Ercolina HB60 User manual

-1-

05/2021 HB60

HB60 Hot Shot Hydraulic Bender

Rotary Draw Bender for Pipe, Tube and Prole Bending

Operator’s Manual

WARNING!

BEFORE USE, BE SURE EVERYONE USING THIS MACHINE READS AND

THOROUGHLY UNDERSTANDS ALL SAFETY AND OPERATING INSTRUCTIONS IN THIS MANUAL

Model Hot Shot HB60___________________ Serial # __________________________

-2- 05/2021HB60

Hot Shot HB60 Hydraulic Rotary Bender

Pipe, tube and prole bending machine

Congratulations on your purchase of an Ercolina® bending machine from CML USA, Inc.

Ercolina® machines are designed and manufactured to deliver years of trouble-free bending

performance. Please take a moment to complete and mail the warranty registration card or

submit the information online at http://ercolina-usa.com/warranty-form/. Doing so validates

machine warranty period and ensures prompt service if needed. Thank you for selecting

products from CML USA, Inc. Ercolina®.

Table of Contents

Important safety instructions........................................................................................................................ 4

Special instructions...................................................................................................................................... 5

1. General notes................................................................................................................................... 6

1.1. Technical data .......................................................................................................................... 6

1.2. The purpose of the user and maintenance manual ................................................................. 7

1.3. List of symbols used ................................................................................................................ 7

1.4. Safety solutions for decreasing risks ....................................................................................... 8

1.5. Personal protective equipment (PPE) ...................................................................................... 9

1.6. Recipients of this document ..................................................................................................... 9

1.7. Storing these Instructions ........................................................................................................ 9

1.8. Marking .................................................................................................................................. 10

2. Packaging....................................................................................................................................... 11

2.1. Packaging ...............................................................................................................................11

2.2. Standard equipment ............................................................................................................... 12

2.3. Reception ............................................................................................................................... 12

2.4. Transport ................................................................................................................................ 12

3. Commissioning.............................................................................................................................. 13

3.1. Workspace ............................................................................................................................. 13

3.2. Environmental parameters ..................................................................................................... 14

3.3. Connecting to the mains ........................................................................................................ 14

-3-

05/2021 HB60

4. Use of the HB60 machine.............................................................................................................. 15

4.1. General overview ................................................................................................................... 15

4.2. Description of the parts .......................................................................................................... 15

4.3. Tools description .................................................................................................................... 17

4.4. Preparing the tube ................................................................................................................. 18

4.5. Controls .................................................................................................................................. 18

4.6. Tool assembly ........................................................................................................................ 19

4.7. Replacing the tank cap .......................................................................................................... 23

4.8. Adjustment of the bending angle ........................................................................................... 24

5. Maintenance ................................................................................................................................... 26

5.1. Routine maintenance ............................................................................................................. 26

6. Notes............................................................................................................................................... 27

Pipe and tube information.......................................................................................................................... 28

Bend formula and conversion tables ......................................................................................................... 29

Minimum distance between bends by center line radius, pipe and tube kits ............................................. 30

Terms and conditions of warranty .............................................................................................................. 31

_____________________________________________________

CML USA Ercolina® reserves the right to make improvements and

modications to design without prior notice.

_____________________________________________________

-4- 05/2021HB60

WARNING!

Important Safety Instructions

When using electric tools, basic safety precautions should always be followed to reduce the risk of re,

shock and personal injury.

1. Keep Work Area Clean

Cluttered areas and benches invite injuries.

2. Consider Work Area Environment

Do not expose power tools to rain.

Do not use the power tools in damp or wet locations.

Keep work area well lit.

Do not use a tool in presence of ammable liquids or gases.

3. Guard Against Electric Shock

Prevent body contact with grounded surfaces. For example; pipes radiators, ranges,

refrigerator enclosures.

4. Keep Children Away

Do not let visitors contact tool or extension cord.

All visitors should be kept away from work area.

5. Store Idle Tools

When not in use, tools should be stored in a dry and high or locked-up place out of

reach of children.

6. Do Not Force Tool

It will do the job better and safer at the rate for which it was intended.

7. Use The Right Tool

Do not force small tool or attachment to do the job of a heavy-duty tool.

Do not use the tool for purpose not intended, for example; do not use a circular saw for

cutting tree limbs or logs.

8. Dress Properly

Do not wear loose clothing or jewelry; they can be caught in moving parts.

Rubber gloves and non-skid footwear are recommended.

9. Use Safety Glasses

Also use face mask or dust mask if operation is dusty.

10. Do Not Abuse Electric Cord

Never yank electrical cord.

Keep electric cord from heat, oil and sharp edges.

11. Do Not Overreach

Maintain proper footing and balance at all times.

12. Maintain Tools With Care

Keep clean for better and safer performance.

Follow instructions for lubricating and changing accessories.

Inspect tool cords periodically and if damaged, have repaired by authorized service facility.

Inspect electrical cords periodically and replace if damaged.

Keep handles dry and clean and free from oil and grease

-5-

05/2021 HB60

13. Disconnect Tools

Disconnect machine from power source when not in use, before servicing and changing

accessories.

14. Remove Adjusting Keys and Wrenches

Form a habit of checking to see that keys and adjusting wrenches are removed from machine

before turning it on.

15. Avoid Unintentional Starting

Always disconnect from power source before moving.

16. Stay Alert

Watch what you are doing. Use common sense, do not operate tool when you are tired.

(Do not use when taking medications that may cause drowsiness.)

17. Check Damaged Parts

Before further use of the machine, guard or other part that is damaged should be carefully

checked to determine that it would operate and perform its intended function.

Check alignment of moving parts, binding of parts, breakage of parts mounting and any

other conditions that may aect its operation. A guard or other part that is damaged should

be properly repaired or replaced by an authorized service center. Do not use this machine

if switches do not turn it on and o. Have defective switches replaced by authorized service

center.

