Ercolina MB-42 Installation manual

Warning: read operators manual before attempting to operate machine

(Be sure the machine is connected to a suitable power source before switching power on!)

Programming Instructions for Models MB-42, SB-48, TB-60, TB-76 & ERD-3000

1. Switch the power to the (ON) position.

2. The display will read: “Forward C.Bending Die”

3. Depress (CURSOR) button on touch pad. The display will read “Data Entry” Select (+) = YES Depress (+) (PLUS) Display

will now read “P.1” or similar. This number refers to the program number. You may depress (+) (PLUS) button on touch pad to

select the program to edit.

4. Hold (-) (MINUS) key down for ve seconds. This erases all data within selected program.

5. Enter a new degree of bend using (+) (PLUS) or (-) (MINUS) keys to enter the desired angle. You may also use pre-set

degree buttons to enter degree of bend.

6. Depress (ENTER) button once to store the bend angle.

7. The display will prompt you to enter another bend angle within the same program. If you desire additional bends within the

same program, you may input them in the same manner. If no additional bends are required depress (ENTER).

8. The display will now indicate the program number you edited. (Example P.1)

9. Depress (ENTER) button again and the display returns to the normal operating screen.

Programming Instructions for MegaBender® 030

1. Switch the machine to the (ON) position.

The display will read “Forward C. Bend Die” or similar

Mm 000.0 P1.1 090

2. Depress the (MENU) button

The display will read “MAIN MENU”

1 -DATA ENTRY MODE

3. Depress the (ENTER) button

The display will read “GRP RPM” or similar

1 1.52xxxxxxxx

The “GRP” refers to the program number. You may depress the (+) (PLUS) or (-) (MINUS) buttons to change the “GRP” or

program number.

The display will periodically ash the following message:

“TO INPUT DATA PUSH FOR 3 SECONDS”

4. Press the (*) button for 3 seconds once you have selected the desired program number. Display will read “Angle 000 Bend 1.”

5. Press the (+) (PLUS) or (-) (MINUS) keys to enter the desired bend angle.

6. Press (ENTER) when nished entering the rst bend within the program.

The machine display will prompt to enter another angle within the same program. If you desire additional bends within that “GRP”

or program, you may input them in the same manner as mentioned above.

7. If no additional bends are required, press (ENTER)

The display will momentarily read “END OF DATA ENTRY”

