ergovent KVADRO-100 User manual

Diuser preparation

Installation Method No. 1

(connected via a exible corrugated pipe)

Installation Method No. 2

(connection via a standard plenum box when the

ceiling panels have not yet been attached)

Integrated diuser nishing

Diuser maintenance

......................................................... page 7

............................................. page 8

............................................ page 9

...................................... page 11

................................................... page 12

Remove the diusers and side brackets from the boxes. Inspect

each diuser for any cracks in the housing. Leave the covers

securely in the boxes (Image 1), as they will only be needed when

starting the painting.

7

KVADRO-100 / KVADRO-125

Use screws to attach the side fasteners. They can be applied to 1

or 2 layers of plasterboard.

1 layer: the element is placed against the edge (Image 2);

2 layers: the fastening is aligned with the protruding brim in the

housing (Image 3).

INSTALLATION METHOD No. 1 (page 8)

METAL DUCT SYSTEM

Connection: via a exible corrugated pipe.

INSTALLATION METHOD No. 2 (page 9)

75 mm PLASTIC DUCT SYSTEM

Connection: via a plenum box (metal/plastic).

Ceiling plasterboards are not yet attached.

DIFFUSER PREPARATION SELECTION OF THE INSTALLATION METHOD

DIFFUSER INSTALLATION GUIDE

EN

Three installation methods are possible. You

will recognise which method is suitable for you

by looking at the images depicting dierent

situations. Choose the installation method

that best suits your situation and follow the

appropriate instructions.

•

1

2

3

www.ergovent.com

Cut a hole for the diuser in the intended place (Image 1.1).

Tilt the diuser at an angle and insert it through the hole (Image

1.4). Then place it in the intended position (the side fastenings

must rest on the plasterboard).

Connection via a exible corrugated pipe

When planning the diuser installation points, make sure that

there are no ceiling frame proles in the diuser installation area.

Any proles present in the area of the cut-out hole and creating

an obstruction must be removed (Image 1.2). Be sure to consult

with the ceiling installers to ensure that you will not damage the

ceiling structure.

Check that the diuser installation is level. The diuser must

be ush with the ceiling surface or can protrude by up to 1 mm

(Image 1.5).

Attach the exible corrugated pipe to the diuser connector. A

clamp or plastic strap will suce (Image 1.3).

The diuser is fastened with self-tapping screws. Insert the

screws directly through the plasterboard into the side fasteners

(Image 1.6).

INSTALLATION METHOD NO. 1

1.3

1.2

1.4

1.5

1.6

When connecting the diusers via a exible

corrugated pipe, the gypsum ceiling panels

must be already attached.

If the diuser is awry, the side brackets have

been attached at dierent levels. Remove the

diuser and readjust the fasteners.

The diuser is ready for nishing.

Go to the nishing instructions (page 11).

8

•

•

0-1mm

Gypsum ceiling

diuser

EN

www.ergovent.com

A

A

1.1

A=242 mm

Connection via a plenum box (75 mm plastic duct system)

• If the plenum box is plastic, a successful installation will require

at least 7 cm of space from the duct to the bottom of the ceiling

prole (Image 2.5). If two layers of plasterboard will be used, the

distance required is 6 cm (Figure 2.6).

min 7,5cm

INSTALLATION METHOD NO. 2

2.1 2.2

Make sure that the gypsum ceiling structure does not interfere

with the installation of the diusers (Image 2.1).

Metal ceiling proles should be at least 7,5 cm away from the

connection pipe (Image 2.2).

Make sure there is enough space for a successful

diuser installation:

• If the plenum box is metal, a successful installation will require

at least 7 cm of space from the box housing to the bottom of

the ceiling prole (Image 2.3). If two layers of plasterboard will be

used, the distance required is 6 cm (Figure 2.4).

