Smith SPS10 User manual

SPS10 Gas

Multi-Use Surface Preparator

User Manual

(954) 941-9744

www.SMITHMFG.com

MANUFACTURING

Cutters / Removers / Parts / Support

1-800-653-9311

www.SmithMfg.com

Phone: 954-941-9744 • Fax: 954-545-0348

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SPS10

VERSION 11/2016

Gas

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

INTRODUCTION

2

Congratulations on purchasing the

SPS10™ Surface Preparator from

SMITH Mfg. Company.

Your machine will:

• Clean surfaces impacted by grease, oil,

plastics, tars, resins, tile adhesives, ice and

more

• Plane or mill asphalt and concrete surfaces

• Remove high spots in curbs and gutters

• Eliminate trip-hazards on concrete sidewalks

• Mill areas for rumble strips

• Clean out cracks and joints

• Create anti-slip patterns in walkways and barns

• Prepare surfaces for new coating applications

• Groove-inlay asphalt for striping

• Permanently remove all road and surface

coatings to include:

epoxy, urethane, thermoplastic, paint,

glue-backed tapes and more...

BEFORE START-UP,

READ THIS..

Please read all operating instructions, including

the provided engine manual and be completely

familiar with your equipment before operating.

When in doubt, please contact SMITH

Manufacturing Customer Service for operational

details. This Owner’s Manual will guide you

through the removal process, from start to nish,

and show you how to care for your machine.

Page Contents

2Index / Introduction

3Safety Guidelines

4Your SPS10 Surface Preparator

5Handle Adjustment Instructions

6Machine Start-Up

7Substrate Removal

8Storage, Ordering, and Warranty Claims

9Troubleshooting

10 Maintenance Check List

11 Drum Replacement

12-14 Belt Replacement and Alignment

15-16 Bearing Replacement

17-24 Optional Equipment

25-26 Drum Options

27-28 Maintenance Log

29 Limited Equipment Warranty

30 Warranty Activation

INDEX

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 11/2016

SPS10

Gas

3

UNCRATING EQUIPMENT

When you uncrate your equipment, make certain

that the machine has not been damaged and

that all fasteners and guards are properly

tightened.

Your machine may not have been shipped

assembled with cutters and other accessories.

Assembly may be required.

REMEMBER: Only authorized, experienced and

properly trained personnel should operate this

equipment. Operating personnel should

practice safety at all times and wear protective

gear (gloves, goggles, safety vests, ear plugs,

steel-toe shoes, etc.)

• Always wear protective equipment, including

ear protection and goggles.

• Never wear baggy or loose tting clothing that

can be caught on controls or moving parts.

• The surface preparator can emit ying

particles and debris during operation. Never

operate the machine near bystanders, animals

or children.

• Check uid levels and get acquainted with

the controls, engine kill switch and other safety

controls (pg. 5).

• Do not operate the machine in an explosive

atmosphere, near combustible materials, or

when gas fumes may not be properly dispersed.

• Repair any fuel leaks immediately and remove

accumulated dust frequently from the air lter

system.

• Never leave the machine unattended when

running, and you must hold onto the handle with

two hands when the cutter drum is engaged.

• Avoid contact with the mufer when the engine

is hot, as it may cause severe burns.

• When using a vacuum system, avoid hose

contact with the mufer.

• Ensure that all guards are in place before the

machine is operated, since rotating and moving

parts will cause injury upon contact.

• Make sure that the engine is shut down and

the spark plug is disconnected

before servicing.

Incorrect use of the surface preparator can

result in property damage, personal injury,

or death. Be sure to read and follow all

directions and precautions as outlined in

this manual.