The display will now show “GRP RPM” or similar

1 1.52xxxxxxxxxxxxxxx

Setting the springback and nishing the bend

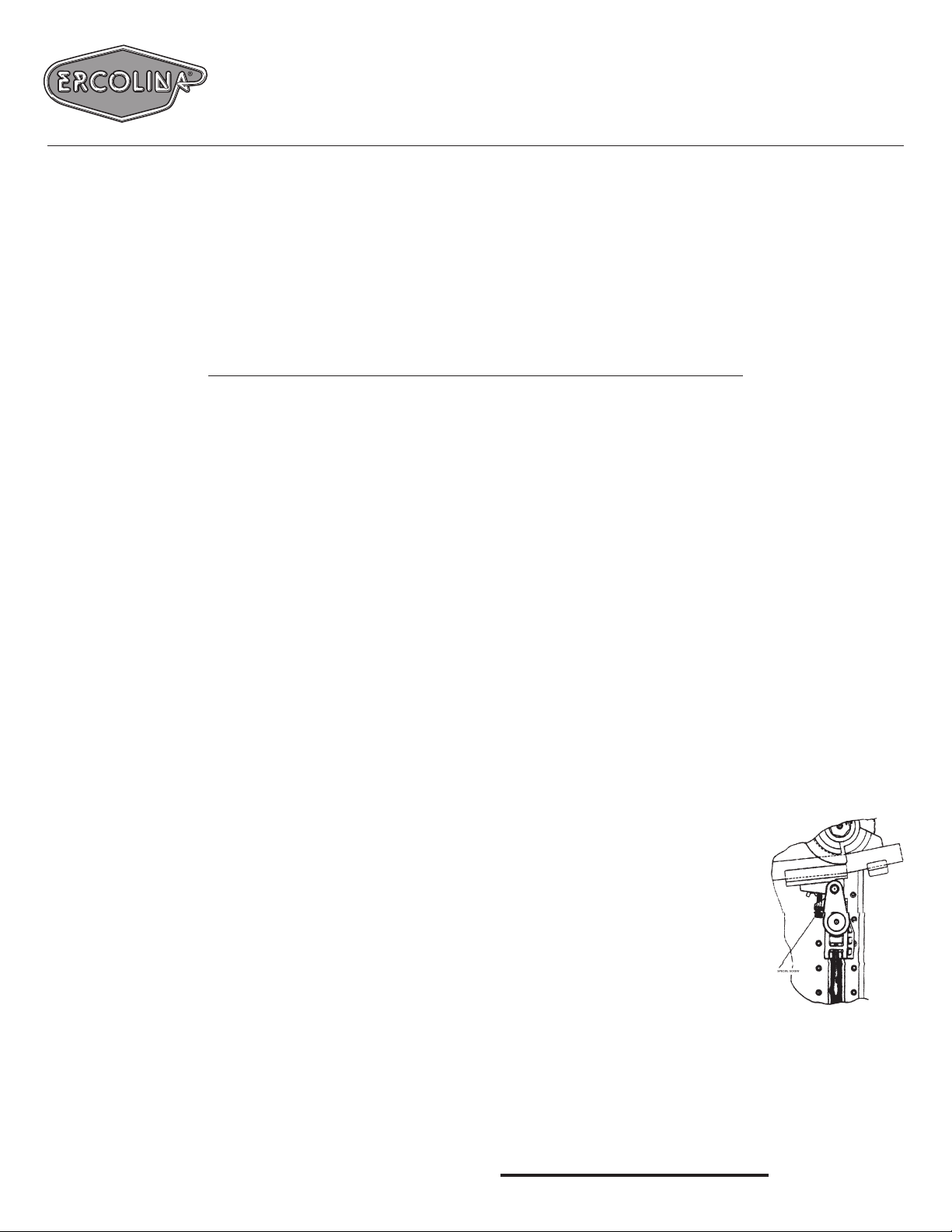

1. Load material into former and move counterbending die vise assembly forward until die contacts material.

Note: counter bending die axis is equipped with an encoder. This axis must be set to zero before the

machine will operate. Depress (ENTER) button once to zero this axis. (Note: Always place material

with the weld-seam up to neutralize the seam. Also, the counterbending die needs to be lubricated

using Ercolina® spray grease Part number PAR 811 prior to bending.)

2. Material springback must to be set at this time. Depress (BEND) button on touch-pad or use the (BEND)

pedal until material begins to deect, refer to diagram. Release the (BEND) button.

3. View LCD display and record angle. The number of degrees it took to make the material deect is

shown on the display. This value is the material springback. Depress (ENTER) button once and the

program automatically compensates for the springback value.

4. Tighten large socket set screw on the side of the vise assembly until it contacts the back of the sup-

port bracket. The springback value has been set for the rst bend within the sequence only. Springback

value must be programmed for each bend within the program.

5. Depress (BEND) button or (BEND) pedal and nish bending process. The machine will automatically stop at programmed

bend angle.

6. Depress (RETURN) button or (RETURN) pedal to return former and material to the starting position.

Ercolina®by CML USA Inc.

Manufacturers of tube, pipe and prole bending machines

3100 Research Parkway • Davenport, Iowa 52806

(563) 391-7700 • (563) 391-7710 Fax • www.ercolina-usa.com

Beware of Imitations!

