Anchor AF-4002 User manual

1 | P a g e

2 | P a g e

IMPORTANT SAFETY INFORMATION. READ ALL INSTRUCTIONS BEFORE

USING

WARNING! For your safety, the information in this manual must be followed

to minimize the risk of property damage or personal injury

Check with your state and local public works department for plumbing and sanitation

codes. You must follow these guidelines as you install the filter system. Using a qualified

installer is recommended.

If house water pressure is over the maximum (100 pounds per square inch), install a

pressure reducing valve in the water supply line to the filter system.

Be sure the water supply conforms with the Specification Guidelines. If the water supply

conditions are unknown, contact your municipal water company or your local health

department for a list of contaminants in your area and a list of laboratories certified by

your state to analyze drinking water.

PROPER INSTALLATION AND MAINTENANCE

Install or store where it will not be exposed to temperatures below freezing or exposed to any

type of weather. Water freezing in the system will damage it. Do not attempt to treat water over

90°F.

Do not install on HOT WATER. The temperature of the water supply to the filter system must be

between the minimum of 40°F and the maximum of 90°F.

This filter system contains a replaceable component critical to the efficiency of the system.

Replacement of the filter system component should be with one of identical specifications, as

defined by the manufacturer, to assure the same efficiency and contaminant reduction

performance.

Recommended installation is under the sink. However, the unit can be installed in a remote

location, up to 20 feet away from the sink. Additional installation materials may be required. Do

not use copper tubing for the connection between the filter system and the refrigerator.

WARNING: Discard all unused parts and packaging material after installation. Small parts

remaining after the installation could be a choke hazard.

WARNING: Before using the filter system for the first time, the system must be

purged. The filter system cartridge contains a food grade preservative that must be

purged from the system. The preservative will give product water an unpleasant

taste and odor.

3 | P a g e

The system makes a good supply of drinking water each day. How much it will make depends primarily

on these things…

Feed water pressure limits—pounds per square inch (psi) . . . . . . . . . . . . . . . . . . . . . . 40–100c

Feed water temperature limits—minimum/maximum degrees F . . . . . . . . . . . . . . . . …40–90

Maximum Total Dissolved Solids (TDS)—parts per million (ppm) . . . . . . . . . . . . . . . . 2000

Installation filter system Instructions

BEFORE YOU BEGIN Read these instructions completely and carefully.

• IMPORTANT — Save these instructions for local inspector’s use.

• IMPORTANT — Observe all governing codes and ordinances.

• Note to Installer – Be sure to leave these instructions with the Consumer.

• Note to Consumer – Keep these instructions for future reference.

• Proper installation is the responsibility of the installer.

• Product failure due to improper installation is not covered under the Warranty.

• A shutoff valve must be available or added near the installation point.

TOOLS AND MATERIALS REQUIRED FOR INSTALLATION

• Drill with 1/2″ Drill Bit (type as required) if mounting is needed for faucet

• Adjustable Open-End Wrenches

• Phillips and Flat Blade Screwdrivers

• Utility Knife

CONTENTS INCLUDED WITH PRODUCT

• Assembly and Tubing

• Product Literature (Owner’s Manual and Installation)

• Water Supply Inlet Parts Bag

• Faucet

• Pipe Thread Tape

4 | P a g e

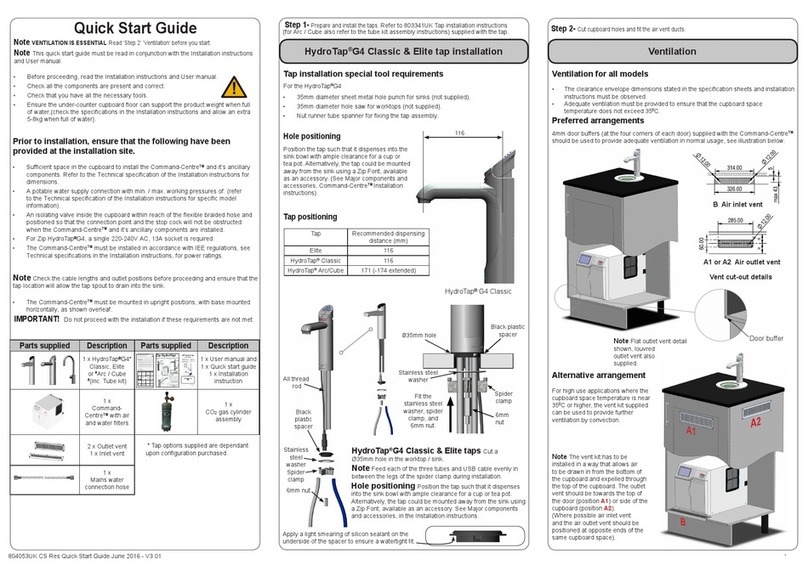

Installation Instructions

Things to Check before Beginning Installation

v

5 | P a g e

FEED WATER

Municipal water supplies most often will have these qualities. Well water may need conditioning —have

the water tested by a water analysis laboratory and get their recommendations for treatment.