SAFETY GUIDELINES

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SPS10

VERSION 11/2016

Gas

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

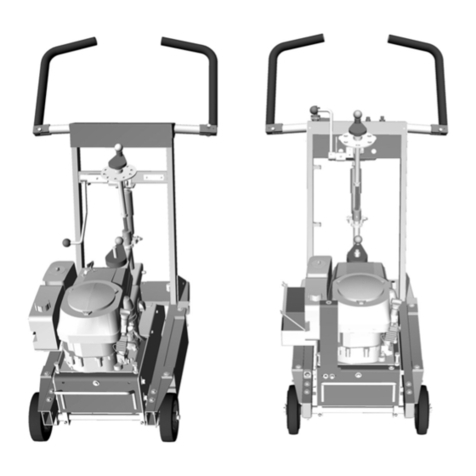

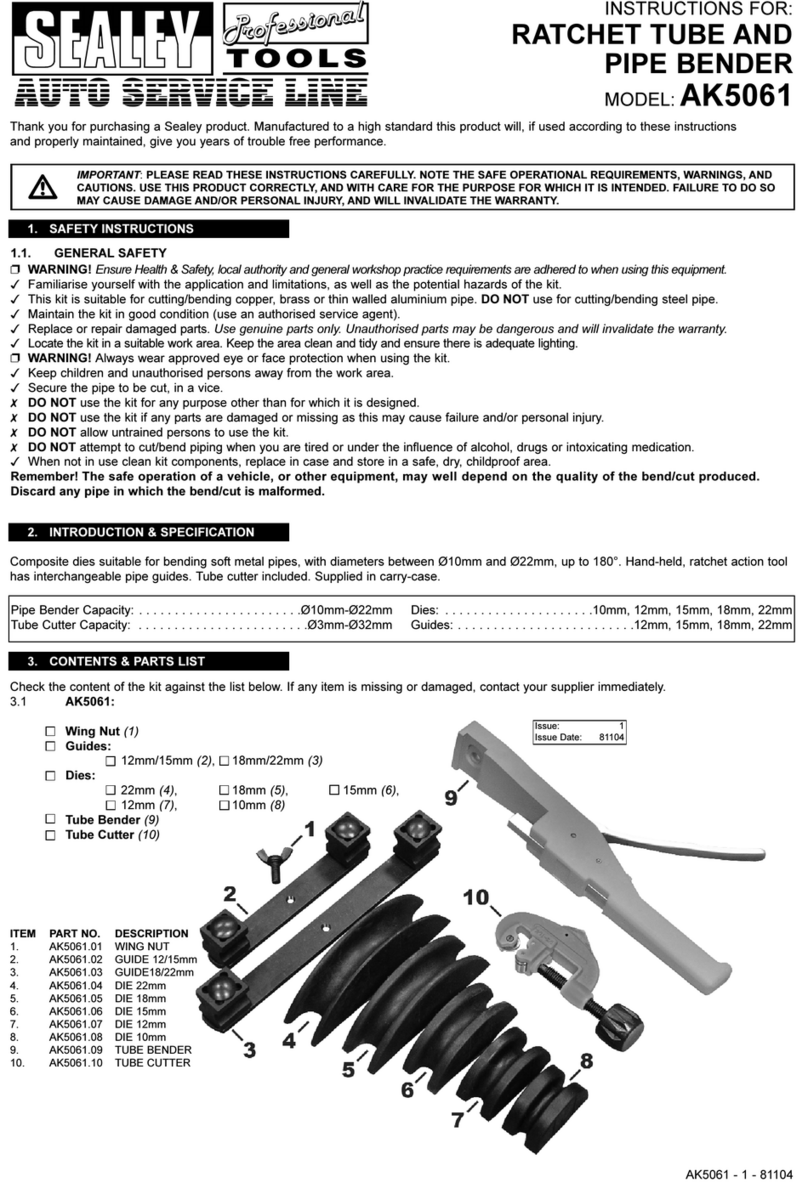

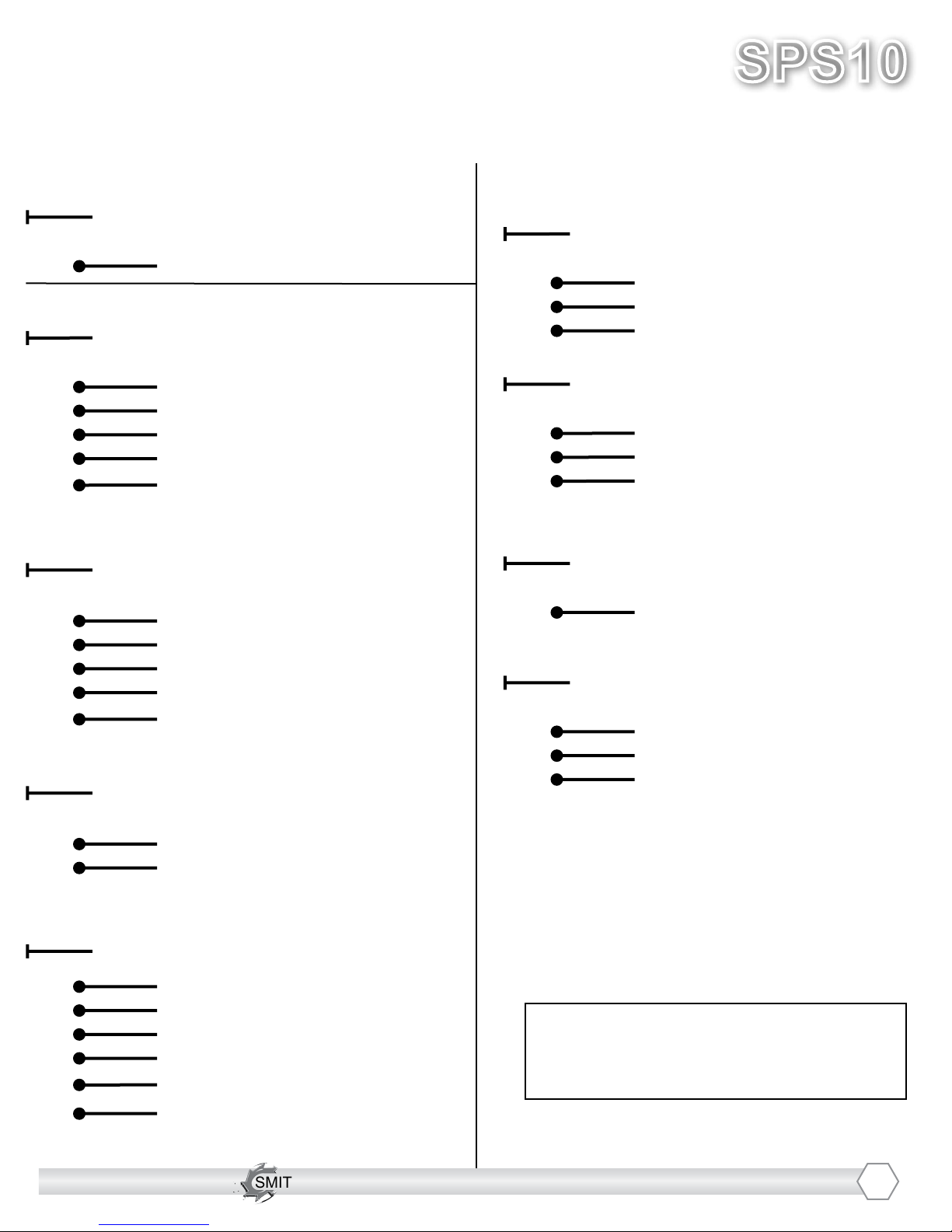

YOUR SPS10TM SURFACE PREPARATOR

Please take time to familiarize yourself with the SPS10™’s

controls, as well as some of the features of your new machine.

Read the engine manual before preparing the engine for starting.

Adjustable Handlebar

Handlebar Adjustment Bolts

Optional Engine Meter

Throttle

Corded “Engine Kill” Button

Fine Adjustment Hand Wheel

Cam Lever

Cyclone Air Cleaner

Oil Dipstick

Engine Shut-Off

Gas Tank

Removable Side Plate

Choke

Fuel Supply Lever

4

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 11/2016

SPS10

Gas

5

The handlebars are equipped with a high-density vibration suppression material to minimize

operator fatigue and increase comfort level when operating equipment.

To adjust the handlebars to a new position for different height operators please follow these steps:

• Using a 9/16” (14mm) wrench or

socket, loosen the bolts on both

sides of the handlebars until the

handlebar moves freely. Take

care not to over-loosen the bolts

to keep them from falling out.

• Stand behind the machine and

lightly tap the handlebar to the

desired position

• Re-tighten the bolts to lock the

handlebars in the new position.

Never operate with handlebars loose.

The bolts must be fastened tightly assuring

the handle is locked into position.

HANDLE BAR ADJUSTMENT

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SPS10

VERSION 11/2016

Gas

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

MACHINE START-UP

Do not start machine while drum is in

contact with the ground. Doing so can

cause the operator to lose control of the

machine, resulting in property damage

and/or personal injury.

NOTE: Do not attempt to raise or lower the cam

lever by force. If it does not move effortlessly,

raise or lower the hand wheel until the cam lever

can be adjusted. Open the fuel cock on the

carburetor and then place the throttle lever at the

“Fast Idle” position. Start the engine, open choke

slightly to prevent ooding. Move throttle control

to open or run position when engine is warmed

up. Increase throttle to maximum operating

position (approx. 2800RPM) and close choke.

Before substrate removal, test run the drum

with cutters not touching the surface. If there is

excessive vibration, you need to re-balance the

cutter set-up, check bearing condition, and/or

make sure that the drive shaft is secured.