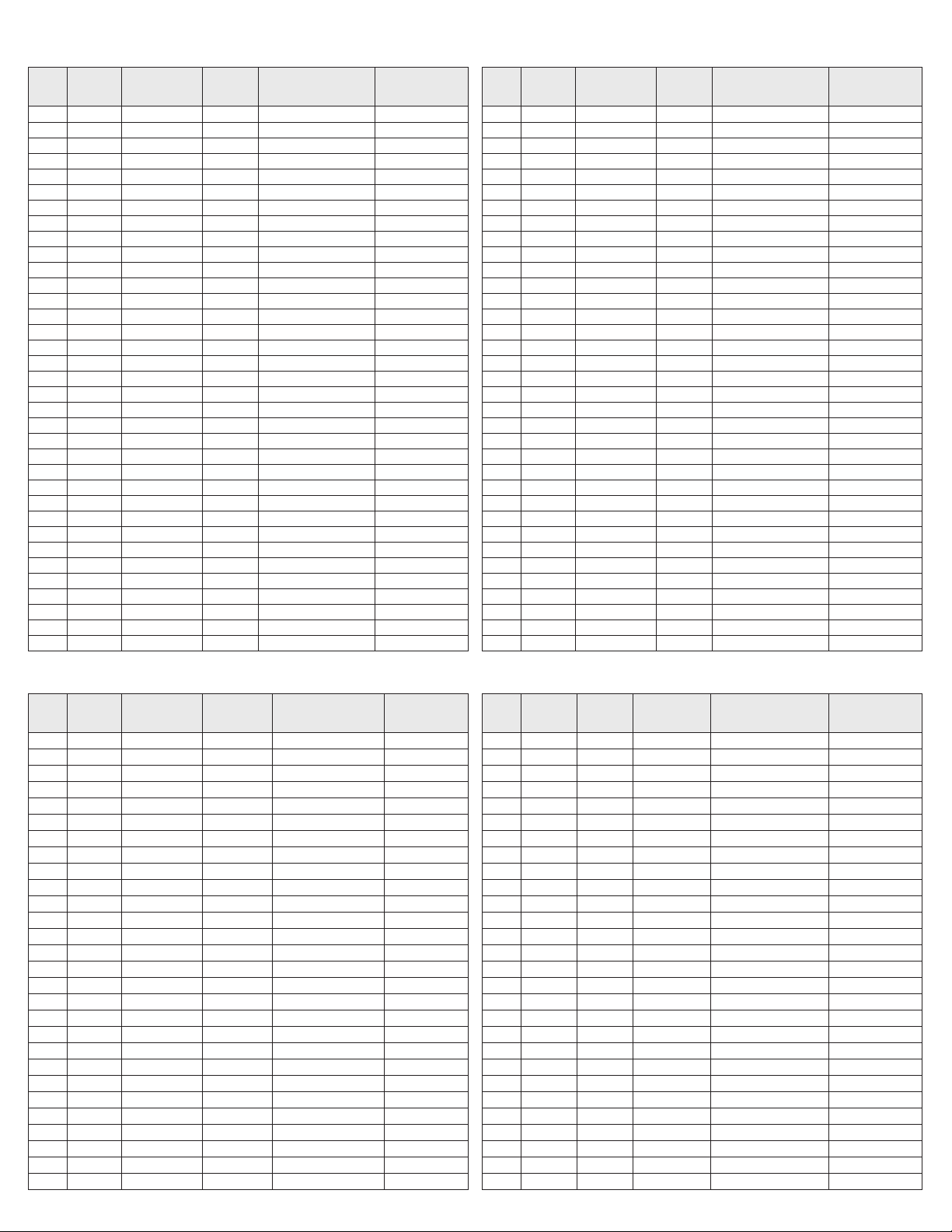

Pipe Outside Schedule Former Counter Bend

size Diameter CLR Wall Thickness Part# Part#

1/4” .520 1.4 / 36mm 40 / .088 T00-153RO36P0250 T00-155P0250

3.8” .680 1.4 / 36mm 40 / .091 T00-153RO36P0375 T00-155P0375

3/8” .680 2.2 / 56mm 10 / .065 T00-153RO56P0375 T00-155P0375

1/2” .840 1.8 / 46mm 40 / .109 T00-153RO46P0500 T00-155P0500

1/2” .840 2.2 / 56mm 10 / .083 T00-153RO56P0500 T00-155P0500

1/2” .840 2.6 / 67mm 5 / .065 T00-153RO67P0500 T00-155P0500

3/4” 1.050 2.2 / 56mm 40 / .113 T00-153RO56P0750 T00-155P0750

3/4” 1.050 2.6 / 67mm 10 / .083 T00-153RO67P0750 T00-155P0750

3/4” 1.050 3.2 / 82mm 5 / .065 T00-153RO82P0750 T00-155P0750

1” 1.315 2.6 / 67mm 40 / .133 T00-153RO67P1000 T00-155P1000

1” 1.315 3.2 / 82mm 10 / .109 T00-153RO82P1000 T00-155P1000

1” 1.315 4.4 / 112mm 5 / .065 T00-153R112P1000 T00-155P1000

1-1/4” 1.660 3.5 / 90mm 40 / .140 T00-153RO90P1250 T00-155P1250

1-1/4” 1.660 3.9 / 100mm 40 / .140 T00-153R100P1250 T00-155P1250

1-1/4” 1.660 5.1 / 130mm 10 / .109 T00-153R130P1250 T00-155P1250

1-1/4” 1.660 5.9 / 150mm 5 / .065 T00-153R150P1250 T00-155P1250

1-1/4” 1.660 7.5 / 190mm 5 / .065 T00-153R190P1250 T00-155P1250

1-1/2” 1.900 3.9 / 100mm 40 / .145 T00-153R100P1500 T00-155P1500

1-1/2” 1.900 5.1 / 130mm 40 / .145 T00-153R130P1500 T00-155P1500

1-1/2” 1.900 5.9 / 150mm 40 / .145 T00-153R150P1500 T00-155P1500

1-1/2” 1.900 6.7 / 170mm 10 / .109 T00-153R170P1500 T00-155P1500

1-1/2” 1.900 7.5 / 190mm 5 / .065 T00-153R190P1500 T00-155P1500

2” 2.375 5.1 / 130mm 40 / .154 T00-153R130P2000 T00-155P2000

2” 2.375 5.9 / 150mm 10 / .098 T00-153R150P2000 T00-155P2000

2” 2.375 7.5 / 190mm 5 / .079 T00-153R190P2000 T00-155P2000

2-1/2” 2.875 9.8 / 250mm 40 / .203 T00-157R250P2500 T00-155P2500

2-1/2” 2.875 10.2 / 260mm 10 / .098 T00-157R260P2500 T00-155P2500

2-1/2” 2.875 11.8 / 300mm 5 / .079 T00-157R300P2500 T00-155P2500

Pipe Tooling

Tube Outside Minimum Former Counter Bend

size Diameter CLR Wall Thickness Part# Part#

3/8” .3750 1.4 .065 T00-1582AR0360375 T00-1591A0375

3/8” .3750 1.8 .049 T00-1582AR0460375 T00-1591A0375

