Eramco Dust Free 3000 Series Manual

Save This Manual For

Future Reference

Installation

and

Service

Manual

Read ALL

INSTRUCTIONS

carefully.

Part No. 775-0299-497 Rev. 1C

Eramco PO Box 519 Royse City, TX 75189-0519 1-972-635-9565

Series 3000

This manual is copyright protected by ERAMCO. Any reproduction of this manual, in part or full, without the written permission of ERAMCO,

constitutes a violation of the U.S. copyright laws and is subject to prosecution.

©Printed in the U.S. by the Graphics Productions Department of ERAMCO, 1998.

Air Cleaners

2PERFORMANCE OVERVIEW

The Series 3000 air purifier is designed to remove airborne particulates and/or gases and odors

from the air that passes through it. It is a modular unit where the filter housing and blower

housing are in separate cabinets that are then assemble in the field. The air volume with clean

filters wil range from 3000 - 4800 CFM depending on the filter configuration and ducting. The

system is designed to accomodate 1.5" w.g. increase in pressure due to filter loading with an air

volume loss of less than 15% when filters are loaded and in need of replacement.

The Series 3000 is constructed of 16 gauge powder coat painted steel. Large access doors are

provided along the right side of the unit for servicing the filters, motor, or blower. The unit comes

standard witha5HPmotor with 7.5 HP motor available as an option. Other options include

vertical air discharge, Inlet/Outlet plenums, roof mounting I-beams, and insulated weather-tight

cabinets. A wide assortment of filter options are also available. Refer to the replacement parts

list at the end of this owners manual.

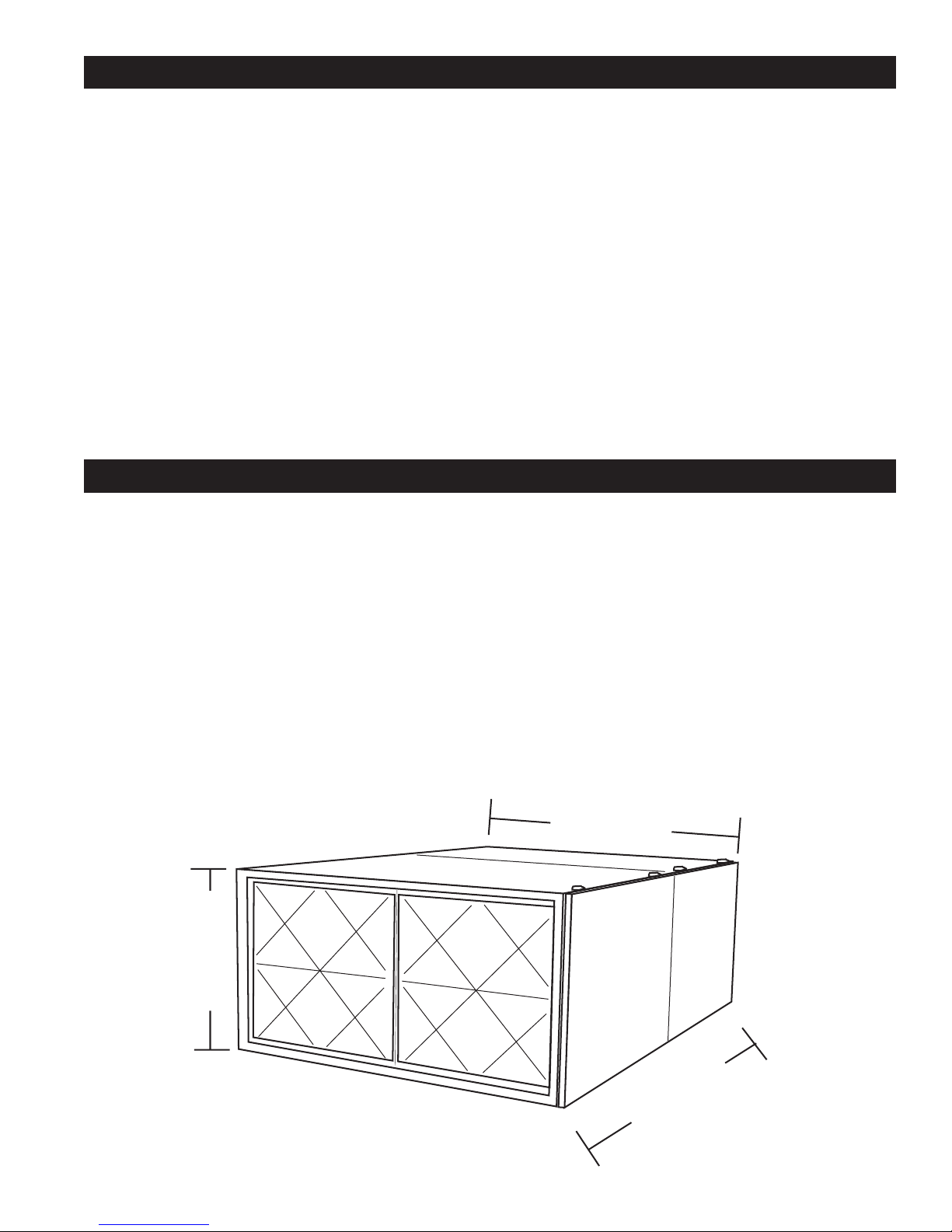

SPECIFICATIONS

Series 3000 Specifications

Dimensions:

