PAGE 10 QualityWaterForLess.com Help: 888-426-5001

4 ›PluMbInG Your fleck 2510 sxt ValVe

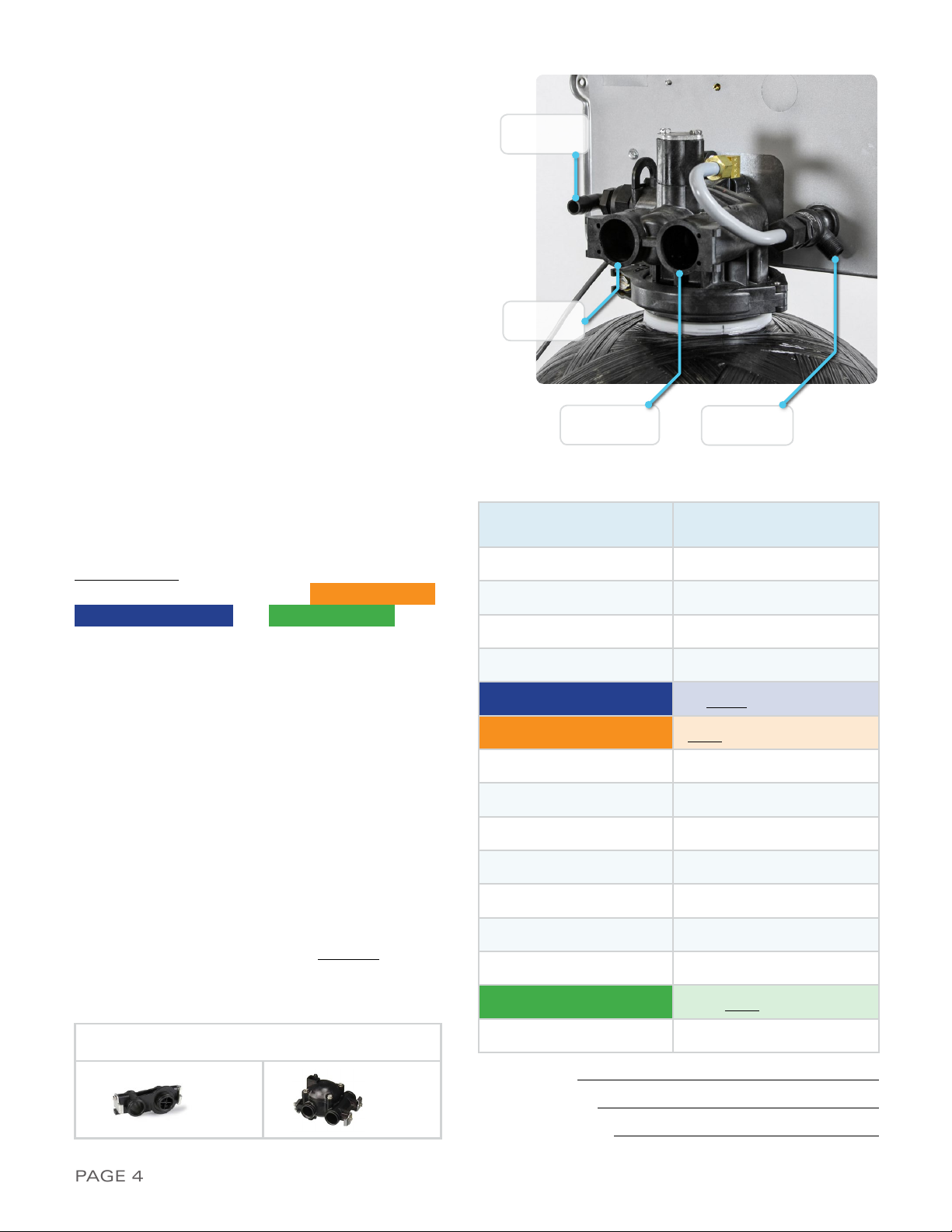

1) Before beginning your installation, please first fa-

miliarize yourself with the IN and OUT ports on the

Fleck 2510 SXT Meter Valve.

In order to prevent

damage to your home and to the softener

system, install the softener according to the

IN and OUT arrows on the softener valve

2) Locate the main shut-off valve for your house

and turn it to the OFF position. If you have a

private well, this valve should be near your well

pressure tank. If you have a city water supply,

your valve should be near your water meter

3) Depressurize and drain your home of water by

turning on all faucets and fixtures in your home,

including those outside

4) Pick your installation point and cut a section of

pipe out to run to and from your softener.