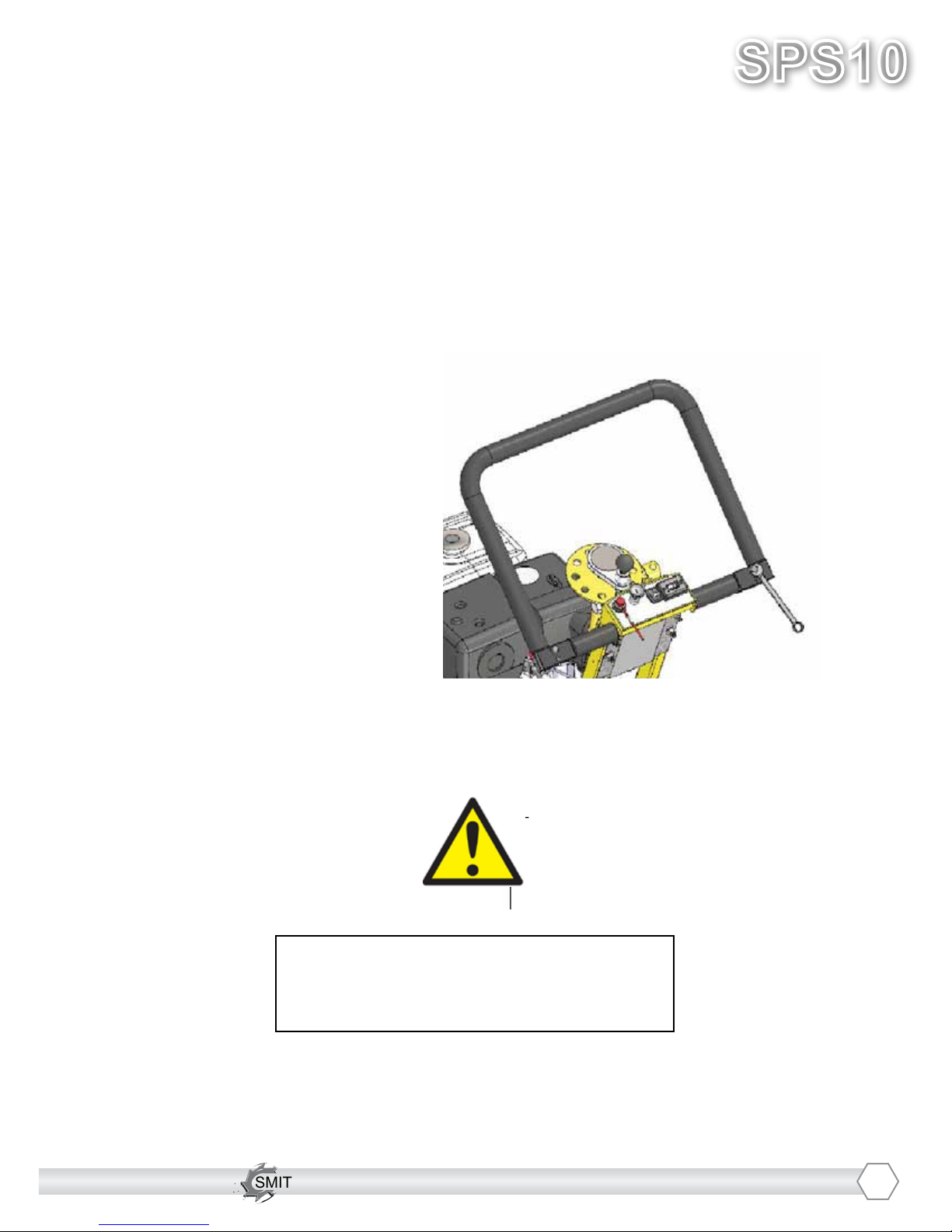

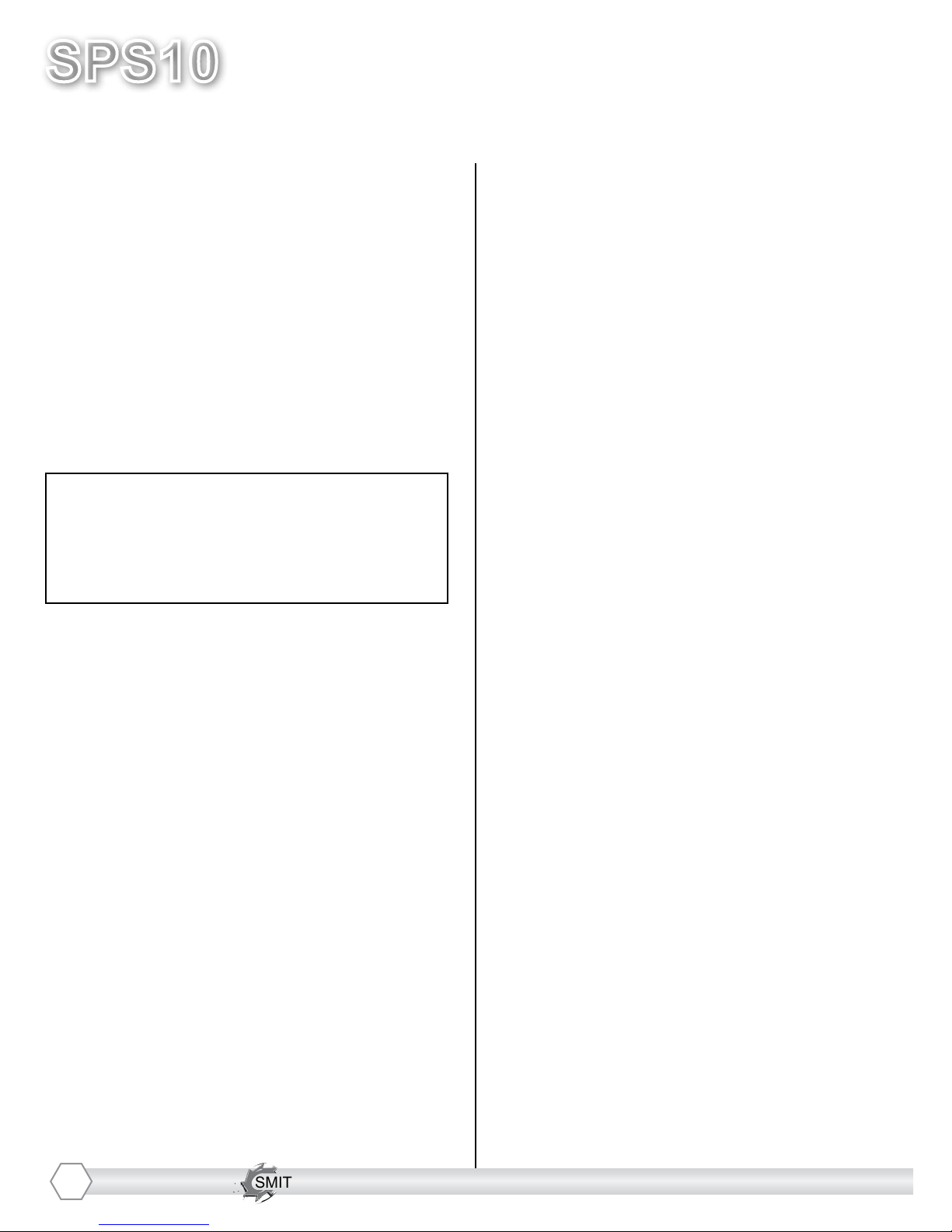

Corded “Engine Kill” Button (not available

on electric motor): In the event of a

malfunction or an accident (such as the

machine operator falling or losing footing), the

SPS10 is equipped with a corded “Engine Kill”

Button. Attach the end of the cord to the opera-

tor’s belt or wrist, and snap the clip into place

on the stop switch by raising the top of the

Engine Kill Button and inserting the clip into the

gap. If the operator becomes distanced too far

from the machine, the cord will detach from the

stop switch, and the machine will stop running.

