bunded Option: 2

Bypass

Mains

Water Supply

Outlet Supply

2

3

7

3

8

56

4

1

1. Ball cock

Isolation valve with

pressure gauge

Bypass isolation valve

Separate Multiboost overflow

Separate drip tray over flow

Multiboost drain off

Drip tray

2.

3.

4.

5.

6.

7.

Removable lid with pump

8.

& controller inbuilt

Multiboost

200L, 270L, 345L and 455L

*EPS recommends the use of a drip tray and insulation jacket with every installation

Scan for Ball Cock

Performance Selection

Bypass

Mains

Water Supply

Overflow to drain from tank

Overflow to drain from drip tray

Outlet

3

3

6

7

5

2

1

4

*EPS recommends the use of a drip tray and insulation jacket with every installation

1. Ball cock

Isolation valve with

pressure gauge

Bypass isolation valve

Multiboost overflow

Multiboost drain off

Drip tray

2.

3.

4.

5.

6.

Drip tray overflow7.

Multiboost

200L, 350L, 450L, 750L

Scan for Ball Cock

Performance Selection

Bypass

Mains

Water Supply

Overflow to drain from tank

Overflow to drain from drip tray

Outlet

3

3

6

7

5

2

1

4

*EPS recommends the use of a drip tray and insulation jacket with every installation

1. Ball cock

Isolation valve with

pressure gauge

Bypass isolation valve

Multiboost overflow

Multiboost drain off

Drip tray

2.

3.

4.

5.

6.

Drip tray overflow7.

Multiboost

200L, 350L, 450L, 750L

Scan for Ball Cock

Performance Selection

Bypass

Mains

Water Supply

Overflow to drain from tank

Overflow to drain from drip tray

Outlet

3

3

6

7

5

2

1

4

*EPS recommends the use of a drip tray and insulation jacket with every installation

1. Ball cock

Isolation valve with

pressure gauge

Bypass isolation valve

Multiboost overflow

Multiboost drain off

Drip tray

2.

3.

4.

5.

6.

Drip tray overflow7.

Multiboost

200L, 350L, 450L, 750L

Scan for Ball Cock

Performance Selection

Bypass

Mains

Water Supply

Outlet Supply

2

3

7

3

8

56

4

1

1. Ball cock

Isolation valve with

pressure gauge

Bypass isolation valve

Separate Multiboost overflow

Separate drip tray over flow

Multiboost drain off

Drip tray

2.

3.

4.

5.

6.

7.

Removable lid with pump

8.

& controller inbuilt

Multiboost

200L, 270L, 345L and 455L

*EPS recommends the use of a drip tray and insulation jacket with every installation

Scan for Ball Cock

Performance Selection

Slimline

Utility

Sample Label

on Control Unit

Tank Serial Number* Control Unit

Date**

Name:

Address:

Email:

Mobile No:

CLIENTS DETAILS

Construction Co:

Project ID:

Engineer:

Mobile No:

PROJECT DETAILS

Place of Purchase:

Plumber/Installer:

Email:

Mobile No:

PURCHASE DETAILS

17

17

Commissioning Checklist Commissioning Checklist

INSTALLATION AND COMMISSIONING CHECKLIST

ITEM STATUS COMMENT

Visual inspection of Multiboost for any defects Yes No

Is a Multiboost installation label on tank? Yes No

Is there a drip tray installation label on tank? Yes No

Is the Multiboost positioned in a safe location? Yes No

Is the Multiboost installed away from direct sunlight? Yes No

Is there a bypass unit tted around system? Yes No

Is there a shut o valve tted on inlet of tank? Yes No

Is a drip tray tted with correct size overow? Yes No

Is an insulation jacket tted? Yes No

Has the correct overow pipe beenW selected for Multiboost? Yes No

Has the correct overow pipework been selected for drip tray? Yes No

Have overows been piped separately, without any sharp

edges which could cause restriction? Yes No

Has incoming water pressure been tested and has the correct

ballcock been selected and tested? Yes No

Has the Multiboost been tted in a ventilated area? Yes No

Has the unit’s power supply to electrical supply been

connected in accordance with current regulations and by a

qualied, trained person?