CAUTION: For water with a hardness greater than 10 grains (at 6.9 pH), the use of

a softener is recommended. Failure to install a softener will reduce the life of the filter system.

FAUCET

The filter product water faucet installs on the sink or on the countertop next to the sink.

Often, it is installed in an existing sink spray attachment hole or a hole may be drilled.

Space is required underneath for tubing to and from the faucet, and for securing the

faucet in place. All faucet connections and installation procedures are done on or above

the sink or countertop. Refer to illustration above.

BASEMENT INSTALLATION

If installing in a basement, leave enough tubing in place during installation to be able

to move unit to floor for ease at servicing and making filter/membrane changes. Additional tubing and

fittings required

6 | P a g e

FEED WATER SUPPLY

Check and comply with local plumbing codes as you plan, then install a cold feed water supply fitting.

A. PREFERRED INSTALLATION

1. Close the cold water supply valve under the sink.

2. Unscrew the flexible tubing from the supply valve that connects to the COLD water riser.

NOTE: If the cold water shut-off valve fails to turn off the water, the house water supply can be

turned off at the main water supply.

3. The water supply adapter can be installed at the faucet connection (A of Fig.#1) of the cold water

line or at the shut-off valve connection (B of Fig.#1) DO NOT OVERTIGHTEN

4. Disconnect the threaded nut at the connection and thread the water supply adapter, with the flat

washer in place, onto the connection and tighten. ConnecttheWhitetubingtothewatersupply

adapterwith thetreadednutandtighten.

5. Thread the needle valve into the adapter tightly and turn the handle clockwise all the way in.

Open the main water supply valve and several house faucets to purge air from the system. Close

faucets when water runs smoothly. Turn on cold watersupplytothesinkfaucetandcheckforleaks

on

DANGER:

Many homes are electrically grounded through the plumbing. To protect yourself from serious

injury or fatal shock, use a battery-powered hand drill only to make the hole.

DO NOT USE AN ELECTRIC DRILL.

7 | P a g e

FAUCET INSTALLATION

Drilling the Faucet Hole

NOTE: Safety glasses should be worn to protect your eyeswhiledrillingthefaucethole.

Be sure there is room underneath the sink to make the needed connections. Select one of the

following locations to install the faucet:

• In an existing sink spray attachment or soap dispenser hole.

• In a hole to be drilled in the sink top.

• In a hole to be drilled in the countertop, next to the sink.

NOTE: Be sure the faucet base will fit flat against the surface at the selected location

so the gasket will seal.

1. For best results, a ½” carbide-tipped drill bit should be used to drill a hole into your sink for the

auxiliaryfaucet.

2. Carefully select the faucet location making sure it will have a neat water fall pattern and that the

faucet stud will beaccessiblefrombelowoncetheholeiscompleted.

3. For Porcelain Sink: Before starting the drill motor, apply firm downward pressure on the bit until

a crunching occurs. This will help keep the drill bit from moving.

4. For Stainless Steel Sink: Before using a ½” carbide drill bit, an indent should be made with a center

punch tokeep the drill bit from moving.Asmall pilot hole will also aid the ½” drillbit.

5. For best results, keep steady firm pressure during the start of the hole will cause excess wear on

the bit and progresswillbeslow.

6. Once the hole is complete, clean the area of metal chips and roughness around the hole. Metal

chips will stain

Figure # 4

8 | P a g e

Mounting the Faucet

Yourunitcomescompletewithalongreachfaucet.

NOTE: Air gap option installation instructions are available upon request. The following

instructions is fornon-airgapoption.

1) Slide chrome cover plate and rubber gasket onto stem of faucet and place faucet onto sink with the

stem going throughthehole.

2) Place metal washer and lock washer over threaded stem of faucet and tighten nut from under the

counter surface to lock the faucet into place. DO NOT OVER TIGHTEN.

