ERKO SH/400 Operator's manual

ERKO

®

SH/400

Metal Works ERKO

®

R. Pętlak

unlimited partnership Pętlak Brothers

Ks. Jana Hanowskiego 7 str 11-042 JONKOWO

POLAND

tel./fax 0048/ 89 /5129273(4 lines)

e-mail: export@erko.pl www.erko.pl

ISO 9001

ISO 14001

Technical and Operational Documentation

Conductor-rail machining station

ERKO company reserves the right to technical changes improving/modernizing its products.

2

DECLARATION OF CONFORMITY

of machines and equipment with all binding work safety and hygiene norms and

regulations

Based on the PN-EN 45014 norm and after an analysis of the Technical and

Operational Documentation, the construction and operation of the machine and the

examination results:

Zakłady Metalowe ERKO R. Pętlak

Spółka Jawna Bracia Pętlak

11-042 Jonkowo

ul. Ks. Jana Hanowskiego 7

with full responsibility declares that the machine:

Conductor-rail machining station,

type SH-400

SWW 0792 Polish Classification of Goods and Services (PKWiU) 29.56.25-90.90,

being the subject of herein statement, conforms with the following norms:

PN-74/E-06401 Electrical power cable lines. Cable fittings. General requirements and

analyses.

PN-90/M-68050/05 Machines for plastics machining, hydraulic presses. Construction

safety requirements.

PN-83/Z-08200 Work protection. Production machines and equipment. General

safety requirements.

ERKO company reserves the right to technical changes improving/modernizing its products.

3

Table of contents:

1. Technical specification ...................................................................................... 4

2. Operation .......................................................................................................... 4

3. Operation manual.............................................................................................. 5

4. Maintenance materials ...................................................................................... 7

5. Work Safety and hygiene manual ..................................................................... 7

6. Troubleshooting ................................................................................................ 8

7. Electrical diagram SH/400................................................................................. 9

8. Spare parts specification ................................................................................. 10

9. Figures ............................................................................................................ 11

10. Hydraulic unit .................................................................................................. 15

11. The warranty ................................................................................................... 18

12. Guarantee certificate....................................................................................... 19

13. REPAIR LIST .................................................................................................. 19

Figures:

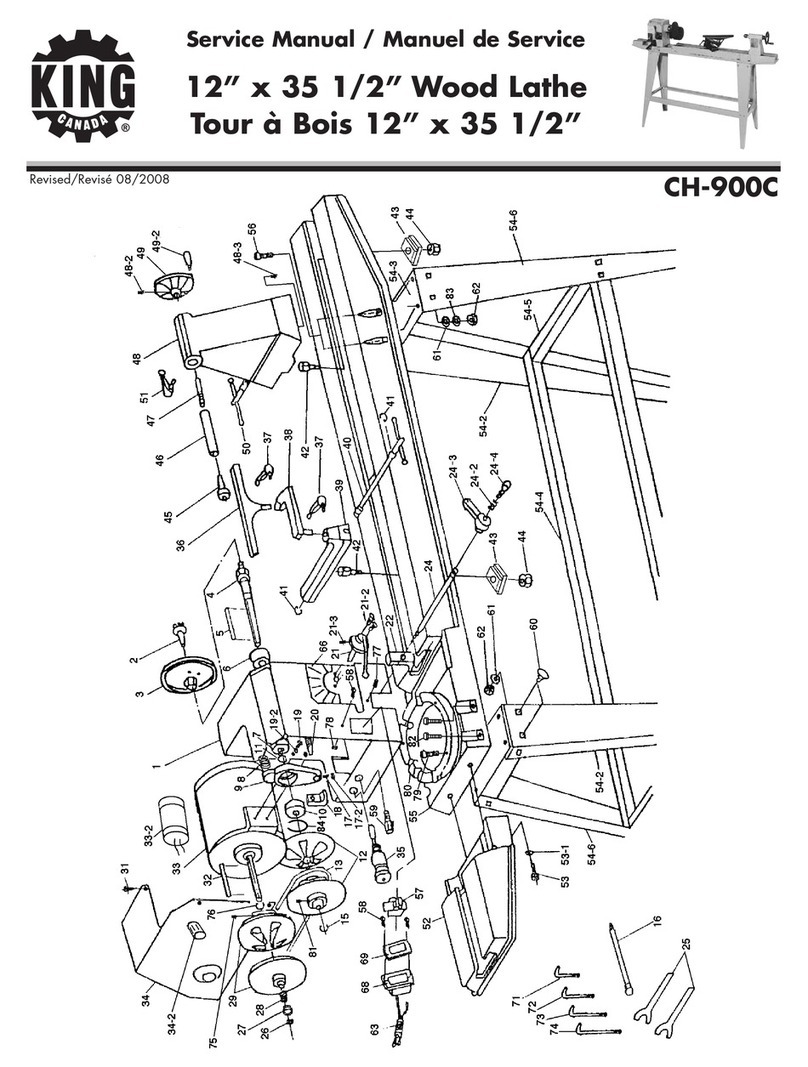

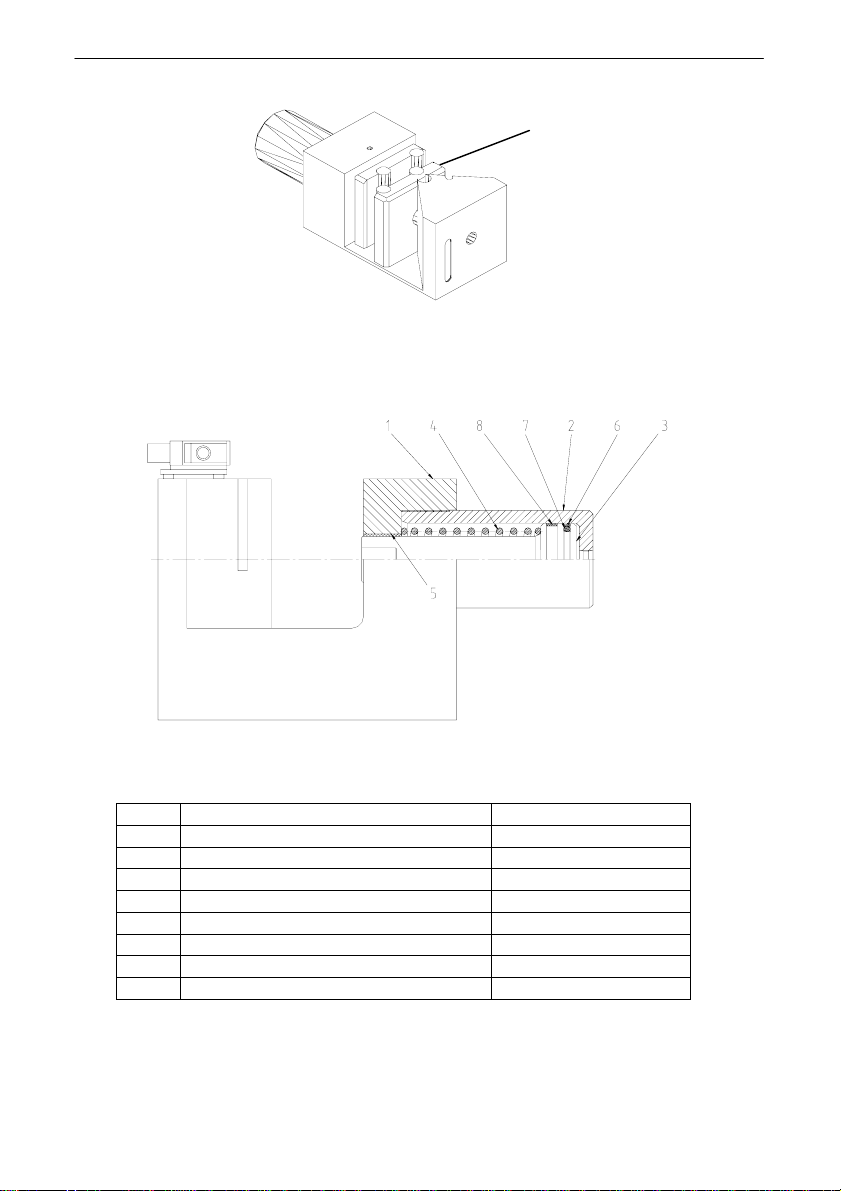

Fig. 1 General view ..................................................................................................... 11