Yes No

Has a full test of overow pipes been done? Yes No

Has the system been correctly installed and fully tested? Yes No

Any pressure reducing valves tted on line ?

If yes, has the control unit been adjusted to the correct

parameters for operation? Yes No

Incoming water pressure to Multiboost PSI

Multiboost cut in pressure PSI

Multiboost close valve pressure PSI

QR CODES

Installation

Video

O&M

Manual

Unit

Schematics

Print Name

(Installer): Signed: Position: Date:

Print Name

(Engineer): Signed: Position: Date:

Yes No

EPS recommends the use of a drip tray for each installation

18

18

Maximum Operating Conditions

Top Multi/ Top Multi Tech NK/UP

Liquid Temperature

+40°C +40°C

Maximum Pressures

4.2bar 9.5 bar

Noise Level of the Multiboost Set

≥48-55dB ≥48-55dB

Pump Type Specications

Pump Type Power Q

l/min 0 10 20 30 40 50 60 70 80

kW HP

Pedrollo Top Multi 2 /

Top Multi Tech

0.55 0.75

H Metres

42

40 38 34 30 24 18 11.5 5

Pedrollo NKm-GE-N 2/3

0.55 0.75 48

46 44.5 42.8 40.5 37.5 33.5 29 23

Pedrollo Upm –GE-N 2/3

0.55 0.75 48

46 44.5 40.5 33.5 23 - - -

Pedrollo NKm –GE-N 2/4

0.75 1 60

58 55 51 47 42 36 30 23

Pedrollo Upm –GE-N 2/4

0.75 1 63

61 59 - 54 - 45 - 31

Pump Type & Control Information

• The declared performances are valid for liquids with density 1,0 kg/dm3and kinematic viscosity 1mm2/s

Date:

Approved by: Enrico Vandin

TOP MULTI 2 50Hz

TEST REPORT EN ISO 9906 Grade 3B

23.09.2015

45

46

47

48

49

50

51

52

53

54

55

0 10 20 30 40 50 60 70 80 90

Flow rate Q (l/min)

dB(A) at 1m

The declared performances are valid for liquids with density 1,0 kg/dm

3

and kinematic viscosity 1 mm

2

/s.

Top Multi 2 dB Level Graph 2015

The declared performances are valid for liquids with density 1,0 kg/dm3and kinematic viscosity 1mm2/s

Please note, when a pump is submerged in liquid, you are no longer dealing with decibel levels, but vibration levels, so the positioning of your

Multiboost is vitally important. The subsequent vibration levels will vary depending on the amount of space surounding the unit and the

type of material it is placed on. The use of insulation jackets will help to reduce vibration noise.

19

19

Pump Type & Control Information

• The declared performances are valid for liquids with density 1,0 kg/dm3and kinematic viscosity 1mm2/s

Conguration Fixed Speed Preso Multiboost

Settable parameters:

Running pressure.

When the pressure in the system

falls below the Pm, PRESFLO®

starts-up the pump. The Pm

should always be higher by at

least 0.2 – 0.3 bar of the pressure

generated by the column of

water overlooking PRESFLO®.

The Pm value can be carried in the

eld between 1 bar and 5 bar.

Maximum current allowed.

PRESFLO® is “tted with a current

sensor, which continually detects

the absorption of the pump. If

the current remains above the set

Imax value for a signi”cant period

of time, PRESFLO® stops the pump

to protect it from damages (LOCK

condition for OVERCURRENT).

PRESFLO® nevertheless allows

the Imax to be exceeded for short

periods during the pump start-up

phase.

For correct functioning, the

Imax should be set at a value

higher by approx. 10 – 20% to

the maximum absorption of the

pump

(normally indicated on the rating

plate of the motor).

If this rating value is not known, it

s better to leave the standard Imax

value (16A) to avoid that the pump

stops also in normal absorption

conditions.

The Imax value may be varied in

the“eld between 4A and 16A.