Special Instructions

1. Read and follow operators manual thoroughly. If you require an additional manual please contact

2. Due to size and weight, it is recommended that qualied professionals transport, position and

install the bending machine. Use proper equipment for installation including lift truck safety

straps, chains binders and bars. Machine must be balanced evenly at all times.

3. Never place hands, nger gloves or clothing near rotation machine parts.

4. Always disconnect machine from power source before changing accessories.

5. Always use eye and hearing protection.

6. Never wear loose clothing, gloves or jewelry when working near machine.

7. Stand in a safe position when operating machine.

8. Always wear safety approved steel toe footwear.

9. Make provision for safe handling of heavy and/or awkward materials.

10. Use only proper tooling, keep tooling securely fastened.

11. Keep machine and tooling free and clear of chips and debris.

12. Keep all safety features functioning and working properly.

13. Do not alter or modify machine. Use only OEM approved parts and accessories.

-6- 05/2021HB60

1. General notes

1.1. Technical data

Operating Range

Resistance module cm3 12

Bending capacity (A53 Grade

A) Inch 2” Schedule 40 Pipe

Minimum external diameter Inch ¼”

Minimum bending radius Inch 1.4”

Maximum bending radius Inch 10.7

Maximum bending angle Degrees 210°

Bending direction - Counter-clockwise

Electrical power supply

Power kW 0.75

Voltage V

120V 1ph standard;

220V 1ph or 480V 3ph on

request

Mains frequency Hz 50-60

Dimensions, weight, other data

Maximum length (approxi-

mate) Inch 29” (machine with cabinet)

Maximum width (approximate) Inch 18.5” (machine with cabinet)

Height (approximate) Inch 40” (machine with cabinet)

Weight (approximate) Pound 450 Pounds

Sound pressure level DB <60

Oil volume in the tank L 10

-7-

05/2021 HB60

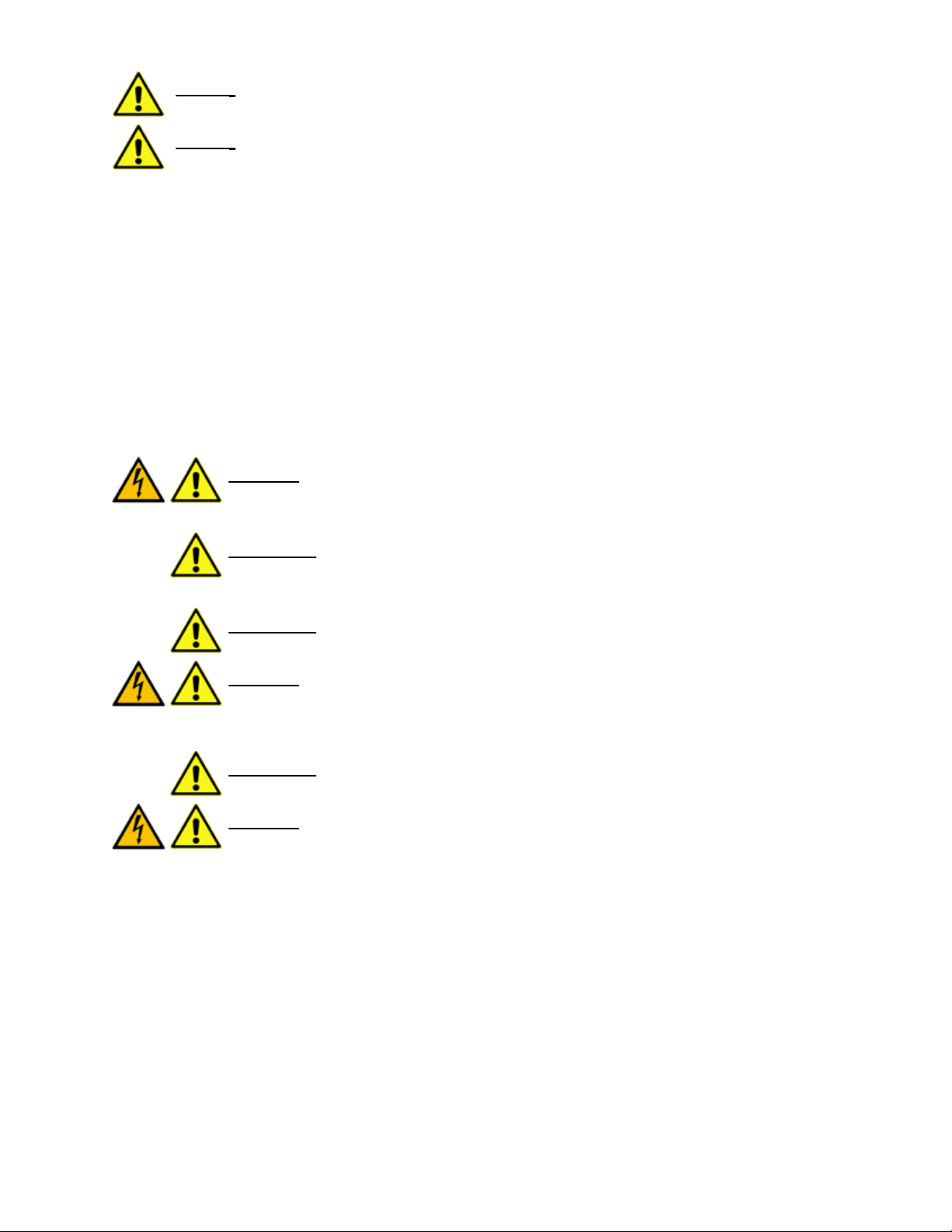

Hazard

It indicates that a danger is imminent which, if not considered properly, will cause

serious or fatal injuries.

Caution

It indicates that there is a potential danger which, if not considered properly, may

cause serious or fatal injuries.

Warning

It indicates a safety warning which can cause property damage if ignored.

Note

Relevant information for optimal product operation is indicated as notes.