Weight:

Motor:

Air Volume:

95.25"L x 51.25"W x 26.25"H

(241.9 x 130.2 x 66.7 cm)

900 - 1200 lbs. (408.2 - 544.3 kg) installed

Add 250 lbs (113.4 kg) for shipping

5 HP, 230/460v, 3 PH, 13 Amps, Class I blower, belt drive, FC.

Optional 7.5 HP TEFC 230/460 VAC, 3 PH, 25 Amps, Class II blower,

belt drive FC, or direct drive BC airfoil. Optional motor starter.

3000 - 4800CFM (85 - 136 CMM) depending on filter configuration.

51.25"

77.25"

26.25"

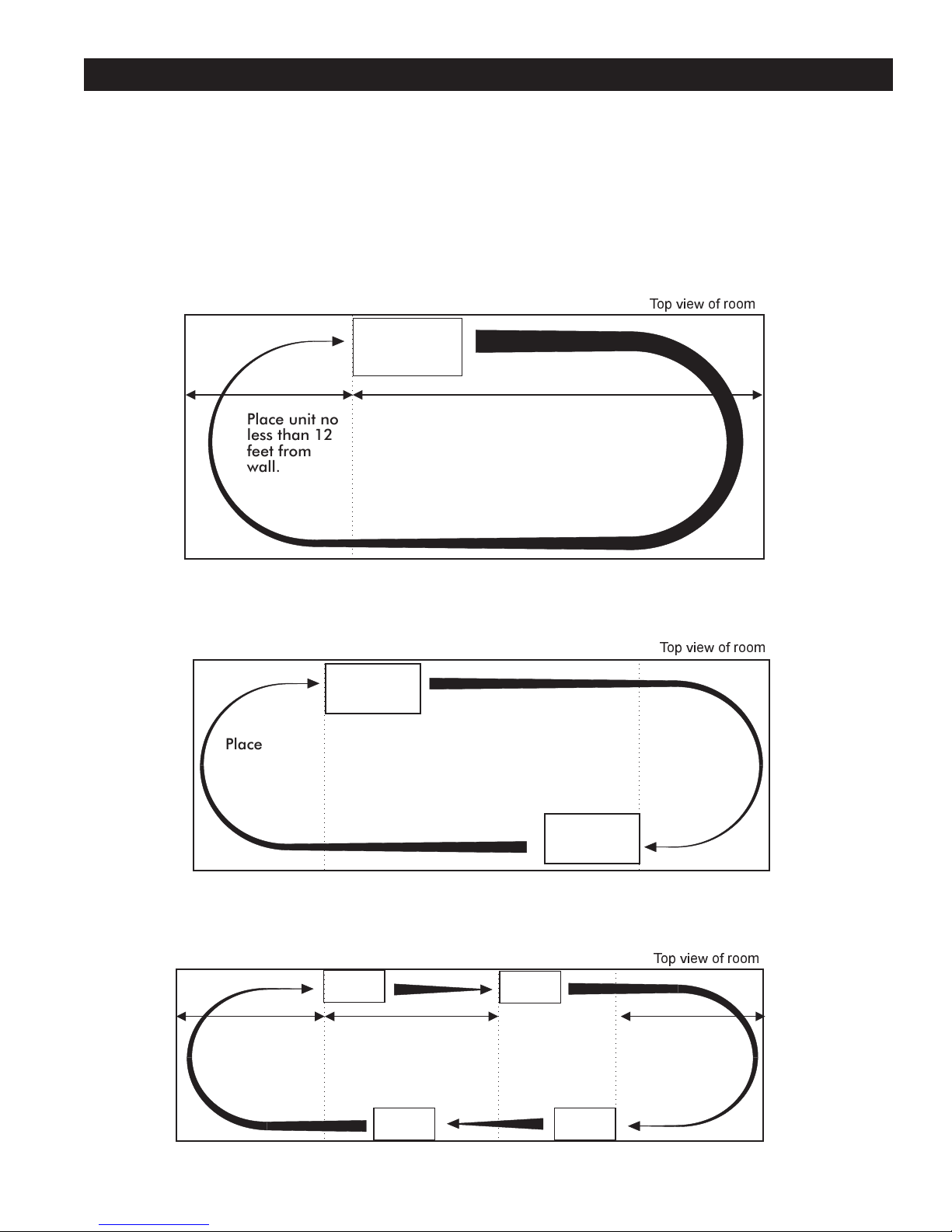

The Eramco air cleaners should be suspended from the ceiling at a height of 15 feet or less

above the floor. Position units as shown in the following illustrations. If you need additional

installation advise contact the distributor/dealer from whom you purchased the equipment. Call

the factory if the distributor/dealer is not available.