3) Connect the blue tube to the faucet stem under the counterand tighten. NOTE: Usea brassinsert and

plastic ferrule when connecting the blue tube to the faucet (Fig.4)

POSITIONINGTHESYSTEM

1. The head assembly will stand up in the sink cabinet or canbehungonscrewsprovided.

CONNECTINGTHESYSTEM

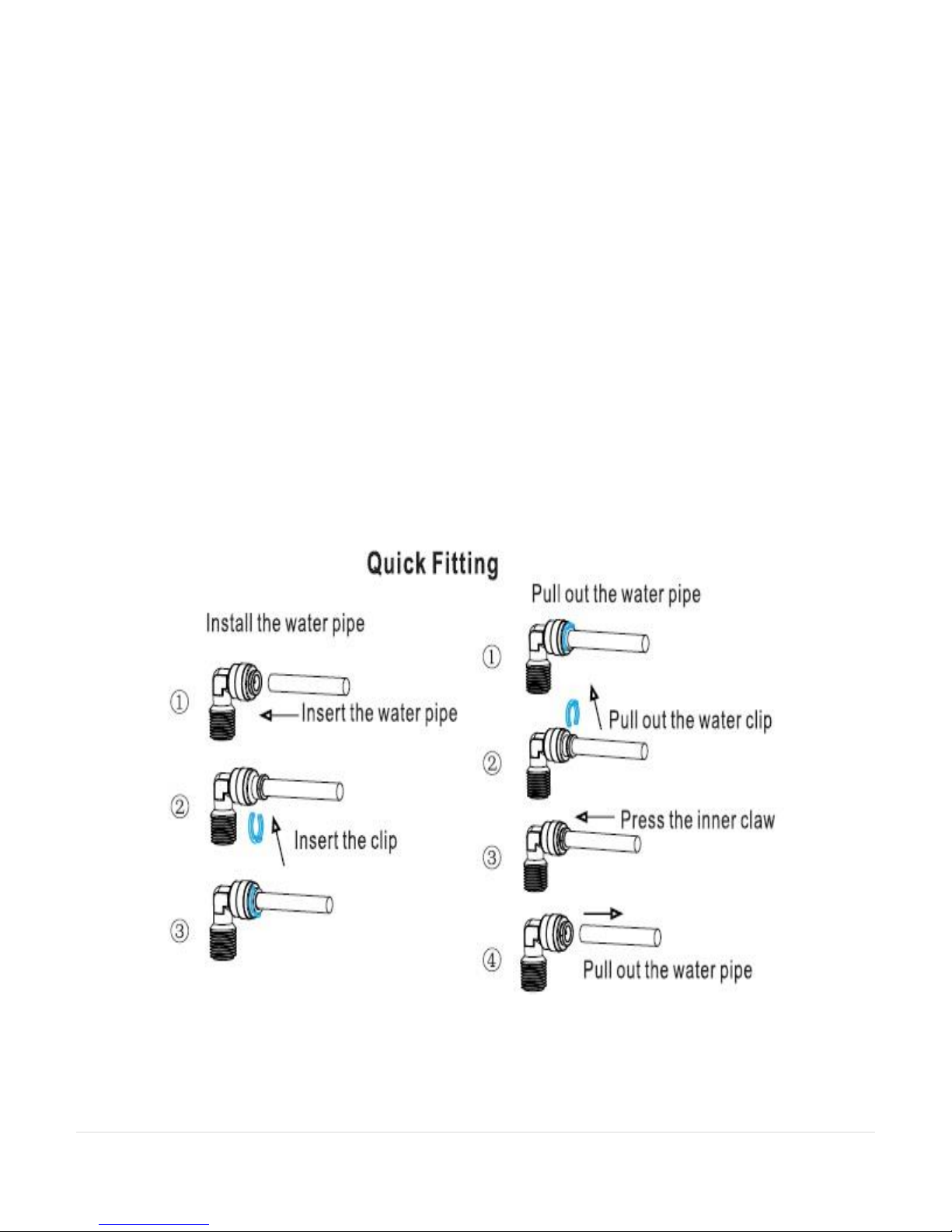

1) Compression fittings may be found on the water supply adapter and the faucet. To

make the connections, slide a compression nut onto the tubing (Fig. #8), slip a white

plastic sleeve onto the tubing with the beveled end towards the end of the tubing,

insert a brass insert into the tubing, bottom the tubing into the fitting, slide the nut up

andtightenwithawrench.DONOTOVERTIGHTEN

Figure # 8

NOTE: Do not use brass sleeves on plastic tubing, useonlyplasticsleevesonplastictubing.

