Ergo ERGO 8 User manual

Water Softener | User Manual

Adoucisseur d’eau | Guide d’utilisation

www.puricom.eu

ENG FR

1. CARACTERÍSTICAS PRINCIPALES

FÁCIL LLENADO DE SAL

Cómodo llenado de sal especial para descalcificadores.

HIDRÁULICO

Sin alimentación eléctrica, ausencia de programación y de problemas.

Mayor caudal de agua dispensada

Grifo de diseño exclusivo.

Minimiza la migración metálica

REGENERACIÓN ULTRA RÁPIDA

Lavados completos en 15 minutos.

BAJO CONSUMO

Regeneraciones más eficientes.

VÁLVULA MEZCLADORA

Permite regular el grado de dureza residual.

BY-PASS INTEGRADO

Permite aislar el equipo de la instalación.

VÁLVULA ESSENTIAL

Lista para funcionar solo con un giro de destornillador.

CONSERVE ESTE MANUAL QUE INCLUYE LOS APARTADOS DE LIBRO DE SERVICIO Y GARANTÍAS, PARA PODER

PROPORCIONARLE UN MEJOR SERVICIO POST VENTA.

PLEASE KEEP THIS MANUAL, WHICH INCLUDES THE SERVICE BOOK, IN ORDER TO

PROVIDE YOU WITH A BETTER AFTER-SALES SERVICE.

1. CARACTERÍSTICAS PRINCIPALES

FÁCIL LLENADO DE SAL

Cómodo llenado de sal especial para descalcificadores.

HIDRÁULICO

Sin alimentación eléctrica, ausencia de programación y de problemas.

Mayor caudal de agua dispensada

Grifo de diseño exclusivo.

Minimiza la migración metálica

REGENERACIÓN ULTRA RÁPIDA

Lavados completos en 15 minutos.

BAJO CONSUMO

Regeneraciones más eficientes.

VÁLVULA MEZCLADORA

Permite regular el grado de dureza residual.

BY-PASS INTEGRADO

Permite aislar el equipo de la instalación.

VÁLVULA ESSENTIAL

Lista para funcionar solo con un giro de destornillador.

CONSERVE ESTE MANUAL QUE INCLUYE LOS APARTADOS DE LIBRO DE SERVICIO Y GARANTÍAS, PARA PODER

PROPORCIONARLE UN MEJOR SERVICIO POST VENTA.

AFIN DE VOUS APPORTER UN MEILLEUR SERVICE APRÈS-VENTE, VEUILLEZ CONSERVER

CE MANUEL, INCLUANT LE LIVRET D’ENTRETIEN.

1. CARACTERÍSTICAS PRINCIPALES

FÁCIL LLENADO DE SAL

Cómodo llenado de sal especial para descalcificadores.

HIDRÁULICO

Sin alimentación eléctrica, ausencia de programación y de problemas.

Mayor caudal de agua dispensada

Grifo de diseño exclusivo.

Minimiza la migración metálica

REGENERACIÓN ULTRA RÁPIDA

Lavados completos en 15 minutos.

BAJO CONSUMO

Regeneraciones más eficientes.

VÁLVULA MEZCLADORA

Permite regular el grado de dureza residual.

BY-PASS INTEGRADO

Permite aislar el equipo de la instalación.

VÁLVULA ESSENTIAL

Lista para funcionar solo con un giro de destornillador.

CONSERVE ESTE MANUAL QUE INCLUYE LOS APARTADOS DE LIBRO DE SERVICIO Y GARANTÍAS, PARA PODER

PROPORCIONARLE UN MEJOR SERVICIO POST VENTA.

HIGH-SPEED REGENERATION - full wash in 15 minutes

RÉGÉNÉRATION HAUTE-VITESSE - régénération complète en 15 minutes

LOW CONSUMPTION - more ecient regeneration

BASSE CONSOMMATION - régénération plus ecace

MIXING VALVE - the residual hardness degree can be regulated

VANNE DE MÉLANGE - L’équipement peut être isolé de l’installation

BUILT-IN BY-PASS - the equipment can be isolated from the installation

BY-PASS INTÉGRÉ - L’équipement peut être isolé de l’installation

ERGO VALVE - ready to work with a single turn from a screwdriver

VANNE ERGO - Prêt à être utilisé d’un simple tour de tournevis

EASY SALT REFILLING - specifically designed easy to load salt

RECHARGEMENT EN SEL SIMPLIFIÉ - Rechargement en sel facilité grâce à

sa conception spécifique pour les adoucisseurs d’eau

HYDRAULIC - no electrical power supply, so no settings to set

FONCTIONNEMENT HYDRAULIQUE - sans électricité, sans paramétrage et

sans contrainte.

The Ergo Water Conditioning Systems are Tested and Certified by

WQA under NSF/ANSI 61 for Materials Safety Requirements Only. Not

Certified for Contaminant Reductions or Structural Integrity by WQA.

L’adoucisseurs d’eau Ergo est testé et certifié par WQA sous la norme

NSF/ANSI 61 seulement pour les exigences en matière de sécurité du

matériel. La réduction des contaminants ou l’intégrité structurelle ne

sont pas certifiées par la WQA.

CONTENTS

1. Presentation_______________________________________________ 4

2. Introduction ______________________________________________ 4

3. Technical Specifications ______________________________________8

4. Unpacking and Verification of the Content______________________ 9

5. Prior Warnings ____________________________________________ 9

6. Equipment Installation ______________________________________ 11

7. Ergo Programmer __________________________________________ 13

8. Hydraulic Start-Up _________________________________________ 14

9. By-pass and Mixing ________________________________________ 15

10. Maintenance and Sanitizing _________________________________ 15

11. Frequently Asked Questions _________________________________ 17

12. Service Book: User ________________________________________ 18

ENG

FR SOMMAIRE

1. Présentation______________________________________________ 20

2. Introduction ______________________________________________ 21

3. Caractéristiques Techniques ________________________________ 24

4. Déballage et Vérification du Contenu __________________________25

5. Avertissements ____________________________________________25

6. Installation de L’équipement _________________________________28

7. Programmation Principale __________________________________ 29

8. Démarrage Hydraulique ____________________________________ 30

9. By-Pass et Mélange ________________________________________ 31

10. Entretien et Assainissement _________________________________32

11. Foire Aux Questions________________________________________33

12. Livret D’entretien: Utilisateur _______________________________ 34

User’s Manual

4

1. PRESENTATION

The Ergo water treatment equipment you

have purchased is a high performance

hydraulic countercurrent water softener

that will provide you and your family

with high quality softened water.

Lime or water hardness may cause

problems in pipes and aect the proper

functioning of the equipment using that

water, thus increasing its maintenance

and reducing its service life. This reality

has prompted us to design this domestic

water softening product, which has

been specially conceived to protect

the plumbing installation in your home

against the scaling eects.

Your Ergo water softener will provide

you and your family the benefits and

advantages outlined below:

• Energy savings.

• Greater feeling of well-being.

• Increases the life of electrical appliances.

• Cost savings: it reduces the

consumption of soap, fabric softeners

and chemical products.

• Low maintenance cost.

• Automatic control of the equipment.

It is very important that you read

and keep this manual before the

installation and start-up of the system. If

you have any questions regarding the

use or maintenance of this system,

please contact your installer.

1.1. WATER SOFTENER SAFETY

Your safety and that of others is very

important. We have included some

safety messages in this manual.

This is the symbol for a safety

alert. This symbol will warn you

about possible situations in which you or

those around you could be at risk.

All safety messages will have the alert

symbol or the word ‘DANGER’ or

‘WARNING’.

Scope of this manual:

• DANGER: Severe or fatal risk if

the following instructions are not

immediately followed.

• WARNING: All safety messages

provide information about the

possible danger, how to reduce the

risk of injury and what might happen

if the instructions are not followed.

1.2. WHAT TO DO BEFORE

See ‘Section 5’ before installing the

water softener. Carefully follow the

instructions (Limited Warranty may be

considered void, if the installation is

faulty). Please read the entire manual

before undertaking installation. Then,

collect all necessary materials and tools

for the installation.

Check the plumbing installation:

All installations must comply with the

law in force in each region or country.

Please be careful when handling the

water softener. Do not knock it over, let

go of it or place it onto sharp objects.

Under no circumstance should the

softener be installed outdoors, since it

must be protected against sunlight and

rough environmental conditions.

2. INTRODUCTION

This system comes with a residual

hardness regulator as standard, this

enables the selection of the appropriate

hardness for your home. The simple

hydraulic controller enables quick and

easy programming within seconds.