UNIT LOCATION 3

Multi-Unit Configuration

Dual-Unit Configuration

Single-Unit Configuration

Top view of room

Top view of room

Top view of room

Place unit no

less than 12

feet from

wall.

Place unit no

less than 12

feet from

wall.

Place unit no

less than 12

feet from

wall.

No less

than 25%

of room

length.

No less

than 25%

of room

length.

30% of

room

length.

70% of room

length but not

more than 45

feet.

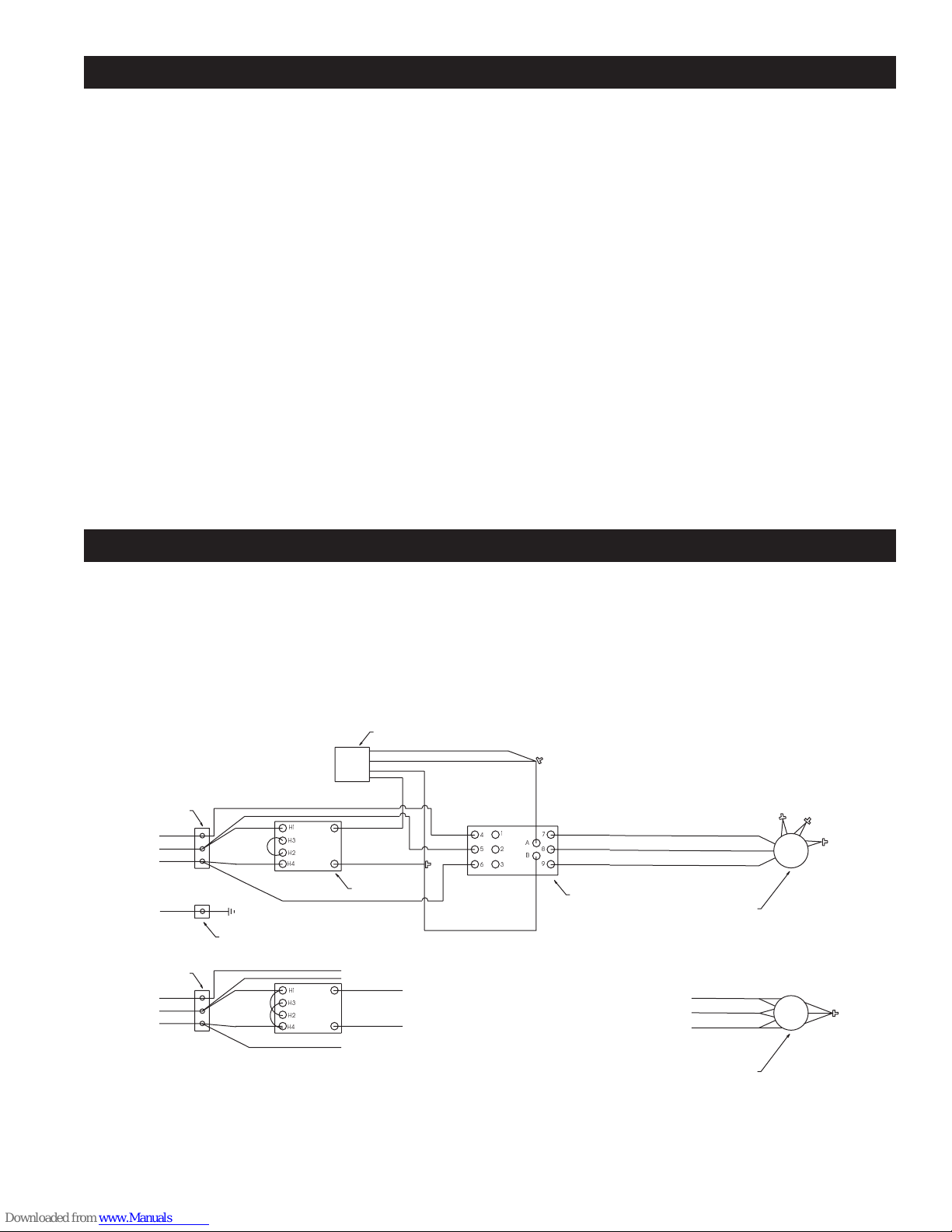

4INSTALLATION

ELECTRICAL

UNPACKING

PREPARATION

Upon receipt, immediately inspect the carton for damage during transit. Signs of rough handling

may indicate internal damage in the air cleaner. Carefully unpack the unit and examine it for

concealed shipping damage. If the unit is damaged, contact the carrier to file a claim.

