IN - 1

INTRODUCTION E215C-E245C

TO THE READER

• This manual is written for an experienced

technician to provide technical information

needed to maintain and repair this machine.

- Be sure to thoroughly read this manual for

correct information concerning the service

procedures.

- If you have any questions or comments, or if you

found any errors regarding the contents of this

manual, please contact:

NEW HOLLAND KOBELCO

CONSTRUCTION MACHINERY S.p.A.

Strada Settimo, 323

San Mauro Torinese (TO)

10099 ITALIA

PRODUCT SUPPORT

Fax. ++39 011 0077357

ADDITIONAL REFERENCES

• Please refer to the materials listed below in

addition to this service manual:

- Operator's Manual

- Service Parts Catalogue

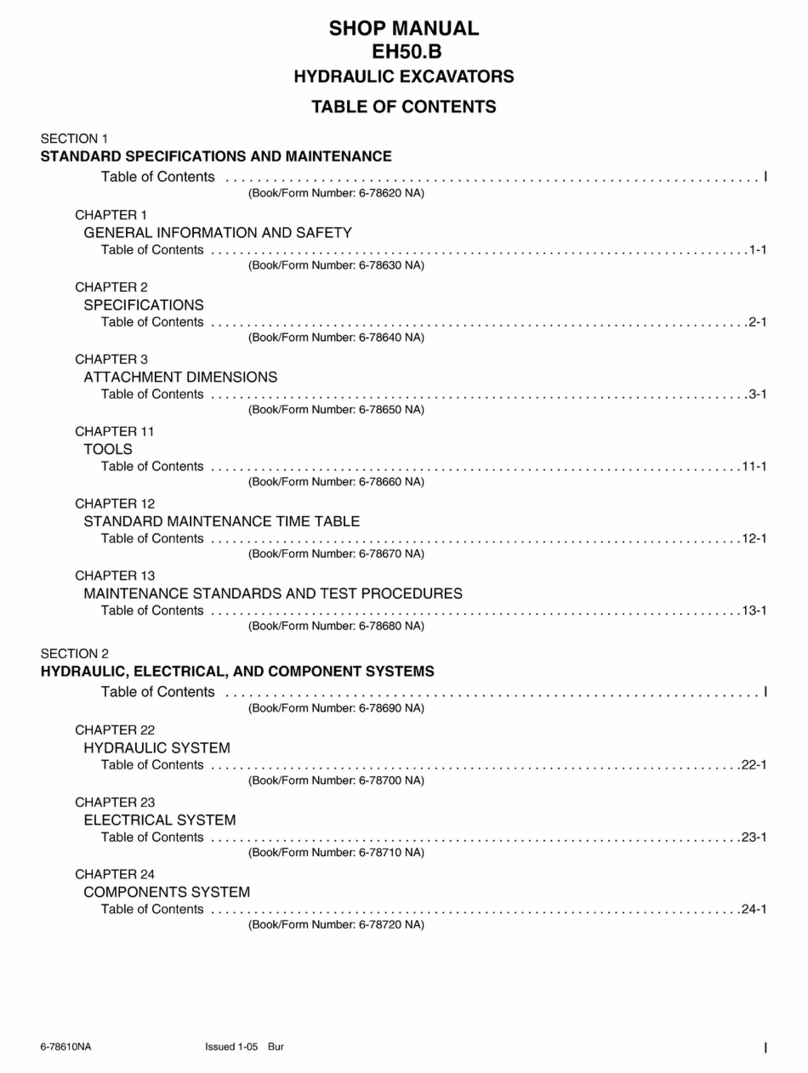

COMPLETE SERVICE MANUAL

• The complete Service Manual consists of two

distinct volumes:

- Service Manual “Crawler Excavators”

- Service Manual “Engine”

The two distinct volumes of the complete Service

Manual can be identified through their print number

as stated below:

• The Service Manual “Crawler Excavators”

consists of five parts:

- “General Safety Information”

- “Operational Principle”

- “Operational Performance Test”

- “Troubleshouting”

- “Repair Instructions”

- The “General Safety Information” part includes the

recommended procedures that, if followed, can

avoid the risk of accident for operator and for staff

related to the work and maintenance machine

operations.

- The “Operational Principle” part includes the

technical information concerning the operation of

main devices and systems.

- The “Operational Performance Test” part includes

the information needed to carry out the machine

operational performance test.

- The “Troubleshooting” part includes the technical

information needed for troubleshooting and

malfunction detection.

- The “Repair Instructions” part includes information

needed for maintenance and repair of the

machine, tools and devices needed for

maintenance and repair, maintenance standards,

removal/installation and assembly/disassembly

procedures.

VOLUME PRINT NUMBER

Service Manual “Crawler Excavators” 84550265A

Service Manual “Engine” 84392403

Find manuals at https://best-manuals.com