Attatch to

operator

*NOTE: the Engine will not start without the

Corded Engine Kill’s clip securely in place.

CAUTION: The machine will still move with

the engine off.

IF THE ENGINE DOES NOT

START

1) Check Engine for proper gas and oil levels

(refer to Engine manual)

2) Check spark plug. Make sure the socket

areas are clean and clear of debris, and that

the proper gap is set. (Replace if needed).

3) Check Brown Electrical clip hanging on the

front of the engine and ensure that the

electrical wires are making contact within the

clip.

4) Turn the On/Off switch, on the front of the

Engine, to “On”.

5) Check Corded Engine Kill Button’s

Connections:

a) Make sure the Corded Safety Stop “C”

Connector is dipped properly.

b) Try switching the connection to the

opposite post (From letter “C” to letter “M”,

for example).

6) Engine may have tilted backwards. If so,

allow oil to drain after removing spark plug and

pulling starter cord several times.

*Engine repair and engine warranty

issues are handled directly

by your local engine service center.

6

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 11/2016

SPS10

Gas

7

SUBSTRATE REMOVAL

Warning: Should you desire to tilt the

machine, always tilt forward. Tilting the

machine backwards at any time will ood

the spark plug with oil and may cause

damage to your engine!

Adjust the height of the cutter drum with

the Hand Wheel and Cam Lever. (Turn the

hand wheel to raise the cutter drum off of the

substrate. Lower or raise the cam lever to

engage or disengage the drum after setting

the proper cutter depth.)

Set the depth of cut to allow the cutters to go

through only the materials to be removed.

Make certain that the drum is positioned to

where only the cutters strike the surface,

and that the drum assembly never comes

into contact with the substrate. The cutter

tips alone should strike the surface (1/8”

to 1/4” maximum depth per removal pass on

new cutters).

The drum will not withstand substrate

contact. Contacting the removal surface

too deeply will cause premature wear to

cutters, shafts, drum and other

components!

Too much downward pressure only has

negative results. Try to remove materials in

several passes rather than one, deep pass.

Several tests will show the best, most

appropriate cutter impact. Use a forward,

backward and/or circular pattern to achieve

your desired nish.

NOTE: Only use a forward motion when the

CM2150 or CM2550 carbide milling cutters

are used.

TIP: Positioning the machine over the

surface in many directions, as well as

dialing the hand wheel up or down can help

create desirable surface patterns.

After several hours of practice, the operator

will become comfortable and should be able

to remove materials faster with enhanced

results.

When the job is completed, or the operator

wants to cease work, stop the engine by rst

lifting the drum above the substrate using the

hand-wheel and/or the cam lever. Stop the

machine only at the engine. Then close the

fuel cock to shut off the fuel supply.

The drum assembly must be removed daily

and inspected for drum wear, hole

elongation and possible weld separation.

Replace the cutter shafts and drum bushings

every 40 hours, or prior to any drum wear. If

the drum’s center holes are elongated, order

another SMITH cutter drum.

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SPS10

VERSION 11/2016

Gas

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

STORAGE

Shut off fuel valve and remove all fuel or

add fuel stabilizer. Start engine and run until

it stalls. Remove spark plug and pour two

ounces of motor oil into cylinder and slowly

crank the engine by hand to distribute oil to

prevent rust during storage. Replace spark

plug and store machine upright in a cool, dry,

and well-ventilated area.

ORDERING

To ensure product safety and reliability,

and to maintain your warranty, always use

genuine replacement cutters and parts

from SMITH when making repairs to the

equipment.

When ordering please specify the model and

serial number of the machine. In addition, give

a part number, description, and quantity as

listed on your parts list.

If you have any questions about the operation

of your machine or would like to order

replacement parts, contact your SMITH

Manufacturing representative directly.

Contact 1-800-653-9311 (954-941-9744)

for information.

Visit our website at

www.smithmfg.com

WARRANTY CLAIMS

The manufacturer reserves the right to

change or improve the machine design

without assuming any obligation to update

any products previously manufactured

before this manual. It is the customer’s

responsibility to complete the warranty card

and mail it to the seller within 10 days from

date of purchase. If a failure occurs during

the warranty period, the customer must con-

tact the seller to determine the appropriate

action.

Any and all transportation charges are to

be borne by the purchaser.

8

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 11/2016

SPS10

Gas

TROUBLESHOOTING

PROBLEM

Possible Reason(s)/Solution(s)

CUTTERS WEARING

UNEVENLY/PREMATURELY

Drum is too low

Incorrect set-up

Material Build-up

Cutters too tightly loaded

Wrong cutters for

application

CUTTERS SHAFT BREAKAGE

UNEVENLY/PREMATURELY

Drum is too low

End plates or bushings worn

Shafts worn

Wrong cutter set-up

Over 40 hours service-life

DRUM WEARING

PREMATURELY OR CRACKING

Drum hitting ground

Shafts and bushings not replaced

within 40 hours

EXCESS VIBRATION

Bearing worn

Hex bushing worn

Drive shaft worn

Improper cutter set-up

Drum contacting ground

Wheels worn out

MACHINE JUMPS

ERRATICALLY

Drum hitting ground

RPM is too low

Surface is severely uneven

DRIVE BELT WEARING

PREMATURELY

Pulley is misaligned

Wrong belt

Drum is contacting

the surface

CAM LEVER WILL NOT

RAISE/LOWER

Raise or lower hand-wheel

HAND-WHEEL WON’T

TURN

Clean & grease threads

Linkage may be bent

Hand-wheel may be

out of position

*Engine repair and engine warranty

issues are handled directly

by your local engine service center.

For any other problems or questions,

please contact your local representative

or

SMITH Mfg today at 800-653-9311

or

(954) 941-9744.

9

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SPS10

VERSION 11/2016

Gas

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

MAINTENANCE CHECK LIST

Note: Make sure the ignition is in the OFF

position, and the spark plug is disconnected

before servicing

• Maintain proper engine oil and crankcase

levels.

Change every 25-50 hours

(see Honda manual).

• Clean spark plugs regularly, and set the

proper gap.

• Wash the air cleaner element in a non oil-

based solvent, then squeeze out residue.

Allow lter to dry before reinstalling in cleaner.

• Keep a coating of grease on the drive shaft

and threads for easy installation or removal,

and for longer hex bushing life.

• Grease the tilt lever, lower linkage. (Clean

dirt off of ttings before greasing.)

• Check all fasteners and re-tighten, since the

machine will vibrate the fasteners loose if they

are not secured. Use locktite.

This includes:

A) Both set screws (P/N 1010051) aligned on

hex shaft (P/N: 1065037) are torqued tight.

B) All three hex Bolts (P/N: 1010023) on

drum retaining plate (P/N: 1065054). Must be

aligned and tight.

• Check the Drive belt for wear, and adjust

(tighten), or replace as required.