1/2” .5000 1.4 .065 T00-1582AR0360500 T00-1591A0500

1/2” .5000 1.8 .049 T00-1582AR0460500 T00-1591A0500

5/8” .6250 1.4 .065 T00-1582AR0360625 T00-1591A0625

5/8” .6250 1.8 .049 T00-1582AR0460625 T00-1591A0625

5/8” .6250 2.6 .039 T00-1583AR0670625 T00-1591A0625

3/4” .7500 1.8 .120 T00-1582AR0460750 T00-1591A0750

3/4” .7500 2.6 .065 T00-1583AR0670750 T00-1591A0750

7/8” .8750 2.6 .120 T00-1583AR0670875 T00-1591A0875

7/8” .8750 3.2 .065 T00-1583AR0820875 T00-1591A0875

7/8” .8750 4.4 .049 T00-1586AR1120875 T00-1591A0875

1” 1.000 3.0 .120 T00-1583AR0761000 T00-1591A1000

1” 1.000 3.2 .120 T00-1583AR0821000 T00-1591A1000

1” 1.000 3.9 .065 T00-1585AR1001000 T00-1591A1000

1” 1.000 4.4 .078 T00-1586AR1121000 T00-1591A1000

1” 1.000 5.1 .083 T00-1587AR1301000 T00-1591A1000

1” 1.000 5.9 .049 T00-1588AR1501000 T00-1591A1000

1-1/4” 1.250 5.1 .120 T00-1587AR1301250 T00-1591A1250

1-1/4” 1.250 5.9 .109 T00-1588AR1501250 T00-1591A1250

1-1/4” 1.250 6.6 .095 T00-1589AR1701250 T00-1591A1250

1-1/4” 1.250 7.4 .083 T00-15810AR1901250 T00-1591A1250

1-1/2” 1.500 5.9 .120 T00-1588AR1501500 T00-1591A1500

1-1/2” 1.500 6.6 .109 T00-1589AR1701500 T00-1591A1500

1-1/2” 1.500 7.4 .095 T00-15810AR1901500 T00-1591A1500

2” 2.000 5.9 .120 T00-1588AR1502000 T00-1591A2000

2” 2.000 6.6 .109 T00-1589AR1702000 T00-1591A2000

2” 2.000 7.4 .095 T00-15810AR1902000 T00-1591A2000

Square Tube Tooling

Pipe Outside Minimum Wall Former Counter Bend

size Diameter CLR Thickness Part# Part#

Round Tube Tooling

1/4” .250 1.4 / 36mm .039 T00-153RO36T0250 T00-154T0250

3/8” .375 1.4 / 36mm .039 T00-153RO36T0375 T00-154T0375

1/2” .500 1.4 / 36mm .039 T00-153RO36T0500 T00-154T0500

5/8” .625 1.4 / 36mm .039 T00-153RO36T0625 T00-154T0625

5/8” .625 1.8 / 46mm .079 T00-153RO46T0625 T00-154T0625

3/4” .750 1.8 / 46mm .079 T00-153RO46T0750 T00-154T0750

3/4” .750 2.2 / 56mm .059 T00-153RO56T0750 T00-154T0750

3/4” .750 2.6 / 67mm .039 T00-153RO67T0750 T00-154T0750

7/8” .8750 1.8 / 46mm .079 T00-153RO46T0875 T00-154T0875

7/8” .8750 2.2 / 56mm .059 T00-153RO56T0875 T00-154T0875