Manufacturer’s setting:

PRESFLO® is supplied with the following STANDARD CONFIGURA-

TION:

Running pressure

Pm = 2 ( bar )

Max. current allowed

I max = 16 ( A )

Conguration:

The adjustment of the starting pressure (Pm) and the maximum

permissible current (I max) is done by means of two trimmers shown

in FIG.

1. Remove the small screwdriver and adjust the trimmer on the

desired limits, according to the values shown on the plate

located under the screwdriver.

2. The start-up pressure can be adjusted continuously from 1 to 5

bar (trimmer A) .

3. The maximum permissible current can be adjusted continuous-

ly from 4 to 12 A (trimmer B)

4. When you nish adjustment close the cover

Fixed Speed - Presflo Multi Controls

Fixed Speed Control Pressure Settings

The Multiboost discharge cut-in pressure is factory set on the controller. The maximum

discharge pressure setting should not be set higher than the pressure the pump can achieve,

otherwise the pump will not stop with “a no water” demand condition, and will result in heating

the liquid in the pump and possible shaft seal damage.

The cut-in pressure is factory set at 2.5 bar pressure and 4.5 Amps

Pre-charge cut in pressure in the pressure tank must be set 2lbs below the cut in pressure. It is

recommended to check the tank air pressure every 4 months.