• Check that the pulleys are aligned properly

to ensure the Drive belt is running true.

• Check wheel for wear and that they are

rotating properly, replace if worn. Clean

wheels of material build-up.

• The inside housing must be clean, and

remove any build-up from inside the cage so

cutters and drum rotate freely.

• Inspect and change drum bushings and

shafts every 40 hours, or when worn.

10

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 11/2016

SPS10

Gas

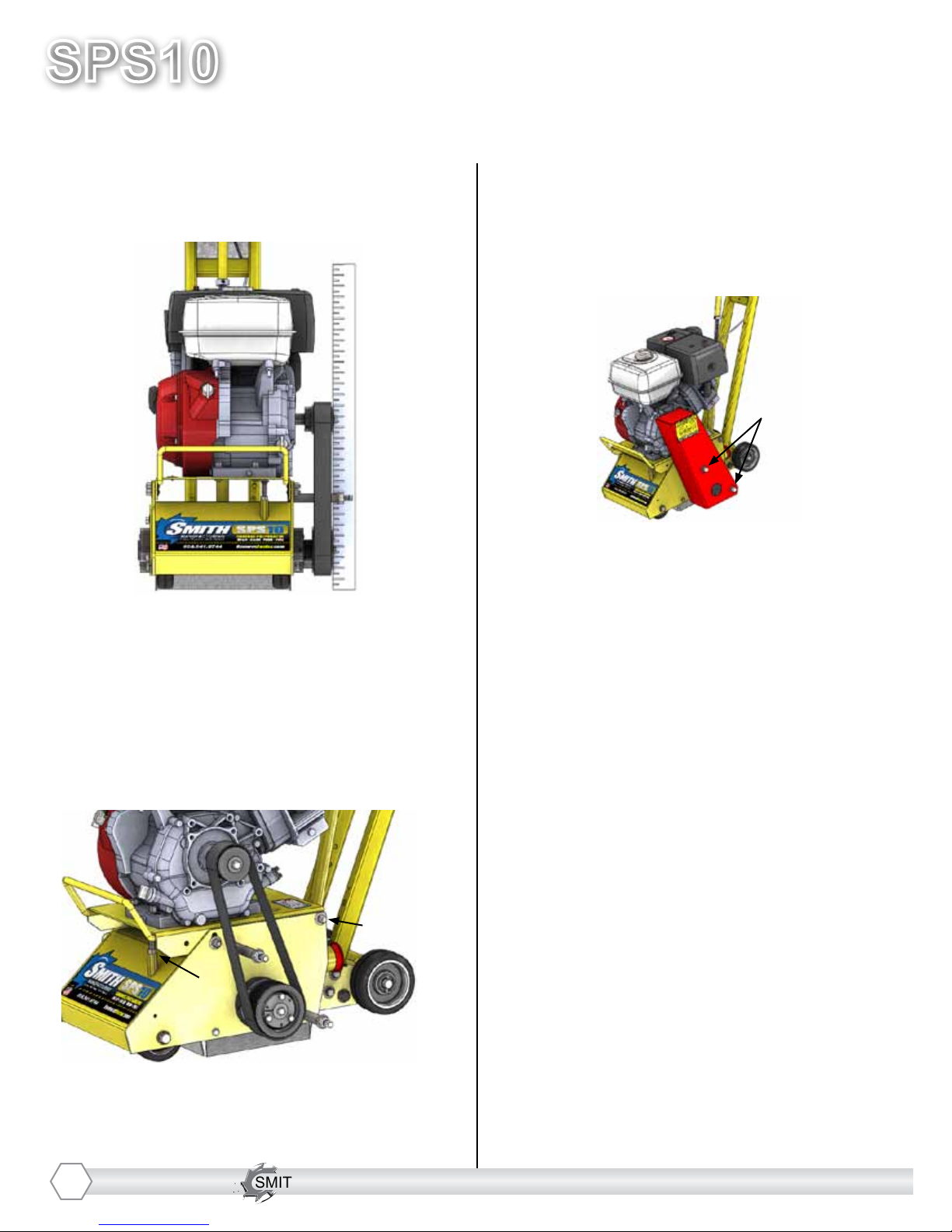

DRUM REPLACEMENT

Normal wear may necessitate belt

tensioning or replacement.

Time of replacement will vary according to

usage and belt load factors.

Replacement is easy and requires a few

hand tools.

1. 9/16” socket or wrench

2. Rubber mallet

Before beginning servicing on any

gasoline-powered unit,

DISCONNECT SPARK PLUG WIRE!

1. Raise the cam lever to the up position so

the cutter drum is off the ground.

3. Remove the sideplate (this may require

the rubber mallet to break it loose)

4. Slide out drum assembly. (use precaution

as it is HEAVY)

1)

2)

3)

4)

5. Once the cutter drum is removed take to a

workbench for assembly.

a) Inspect condition of cutters,

spacers, shafts, bushings and drum.

6) Before replacing the drum onto hex shaft:

a) Check that all bearings are in

good working order

b) Remove dirt and material build-up

from inside drive carriage and drum.

c) Lube all metal contacts

7) Align and slide drum back onto the hex

shaft.

8) Replace side plate (lift-up and lock into

place) over hex shaft and secure hardware.

2. Remove the four hex head cap screws

from the sideplate using the 9/16” socket or

wrench.