Carefully read the entire manual before starting installation. Authorities having jurisdiction should

be consulted prior to installation. Permits may be required. If there are no local codes, installation

should conform to the National Electrical Code. The electrical supply, volts, amps, hertz, and

phase, must correspond to that on the unit rating plate. Refer to dimensional drawings for the inlet

and supply dimensions for the duct connections, electrical inlets, and unit clearances before

setting the unit in place. The supply side duct opening at the discharge end of the unit is small

and operates at high velocity. A gradual transition to the larger supply duct should be used and

extra care taken to prevent the accidental dislodging of internal duct insulation in the transition.

Take note of the side clearance required to access blower motor and drive belts, and the space

required to replace the filters. Recommended minimum side clearance is 25" on the door side

and 12" on the power side.

The Series 3000 can be wired for 230 or 460 line voltage. Typical running amps at 230 volts

range from 8.3 to 13 amps depending on the filter configuration and external static load. The

schematic below illustrates the wiring required for each line voltage. The control box will

accommodate conduit from 1/2" to 1 1/4" in each of two bottom knockouts. Field wire the unit with

wire suitable for a 30 amp service and a full load of 13 amps.

BLUE

BLUE

BLUE

240V 3PH

460V 3PH

TERMINAL BLOCK

LINE

LINE

JUMPER

JUMPER

BLUE

GROUND LUG

GROUND

CHASSIS GRND

TERMINAL BLOCK

BLUE

BLUE

BLUE

BLUE

BLUE

YELLOW

YELLOW

BLUE

BLUE

BLUE

BLUE

BLUE

BLUE

TI

TI

T2

T2

T3

T3

T4

T4

T5

T5

T6

T6

T9

T9

T7

T7

T8

T8

24V RELAY SOCKET

460V 3PH 1-SPEED MOTOR

240V 3PH 1-SPEED MOTOR

240/460 V /24V

TRANSFORMER

YELLOW

YELLOW

RED

RED

BROWN

BROWN

BROWN

BLACK

BLACK

CONTROLLER

BLUE

17

8

9

2A

B

3

4

5

6

H1

H1

H2

H2

H3

H3

H4

H4

5INSTALLATION

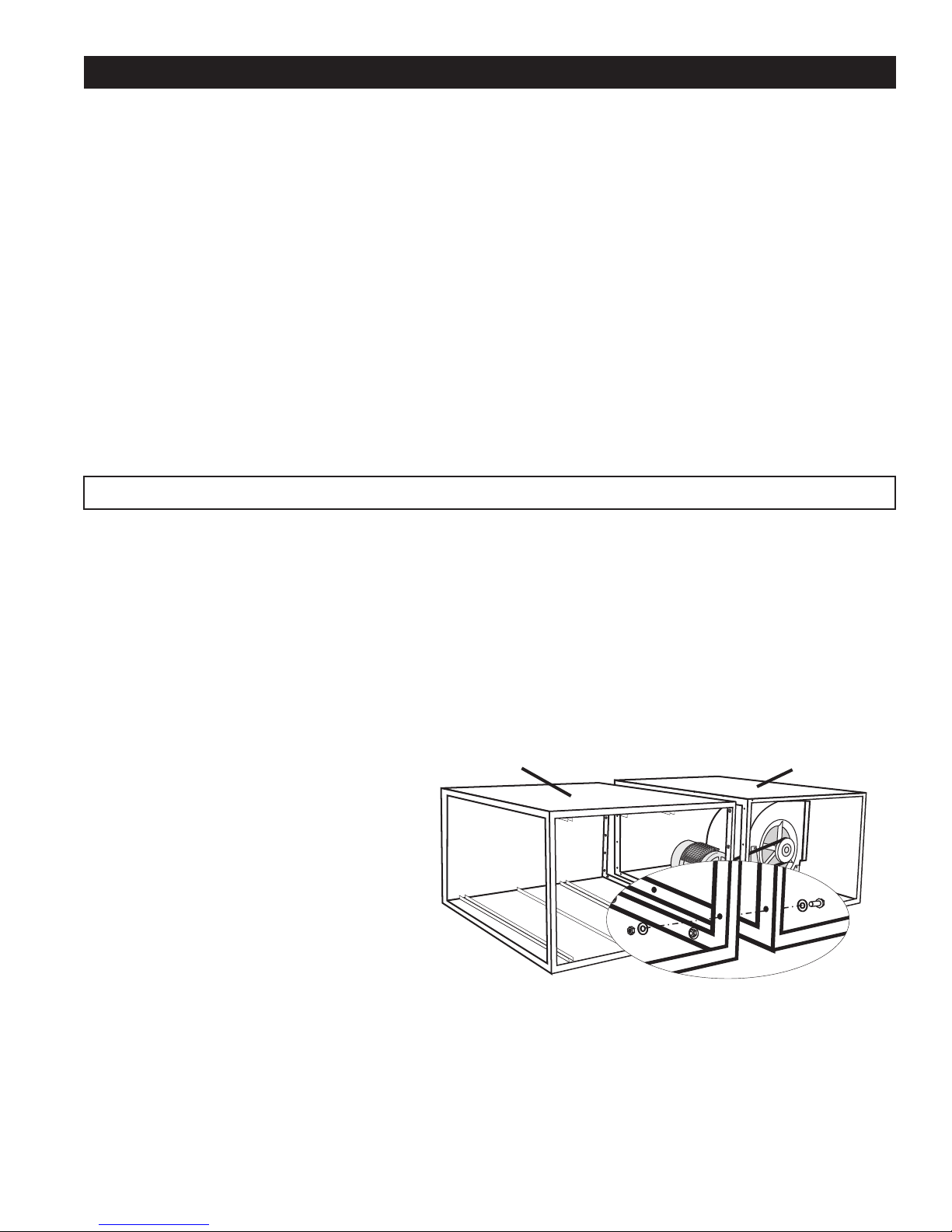

The unit is shipped in two sections for easier field installation. The blower cabinet comes with a

motor and a belt driven blower. The unit must be mounted with the motor mount base plate down.

The filter cabinet comes with the filter rails and the adsorbent racks pre-installed.

The unit can be lifted into position with the blower housing on the bottom and the filter housing on

top. The unit may also be positioned as two separate pieces. The side doors should remain on

the unit to protect the door gaskets and add rigidity to the door side of the unit. Place the heavier

blower housing in place first and position on the supports and attach to support structure if

required. After the blower housing is in place the filter housing can be positioned and joined.

1. Mount the filter cabinet with the

supply end bolted to the return end of

the blower cabinet. Join the two parts

using the 5/16" x 1" bolts, nuts, and

