SAFETY

Understand that your safety and the safety of

other persons is measured by how you service

and operate this backhoe. Know the position

and operations of all controls before you they

to operate. Make

MakeMake

Make sure

suresure

sure you

youyou

you check

checkcheck

check all

allall

all controls

controlscontrols

controls

in all safe area before starting.

in all safe area before starting.in all safe area before starting.

in all safe area before starting.

Read

ReadRead

Read this

thisthis

this manual

manualmanual

manual completely

completelycompletely

completely and

andand

and thoroughly

thoroughlythoroughly

thoroughly

and make sure you understand all controls. All

equipment has a limit. Make sure you are aware

of the stability and load characteristics of this

backhoe before you begin operation.

The safety information given in this manual

does not replace any safety codes, insurance

needs, federal, state and local laws. Make

sure your machine has the correct equipment

required by your local laws and regulations.

This safety alert symbol indicates important safety messages in this manual.

This safety alert symbol indicates important safety messages in this manual. This safety alert symbol indicates important safety messages in this manual.

This safety alert symbol indicates important safety messages in this manual.

When you see this symbol, carefully read the message that follows and

When you see this symbol, carefully read the message that follows and When you see this symbol, carefully read the message that follows and

When you see this symbol, carefully read the message that follows and

be alert to the possibility of personal injury or death.

be alert to the possibility of personal injury or death. be alert to the possibility of personal injury or death.

be alert to the possibility of personal injury or death.

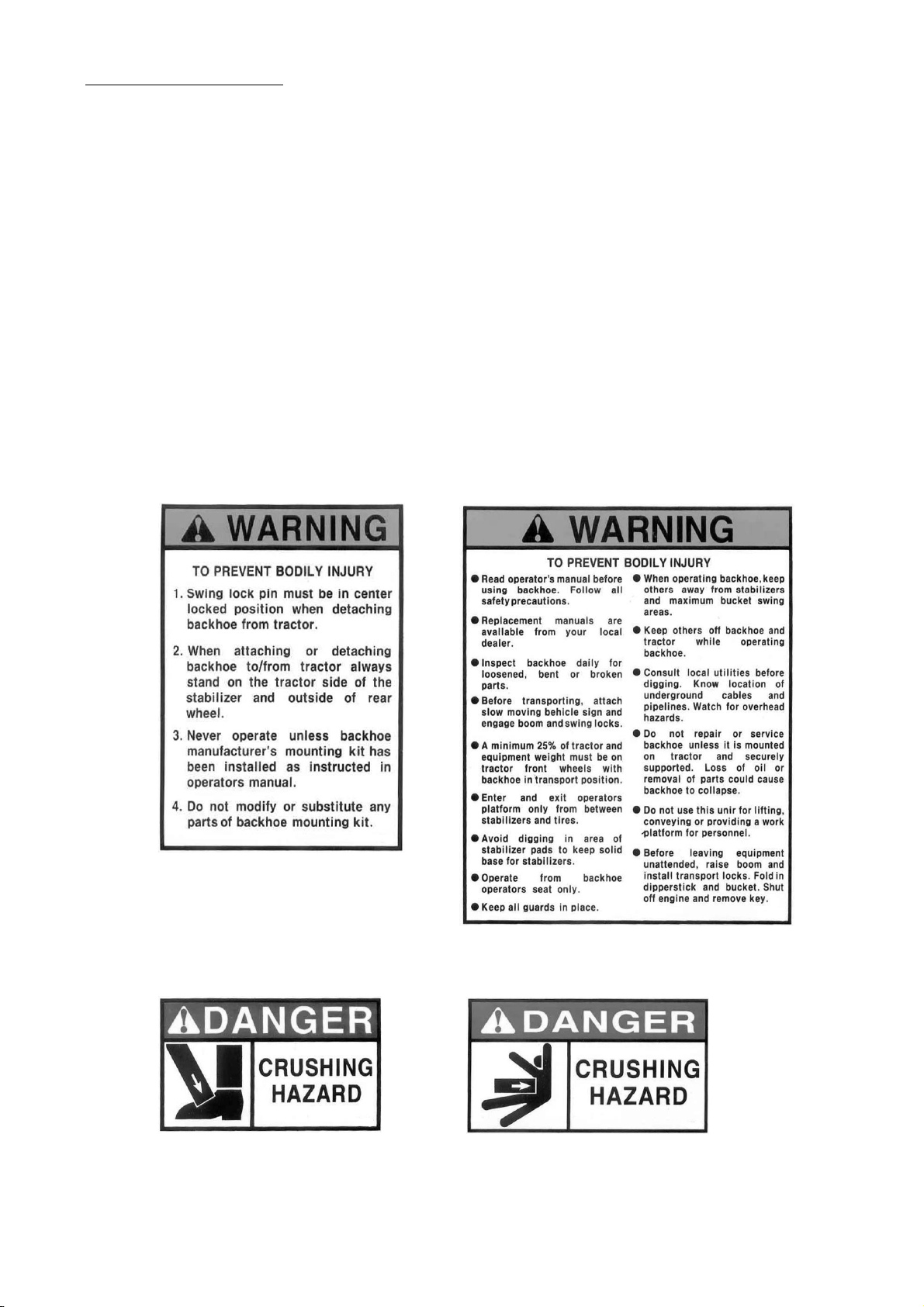

SAFETY PRECAUTIONS

SAFETY PRECAUTIONSSAFETY PRECAUTIONS

SAFETY PRECAUTIONS

Before starting the engine of your tractor,

make sure all operation controls are in park

lock or neutral position.

Stop the backhoe arms gradually when lowering

or lifting loads.

- 4 -

Before applying hydraulic pressure, make sure

all hydraulic connections are tight and

components are in good condition.

When using remote hydraulic tractor valves on

some tractors, the backhoe lift and dump

cylinders will continue moving unless the

control levers are manually returned to neutral,

or until relief pressure is reached at the ends

of piston strokes. Observe the bucket

movement and maintain control with the

control levers.

Equip your tractor with a ROPS cab or frame

for your protection. See your tractor operator's

manual for correct seat belt usage.

Travel speed should be such that complete

control and machine stability is maintained at all

times. Where possible, avoid operation near

ditches, embankments and holes. Reduce

speed when turning, crossing slopes, and on

rough, slick or muddy surfaces.

A frequent cause of personal injury or death is

persons falling off and being run over. Do not

permit others to ride on your tractor. Only one

person, the operator, should be on the

machine when it is in operation.

Never use your hand to check for suspected

leaks under pressure. Use a piece of cardbord

or wood for this purpose. Escaping hydraulic oil

or diesel fuel leaking under pressure can have

have sufficient force to penetrate the skin and

cause infection or other injured by leaking fluid,

seek medical attention immediately.

Before leaving the tractor, stop the engine,

put all controls in neutral, engage the parking

brake and remove the key from the ignition.

To prevent personal injury, relieve all pressure

before disconnecting fluid lines.

lock or neutral position.

Stay off of slopes too steep for safe operation.

Shift down before you start up or down a hill

with a heavy load. Avoid "free wheeling"

Operate controls only when seated in the

operator's seat.

- 4 -