*TIP: To reduce downtime, stock a

machine wear parts kit with spare

cutter drum assembly

11

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SPS10

VERSION 11/2016

Gas

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

12

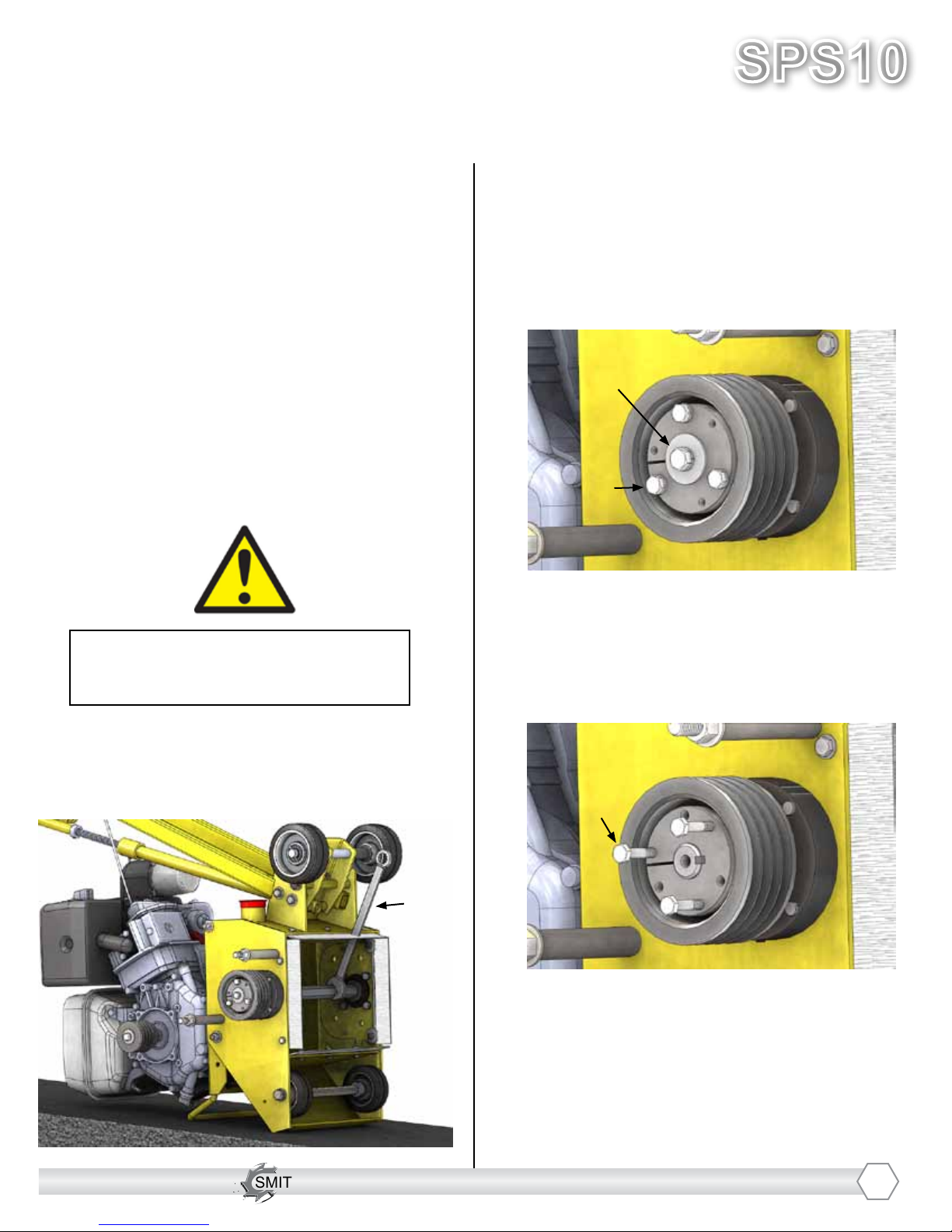

BELT REPLACEMENT

Normal wear may necessitate belt

tensioning or replacement.

Time of replacement will vary according to

usage and belt load factors.

Replacement is easy and requires a few

hand tools.

1. Two 9/16” wrenches

2. 3/4” wrench

3. 3/8” open-end wrench

4. Carpenters square or a straightedge

5. WD-40

6. Spark plug wrench

Before beginning servicing on any

gasoline-powered unit,

DISCONNECT SPARK PLUG WIRE!

1. Make sure the removable side cover is

installed. This ensures the drive ends are in

the proper position for servicing.

2. Remove the spark plug.

3. Clean the machine exterior so you can

locate all the appropriate parts.

4. Using a 3/4” wrench, remove the two

acorn nuts attaching the belt cover to the

side of the machine. Remove the cover and

set it aside.

2)

4)

5. Lubricate the motor plate (belt

tensioning) jackscrew with WD-40 on the

front left of the machine.

6. Use a 9/16” wrench to loosen the jack-

screw jam nut.

7. Using the 3/8” open-end wrench, begin to

screw the motor plate jackscrew back into

the long hex nut below it. Screw it all the

way until resistance is felt.

5), 6), 7

8)

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 11/2016

SPS10

Gas

BELT REPLACEMENT

(CONTINUED)

8. Loosen (do not remove) the four bolts (2

per side) that secure the motor mount plate

to the main machine frame.

9. Loosen the four bolts attaching the mo-

tor to the motor plate. After sufciently

loosening all four, slide the motor back all

the way to the rear. This will loosen the belt

sufciently to remove it.

10. Either cut or roll off the belt from the

pulleys. If you roll it off, move it over one

groove at a time on the upper and lower

pulleys to completely remove it.

8)

9)

11. Roll the new belt on one groove at a

time (two or single multi-groove belt) on

both the top and bottom pulleys.

12. Using the straight edge, lay it across the

lower pulley outer face and against the

upper pulley. They must be directly over

top of each other to insure long belt life. If

adjustment is required, align before

tensioning the belt.

13. After installation, use the 3/8” open-end

wrench to screw out the belt tensioning

jackscrew under the motor plate to tension

the belts to your desired tension. Do not

over-tension the belt.

14. After the correct tension is reached,

tighten the front motor plate securing screw

on the belt side with the 9/16” box end

wrench.

12)

13)

14)

15. Now from the front of the machine

observe the motor plate to machine

alignment. Tightening the belts with the

jackscrew tends to cause the right side of

the motor plate to lift higher than the left

side. By pushing down on the right front

side you can level the plate and then

tighten the front right screw to secure in a

level position.

13

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SPS10

VERSION 11/2016

Gas

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

BELT REPLACEMENT

(CONTINUED)

18. Replace the belt cover using the 3/4“

box wrench.

19. Replace the spark plug and the spark

plug wire.

16. Now tighten the rear securing bolts with

the two 9/16” wrenches.

17. Tighten the motor plate jackscrew

retaining nut with a 9/16” wrench to prevent

it from turning.

17)

16)

18)

BELT ALIGNMENT

If the unit has premature belt wear, breakage

or pulley problems, the issue may be

incorrect alignment or excessive belt

tensioning. All pulleys must be aligned

directly above each other to ensure belt

integrity.

This includes possible timing belts used on

newer models. Incorrect alignment wears

the sides of the belts excessively and will

cause slippage.

1. Use a long straight edge (carpenters

square) to check alignment during belt

tensioning or belt replacement time.

2. By laying the straight edge against the

outer face of the lower pulley, the square will

extend up and rest against the outer face of

the upper (engine pulley). If not, move the

motor pulley in or out to obtain alignment.

3. If replacing pulleys (top or bottom) be sure

to place the pulley on the same plane as the

original one to ensure alignment.