USER'S

MANUAL

FOR WATER SOFTENERS

5

User’s Manual

What is hardness?

Hardness is the quantity of scaling

salts present in water, which are mainly

composed of low solubility salts of

calcium and magnesium. The main salts

causing hardness are listed below:

Calcium bicarbonate: Ca(CO3H)2

Calcium chloride: CaCl2

Calcium sulphate: CaSO4

Magnesium bicarbonate: Mg(CO3H)2

Magnesium chloride: MgCl2

Magnesium sulphate: MgSO4

These salts, due to their chemical

properties, have a tendency to

precipitate, producing scale on pipes and

obstructing them as they accumulate.

In the same way, hardness has a high

tendency to scale on the electrical

resistors from heaters and to precipitate

in heaters when temperature increases.

The combination of hard minerals and

soap produces a soap curdling, which

reduces the cleansing properties of

soap.

The precipitation of hard minerals builds

a layer on cooking utensils, connections

and plumbing fixtures. It may even alter

the taste of food.

Main problems:

• Precipitation on pipes, fixtures and

appliances.

• Increase in energy consumption due to

generated isolation.

• Higher soap consumption.

• Reduction of the electrical appliances’

service life and increase of the

maintenance needed.

All these problems are greatly reduced

when using a water softening system.

For the most part of Europe, hardness is

indicated in French hydrometric degrees,

but there are also other measuring units,

according to each region.

The most common measurements to

follow.

UNITS ppm

of CaCO3 ˚French

1 ppm of Calcium 2.5 0.25

1 ppm of Magnesium 4.13 0.413

1 ppm of CaCO31 0.1

1º French (ºHF) 10 1

1º German (ºd) 17.8 1.78

1º English (ºe) 14.3 1.43

1 mmol/L 100 10

1 mval/L=meq/L 50 5

How does your system work?

Water softening is carried out by means

of an ion exchange process. The system

uses resin with the chemical capacity of

capturing Calcium (Ca) and Magnesium

(Mg) ions to remove them from water.

When Calcium and Magnesium ions

are captured by the resin, two Sodium

(Na) ions are released which, due to

its chemical properties, produce salts

with a higher solubility, thus avoiding all

hardness-related problems.

Therefore, when water gets softened,

its sodium level increases. Further

information on this procedure can be

found in ‘Section 2.8’.

Ion exchange resins:

These are synthetic compounds, usually

with a spherical shape, able to capture

certain chemical substances present

in water, which they then exchange

for other substances. Water softening

uses strong cation resins, which are

composed of styrene copolymers and

divinylbenzene with a sulphur base.

The exchange resin charge is inside the

column of the water softener and takes

up a significant part of the total volume.

During the process, water goes into the

Ergo valve through the inlet connection,

flows towards the bottom of the tank

through the distributing pipe and

goes upwards through the resin bed.

Treated water is collected by the upper

nozzle and supplied through the outlet

connection. At this point, the equipment

has a water meter which counts the

volume of treated water.

User’s Manual

6

Salida

de agua a servi

-

cio

Entrada

de agua de red

Tap

water

inlet

Water

outlet to

service

Regeneration of the system:

The quantity of calcium and magnesium

ions that the resin may retain is limited;

therefore, the volume of water that a

water softener can treat is limited as

well.

The system must periodically carry

out a process known as regeneration,

which allows the resin to recharge with

sodium ions, so it can continue softening

water. In the Ergo, the regeneration

process starts automatically when the

programmed water volume is achieved.

Regeneration is composed of several

stages, which are described below:

Note: During the regeneration process,

the system will allow untreated water to

pass through, in order to maintain the

water supply.

Salida

de agua a

servicio

Salida

de la solución de

salmuera hacia

desagüe

Succión de la

salmuera

Entrada

de agua de red

Tap

water

inlet

Brine

suction

Outlet

to the

drain for

the brine

solution

Water

outlet to

service

Rinsing with brine/slow rinsing:

Hard water enters the equipment

through the inlet, flows towards the

compartment of the Venturi tube, which

carries the brine (or sodium chloride

solution) from the brine tank. Brine

flows downwards towards the resin and

then enters the central tube through the

lower distributor.

Following this, the brine flows towards

the drain tube through the drain valve.

The resin beads are replaced by sodium

ions from the brine solution during the

rinsing with brine and the slow rinsing

stages, in order to force the calcium and

the magnesium out of the resin beads.

Subsequent washing:

Hard water enters the equipment

through the inlet of the valve, flows

downwards to the resin bed and the

lower distributor, until the central tube.

Then, the water for the subsequent wash

flows towards the drain tube through the

drain valve.

Salida

de agua a servi

-

cio

Eliminación total

de salmuera,

lavado rápido

Entrada

de agua de red

Tap

water

inlet

Full

removal

of brine,

quick

wash

Water

outlet to

service

Refilling the brine tank:

Once the subsequent wash is done, the

brine tank refills with hard water through

the brine valve, in order to prepare the

brine solution for the next regeneration.

A brine level float controls the water

level in the tank. This process is fully

automatic, therefore it is not necessary

to add any water to the brine tank

(except during the start-up, as indicated

in ‘Section 7’).

Note: The brine line is under pressure

when in service. Please check carefully

that there are no leaks in the brine line

during water treatment.

Regeneration degree and capacity:

The exchange capacity is the quantity of

hardness that a certain resin volume can

retain before getting exhausted. This

7

User’s Manual

value is usually expressed as ºHFxm3.

The higher the resin volume of the

system is, the higher will be the quantity

of hardness that can be retained before

the resin gets exhausted.

2.1 WORKING FLOW RATES

Please see the minimum and maximum

flow rates indicated in the “Technical

Specifications” section. If the working

ranges are outside the recommended

ranges, the proper operation of the

system will be aected (excessive loss

of charge, hardness leakage, etc.)

2.2 HARDNESS LEAKAGE

The ion exchange process may be

aected by dierent factors, which can

reduce its eciency and cause a certain

level of hardness leakage.

High sodium concentration on water

to be treated. This may interfere in the

exchange process.

Excessive flow rates. Since there is

not enough contact time, some of the

hardness may not be retained by the

resin.

2.3 RESIDUAL HARDNESS

Depending on the final use of treated

water, it may be necessary to obtain fully

softened water or, on the contrary, it

may be desirable to leave some residual

hardness.

This system has been designed to

supply fully softened water, but the

by-pass integrates a residual hardness

mixer, which allows the regulation of

the desired hardness degree in treated

water (see ‘Section 7’).

NOTE: For human consumption water, it

is recommended in most cases, to have a

residual hardness between 5 and 8 ºHF if

pipes are made of copper, and between

8 and 10 ºHF if they are made of iron

(for the latter, it is also recommended

to install a silicopolyphosphates filter

afterwards).

2.4 SODIUM INCREASE

Most of the sodium we consume on a

daily basis comes from food, salt is an

excellent preservative and is used as an

additive in prepared products. Sodium

consumption through the water we

drink is rather low when compared with

that obtained from food.

WARNING: As mentioned above,

water softeners reduce the

Calcium and Magnesium concentration

in water by replacing it for Sodium.

Thus, they increase the sodium level in

water.

The maximum recommended sodium

level in water for human consumption is

of 200 ppm. Depending on the sodium

concentration and the hardness of water

to be treated, it is possible that softened

water contains a higher concentration of

sodium than that recommended.