Hazard

It indicates a crushing hazard for upper limbs which may cause serious or fatal

injuries.

Hazard

It indicates a crushing hazard for upper limbs which may cause serious or fatal

injuries.

1.2. The purpose of the user and maintenance manual

This manual provides guidelines and instructions to use the HB60 machine: these do not replace, alter

or supplement any regulation, prescription, decree or law, regardless of it being general or specic, in

force in the place where the machine is installed and used, concerning safety, use and maintenance of

equipment or systems that may be mechanical, electrical, chemical or otherwise. Manual provides

maintenance personnel with recommendations and support but assumes that they are experienced and

generally well-prepared in handling any maintenance issue, regardless of it being mechanical or

electrical.

In this manual you will nd information about:

● Machine use;

● Technical specications;

● Electrical and mechanical parts;

● Handling, installation and assembly operations;

● Adjustments, start-up, stopping, commissioning and decommissioning operations;

● Safety requirements and guidelines on residual risks;

● Routine maintenance requirements;

● Special maintenance requirements;

● Spare parts;

● Tooling and accessories.

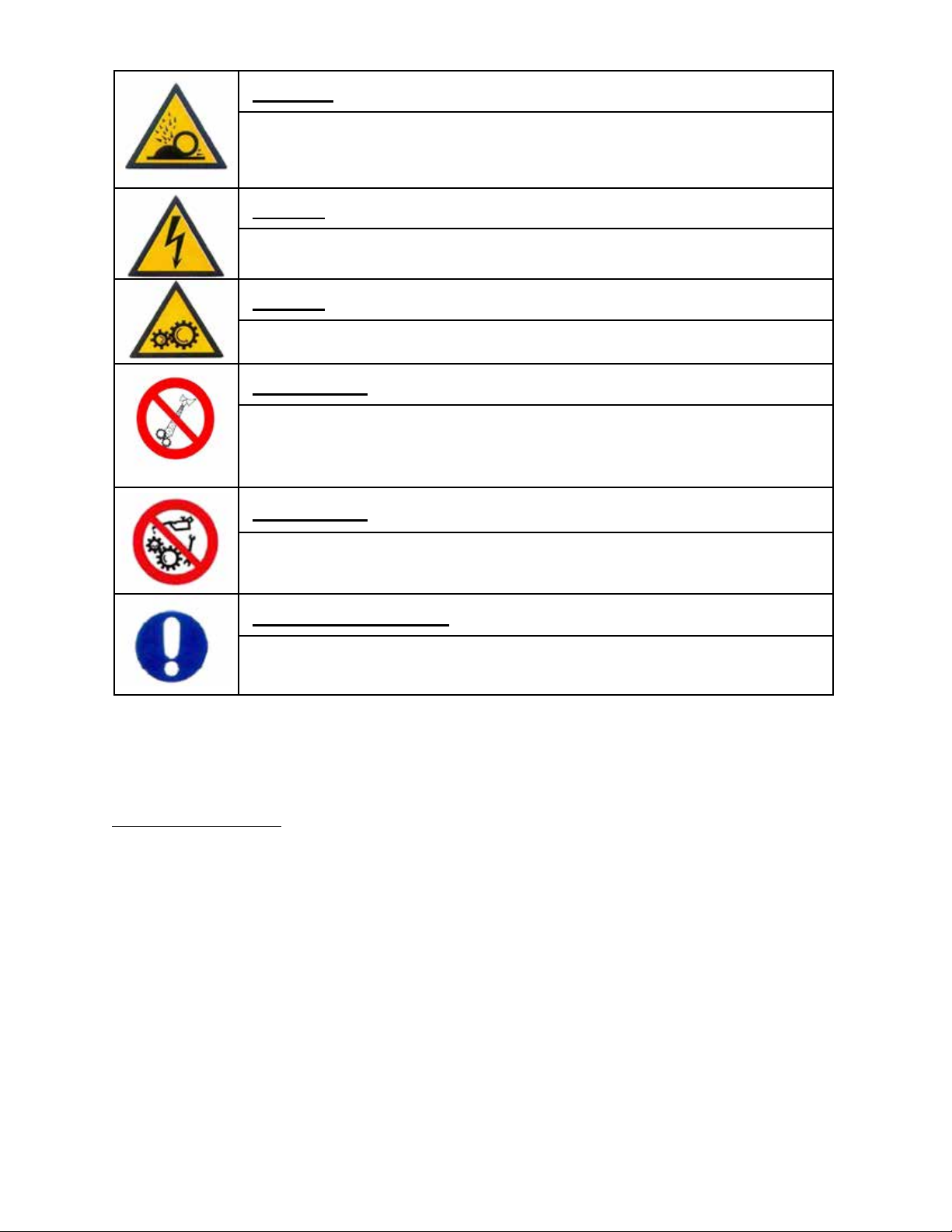

1.3. List of symbols used

-8- 05/2021HB60

Caution

Indicates a risk of being hit by metal fragments, from piece being processed.

Hazard

This indicates the presence of electrical voltage which can lead to serious or fatal

injury.

Hazard

This indicates the presence of moving mechanical parts which can lead to

serious or fatal injury.

Prohibition

This informs the operator not to use unsuitable clothing which can even lead to

serious injury.

Prohibition

It informs the operator not to carry out routine and/or extraordinary interventions

during machine operation that may lead to serious or fatal injuries.

Compulsory action

This indicates mandatory operations to be carried out by the personnel, which

can lead to serious injury if missing.

1.4. Safety solutions for decreasing risks

Machine is equipped with emergency button placed in front position to be easily reached operator. Inter-

rupts power supply and any machine movement.

Risks of electrical nature

The machine control devices are low voltage at 24 Volt.

Electrical components are also encased inside base cabinet and accessible by removing screws securing

cabinet door.

-9-

05/2021 HB60

1.5. Personal protective equipment (PPE)

Always operate with personal protective equipment (PPE). Personnel in charge of installation,

maintenance or operation machine must not wear clothes with loose sleeves, laces, belts, bracelets,

long hair or other items that can be hazardous.