14

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 11/2016

SPS10

Gas

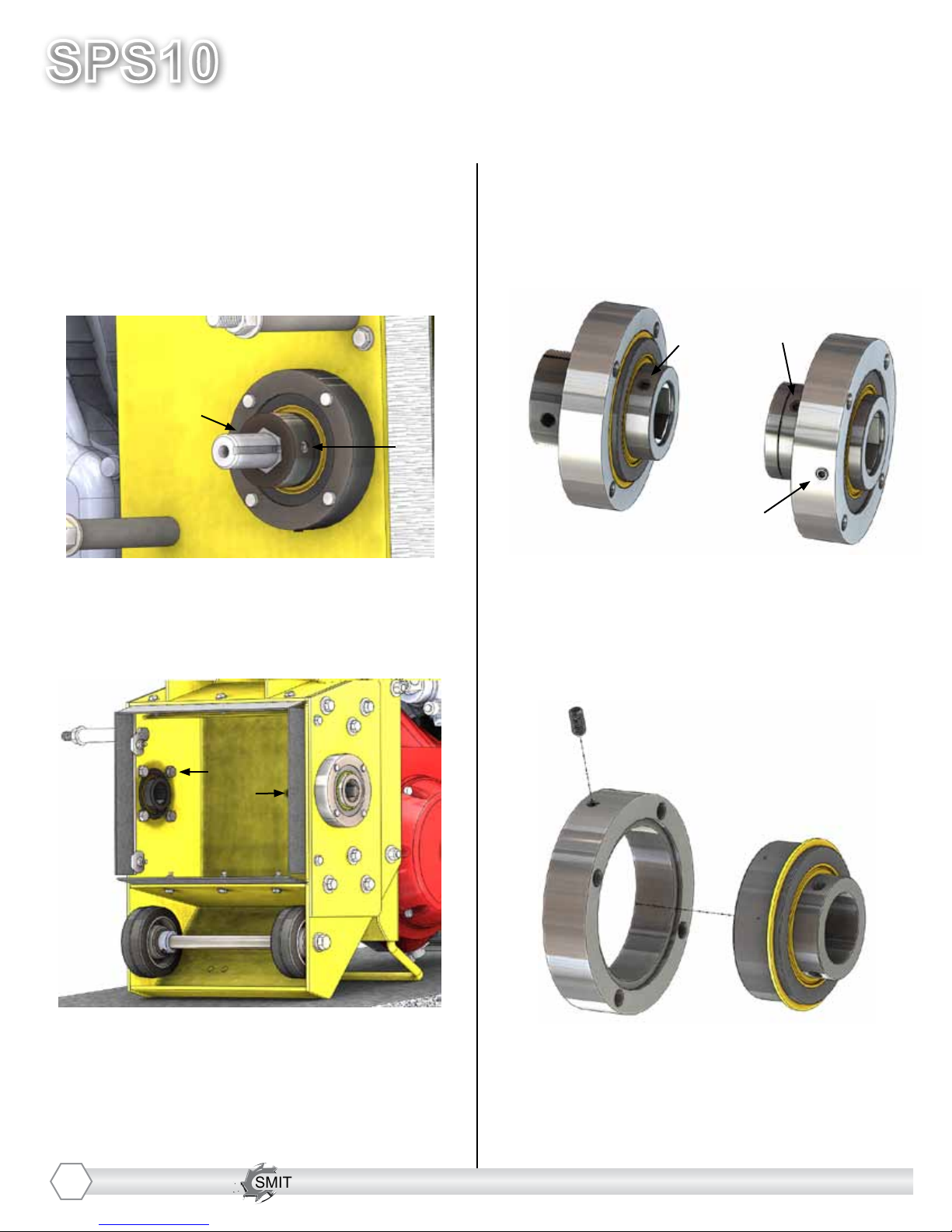

BEARING REPLACEMENT

Before reading ahead go back and follow

the instructions on how to remove the belt

from the machine. Bearing replacement is

easy and requires a few additional hand

tools.

1. 7/16” socket or wrench

2. 1/2” socket or wrench

3. 1” open-end wrench

4. 3/16” Hex Key

5. 5/32” Hex Key

6. 1/8” Hex Key

Before beginning servicing on any

gasoline-powered unit,

DISCONNECT SPARK PLUG WIRE!

1. Once the belt is removed from the ma-

chine, tip the machine over towards the

FRONT and place the 1” wrench over the

hex shaft to prevent it from rotating.

2. Remove the center screw using the 1/2”

socket

3A. Remove the remaining 3 screws using

the 7/16” socket and insert them by hand

into the threaded holes as shown below (3B)

1)

2)

3A)

3B. Once all 3 screws are in, begin to turn

them using a socket and do so EVENLY to

allow the bushing to back out smoothly.

Once the bushing is out, remove the pulley

and key.

3B)

15

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SPS10

VERSION 11/2016

Gas

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

BEARING REPLACEMENT

(CONTINUED)

4. Slide the shaft out by removing the 2 set

screws locking it in place using the 3/16”

hex key

5. Remove the bearing assemblies on both

sides on the machine using the 9/16” socket

6. At this point remove the hex bushings

from the bearing assemblies (note that the

belt side bushing is much thicker and has

holes for set screws) using the 5/32” hex

key

6)

4)

4)

5)

5)

6)

BELT SIDE

7. With the hex bushings out, the remaining

bearings and housings are the same. To

remove the bearing from the housing use

the 1/8” hex key to remove the set screw on

the housing and then tap out the bearing us-

ing a mallet

7)