washers supplied with the unit (Fig. 2).

Be careful not to distort or bend the

mating parts. Install one bolt in each

corner and tighten to bring module into

alignment. Install the remaining bolts.

2. Apply the flexible sealant (butyl

caulk) to the outside of the joint to cover

the gasket and to assist in developing

an air and water tight joint.

ASSEMBLY

Verify that the electrical service is the correct voltage, current capacity and phase as listed on the

unit nameplate. Refer to the wiring diagram and verify that the motor and the control transformer

are wired correctly.

Install an electrical disconnect to ensure safe servicing of the unit and emergency shut down.

Check electrical code for location and type of disconnect required.

Size breaker to accommodate the motor start current and the wire size. Field wire the unit using

wire and conduit in compliance with the applicable local electrical code. Verify that the correct

type of four conductor low voltage control wire in accordance with the local electrical code and

ordinances. Standard thermostat wire can be used for most applications. Test the motor for

starting and proper rotation. The blower wheel must rotate toward the cutoff for proper operation

of the unit. Short periods of operation, less than 30 seconds, without filters or with the service

access doors open to verify blower rotation are permitted and will not cause tripping of the

automatic overload protection. If the motor does not rotate in the correct direction (Fig. 4) swap

any two of the main power leads to reverse the rotation.

FILTER CABINET BLOWER CABINET

FASTENER CONFIGURATION

Fig. 2

3. Check the blower fan for proper

alignment. The fan should be centered in the

housing. The belt should be tightened so

that you can push down on the belt with one

finger depressing the belt one inch in the

center between the pulleys (Fig. 3).

4. The pulleys should be lined up so that a

straightedge will lay flat against the sides of

both pulleys (Fig. 5). If the pulleys are out of

alignment they must be aligned prior to

operation of the unit. Incorrect alignment will

result in premature belt failure and excessive

pulley wear.

FAN SHAFT POSITION ADJUSTMENT

If the shaft is not properly centered, the fan may scrape against the scroll. To center the assembly,

loosen the Allen set screw on the locking collar of each fan shaft bearing. Slide the shaft into the

proper position and replace the locking collar.

To replace the collar, push it against the

inner race of the bearing, turn the collar in

the direction of the shaft rotation until tight,

then tighten the set screws. Tightening the

locking collar in the direction of the fan

rotation will result in further tightening of the

collar should the set screw work loose.

FAN WHEEL ADJUSTMENT

If the fan is not centered in the scroll and/or

is rubbing against the scroll, it should be

repositioned. Loosen the square head bolt

holding the fan wheel hub to the shaft.