Recommended protective equipment to be worn.

1.6. Recipients of this document

This documentation is specic to HB60 model and intended for all machine installers and users

1.7. Storing these Instructions

All instructions regarding HB60 machine must be stored with machine and always be accessible.

Compulsory action: in the related situations, wear the personal protective

equipment indicated in the table below.

Safety shoes

Use: always

Protective clothing

Use: always

Work gloves

Use: always

Safety goggles

Use: always

Helmet

Use: in the presence of suspended loads

Prohibition: do not wear unsuitable clothing which, for example, may get

stuck in moving parts and result in dangerous situations.

-10- 05/2021HB60

1.8. Marking

● Logo of CML INTERNATIONAL S.p.A. and its references;

● Year of manufacture of the machine;

● Weight of the machine;

● Model of the machine;

● Operating voltage;

● Mains frequency;

● Maximum amperage;

● Power;

● RPM of bending shaft

● Serial number.

Figure 1 - Identication plate

-11-

05/2021 HB60

2. Packaging

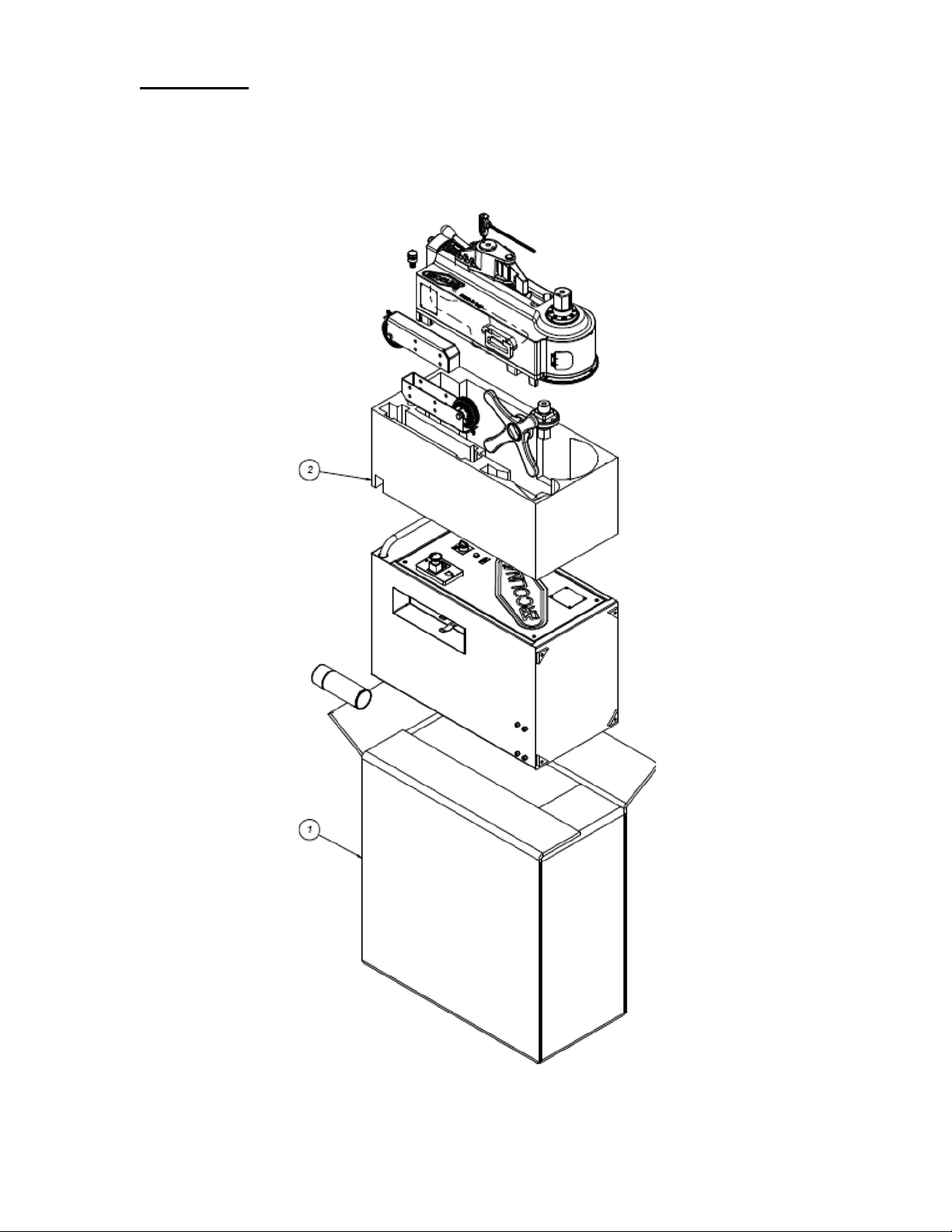

2.1. Packaging

Figure 2 - Package contents

-12- 05/2021HB60

Figure 3 - Indicating wheels and retractable handle

2.2. Standard equipment

The following are supplied with machine

● Can of spray grease part number P810, intended for lubricating the groove of counter-bending die

● 40 mm and 50 mm hexagonal tooling shafts

● Hand wheel to move the cursor longitudinally

● Pedal control for bend and return function

● Hex key, for opening the cabinet;

● User and maintenance manual.

2.3. Reception

Upon receipt of machine carefully inspect all packaging to verify no damage has occurred during transport

and all standard items are present. Immediately inform the shipping company and CML USA Inc of any

damage or shortage of goods.

2.4. Transport

The HB60 is equipped with two wheels and retractable handle to assist in moving the machine. as shown

in Figure 3.

Attention: Oil reservoir contains oil and is properly sealed prior to shipment. Conrm no oil has

escaped the reservoir during shipment.

Attention: the head can be separated from the cabinet and handled using the specic side

handles.