8. Reverse the process and apply thread

locking uid (loctite) to the set screws

16

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 11/2016

SPS10

Gas

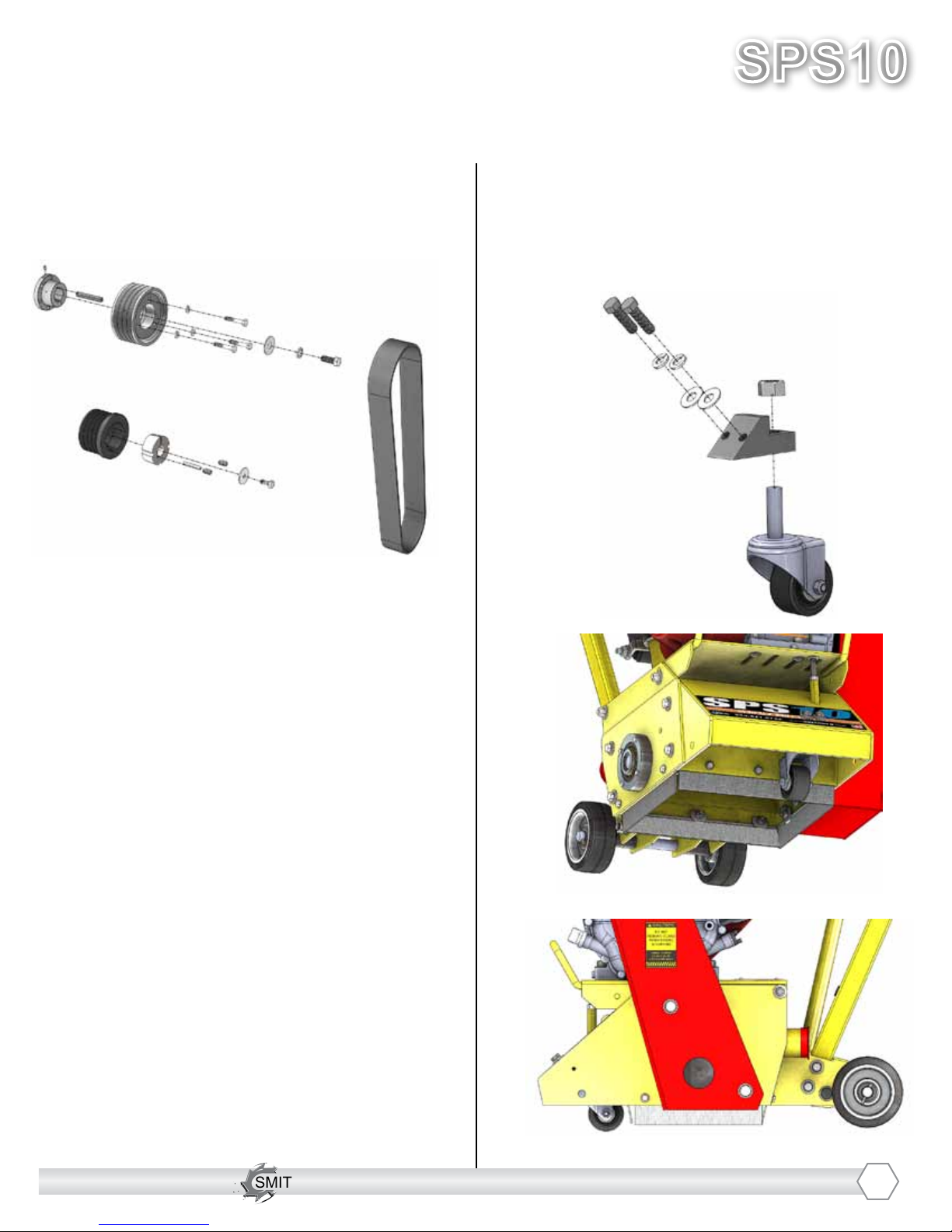

OPTIONAL EQUIPMENT

• HIGH SPEED KIT

The high speed kit is used with the Diamond

Shave-it Drum Assembly ONLY

• SWIVEL WHEEL

The swivel wheel allows you to move the

machine not only forward and backward in

a straight line, but also from side to side to

eliminate grooves!

17

1. Remove belt guard, belt (1081008), and

both pulleys from the ail setup machine.

2. Set the pulley (1010554) from the motor

aside, and move the pulley (1065020) from

the drive shaft to the engine’s shaft (the

bushing required (1010559) is part of the

high speed kit).

3. Place the pulley (X3.00.219.1) and other

bushing (X3.00.220.3) on the drive shaft.

4. Before tightening the pulleys in place with

the bushings, put the new belt (1081008.W)

into place over the pulleys.

5.Align the pulleys using a straight edge, and

tighten them into place with the bushings.

Use locktite 243 on all pulley set screws.

6. Replace belt guard.

HIGH SPEED KIT INSTALLATION

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SPS10

VERSION 11/2016

Gas

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

OPTIONAL EQUIPMENT

• SPS CRADLE

(Cam Release Adjustment Dampener Life

Extender) shock assembly prevents hard

drum drops

• CENTER STAND BRAKE KIT

The Center Stand Brake Kit allows for safe

“parking” of the SPS10 on inclined surfaces

18

• TACH/HOUR METER

Maintenance meter for service and use

control

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

VERSION 11/2016

SPS10

Gas

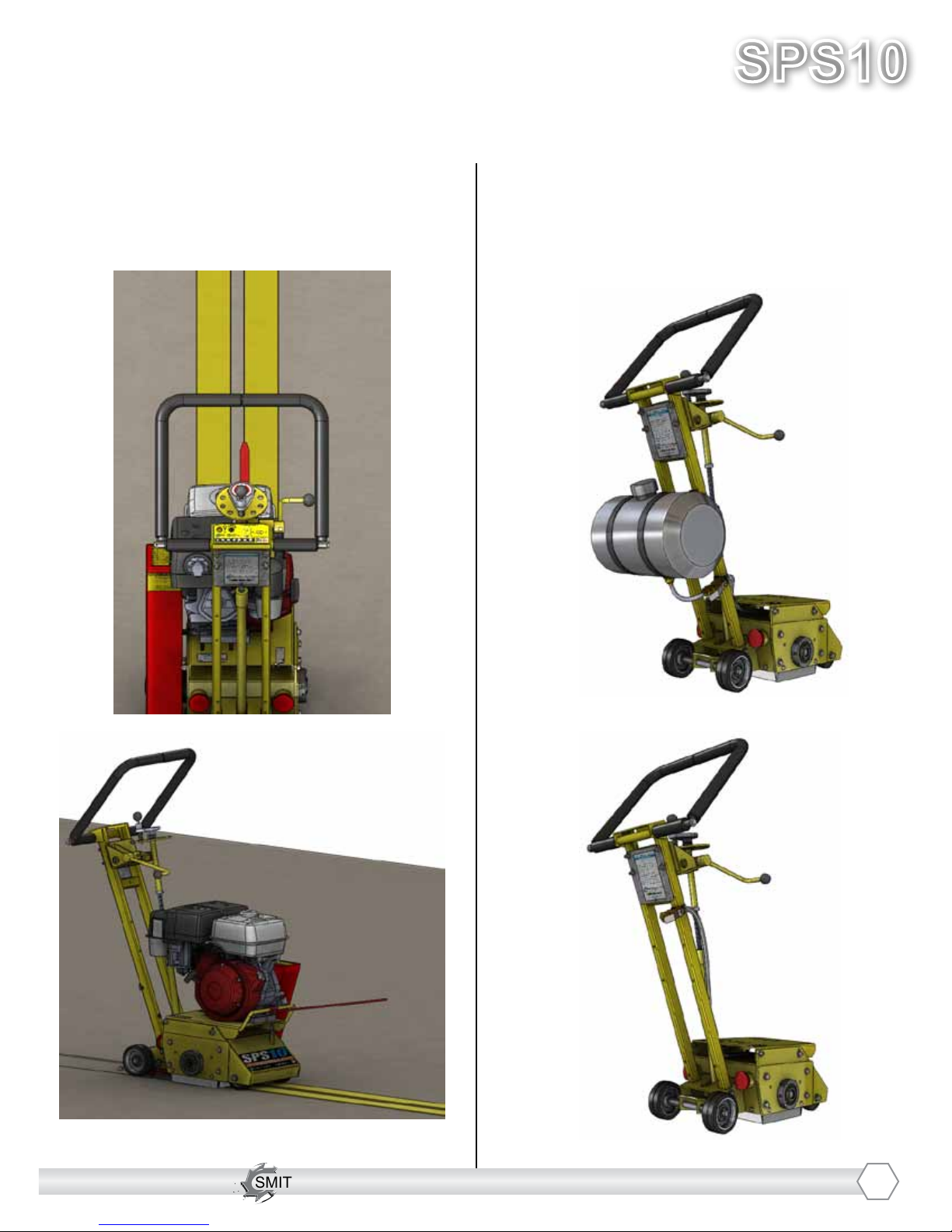

OPTIONAL EQUIPMENT

• POINTER/DIRECTIONAL

SIGHT GUIDE SYSTEM

Allows operator to make straight passes

easier

• WATER CONTROLS

Used to extend life on Diamond drum

applications and for dust control on all others.

Available with or without 5 gallon tank.

19

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

SPS10

VERSION 11/2016

Gas

SMITH Manufacturing 1-954-941-9744 www.SmithMfg.com

OPTIONAL EQUIPMENT

• BALL MOUNT HITCH

Allows attachment to other components

• EDGER DRUM ASSEMBLY

Available for Diamond blades and cutter

applications

20

Other manuals for SPS10

1

Table of contents

Other Smith Construction Equipment manuals