Should this be the case, or if water

is to be consumed by persons who

must follow a low-sodium diet, it is

recommended to install a household

reverse osmosis system to drink the

water. The table below can be used as

a guideline to know the increase on

sodium concentration in treated water

depending on the entry hardness:

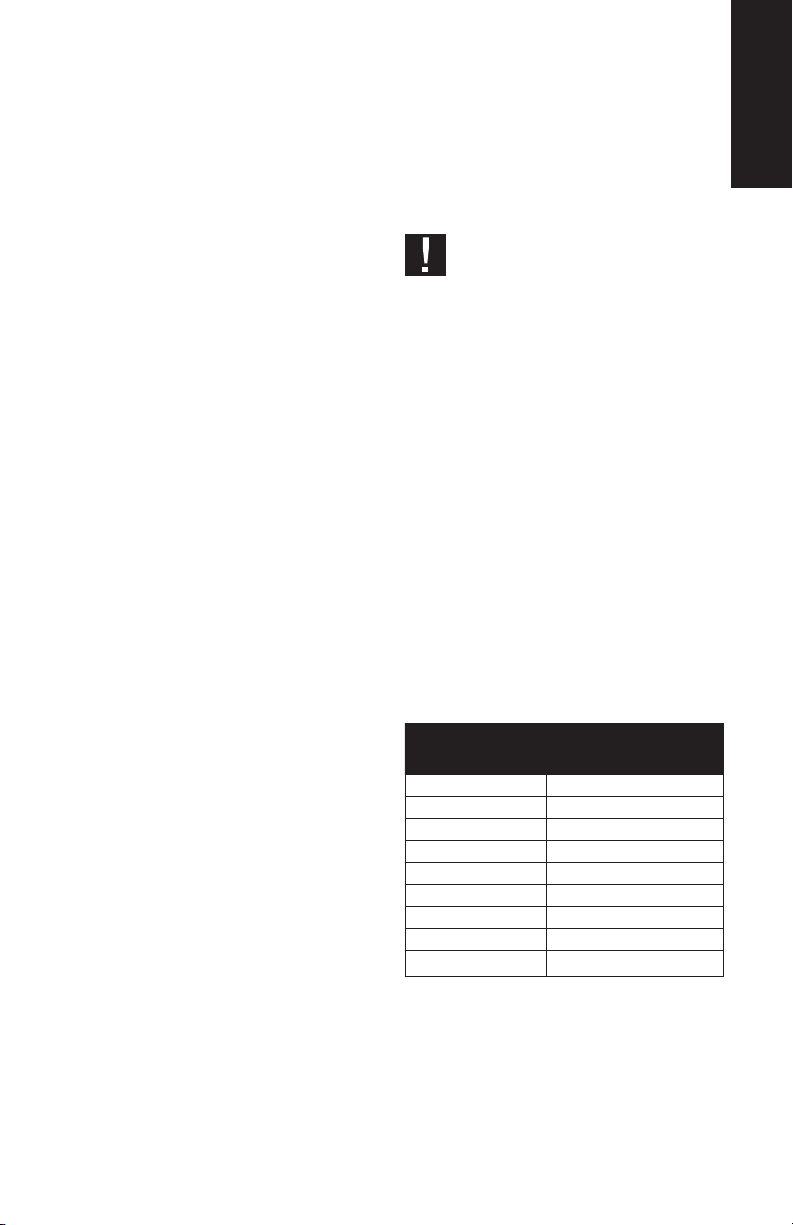

Initial hardness in

water (ºHF)

Sodium added by

softener (mgNa/litre)

10 43

15 65

25 108

30 130

35 152

40 173

45 195

50 217

60 260

User’s Manual

8

3. TECHNICAL SPECIFICATIONS

Model: ERGO 8ERGO 11

Resin Volume: 7.4 litres 10.5 litros

Tank: 203x330 203x432

Working flow: 1.8m³/h 2.1m³/h

Maximum flow: 2.1m³/h 2.1m³/h

Exchange capacity: 17.6ºHFxm³23.7ºHFxm³

Salt/regeneration: 0.36 Kg Salt 0.36 Kg Salt

Salt/resin litre: 49.3 g/L 33.7 g/L

Maximum hardness: 60 ºHF 73 ºHF

Rinse flow: 3.78 LPM 3.78 LPM

Water comsumption/reg: 25

Regeneration time: 15 min

Max. iron (ferrous): <0.5 mg/L

Max. iron (ferric): <0.01 mg/L

Max. free chlorine: ≤1 mg/L

pH range: 5-10

Room temperature: Protection against freezing

Temperature range: 1.7-35°C

Pressure range: 2.5 - 5.5 bar

Min. flow rate: 0.17m3/h

Pressure rating: 8.6 bar

Electrical connection: NA

Rated eletrical power: NA

Protection class: NA

Dimensions (h x d x w): 506 x 293 x 498 608 x 298 x 501

Setting of the hardness regulator

ERGO 8ERGO 11

Letter Hardness Letter Hardness

ppm ˚dH ˚TH ppm ˚dH ˚TH

A 112 6 11 A 79 4 8

B124 7 12 B 88 5 9

C 138 8 14 C 98 6 10

D157 9 16 D 111 6 11

E 180 10 18 E 128 7 13

F 213 12 21 F 152 9 15

---- 235 13 23 ---- 167 9 17

G 262 15 26 G 185 10 19

---- 293 16 29 ---- 209 12 21

H 336 19 34 H 238 13 24

-352 20 35 ---- 278 16 28

---- 390 22 39 I 334 19 33

-441 25 44 - 358 20 36

I470 26 47 ---- 417 23 42

-502 28 50 - 501 28 50

---- 561 31 56 J 549 31 55

- 600 34 60 - 602 34 60

LIMIT 730 41 73

IMPORTANT: Please note that not all settings shown on the disc may be found in

the chart. Those settings not found in the chart are NOT APPLICABLE.

---- Represents the setting in between two letters

- Represents the setting either 1/4 after or 1/4 before a letter.

9

User’s Manual

4. UNPACKING AND

VERIFICATION OF CONTENT

It is important that prior to installing

and starting the system you check the

parts to ensure that they have not been

damaged during transportation.

Any claims for damages during

transportation must be presented along

with the delivery note or invoice to

the distributor, including the name of

the carrier, within a period of 24 hours

following the receipt of goods. All

systems are composed of the elements

below:

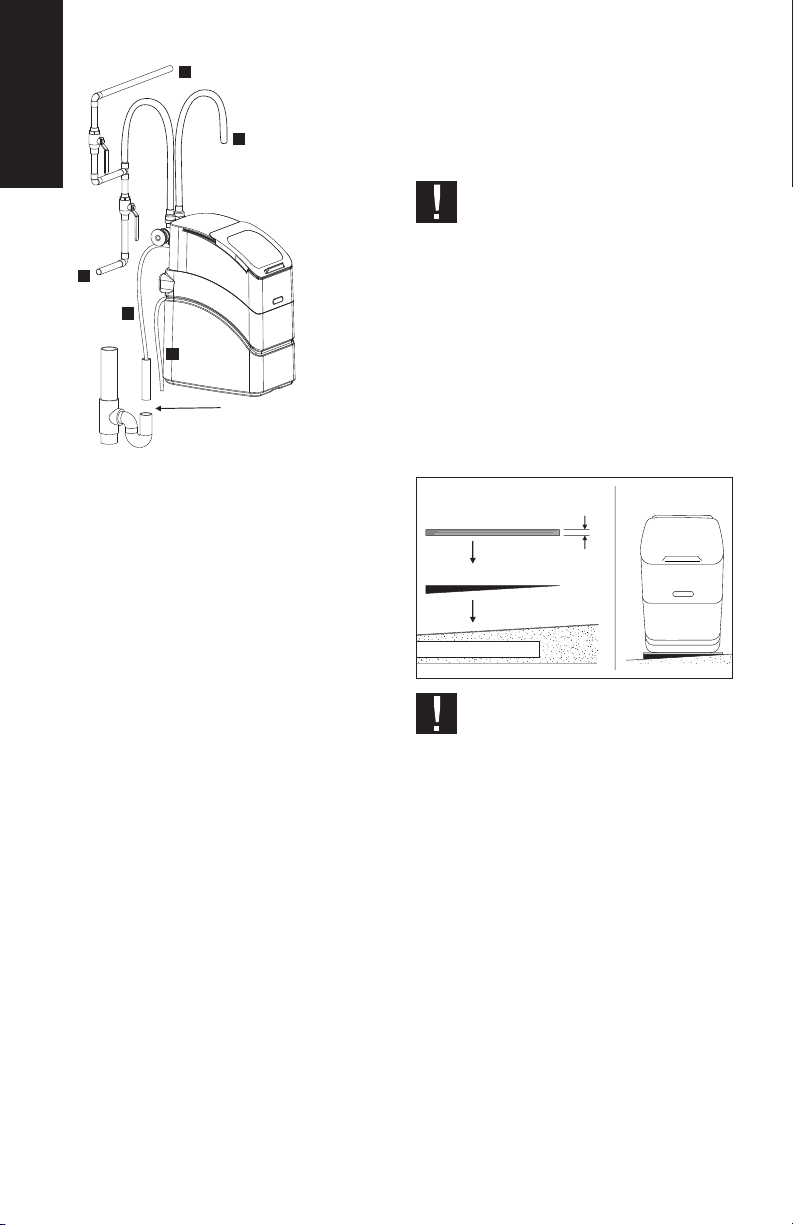

1. ERGO 8 and 11 water softeners.

1

2

4

3

2. 2m hose for the drain connection

(1/2”) and 2m hose for the overflow

drain connection (5/8”).