Attention: while handling the machine, do not use safety ropes and/or chains near hydraulic

pipes and power cables.

Attention: weight distribution of machine can change according to capacity of hydraulic oil

and tooling tted on machine. To facilitate moving and handling packaging labels

indicate lifting area and weight.

Retractable handle

Wheels

-13-

05/2021 HB60

Hazard: it is strictly forbidden to lift the machine with any means other than forklifts, as shown

in Figure 4.

Figure 4 - Incorrect handling

3. Commissioning

3.1. Workspace

The minimum space necessary for using the HB60 machine can be calculated based on the length of

the material to be processed: to obtain it, refer to what is shown in Figure 5. Be very careful to allocate

enough space in order to ensure the materials can be handled near the machine.

Figure 5 - Space necessary for using the HB60 machine

-14- 05/2021HB60

Danger: in the work area only one single operator can be present at one time.

Danger: during the bending phases, the operator must always be in a position opposite the

movement direction during bending. Operator must always be in position to press emergency

stop button.

3.2. Environmental parameters

The HB60 machine was designed to resist corrosion. All of its components, excluding moving ones, are

covered with oven-baked epoxy paint. However, the machine has been designed to be used indoors and

in environments away from the sea coast: contact the Customer Service of the Manufacturer for installa-

tions other than those mentioned above. The recommended environmental conditions are: Temperature:

5°C - 30°C. with Humidity: 40% - 75%. If the temperature of the installation area differs from the indicated

range, the recommended hydraulic oil may no longer be suitable to guarantee machine performance: con-

tact the manufacturer’s customer service for advice.

3.3. Connecting to the mains

Danger: HB60 machine must be powered with alternating current (AC) at the indicated

frequency and voltage.

Attention: manufacturer is not liable for faults caused by an incorrect electrical

connection implemented by the user.

Attention: Connection to power mains must be made by qualied personnel.

Danger: Electrical panel must be opened by qualied personnel Opening and

tampering with electrical components can jeopardize operator safety and

correct machine operation.

Attention: Make sure power phasing is correct.

Danger: Switch main power to o and disconnect from power source before accessing

electrical compartment of machine make sure that it is switched.

-15-

05/2021 HB60

4. Use of the HB60 machine

4.1. General overview

The HB60 bends pipe, tube and profiles within its capacity. Refer to Ercolina catalog for proper tooling

selection. Bending results depends on:

● Material type and grade

● Conditions of material when supplied

● Capability of the operator.

The same operation completed on different materials may have completely different results. To obtain

best results ensure material to be processed is guaranteed in its chemical composition and has received

adequate stretching treatment. Verify that section dimensions are within supply tolerance.

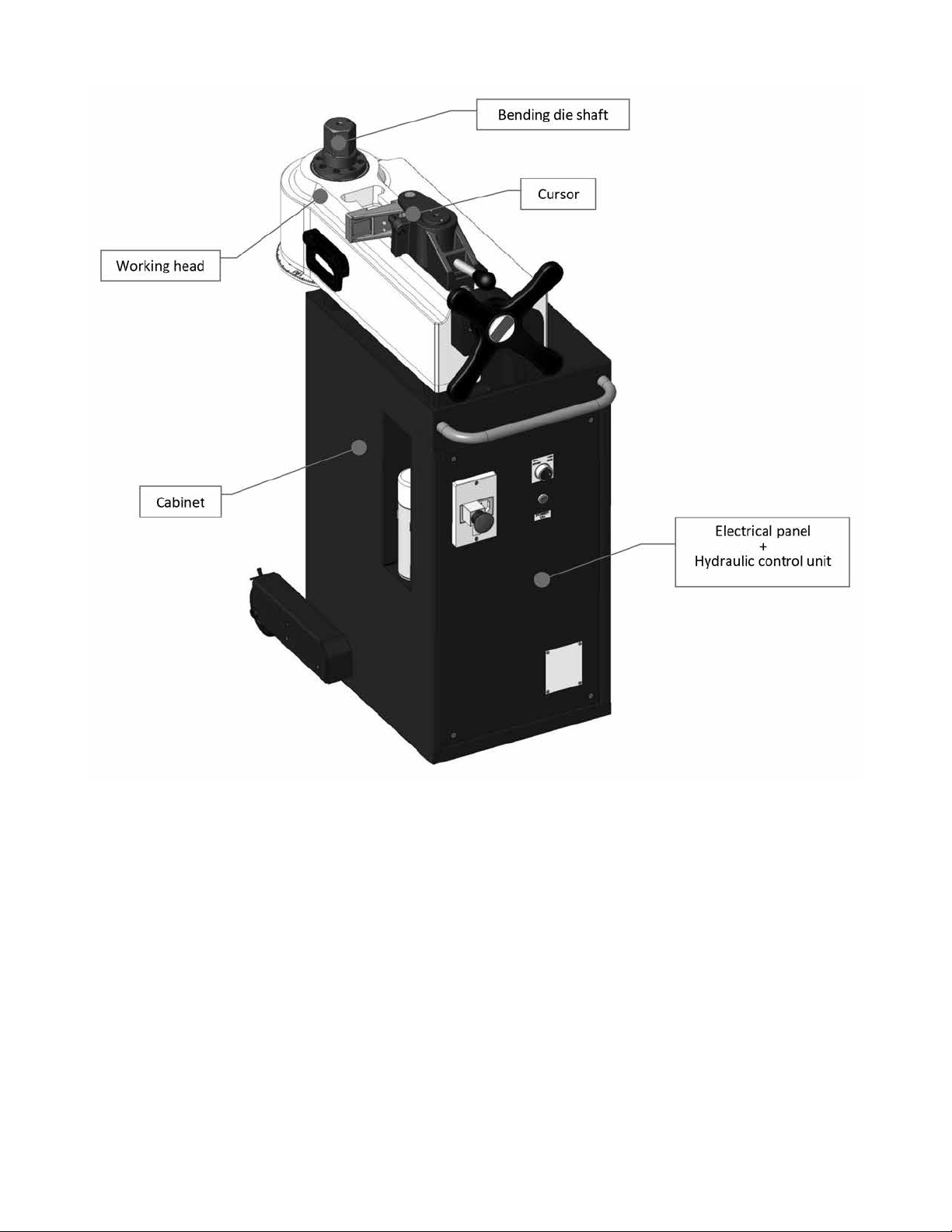

4.2. Description of the parts

The HB60 machine consists of the following parts:

● Cabinet

Supports machine and house electrical, hydraulic, mechanical and protective parts are assembled

on it.