In

most cases it is preferred to keep outside

lines UNSOFTENED. If you wish to keep

your outside lines unsoftened, you must

plumb BYPASS lines to run hard water to

these fixtures

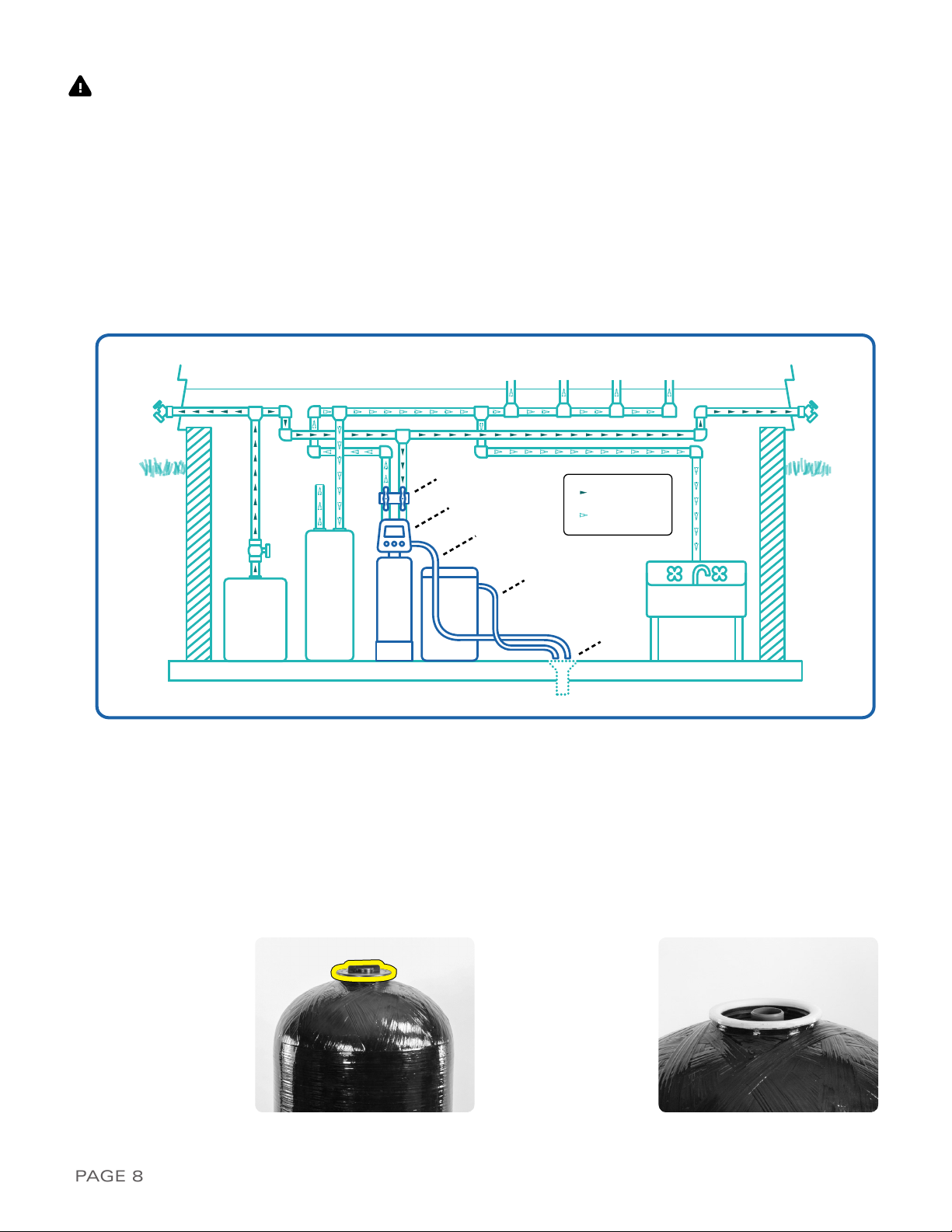

5) Using soldered copper, PVC plastic pipe, or flex-

ible connections, plumb the system according to

all local plumbing codes.

If using copper pipe,

please pre-fabricate at least a 12” section

of pipe for the IN and OUT bound lines and

use a wet rag on the lines being soldered to

prevent heat damage during soldering

6) Once all connections have been made, place the

system into bypass by either using your existing

3-valve bypass (if ordered with a YOKE adap-

tor), or by switching your included bypass ON (if

ordered with a bypass)

7) Next, gradually open your main valve and allow

all air in your plumbing lines to escape slowly.

Also, you may turn off all outside and inside

faucets and fixtures

8) Check for leaks at your plumbing site for signs

of slow drips and rectify if necessary.