7/8” .8750 2.6 / 67mm .039 T00-153RO67T0875 T00-154T0875

1” 1.000 2.2 / 56mm .079 T00-153RO56T1000 T00-154T1000

1” 1.000 2.6 / 67mm .059 T00-153RO67T1000 T00-154T1000

1” 1.000 3.2 / 82mm .039 T00-153RO82T1000 T00-154T1000

1-1/8” 1.125 2.2 / 56mm .098 T00-153RO56T1125 T00-154T1125

1-1/8” 1.125 2.6 / 67mm .079 T00-153RO67T1125 T00-154T1125

1-1/8” 1.125 3.2 / 82mm .039 T00-153RO82T1125 T00-154T1125

1-1/4” 1.250 2.6 / 67mm .098 T00-153RO67T1250 T00-154T1250

1-1/4” 1.250 3.2 / 82mm .079 T00-153RO82T1250 T00-154T1250

1-1/4” 1.250 4.4 / 112mm .039 T00-153R112T1250 T00-154T1250

1-3/8” 1.375 3.2 / 82mm .079 T00-153R112T1375 T00-154T1375

1-3/8” 1.375 4.4 / 112mm .039 T00-153R112T1375 T00-154T1375

1-1/2” 1.500 3.5 / 90mm .118 T00-153R090T1500 T00-154T1500

1-1/2” 1.500 3.9 / 100mm .079 T00-153R100T1500 T00-154T1500

1-1/2” 1.500 4.4 / 112mm .079 T00-156R100T1500 T00-154T1500

1-1/2” 1.500 5.1 / 130mm .059 T00-153R130T1500 T00-154T1500

1-1/2” 1.500 5.9 / 150mm .047 T00-153R150T1500 T00-154T1500

1-1/2” 1.500 6.7 / 170mm .039 T00-156R170T1500 T00-154T1500

1-1/2” 1.500 7.5 / 190mm .039 T00-153R190T1500 T00-154T1500

1-5/8” 1.625 3.5 / 90mm .118 T00-153R090T1625 T00-154T1625

1-5/8” 1.625 3.9 / 100mm .079 T00-153R100T1625 T00-154T1625

1-5/8” 1.625 5.1 / 130mm .059 T00-153R130T1625 T00-154T1625

1-5/8” 1.625 5.9 / 150mm .047 T00-153R150T1625 T00-154T1625

1-5/8” 1.625 6.7 / 170mm .039 T00-156R170T1625 T00-154T1625

1-5/8” 1.625 7.5 / 190mm .039 T00-153R190T1625 T00-154T1625

Pipe Outside Minimum Wall Former Counter Bend

size Diameter CLR Thickness Part# Part#

1-3/4” 1.750 3.9 / 100mm .118 T00-153R100T1750 T00-154T1750

1-3/4” 1.750 5.1 / 130mm .098 T00-153R130T1750 T00-154T1750

1-3/4” 1.750 5.9 / 150mm .098 T00-156R150T1750 T00-154T1750

1-3/4” 1.750 6.7 / 170mm .059 T00-153R170T1750 T00-154T1750

1-3/4” 1.750 7.5 / 190mm .039 T00-153R190T1750 T00-154T1750

1-7/8” 1.875 3.9 / 100mm .118 T00-153R100T1875 T00-154T1875

1-7/8” 1.875 5.1 / 130mm .098 T00-153R130T1875 T00-154T1875

1-7/8” 1.875 5.9 / 150mm .079 T00-156R150T1875 T00-154T1875

1-7/8” 1.875 6.7 / 170mm .059 T00-153R170T1875 T00-154T1875