SHORTENING THE CONNECTION PIPES

The connecting pipes must be shortened by measuring Distance

A from the level of the lower prole surface (Images 2.7 and 2.8).

min 7cm

min 6cm

min 7cm

A

For 1 layer of plasterboard, A = 4,5 cm

For 2 layers of plasterboard, A = 3,5 cm

min 6cm

9

2.3

2.4

2.5

2.6

2.7

2.8

EN

www.ergovent.com

The diuser coupling is then inserted into the connection pipe

(Image 2.9). Continue moving the coupling inwards until it touches

the pipe (Figure 2.10).

Check that the diuser is level with respect to the visible

ceiling surface (Image 2.13). The visible edge of the diuser

must be ush with the ceiling or can protrude by up to 1 mm.

If the diuser is awry, the side brackets have been attached at

dierent levels. In this case, remove the diuser and readjust the

fasteners.

For 2 layers of plasterboard:

After attaching the rst layer of plaster, the diuser housing

should protrude by about 13 mm (Image 2.14). After attaching the

second layer, the housing must be ush with the plasterboard or

protruding by up to 1 mm.

After inserting the diuser, make sure that it is being held

securely and will not fall out while you prepare the ceiling panel. If

necessary, use mounting tape for a temporary fastening to prevent

the diuser from falling out (Image 2.11).

For 1 layer of plasterboard:

Cut out a hole in the required place and attach the board using

screws (Image 2.12).

The diuser is fastened with self-tapping screws (Image 2.15).

Insert the screws directly through the plasterboard into the side

fasteners.

The diuser is ready for nishing.

Go to the nishing instructions (page 11).

0-1mm

13mm

Gypsum ceiling

Gypsum ceiling

diuser

diuser

INSERTING THE DIFFUSER

ATTACHMENT OF THE PLASTERBOARD

DIFFUSER ATTACHMENT

10

Insert the diuser just before preparing to

attach the ceiling plasterboards.

•

2.9

2.11

2.12

2.10 2.13

2.14

2.15

EN

www.ergovent.com

A

A

A=242 mm

Rendering / reinforcement / painting

Fill the gap between the diuser and the plasterboard with putty.

We recommend using Knauf Fugenfuler or Uniott putty (Image

3.1).

Apply another coat of putty (Image 3.4). Once the putty has

hardened, rub it with a ne sandpaper.

When the putty has dried, cut out the breglass cloth in the central

part of the diuser. Use a sharp knife to cut it ush with the inner

edge of the diuser, while making sure not to damage the gypsum

housing (Image 3.3).

Cut out 35 x 35 cm sheets from a thin breglass cloth. Press the

breglass cloth into the putty, directly over the diuser area. When

pressing the cloth into the putty, smooth it out to ensure an even

covering with the layer of putty (Image 3.2).

The centre cover does not need to be plastered prior to painting,

as priming it will suce. Paint only the visible surfaces of the

centre cover (Image 3.6).

The entire inner surface of the diuser must be painted with the

ceiling paint (Image 3.5).

FINISHING INSTRUCTIONS

Prior to painting, impregnate the rendered

surfaces with a deep primer; use a moisture-

resistant primer for damp rooms.

In damp rooms, use moisture-resistant ceiling

paints that are specially designated for these

types of rooms.

•

•

RENDERING AND REINFORCEMENT

PAINTING

11

3.1

3.2 3.5

3.4

3.3

We recommend using the Knauf nishing

technology for your nishing work.

Remove dust from surfaces and gaps. Use

Ceresit CT-17 or Knauf Tiefgrund primers.

To avoid cracks in the seam, we recommend

reinforcing the entire seam area with breglass

cloth.

•

•

•

EN

www.ergovent.com

When the paint is completely dry, the cover can be put in place.

The cover is attached to three magnetic holders (Image 3.7).

Adjust the magnetic holders so that each holder protrudes by 15

mm from the diuser housing (Image 3.8).

The diuser installation is now complete (Image 3.9).

Valve installation. Remove the diuser cover. Insert the exible

valve into the diuser connection branch. The air ow is regulated

by changing the number of valve segments (Image 3.10).

We recommend cleaning the diuser at least once a year. Use

a soft duster to clean the inside of the diuser, to prevent dirt

from accumulating and sticking to the device if it is left unclean for

prolonged periods of time. Accumulated dust can also be removed

with a vacuum cleaner. Avoid damaging the painted surface.