● Work head

Is main body of machine where tooling shaft, bending center former and counterbending die are

located.

● Cursor

Handwheel adjusts position of the counterbending die axis during machine set-up and allows the

tube to be released after bending.

● Bending die shaft

Component retains bending center former

● Hydraulic control unit

Supplies hydraulic force

● Electrical panel

Components related to electrical power supply of machine. The electrical panel is inserted within

the cabinet: Construction details are found in wiring diagrams.

● Foot Pedal

Controls bend and return functions and returns machine to starting initial position.

-16- 05/2021HB60

Figure 6 - Constructive elements of the machine

-17-

05/2021 HB60

4.3. Tools description

Refer to manual for machine capacity

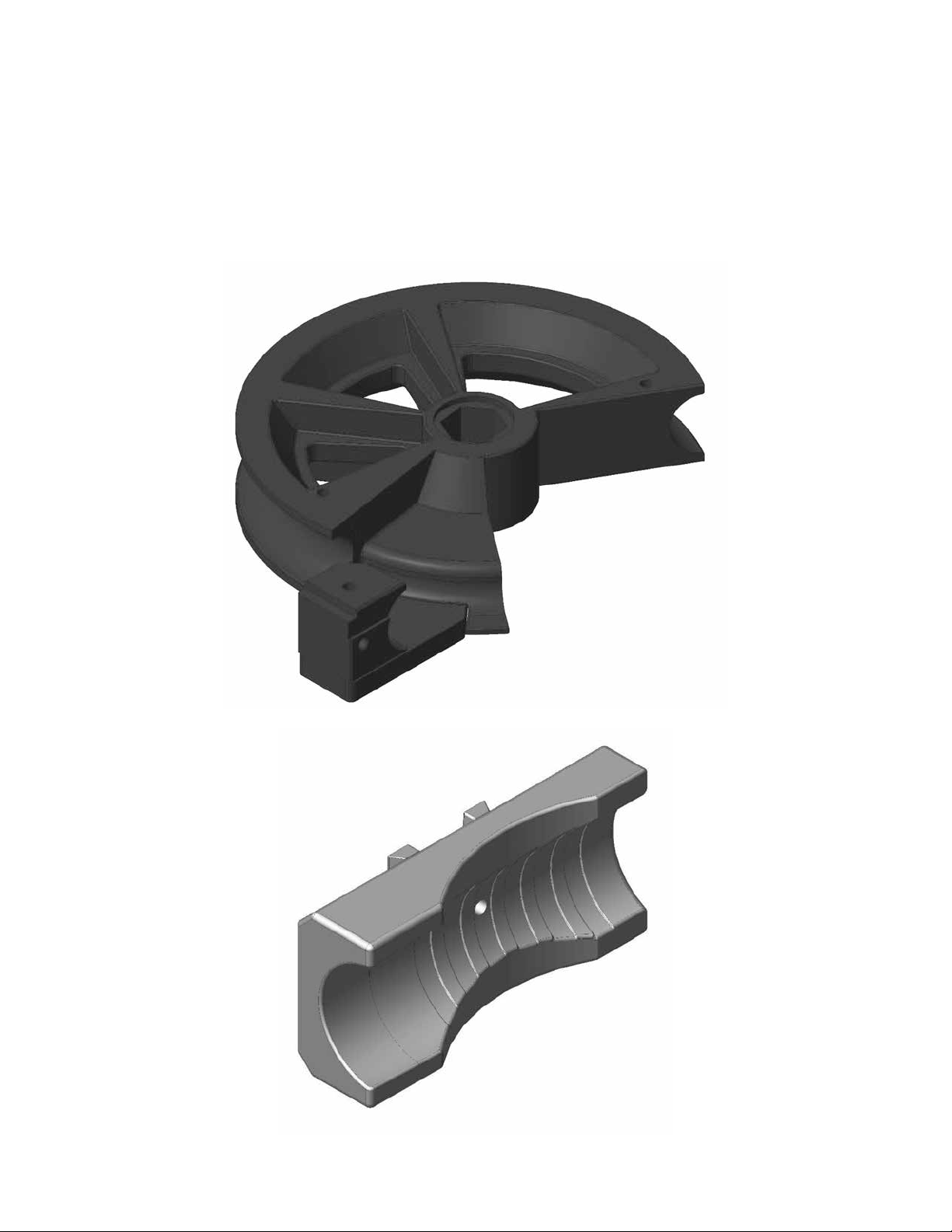

Tooling components: Shown in Figure 7, 8, 9:

● Bending Die

● Counterbending die

● Hexagonal shaft 40 and 50 MM are supplied to accommodate the machine capacity

Figure 7 - Center Former Bending Die

Figure 8 - Counterbending Die

-18- 05/2021HB60

4.4. Preparing the tube

● Verify that the dimensions of the tube/profile match the tooling mounted on machine;

● Tube dimensions and type of material are correct for tooling and bending

● Deburr inner and outer edges of the material to be bent

● Tooling gripping area clean and degreased.

4.5. Controls

The HB60 machine also has:

● General power supply switch;

● Emergency button;

● Start button;

● Speed selector;

● Foot pedal.

General power supply switch

To power machine, rotate selector from “OFF - 0” position to “ON - 1” position. This operation sends

electrical power to all electrical and safety devices. Electrical motor of the hydraulic control unit will only

start after pressing the reset button.