1-7/8” 1.875 7.5 / 190mm .039 T00-153R190T1875 T00-154T1875

2” 2.000 4.7 / 120mm .118 T00-153R120T2000 T00-154T2000

2” 2.000 5.1 / 130mm .118 T00-156R130T2000 T00-154T2000

2” 2.000 5.9 / 150mm .098 T00-153R150T2000 T00-154T2000

2” 2.000 6.7 / 170mm .079 T00-156R170T2000 T00-154T2000

2” 2.000 7.5 / 190mm .059 T00-153R190T2000 T00-154T2000

2-1/8” 2.125 4.7 / 120mm .138 T00-153R120T2125 T00-154T2125

2-1/8” 2.125 5.1 / 130mm .118 T00-153R130T2125 T00-154T2125

2-1/8” 2.125 5.9 / 150mm .079 T00-153R150T2125 T00-154T2125

2-1/8,” 2.125 6.7 / 170mm .079 T00-156R170T2125 T00-154T2125

2-1/8” 2.125 7.5 / 190mm .059 T00-153R190T2125 T00-154T2125

2-1/4” 2.250 5.1 / 130mm .118 T00-153R130T2250 T00-154T2250

2-1/4” 2.250 5.9 / 150mm .098 T00-153R150T2250 T00-154T2250

2-1/4” 2.250 6.7 / 170mm .079 T00-156R170T2250 T00-154T2250

2-1/4” 2.250 7.5 / 190mm .079 T00-153R190T2250 T00-154T2250

2-3/8” 2.375 5.1 / 130mm .118 T00-153R130T2375 T00-154T2375

2-3/8” 2.375 5.9 / 150mm .098 T00-153R150T2375 T00-154T2375

2-3/8” 2.375 6.7 / 170mm .079 T00-156R170T2375 T00-154T2375

2-3/8” 2.375 7.5 / 190mm .079 T00-153R190T2375 T00-154T2375

2-1/2” 2.500 8.9 / 225mm .079 T00-157R225T2500 T00-154T2500

2-1/2” 2.500 9.8 / 250mm .079 T00-157R250T2500 T00-154T2500

2-1/2” 2.500 10.2 / 260mm .059 T00-157R260T2500 T00-154T2500

2-1/2” 2.500 11.8 / 300mm .049 T00-157R300T2500 T00-154T2500

3” 3.000 9.8 / 250mm .156 T00-157R250T3000 T00-154T3000

3” 3.000 10.2 / 260mm .118 T00-157R260T3000 T00-154T3000

3” 3.000 11.8 / 300mm .079 T00-157R300T3000 T00-154T3000

NOTE: Larger materials may slip slightly in former during bend cycle.

This manual suits for next models

5

Other Ercolina Construction Equipment manuals

Popular Construction Equipment manuals by other brands

Barreto

Barreto 1324TK owner's manual

Bosch

Bosch Professional GDE 12 Original instructions

Fayat

Fayat BOMAG BW 120 AD-5 Operating instruction

Epiroc

Epiroc EC Series Safety and operating instructions

Highway Care

Highway Care BG800 Product and installation manual

probst

probst HVZ-LIGHT operating instructions