Please do

NOT take the softener out of BYPASS as the

installation is not completed yet. Please take

this opportunity to check and re-check the IN

and OUT ports to make sure they are correct

fIGure 10-c

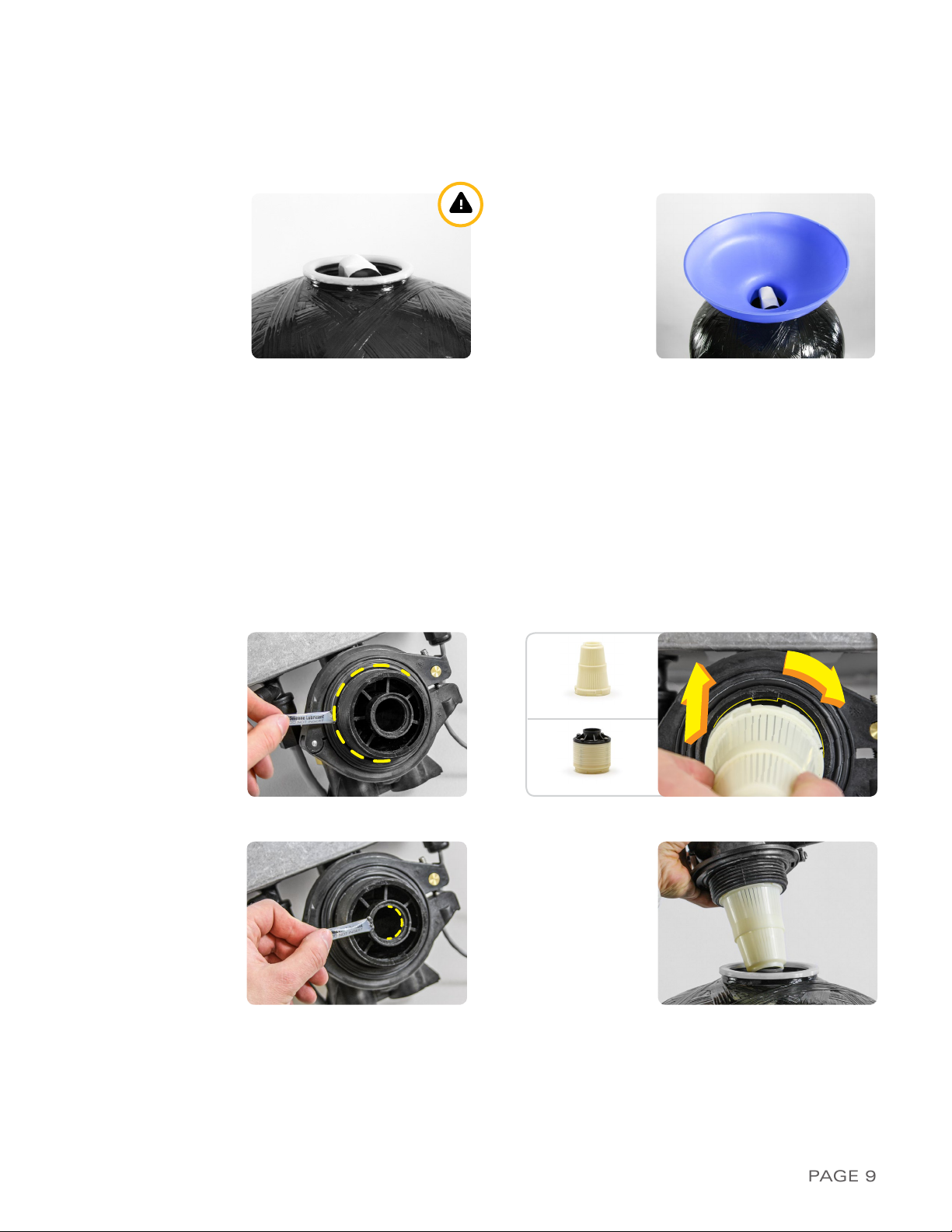

5) Assemble the plumbing adaptor to the valve as

shown in Figure 10-C (your bypass/plumbing

adapter model may vary). When assembling

the clips back onto the valve, leave the first clip

loose, tighten the second clip, and complete the

assembly by tightening the first clip. i

Please

lightly tighten the screws into the meter as

overtightening will easily cause cracking

3) Locate the plumbing adapter that was shipped

with your system and disassemble the plumbing

adaptor clips as shown in Figure 10-A

4) Using the included silicone lubricant packet, lu-

bricate the o-rings on the Fleck 2510 SXT Meter

Valve as shown in Figure 10-B

fIGure 10-a fIGure 10-b