Emergency stop button

Pressing the emergency stop button will stop all movement. The emergency stop button is fitted with an

automatic locking system once pressed remains in position. The machine cannot be reset in this phase.

The emergency button is released by rotating it in the direction indicated by the embossed arrow.

Start button

Release emergency stop button by rotating it in the direction indicated by arrow, press the start button to

restart the machine and restart operation.

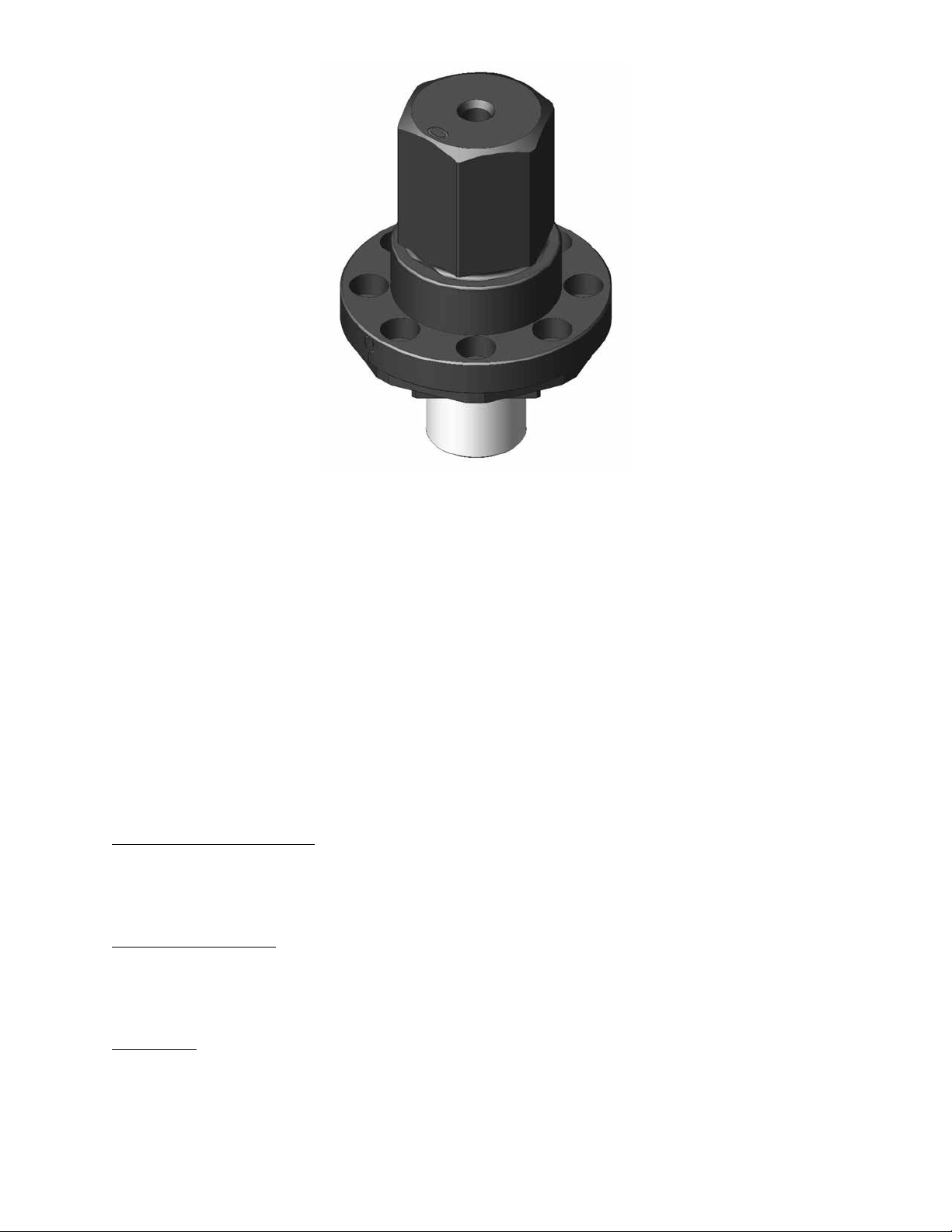

Figure 9 - Hexagonal Shaft

-19-

05/2021 HB60

Speed selector

Machines with single phase power supply are equipped with an inverter, there is also a speed selector

present. Selector rotation changes speed of the motor - speed 1 allows the machine to deliver maximum

bending torque; speed 2 increases machine productivity, however it does not supply maximum machine

torque.

Foot Pedal

Initiate bend or return function.

4.6. Tool assembly

Attention: before assembling the tools, make sure machine is not powered rotate main switch

to “0” position.

Attention: when assembling any tool (shaft, bending die, counterbending die) pay careful

attention to the risk of crushing ngers between the parts.

Assembling the bending die shaft

The machine is supplied with two hexagons drive shafts

● Shaft with hex key 40;

● Shaft with hex key 50.

The choice of the shaft depends on the type of bending die being used.

The assembly procedure is the same for both shafts:

● Insert shaft and the supplied screws.

shaft is designed in such a way there is only one position between parts.

“0” marks are found on both the bending die shaft and the machine. These must always be

aligned machine in the start or zero position.