Position the fan wheel in the center of the

fan housing and tighten the locking bolt.

Clearances between the wheel and housing

should be the same on each side.

6INSTALLATION

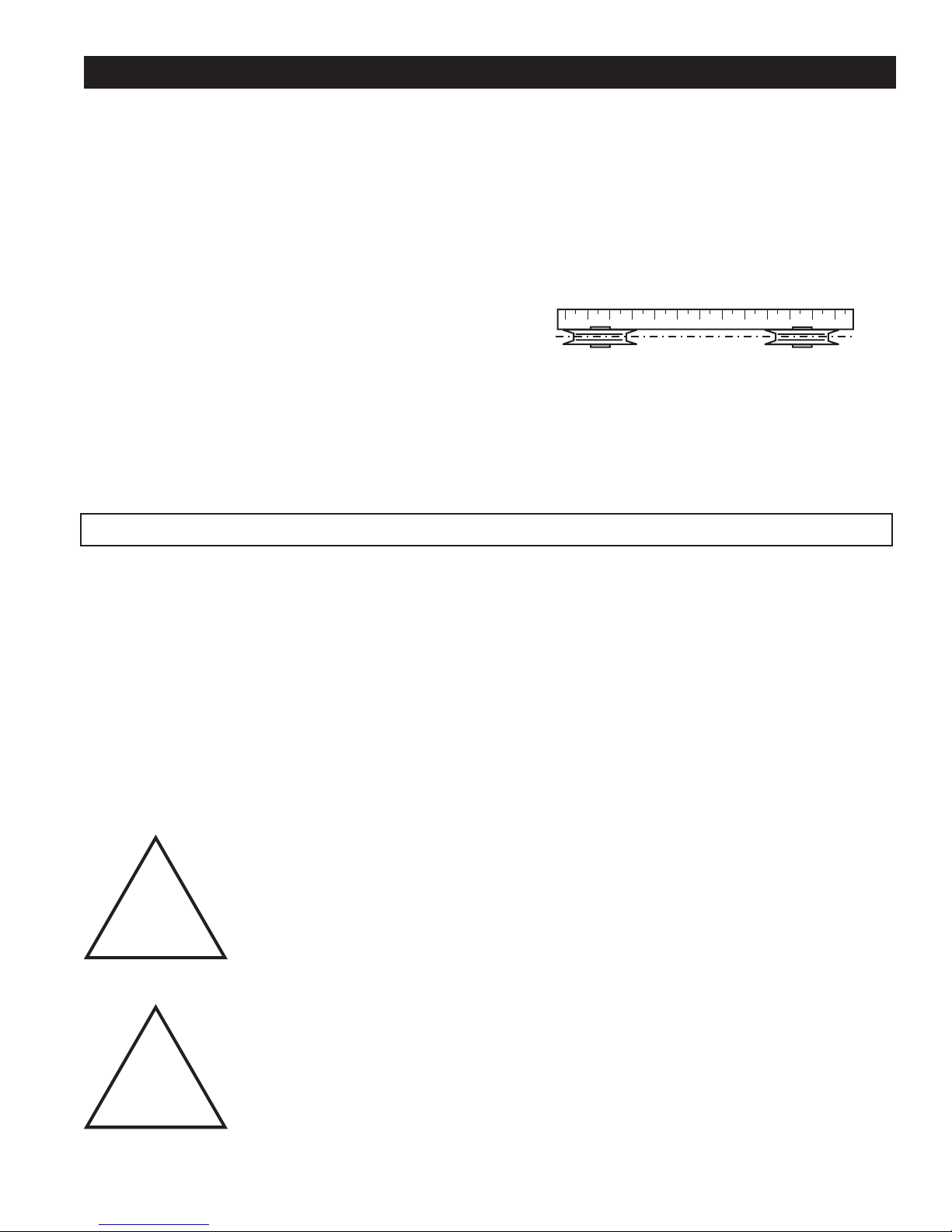

BELT TENSION

(1" Maximum)

BLOWER ROTATION

Fig. 3

Fig. 4

!Do not change the pulley sizes on the unit without factory

authorization. The motor size and blower RPM are balanced with

the standard filter configuration to provide optimum performance

and protect the motor from overload and permanent damage.

ADJUSTMENTS

FAN ROTATION

Fan rotation is toward the cutoff point or clockwise viewed from the pulley end of the blower shaft

(Fig. 4).

PULLEY ALIGNMENT

Proper pulley alignment is necessary to prevent

excess wear of the fan belt and pulleys. To adjust,

remove the two 1/4" bolts from the tapered hub

bushing. Thread them into the two threaded openings

to separate the hub from the pulley. Move the hub in

the direction necessary to align the pulley. Remove

the bolts and place them through the holes in the hub

and into the threaded holes in the pulley. Take up the

slack and tighten the bolts to relock the pulley to the

shaft. Use the straightedge to check alignment (Fig.