1. Use the color coded tubing to make the following connections:

A. Thewhite tubingconnectsthewatersupplyadaptertothe firstclearhousingofthehead

assembly

B. The blue tubing connects the faucet to the outlet side ofthepostcarbon.

9 | P a g e

START-UPPROCEDURE

1. Checktoseeallconnectionsaremade.

2. Check that the pre-filter and pre-carbon sumps are secureusingthehousingwrenchprovided.

3. Slowly turn on the water by turning the needle valve counterclockwise.

4. Thehandleof thefaucet shouldbeperpendiculartothe spigot(closed).

5. Checkforleaks.

WARNING: Before using the filter system for the first time, the system must be purged.

The filter system cartridge contains a food grade preservative that must be purged from

the system. The preservative will give product water an unpleasant taste and odor.

If you have any difficulties with the installation, or require additional information on your unit,

please consultwithourfactorytechnicians.

RECOMMENDEDMAINTENANCE

1. Sediment Pre-filter: The pre-filter protects the system and should be maintained

regularly, a clear housing has been provided for your convenience. The show-white pre-

Filter should be changed when the outside discolors to a cardboard brown color and

before the inner surface discolors. The life of the pre- filter will depend upon the condition

of your water supply and should be checked at 6-month intervals until a filter life is

established(averagelife6months).

2. GAC and Carbon Block: Designed toremove chlorine form the water supply, as well as organic

and inorganic substance before entering the TFC membrane (average life12months).

3. Post-Carbon: The post-filter should be changed when you experience an unusual taste and/or

odor to the water andhasanominallifeof1year.

CHANGINGTHESEDIMENT,GAC,ANDCARBON BLOCKPRE-CARBONBLOCKPRE-

FILTERS

1. Shut off the feed water to the system by turning the saddle valve on the water supply adapter

clockwiseuntilit stops.

2. Pressdownonfaucethandletorelivepressure.

3. Allow2-3minutesforpressureinthesystemtodrop

4. Remove the filter sumps with the housing wrench by turning the sump to the left

(counterclockwise). If the O- ringinthesumpisstretchedorworn,itshouldbereplaced tomaintain

aproperseal

5. Remove theold filter andgaskets(if any)and insertthe newfilter.

6. Replace the sump onto the cap by turning it to the right (clockwise) until the O-ring makes firm

contact, like an oil filteronacar.DONOTOVER-TIGHTEN.

7. Turn on the feed water to the system by turning the saddle valve at the water supply adapter

counter- clockwise.

10 | P a g e

TROUBLESHOOTING

LEAKS

1. Filter sump:The O-ring in the sump may not bemaking firm contact, have dirt or hair on it or be

stretched. Clean or replaceO-ringandtightensumptomakefirmcontactwithcap.

2. FittingConnection:Compression-Checkthatthefittingis tightenedwithallpartsin properplace

(refertoFig.#8).

NO WATER OR SLOW FLOW

1. Check colored tubing for correct connections

2. Check the saddle valve at the water supply adapter is turned all the way counterclockwise for

feed water and that thereisnorestrictionsalongthewhitetubing.

3. Check the pre-filter, if it has a heavy dirt load it can restrict water flow to the system. Change

sediment pre-filter regularly.

CUSTOMER SATISFACTION IS OF PRIMARY CONCERN, PLEASE CALL IN THE

EVENT THERE ISASERVICEPROBLEM.

Warning: Do not use this system if feed water has biological contamination or of unknown source.

For operating parameters,pleasecontactourtechnicalsupportdepartment.

This manual suits for next models

1

Table of contents

Popular Water Dispenser manuals by other brands

Rain Soft

Rain Soft EC5 Series Installation & service manual

Water Care

Water Care CareSoft Series Installation instructions & owner's manual

Tier1

Tier1 Elite Series owner's manual

Water Care

Water Care Evolve EV1-1044TW Installation instructions & owner's manual

Perma Tech

Perma Tech BOTTLE-FREE WATER DISPENSER owner's manual

Puretec

Puretec K series Operation & installation instructions

Lancaster

Lancaster IRONSOFT X- FACTOR Series Installation, operating and service manual

Water Well

Water Well V53C user manual

Borg & Overstrom

Borg & Overstrom T2 user guide

Sammic

Sammic DA-12 user manual

Sensiblue

Sensiblue 315 Installation, use and servicing manual

Metos

Metos PROFF WD Installation and operation manual