3. By-pass valve, mixing valve and

installation instructions.

4. Installation kit, including o-rings (for

the by-pass valve), clevis pin and

inlet/outlet clamping.

The packaging materials can be

recycled and must be disposed of in the

appropriate recycling bins or a specific

centre for the collection of waste

material.

The machine that you have acquired has

been designed and manufactured with

high quality materials and components

that can be recycled and reused. This

product must not be thrown away into

the usual urban rubbish bins. When you

wish to dispose of the machine it must

be taken to a specific centre for the

collection of materials, and you must

state that it contains ion exchange resin.

In order to obtain more information

about the disposal of your equipment,

contact your local urban waste centre or

the establishment where you acquired

the system.

The proper collection and treatment

of the machines that can no longer be

used contributes to the preservation of

natural resources and also to avoiding

potential public health risks.

5. PRIOR WARNINGS

The Ergo water softener IS NOT A

WATER PURIFIER. It removes the

hardness from water, leaving softened

and treated water which will prevent all

problems associated with hard water.

Should the water to be treated not

come from a public water supply,

that is from an unknown source, a

physical-chemical and bacterial analysis

of the water shall be necessary, with the

aim of ensuring its proper purification by

applying the techniques and systems

appropriate to each case, PRIOR TO THE

INSTALLATION of the system.

Contact your distributor in order to

get advice about the most appropriate

treatment for you.

User’s Manual

10

5.1 CONDITIONS FOR THE CORRECT

WORKING OF THE EQUIPMENT

• Do not use hot water in the system

(T>35ºC).

• The ambient temperature must be

between 4 ºC and 35 ºC.

• The system should be installed in a

dry environment, free of acid vapours.

Otherwise, please ensure a proper

ventilation.

• Water to be treated must be properly

filtered, therefore, it is recommended

that a pre-filter is installed to guarantee

the removal of suspended particles,

which may be swept along by inlet

water.

Failure to install an appropriate

filter would result in particles

obstructing the inner holes or injectors

of the system, thus aecting its proper

operation.

• A minimum pressure of 2.5 bars must

be ensured. Should this minimum

pressure not be available, a pressure

system must be installed.

• If inlet pressure is higher than 5.5 bars,

a pressure regulator must be installed.

5.2 INSTALLATION OF THE SYSTEM

If the water softener must treat the whole

water supply, connect it to the general

supply pipe before connecting the rest

of the pipes, except for pipes supplying

the outside. Taps located outside the

house must supply hard water. Due to

the sodium increase in softened water,

it is not recommended to use it for

watering, since it can negatively aect

the growth of plants and vegetables.

In the event of modifying the home/

workplace in order to install the

equipment in the planned location,

it should be done following national

guidelines for interior installations of

water and electric supply.

The installation location should have

sucient space for the machine itself, its

accessories, connections and room for

servicing and repair. The system should

not be installed next to a heat source or

where it receives a direct flow of hot air.

The drain connection, where water from

regeneration will be driven, must be

underneath the installation if possible.

The drain connection must always

have a free outlet. The diameter of this

connection must have a minimum size

of 1”. The maximum distance between

the water softener and the drain intake

cannot be higher than 6m.

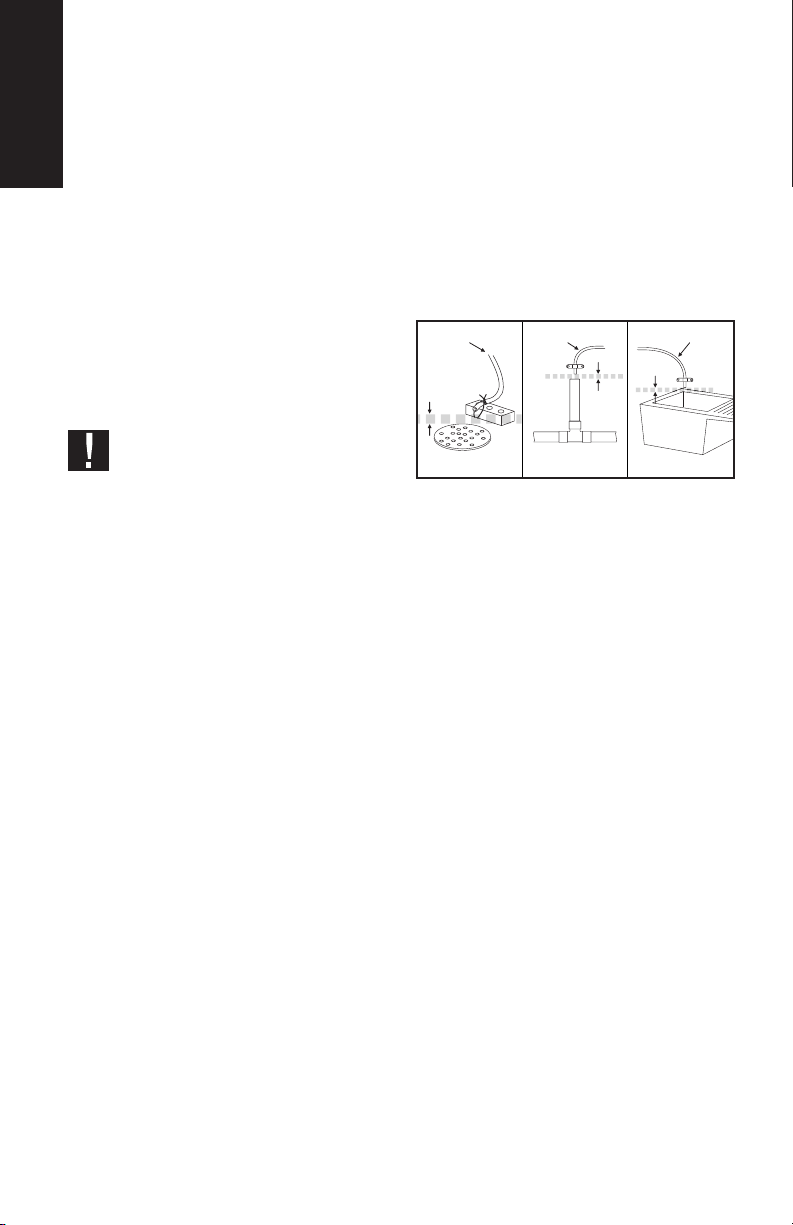

Drain pipe Drain pipe Drain pipe

Subterranean drainage Feed pipe Sink outlet

4 cm

aeration

4 cm

aeration

Raising the drain intake above the water

softener level is not recommended, since

it can aect the brine suction and, thus,

impair the regeneration process.

In the event that this is deemed essential,

it can be raised a maximum of 1.5m,

provided that the inlet pressure is higher

than 4 bar.

If the height is greater or there is

not enough pressure, contact your

distributor. Under no circumstances

should the equipment be

installed outdoors. The environment

where the equipment is to be installed

should adhere to any appropriate

hygiene and sanitation conditions.

Avoid any external dripping liquids

from pipes, wastewater, etc. onto the

equipment.

Should softened water be supplied to a

hot water or vapour generator, it will be

necessary to install a dependable check

valve between the water softener and

the generator, in order to prevent hot

water from returning to the system and

damaging it.

The existing pipelines must not have

deposits of either iron or limescale.

Replace all pipelines containing a great

amount of iron or limescale deposits.

11

User’s Manual

In the event that pipelines are blocked

with iron, install a separate iron filter unit

before the water softener.

It is recommended valves are installed

to take samples for both treated and

untreated water, as close as possible to

the water softener.

If there are quick-closing valves, it is

recommended to install a device to

prevent water hammers.

PRECAUTIONS:

1. Reading and review: Carefully read all

procedures, guides and regulations

before installing and using the Ergo

water softening equipment.

2. Treatment of chemicals: Avoid the

presence of flammable products or

materials as a safety measure for

preventing the risks of explosion and

fire. Make sure to use the glue and the

cleaning product for PVC in a well-

ventilated area.

3. Eye protection: Wear safety goggles

during the installation process to

prevent any injury in your eyes,

caused by the ejection of welding

materials or metal and plastic chips.

4. Welding: Use adequate protective

equipment to protect the exposed

surfaces against the flame of the gun

or an excessive temperature increase.

Only use welding guns WITHOUT

LEAD.

5. Grounding: When installing a plastic

pipe between two metallic pipes, a

grounding cable must be installed to

prevent the interruption of grounding

continuity.