5). Repeat the adjustment process as required.

The unit requires a minimum of six (6) points of support that are three inches square and elevate

the door side three (3) inches from the surface to provide door latch clearance. The mounts should

be positioned at each of the four corners and two to support the joint of the unit halves. Support

beams or pads must be located three (3) inches away from the bottom to allow operation of the

bottom door latches. If 4"x4" timers are used be sure that they are both long enough to support the

weight and oriented so as to transfer the weight of the unit to the underlying support structure. If

attachment to the support structure is required, the floor or back side may be field drilled for bolts

or screws. Seal all penetrations with silicone rubber or butyl rubber to avoid water and air leaks.

Take care to place bolts where they will not interfere with filter insertion or removal. The standard

unit is NOT designed to be stacked two high or mounted vertically. Contact the factory for special

mounting requirements.

7INSTALLATION

PULLEY ALIGNMENT

Fig. 5

MOUNTING

!

!

Take note of the units weight and the maximum safe static load that

the mounting location will support. The blower end of the unit may

be heavier than the filter end. For roof mounting, add the expected

snow and ice load to the unit weight in order to arrive at a safe load

requirement.

Keep loose objects out of the blower and filter housing. Loose

objects pulled into the blower can cause the mechanical failure of

the blower wheel and result in severe injury to persons in the

discharge path.

ROOF MOUNT

The unit should be supported on beams or pads that are high enough so that water on

the roof cannot rise to the bottom of the unit. If 4"x4" timers are used, be sure that they

are both long enough to support the weight and oriented so as to transfer the weight of

the unit to the roof and the underlying support structure. If attachment to the support

structure is required, the floor or back side of the unit may be field drilled for bolts or

screws. Seal all penetrations with silicone rubber or butyl rubber to avoid water and air

leaks. Place bolts or screws where they will not interfere with filter insertion or removal.

Take care to locate the duct work so that the filter and motor are easily serviced. Locate

and shim the support beams or pads so they equally support the load.

PAD MOUNT

The unit should be supported on beams or pads that are high enough that water cannot

rise to the bottom of the unit and damage the filters or the motor. If 4"x4" timbers are

used be sure that they are both long enough to support the weight and oriented so as to

transfer the weight of the unit to the pad. Take care to place the duct work so that the

filters and motor are easily serviced. Locate and shim the support beams or pads so

they equally support the load.

8INSTALLATION

MAINTENANCE 9

Filters must be replaced with filters of the same size, type, and efficiency rating in order to

maintain the performance of the unit. Incorrect filters can lead to premature motor failure and will

void the manufacturer's warranty. Check with the distributor or manufacturer to determine the

exact filter configuration for the specific installation.

Remove the filter cabinet door by unlatching the top and bottom latches and removing the door.

Remove the dirty filters by sliding them out of the open door side. Place the new filters in the

same location, observing the air flow direction.

Adsorbent Filter Tray

The unit is shipped with the adsorbent filters wrapped in a protective film. The protective film must

be removed prior to operation. Remove the filter cabinet door and slide out the adsorbent filter

tray. Remove the screws that hold the end panel in place and remove the end panel. Slide the

individual adsorbent filters from the tray, remove the protective wrap and place the filters back into

the adsorbent filter tray. Replace the end panel and the screws. Repeat the process for the

remaining filters.

!

!

!

Do not operate the unit without the filters in place or with an access

door open as this will place a load on the motor that exceeds its

rating and will damage the motor.

Replace filters only with factory supplied or factory approved filters

to ensure continued performance and continuance of factory

warranty.

Do not operate the unit without a discharge duct or a shield to

protect personnel from the high velocity air discharge. Dirt and other

material can be propelled with sufficient force to cause injury.