20

20

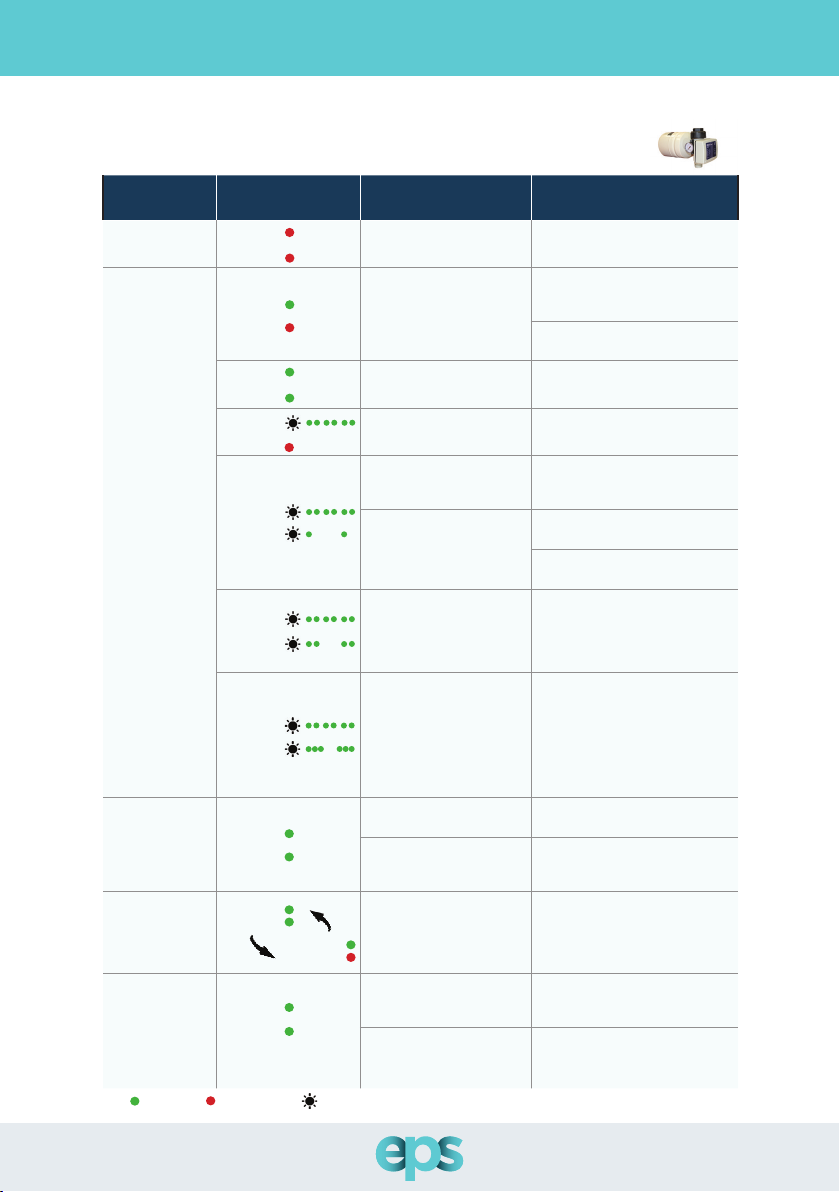

Troubleshooting

Problems Signals Possible causes Solutions

PRESFLO®(Multi)

will not turn on

POWER ON

PUMP ON

No power Check the electrical connections

The pump will

not start when a

tap is turned on

POWER ON

PUMP ON

PRESFLO® model with an inad-

equate start-up pressure (Pm)

for the chosen application

Relocate PRESFLO® to another

position

Install a model with a higher start-up

pressure (Pm)

POWER ON

PUMP ON

Faulty electrical connections

or pump out of service

Check the electrical connections and

that the pump is working

POWER ON

PUMP ON

PRESFLO®“STAND-BY”” Reset PRESFLO® (See Operation,

point 3).

POWER ON

PUMP ON

PRESFLO® in temporary shut

down due to“DRY RUNNING”

due to lack of water

Wait for the automatic restart or

press START to restart manually (See

Operation, point 4a)

Maximum pump pressure is

insucient

Replace the pump with one with

more suitable characteristics

Install a model with a lower start-up

pressure (Pm)

POWER ON

PUMP ON

PRESFLO® in temporary shut

down due to“FREQUENT

START-UP”

Wait for the automatic restart or press

START to restart manually (See Oper-

ation, point 4b). Remove any cause

of leakage from system or install an

expansion tank

POWER ON

PUMP ON

PRESFLO® stops due to“OVER-

CURRENT”

Check if the setting of the maximum

current (Imax) is congruent with the

data of the pumps’ratingplate. If after

manually restarting the pump after

correctly setting PRESFLO®, it again

signals an anomaly, check that the

motor has no mechanical or electrical

problems.

The pump

delivers no or

low pressure

POWER ON

PUMP ON

Filters or pipes may be partly

blocked

Check the water pipes

PRESFLO®’s valve will not open

completely

Check that the valve is not blocked

by any foreign objects and clean if

necessary

The pumps

stops and starts

repeatedly

POWER ON

PUMP ON

POWER ON

PUMP ON

Leaks within the system (less

than the shut-o ow rate Qa)

Check the hydraulic connections and

repair any leaks. If a leak cannot be

repaired, install an expansion tank

The pump will

not stop

POWER ON

PUMP ON

The ow rate is higher than

the shut-o ow rate (Qa)

Make sure that all taps are turned o

and that there are no leaks within

the system

PRESFLO®’s check valve will

not close or is damaged

Check that the valve is not blocked

by any foreign objects and clean if

necessary

On FlashingO

Presflo Multi

Presflo Vario

This manual suits for next models

61

Table of contents

Popular Water Pump manuals by other brands

Goulds Pumps

Goulds Pumps 3935 Installation, operation and maintenance instructions

Adam Pumps

Adam Pumps G FLOW TRANSLATION OF ORIGINAL INSTRUCTIONS

EBARA

EBARA 3D Operating and maintenance manual

Pfeiffer Vacuum

Pfeiffer Vacuum ES 25S operating instructions

Grundfos

Grundfos UPM3 instructions

Graco

Graco Husky 715 instructions

Kessel

Kessel Aqualift F Duo/XXL SPF 550 KE Installation, operating and maintenance instructions

Calpeda

Calpeda CAL170 TECHNICAL INSTRUCTIONS FOR USE

Denso

Denso first time fit instructions

Grundfos

Grundfos alpha2 l Installation and operating instructions

Bestway

Bestway Sidewinder 62097 operating instructions

Grundfos

Grundfos Hydro Multi-B instructions