6. Easy reach: Use a ladder for working at

heights which are out of reach. If you

must work at heights for a prolonged

period of time, use adequate safety

devices.

Note: We recommend that the

installation is carried out by a qualified

installer. Failure to install the equipment

in accordance with this manual will

render the Limited Warranty void.

If daytime pressure is higher than 5.5

bars, night-time pressure may exceed

the maximum. Please use a pressure-

reducing valve if necessary (a pressure-

reducing valve may reduce the flow).

Note: The Limited Warranty of the

equipment does not cover any damages

due to the freezing of the equipment.

If you have questions about the Ergo

water equipment or if you think that it

is not working properly, contact your

distributor.

5.3 START-UP AND MAINTENANCE

The system must be periodically

sanitised. See ‘Section 8’ for further

information. Maintenance should be

carried out by qualified technicians who

work under the appropriate hygienic

conditions. (For further information

contact your installer.)

6. EQUIPMENT

INSTALLATION

The installation of the water softener

must be carried out by skilled technical

personnel. Follow the recommendations

in ‘Section 5’.

Given that the system that you are going

to install improves the quality of the water

you consume and is considered a food,

all of the tools that you are going to use

for the assembly and installation must

be clean and, under no circumstances,

contaminated or impregnated with

grease, oils or rust. Please be extremely

careful when handling the materials that

are going to be in contact with treated

or untreated water.

(For further information, please contact

your distributor.)

User’s Manual

12

1

2

3

4

5

Provides an air gap for all

drainage lines. See page 11

for further information.

The installation of the equipment should

be carried out in this order:

A. System configuration.

B. Pipe connection.

C. Start-up of the system.

1. Water to be treated.

2. Soft water towards the house.

3. Drain tube.

4. Water to be treated.

5. Overflow line.

Note: This configuration is a typical

installation for the Ergo. Your

installation may dier. Install a pressure

regulating valve and a check valve, when

necessary, in the water supply of the

softener. The by-pass may be installed

with the connections either upwards or

downwards, whilst respecting the inlet

and outlet connections towards the

head, which have embossed marks.

1. The system must always be installed

with the supplied by-pass valve.

Additionally, a three-valve by-pass

can be installed.

2. Close the general water supply valve,

which should be next to the main

pump or the water-meter.

3. Open all taps in order to empty the

pipes from all water.

Note: Make sure that the heater is

not emptied, in order to prevent any

damage.

‘DANGER’. There is a danger of

injury due to an excess of weight. It

is necessary that at least two people

move and install the system, as well as

move and rise the salt bags. There is a

danger of back injuries and other body

injuries.

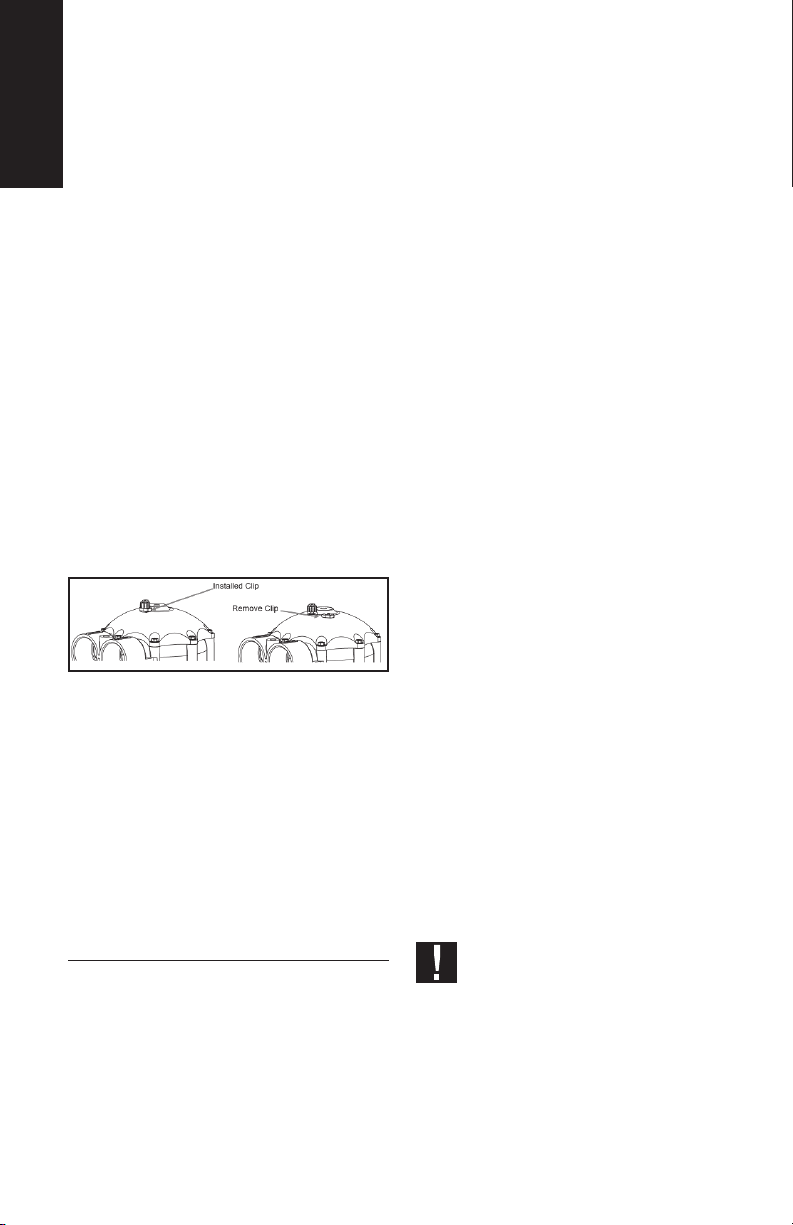

4. Move the water softener towards the

installation location. Place it on an

even surface. If necessary, place it on

a plywood platform with a minimum

thickness of 2cm. Then, level the

platform using a wedge.

Minimum

depth of 2cm

Plywood

Wedge to level the platform

Installation surface

Plywood

‘WARNING’. Do not place the

wedges directly underneath the

salt tank. The weight of the tank filled

with water and salt may cause the tank

to break against the wedge.

5. First make a visual check and clean

the inlet and outlet connections of the

softener to remove any residues.

6. Assemble the by-pass in the body of

the valve by previously lubricating all

joints with the lubricant supplied.

7. The tubes and accessories used to

connect the main supply pipe to the

inlet and outlet of the water softener

valve must be loosely measured,

cut and assembled. Please keep all

fastenings, joints and tubes centred

and straight. Check that water flows

from the pipe towards the inlet of the

water softener.

13

User’s Manual

Once the installation of all pipes is

finished and before connecting the by-

pass, let water flow through the inlet and

outlet pipes to remove all residues and

check the tightness of the installation.

Note: The inlet and outlet are indicated

in the valve. Draw the sense of the flow

to be sure.

‘WARNING’ Check that the pipes

are fixed, aligned and supported in

order to avoid any pressures on the inlet

and outlet of the water softener. A

wrong pressure coming from a

misaligned pipe, or not supported, could

damage the valve.

WELDED COPPER

1. Clean carefully and apply welding

paste on all joints.

2. Carry out all the welding.

Note: Do not weld to the installation

the pipes of the by-pass valve. The heat

from the welding could damage the

valve.

THREADED PIPE

1. Apply a sealing paste for pipes or Teflon

tape on all male threaded pipes.

2. Tighten all threaded connections.

CPVC PLASTIC PIPE

1. Clean, prepare and glue all joints

according to the manufacturer’s

instructions.

OTHER

Please follow the instructions from the

pipes’ manufacturer when using other

types of pipes and fixtures approved for

drinking water.

6.2 INSTALLATION OF THE DRAIN

AND THE OVERFLOW.

Take the drain tubes towards the

discharge point. Connect the 1/2” tube

to the drain elbow of the valve (2). The

drain tube must penetrate into the elbow

about 18mm (3).

Take the tube towards the drain of the

installation. The section towards the

drain must be as straight as possible to

avoid bottlenecks or syphonage. The

drain must be evacuated in a sump or

drainage outlet with a suitable aeration

to prevent waste water from returning

to the equipment. In the event that the

drain tube must be raised, it can be raised

a maximum of 1.5 metres, provided that

the minimum inlet pressure is 4 bar.

The drain tube must bend around the

Ergo valve anti-clockwise (see previous

figure). Failure to comply with these

instructions may result in damages in

the drain pipe and your new Ergo water

softener.