AIR FLOW REGULATION

DIFFUSER MAINTENANCE

The diuser cover must always be ush with

the ceiling.

If is it necessary to regulate the air ow, we

recommend the additional purchase and use

of an INNO valve. These come in standard

diameters of 100 mm, 125 mm or 160 mm.

To maintain a clean device, change the

actuator lters inside the air diuser regularly.

This will reduce the penetration of impurities

from outside and keep the diuser clean for

longer.

•

•

•

12

3.6

3.7 3.10

3.8

3.9 3.11

15mm

EN

www.ergovent.com

This manual suits for next models

1

Table of contents

Other ergovent Fan manuals

Popular Fan manuals by other brands

El Corte Inglés

El Corte Inglés VT-90 instruction manual

Hunter

Hunter Builder Deluxe 53089 Owner's guide and installation manual

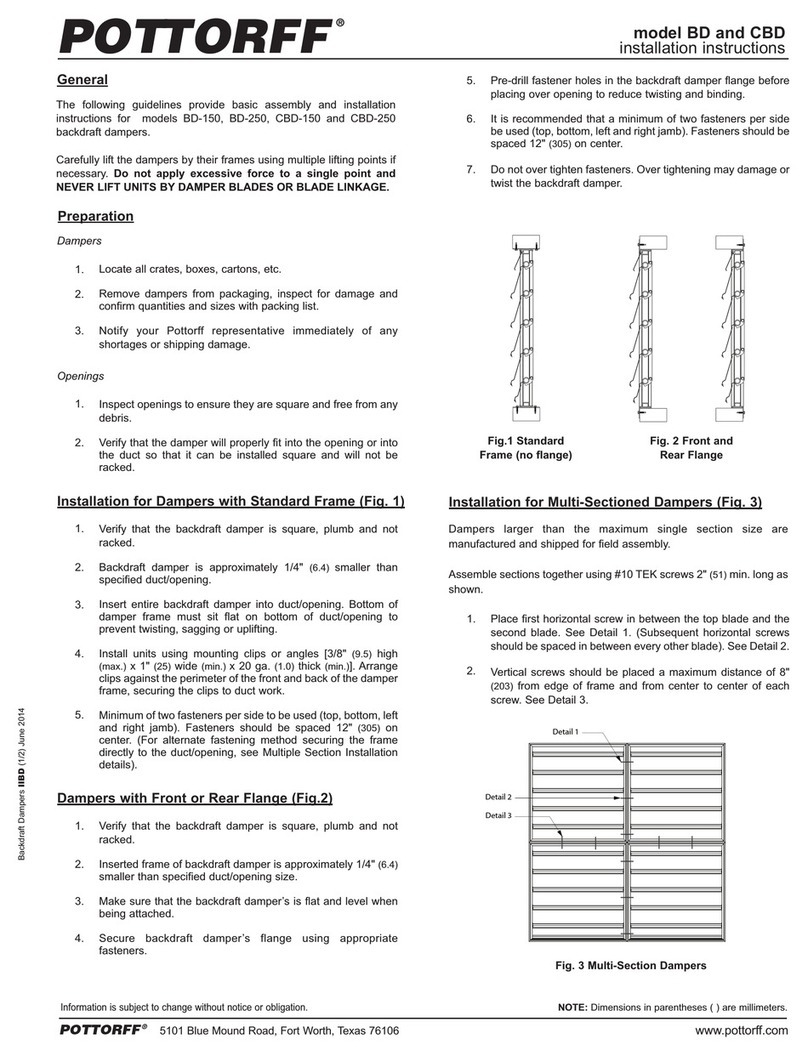

pottorff

pottorff BD Series installation instructions

MTD

MTD MTD-ERV 350 Installation & operating manual

BLAUBERG Ventilatoren

BLAUBERG Ventilatoren Iso-Mix user manual

Craftmade

Craftmade Stonegate STO52 installation guide