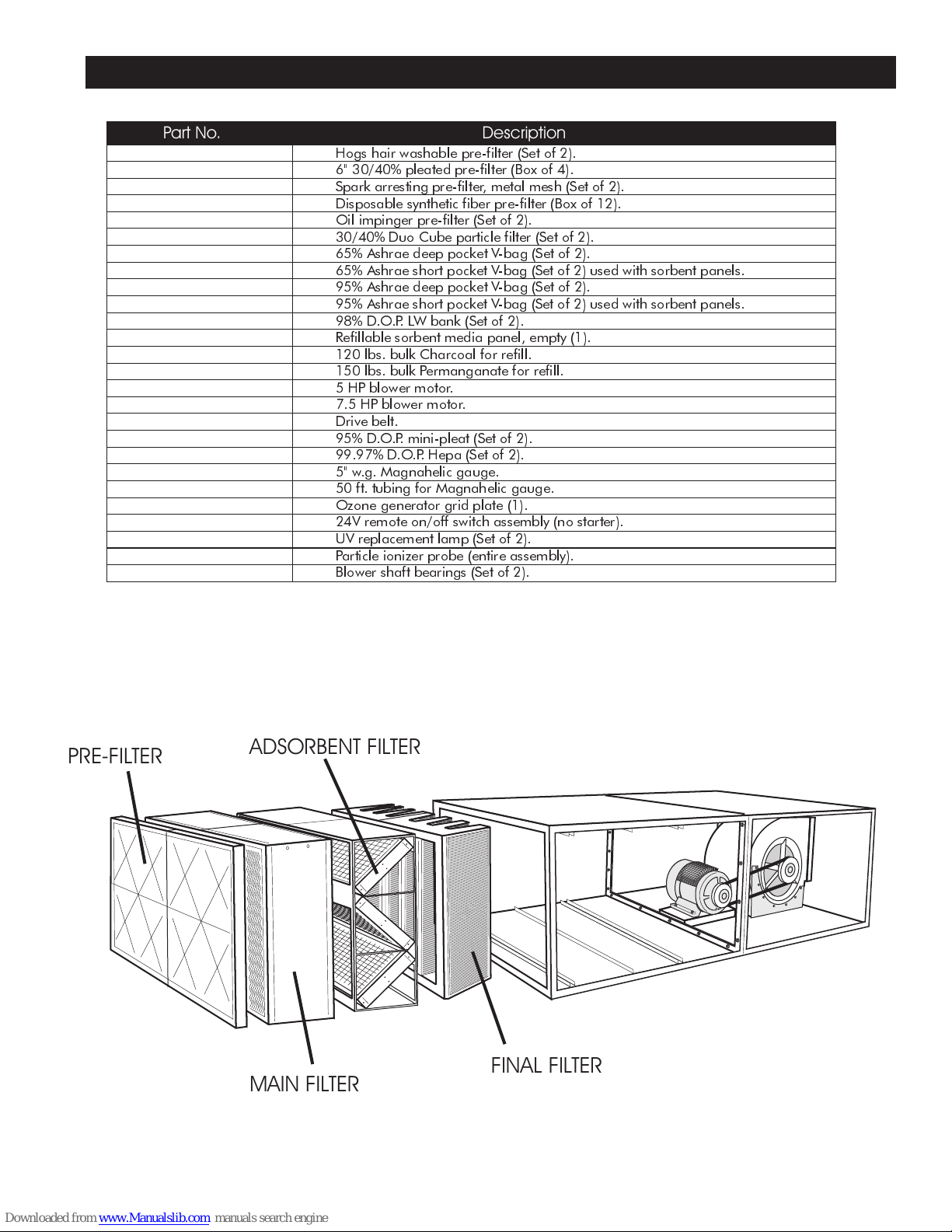

REPLACEMENT PARTS LIST 7

Hogs hair washable pre-filter (Set of 2).

6" 30/40% pleated pre-filter (Box of 4).

Spark arresting pre-filter, metal mesh (Set of 2).

Disposable synthetic fiber pre-filter (Box of 12).

Oil impinger pre-filter (Set of 2).

30/40% Duo Cube particle filter (Set of 2).

65% Ashrae deep pocket V-bag (Set of 2).

65% Ashrae short pocket V-bag (Set of 2) used with sorbent panels.

95% Ashrae deep pocket V-bag (Set of 2).

95% Ashrae short pocket V-bag (Set of 2) used with sorbent panels.

98% D.O.P. LW bank (Set of 2).

Refillable sorbent media panel, empty (1).

120 lbs. bulk Charcoal for refill.

150 lbs. bulk Permanganate for refill.

5 HP blower motor.

7.5 HP blower motor.

Drive belt.

95% D.O.P. mini-pleat (Set of 2).

99.97% D.O.P. Hepa (Set of 2).

5" w.g. Magnahelic gauge.

50 ft. tubing for Magnahelic gauge.

Ozone generator grid plate (1).

24V remote on/off switch assembly (no starter).

UV replacement lamp (Set of 2).

Particle ionizer probe (entire assembly).

Blower shaft bearings (Set of 2).

Part No. Description

PRE-FILTER ADSORBENT FILTER

MAIN FILTER FINAL FILTER

Table of contents

Other Eramco Air Cleaner manuals

Popular Air Cleaner manuals by other brands

Whirlpool

Whirlpool Whispure APMT2001M Specifications

Robur

Robur AD 14 instruction sheet

LG

LG AS601H Series owner's manual

Dometic

Dometic Breathe Easy AU6 installation manual

Pure n Natural Systems

Pure n Natural Systems LA-1000-FM Installation manual and user's guide

Nordic Home Culture

Nordic Home Culture CF-6500 user manual