3

2Drain tube

7. ERGO PROGRAMMER

1. Hardness adjustment knob.

2. Meter dial.

3. Regeneration activator.

4. Viewer for programming.

First, check that the hardness indicator

arrow is located in the round viewer (see

previous diagram). Otherwise, rotate

the inner dial for a full turn (see Manual

Regeneration further on).

1

2

3

4

User’s Manual

14

How to configure hardness:

To ensure a correct functioning of the

water softener, the inlet water hardness

must be configured in the equipment.

Using the hardness adjustment knob,

turn the hardness dial. The configured

value will be that matching the indicator

arrow. The hardness configuration tables

below indicate the equivalence of the

dierent types of hardness (see ‘Tables

for the adjustment of the hardness

regulator’ in page 8). It is recommended

to apply a ‘safety margin’ in the

configured hardness so the equipment

can adapt to the possible fluctuations

that there may be (e.g. if 27ºHF are

measured, 30ºHF must be configured).

NOTE: The hardness adjustment knob is

protected by a blue plastic locking clip

to prevent any tampering or misuse.

To configure hardness, remove the

locking clip. Once hardness has been

configured, put the locking clip back

on its place.

7.1. MANUAL REGENERATION.

Using a no. 2Phillips screwdriver, press

firmly the regeneration activator of

the water softener and turn it slowly

clockwise until you hear the four clicks

to initiate the regeneration. At this point,

the flow of water inside the equipment

should be audible. If you cannot hear

water moving through the system, maybe

the dial has not advanced enough.

8. HYDRAULIC START-UP

Before starting the system up, please

check that all steps prior to installation,

assembly and programming have been

properly followed, according to this

instructions’ manual, as well as the

regulations in force. To start the system

up, please follow the instructions below:

Do not charge the system with salt

until the end of the start-up. In order to

prevent any air pressure on the water

softener and the pipes, please follow

these instructions in order.

1. Keep the by-pass valve in the “by-

pass” position.

2. Fully open two or more cold and

treated water taps located near the

water softener.

3. Start a manual regeneration as stated

in section ‘Manual regeneration’.

4. Slowly open the by-pass to allow the

entrance of water inside the system.

Keep the by-pass partially open. At

this point, the inlet flow must be

rather low, since in this position water

will come in from the bottom of the

bottle and move upwards to the drain.

5. When water starts flowing

continuously through the drain, fully

open the water inlet of the system.

At this point, the bottle will be full of

water and so a higher flow will not

produce any damage. Water going

out to the drain may be a bit yellowish

or brown. This is completely normal,

since it is due to the preservatives of

the resin.

6. After a few minutes, you will notice

an increase of the water flow towards

the drain. This means that the system

is in the washing position. Let the

equipment finish the process. After

a few minutes, cut the flow of water

towards the drain and refill the brine

tank.

7. Leave the equipment in this position

until water stops flowing in. At this

point, the water level should be

approx. 7-10cm above the bottom of

the tank.

IMPORTANT: Check the tightness

of the brine line, and make sure

that there are no leaks and that the

refilling process has come to a halt.

Note: Since air accumulates inside the

equipment, it is possible that at this

point the equipment might be blocking

the brine level float, which would end the

washing without refilling the brine tank.

If this occurs, repeat the previous steps.

15

User’s Manual

8. Start another regeneration as

indicated in the previous section.

Check that the water level in the

salt tank goes down during the first

minutes of the regeneration. This

means that the brine suction process

is being carried out properly. Let the

regeneration end.

‘WARNING’ It is essential to check

that the brine suction is being

carried out properly, since an incorrect

or insucient suction will aect the

equipment performance and the quality

of treated water.

9. Charge the brine tank with salt.

10.The system is ready to operate.

‘WARNING’ There is a danger of

injury due to an excess of weight. It

is necessary that at least two persons

move and rise the salt bags. There is a

danger of back injuries and other body

injuries.

9. BY-PASS AND MIXING

12

1. Service position: blue.

2. By-pass position: red.

3. Fully closed.

4. Fully open.

As mentioned in “Section 2.7”, it is not

recommended to supply completely

softened water to household supplies.

In order to modify the residual hardness,

slightly open the regulating valve, as

indicated in the images below.

Then measure the water hardness

present on the outlet of the system

and check that it fits within the desired

values. Otherwise, adjust the regulator

and check again.

34

‘WARNING’ The hardness regulator

is supplied in the closed position,

therefore, if the system is not adjusted, it

will supply fully softened water.

10. MAINTENANCE

AND SANITATION

In order to guarantee the proper

operation of the system, the following

verifications must be carried out as

frequently as indicated:

Verification Period

Check the salt level in the tank Monthly

Check entry hardness Monthly

Check treated water hardness Monthly

Sanitation Yearly

Cleaning of the salt tank Yearly

Technical service verification Yearly

It is very important to carry out

the sanitation and descaling tasks

separately, since the chemical products

used for this purpose could have a bad

reaction when mixed. The sanitation

and descaling tasks must be carried

out by turns, according to the indicated

frequency.

Salt refilling:

The salt level in the tank must be

frequently checked. The minimum salt

level must be kept, which corresponds

to the half of the tank volume. If salt

runs down before filling it up again, the

system will produce hard water. After

the verification, check that the salt cover

is properly closed.

Note: For humid areas, it is

recommended to keep a lower salt

level, filling it up more frequently.

Only use salt manufactured for use in

water softeners. The use of block salt

is not recommended. DO NOT USE

User’s Manual

16

ROCK OR GRANULAR SALT in your

system. They contain impurities that can

interfere with performance and could

invalidate the Limited Warranty.

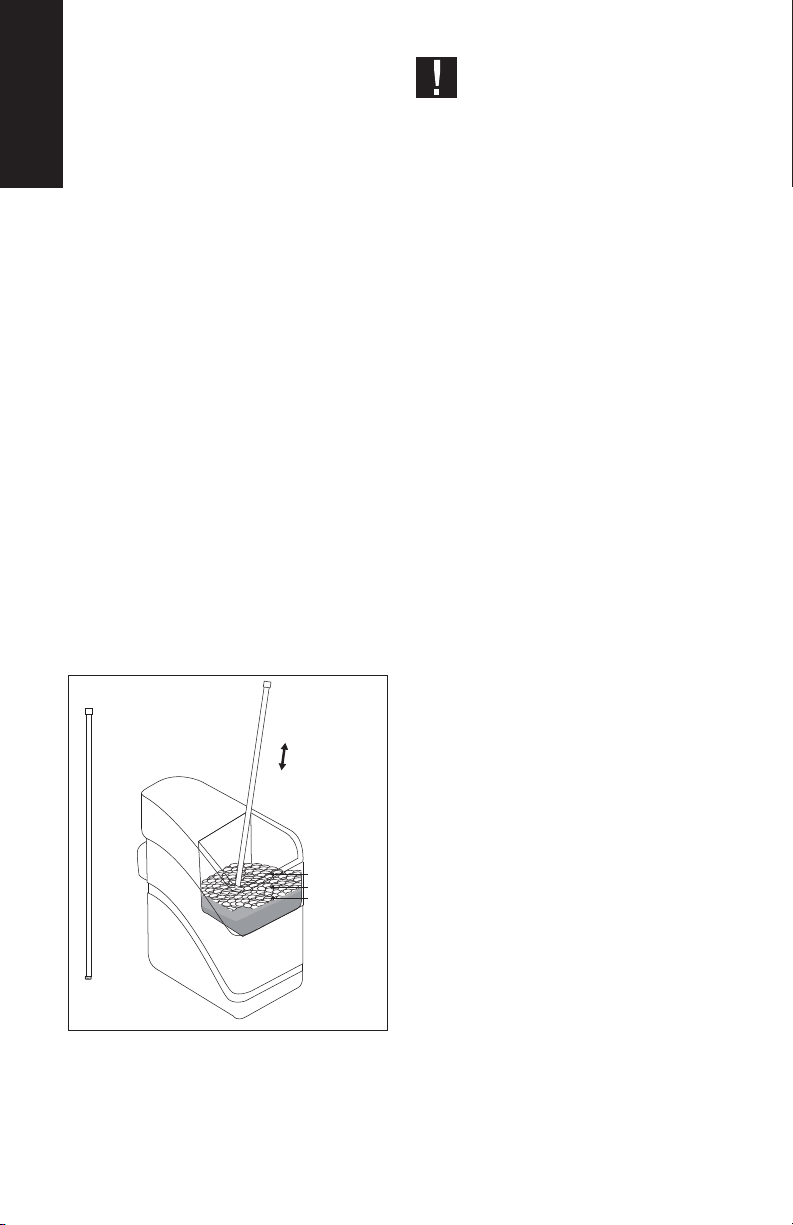

How to break a salt bridge:

Sometimes it is possible that a salt

bridge builds up inside the salt tank.