-20- 05/2021HB60

Table of contents

Other Ercolina Construction Equipment manuals

Popular Construction Equipment manuals by other brands

Case

Case 650M Service manual

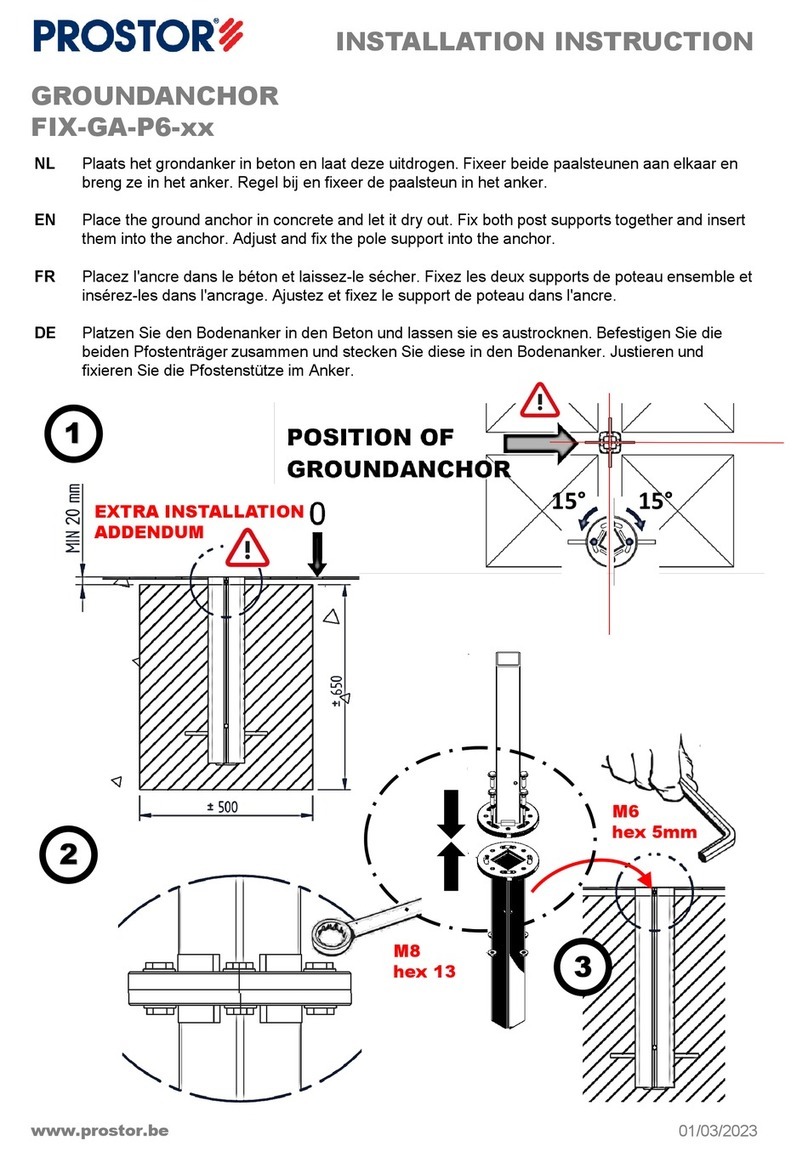

Prostor

Prostor FIX-GA-P6 Series Installation instruction

probst

probst FTZ-UNI-25 operating instructions

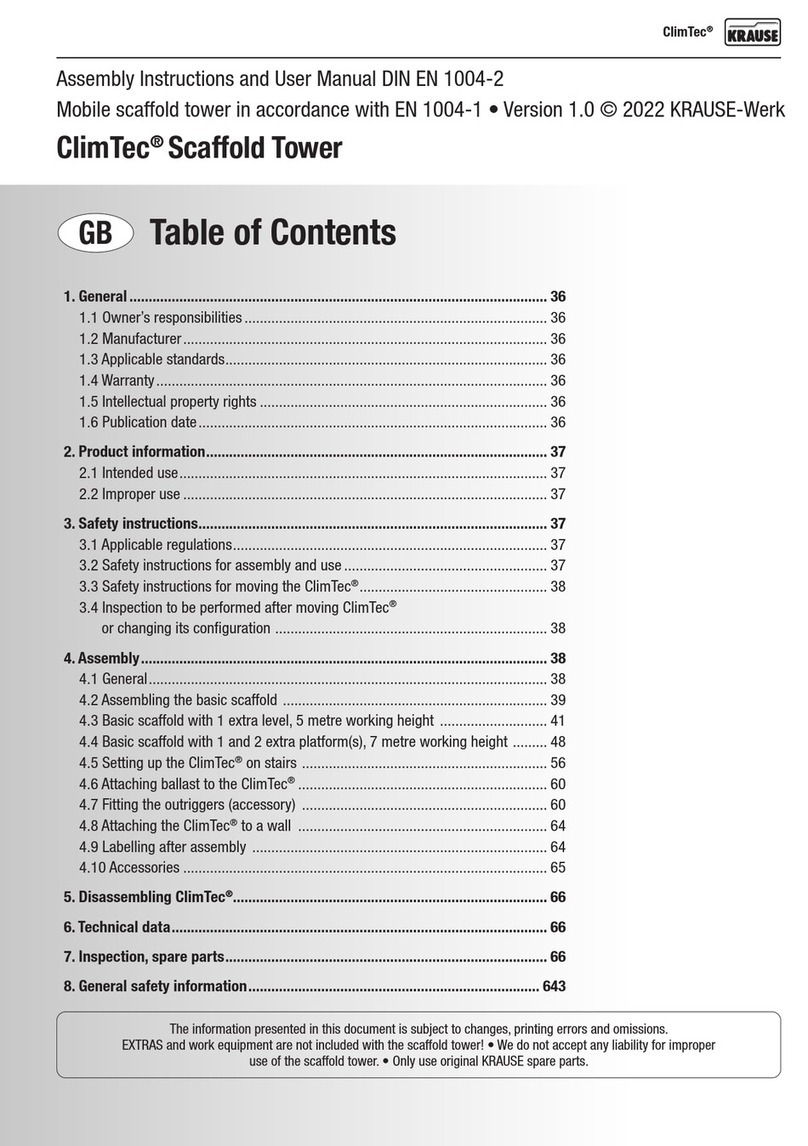

KRAUSE

KRAUSE ClimTec 710116C0 Assembly instructions and user's manual

JLG

JLG R1532i Operation and safety manual

BUFFALO TURBINE

BUFFALO TURBINE BT-G12DB Original instructions and parts manual