This is due to a high level of humidity

or to the use of an inappropriate salt.

When there is a salt bridge, there is an

empty space left between water and salt

which prevents it from dissolving. This

means that the water softener will not

regenerate properly and so, it will supply

hard water.

If the tank is full of salt it is difficult to

know whether there is a salt bridge, since

the salt on the surface may seem loose,

even if the lower part is solid. In order to

check the existence of a salt bridge, take

a long rigid tool (e.g. a broom handle)

and keep it next to the water softener to

measure the distance from the floor up

to the salt edge. Then put the tool in the

salt. If there is a hard object, it may be a

salt bridge.

Carefully apply some pressure on several

places until it breaks.

Press

Tool

Press

Salt bridge

Water level

‘WARNING’ Do not use sharp or

pointed objects, since they could

damage the water softener tank.

Sanitation: It is recommended to carry

out a sanitizing process once per year, as

indicated below:

1. Open the cover of the salt tank and

pour between 20 to 30 ml (2or 3

caps) of household, unscented bleach

inside the brine chimney. Close it

again.

2. Check that the by-pass valve is in

service.

3. The disinfection process will be

carried out after the regeneration and

the disinfecting solution will be sent

to the drain.

Anti-scaling: A full regeneration must

be started if the water softener has been

out of service for more than 96h.

If the equipment will not be used for

a long time (holidays, second homes,

etc.), it is recommended to carry out a

full regeneration process before putting

it back into service (according to the

instructions of this manual).

17

User’s Manual

11. FREQUENTLY

ASKED QUESTIONS

The water pressure at home has

dropped. Why has this happened?

A drop in water pressure may indicate

that it is time to change the pre-filter.

If your equipment does not have a pre-

filter, or if you have replaced the filter,

but the problem persists, contact your

distributor.

It seems that the frequency of

regenerations has increased. Is this

normal?

Keep in mind that your equipment

is demand-driven, therefore, it

automatically adapts to your water

consumption. If you believe that your

water consumption has not increased

due to the presence of more people

in the house, additional laundry or

any other reason, please contact your

distributor.

My water does not seem soft to me.

How can I be sure that my equipment is

regenerating properly?

Make sure there is no by-pass in the

water supply of the water softener.

Follow the instructions from page 14

to manually regenerate the tanks of

the water softener. If the equipment

does not automatically move to the

next regeneration, please contact your

distributor to receive further assistance.

I can hear my equipment running or

carrying out the regeneration during

daytime. My previous softener only

worked at night. Is this normal?

Unlike traditional water softeners, this

equipment is demand-driven in function

of water consumption. It has no timers or

electronic components. Therefore, your

equipment regenerates when necessary,

at any time.

How will I know when to add salt?

Lift the cover of the tank to check the

salt level. If you can see water, then you

need to add salt. You can always add salt

if there is enough space to allocate more

salt tablets.

Can I drink soft water?

Yes, soft water is suitable for drinking and

cooking. If the water softener carries out

the regeneration with sodium chloride

(salt), keep in mind that soft water will

include a small amount of added sodium.

If you are following a low-sodium diet,

please take into account the addition of

sodium in water in the total amount of

mineral intake.

If, at any stage, you think that your

equipment is not working correctly,

activate the by-pass mode of the

equipment and contact your installer.

User’s Manual

18

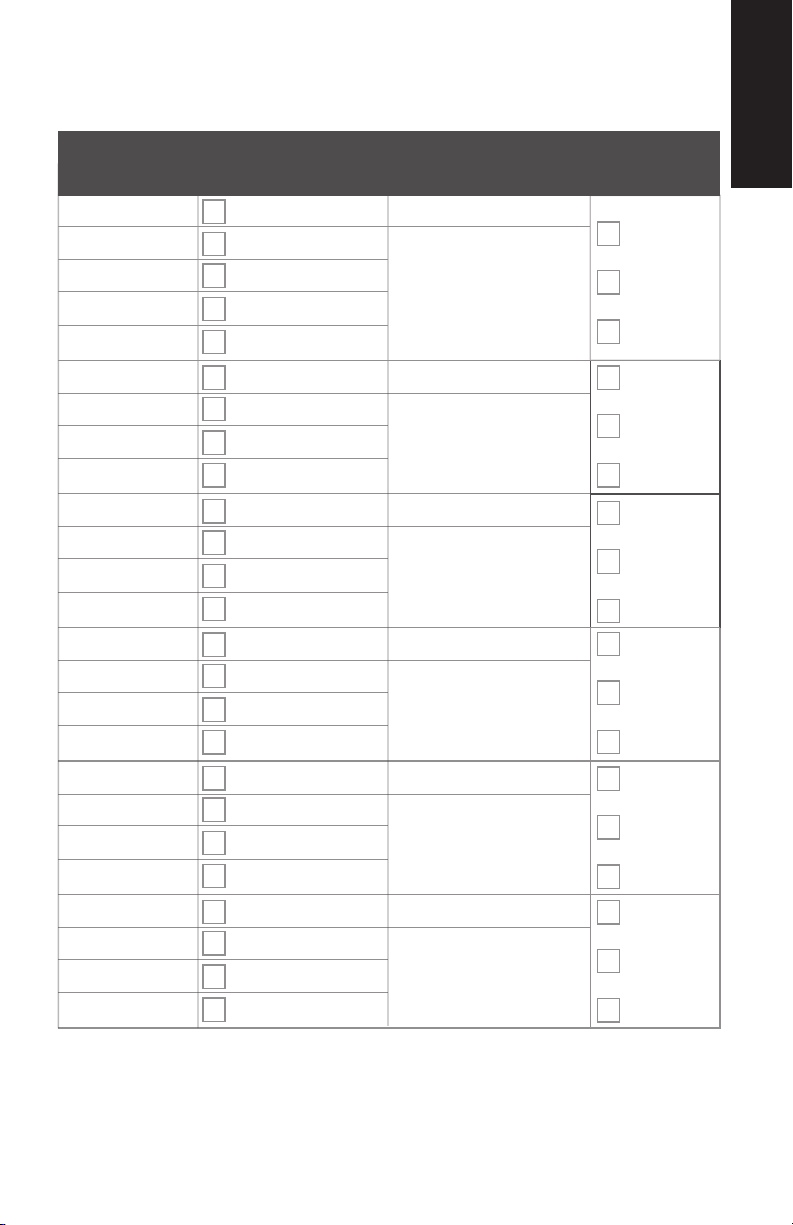

MAINTENANCE COMPLETE

REPAIR

SANITATION

OTHERS

/ /

/ /

/ /

/ /

MAINTENANCE COMPLETE

REPAIR

SANITATION

OTHERS

/ /

/ /

/ /

/ /

MAINTENANCE COMPLETE

REPAIR

SANITATION

OTHERS

/ /

/ /

/ /

/ /

MAINTENANCE COMPLETE

REPAIR

SANITATION

OTHERS

/ /

/ /

/ /

/ /

MAINTENANCE COMPLETE

REPAIR

SANITATION

OTHERS

/ /

/ /

/ /

/ /

TYPE OF SERVICEDATE NAME, SIGNATURE AND

STAMP OF AUTHORISED TECHNICIAN

MAINTENANCE COMPLETE

REPAIR

SANITATION

OTHERS

/ /

INITIAL OPERATION

/ /

/ /

/ /

/ /

TECHNICIAN

ORDINARY

EXTRAORDINARY

WARRANTY

STAMP

TECHNICIAN ORDINARY

EXTRAORDINARY

WARRANTY

STAMP

TECHNICIAN ORDINARY

EXTRAORDINARY

WARRANTY

STAMP

TECHNICIAN ORDINARY

EXTRAORDINARY

WARRANTY

STAMP

TECHNICIAN ORDINARY

EXTRAORDINARY

WARRANTY

STAMP

TECHNICIAN ORDINARY

EXTRAORDINARY

WARRANTY

STAMP

12. SERVICE BOOK: USER

19

User’s Manual

MAINTENANCE COMPLETE

REPAIR

SANITATION

OTHERS

/ /

/ /

/ /

/ /

MAINTENANCE COMPLETE

REPAIR

SANITATION

OTHERS

/ /

/ /

/ /

/ /

MAINTENANCE COMPLETE

REPAIR

SANITATION

OTHERS

/ /

/ /

/ /

/ /

MAINTENANCE COMPLETE

REPAIR

SANITATION

OTHERS

/ /

/ /

/ /

/ /

MAINTENANCE COMPLETE

REPAIR

SANITATION

OTHERS

/ /

/ /

/ /

/ /

TYPE OF SERVICEDATE NAME, SIGNATURE AND

STAMP OF AUTHORISED TECHNICIAN

MAINTENANCE COMPLETE

REPAIR

SANITATION

OTHERS

/ /

INITIAL OPERATION

/ /

/ /

/ /

/ /

TECHNICIAN

ORDINARY

EXTRAORDINARY

WARRANTY

STAMP

TECHNICIAN ORDINARY

EXTRAORDINARY

WARRANTY

STAMP

TECHNICIAN ORDINARY

EXTRAORDINARY

WARRANTY

STAMP

TECHNICIAN ORDINARY

EXTRAORDINARY

WARRANTY

STAMP

TECHNICIAN ORDINARY

EXTRAORDINARY

WARRANTY

STAMP

TECHNICIAN ORDINARY

EXTRAORDINARY

WARRANTY

STAMP

20

Manuel d’utilisation

1. PRÉSENTATION

L’appareil de traitement de l’eau ERGO que

vous avez acheté est un adoucisseur d’eau

à contre-courant hydraulique à hautes

performances qui fournira une eau adoucie

de grande qualité à toute la famille.

Le calcaire ou la dureté de l’eau peut

poser des problèmes à vos canalisations

et empêcher les appareils du réseau

de fonctionner correctement, ce qui

augmente les travaux d’entretien et

réduit leur durée de vie.

Partant de ce constat, nous avons

conçu cette gamme de produits

d’adoucissement de l’eau sanitaire,

spécialement conçue pour protéger la

plomberie de votre maison contre les

eets de l’entartrage.

Grâce à l’adoucisseur d’eau ERGO, vous

et votre famille profitez des bénéfices et

avantages suivants:

• Économies d’énergie.

• Bien-être augmenté.

• Durée de vie de vos appareils

électroménagers renforcée.

• Économies : la consommation de

lessives, adoucissants et produits

chimiques est réduite.

• Faible coût d’entretien.

• Contrôle automatique de l’équipement.

Vous devez impérativement lire et

conserver ce manuel avant

l’installation et le démarrage du système.

Si vous avez toute question quant à

l’utilisation ou à l’entretien de ce système,

veuillez contacter votre installateur.

1,1. SÉCURITÉ DE L’ADOUCISSEUR

D’EAU

Votre sécurité et celle des autres est

capitale. Nous avons inclus des messages

de sécurité dans ce manuel.

Voici le symbole utilisé en cas

d’alerte de sécurité. Ce symbole

vous avertit des situations dans lesquelles

vous ou votre entourage courez un risque

potentiel.

Tous les messages de sécurité seront

accompagnés d’un symbole d’alerte ou

du mot «DANGER» ou «ATTENTION».

Portée de ce manuel:

• DANGER : Risque de mort ou de

blessure grave si les consignes

suivantes ne sont pas immédiatement

suivies.

• ATTENTION : Tous messages de

sécurité fournissant des informations

sur les dangers possibles, sur la façon

de réduire le risque de blessure et sur

ce qu’il est susceptible d’arriver si les

consignes ne sont pas suivies.

1,2. MESURES PRÉALABLES

A L’INSTALLATION

Consultez la «Section 5» avant d’installer

l’adoucisseur d’eau. Suivez attentivement

les instructions (la garantie limitée peut

être tenue pour nulle en cas d’installation

inadéquate). Veuillez lire l’intégralité du

manuel avant de commencer l’installation.

Ensuite, rassemblez le matériel et les

outils nécessaires.

Contrôlez votre plomberie.

L’ensemble des installations doivent être

conformes aux lois en vigueur dans toute

région ou pays. Manipulez l’adoucisseur

d’eau avec soin. Ne le renversez pas, ne le

faites pas tomber et ne le placez pas sur

des objets tranchants. Il est strictement

interdit d’installer l’adoucisseur d’eau

à l’extérieur, car il doit rester à l’abri de

la lumière du soleil et des conditions

climatiques diciles.

2. INTRODUCTION

Nos systèmes sont livrés de série avec un

régulateur de dureté résiduelle, afin de

sélectionner la dureté appropriée à votre

logement. La commande hydraulique

simple permet une programmation facile

et rapide en quelques secondes.

MANUEL

D’UTILISATION

POUR LES ADOUCISSEURS D’EAU

This manual suits for next models

1

Table of contents

Languages:

Popular Water Dispenser manuals by other brands

GE

GE GXCFI5HWW owner's manual

NATURA

NATURA NWSBU2 SER.4 Installation and maintenance guide

elysator

elysator PUROTAP Compenso Series Installation Function Operation Service

Whirlpool

Whirlpool WHES20 Installation and operation manual

Honeywell

Honeywell KaltecSoft KS30E Series installation instructions

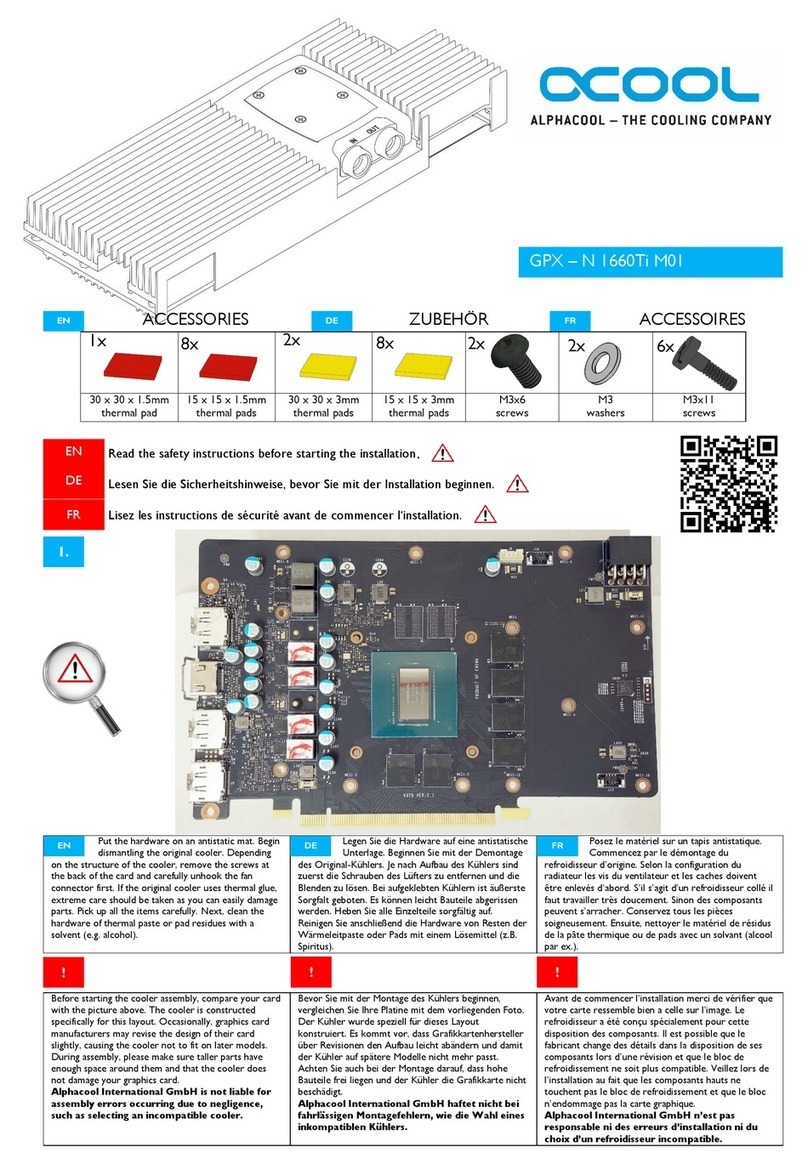

Alphacool

Alphacool GPX-N 1660Ti M01 manual

Elkay

Elkay EWCA8 1L Series Installation, care & use manual

BRIO

BRIO Moderna CLPOU730UVRO4 user manual

First Sales

First Sales FS Series Installation instructions and owner's manual

Philips

Philips Micro Pure WP3911 Specifications

Quality Water For Less

Quality Water For Less Fleck 2510 installation guide

WaterLogic

WaterLogic WL3 Firewall Technical manual