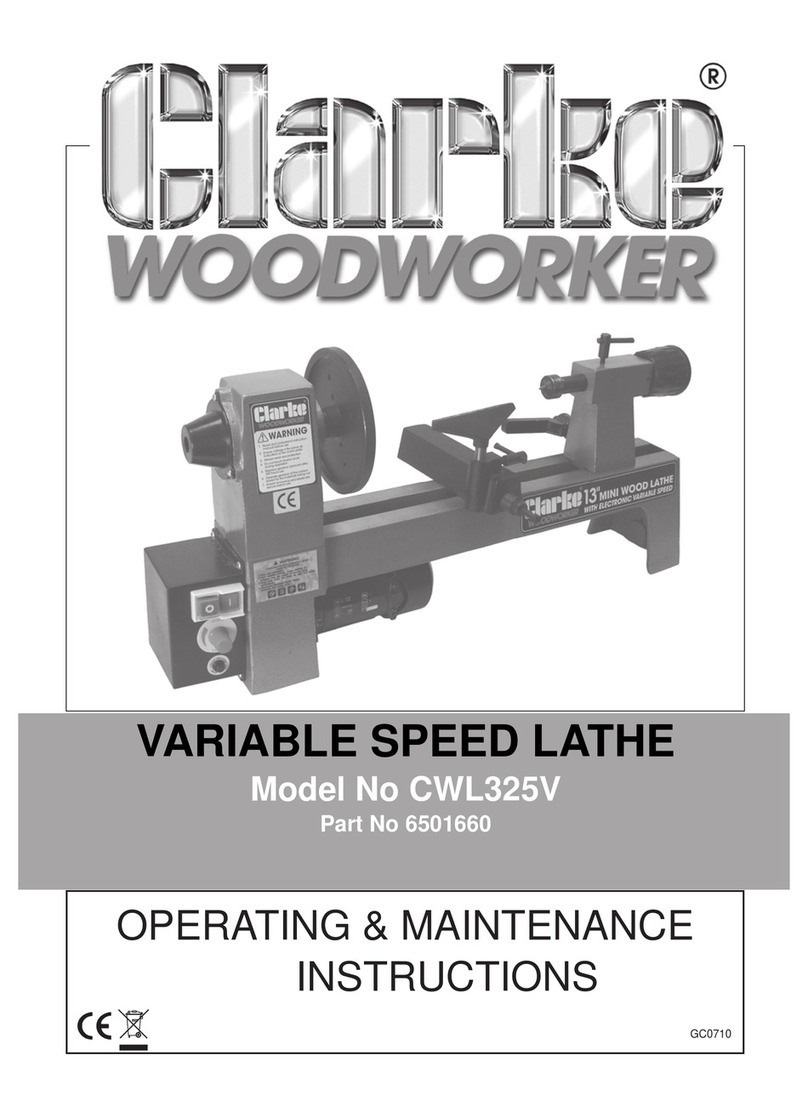

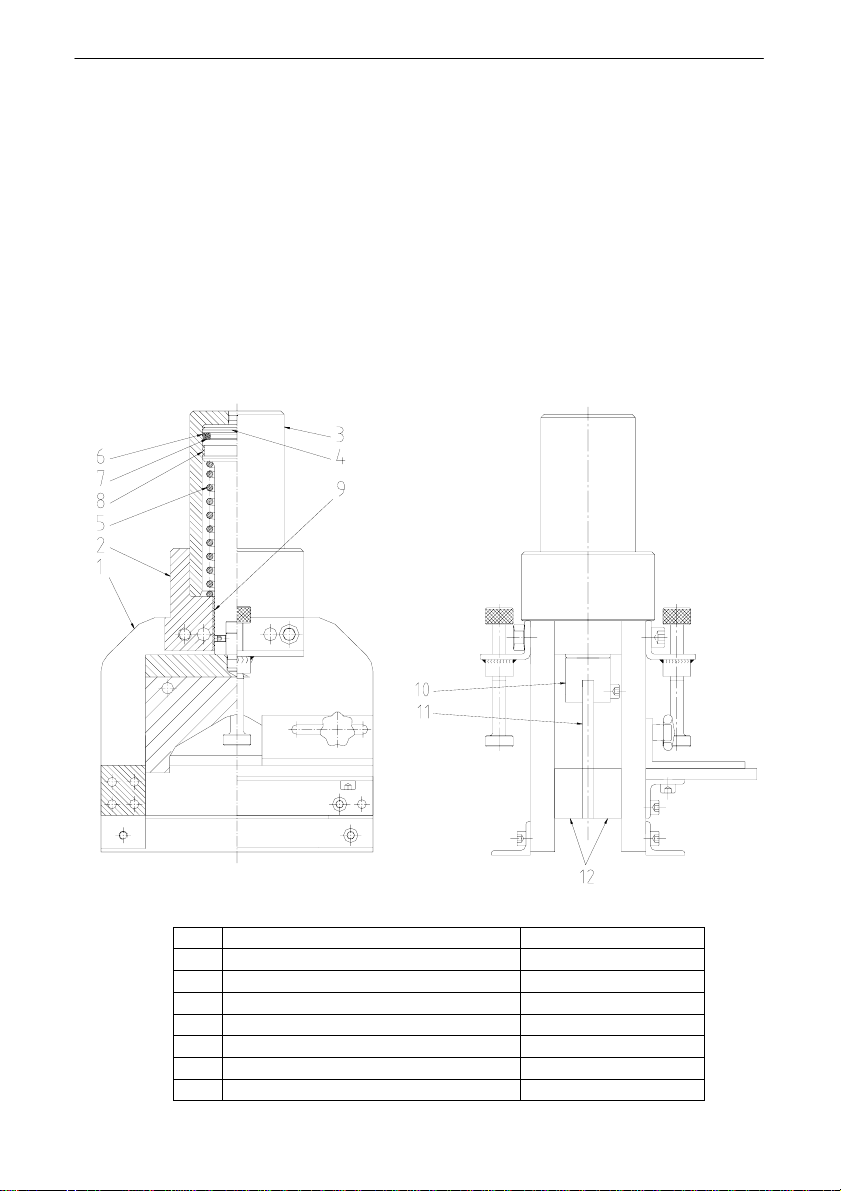

Fig. 2 Punching and profiling segment – punching holes ............................................ 12

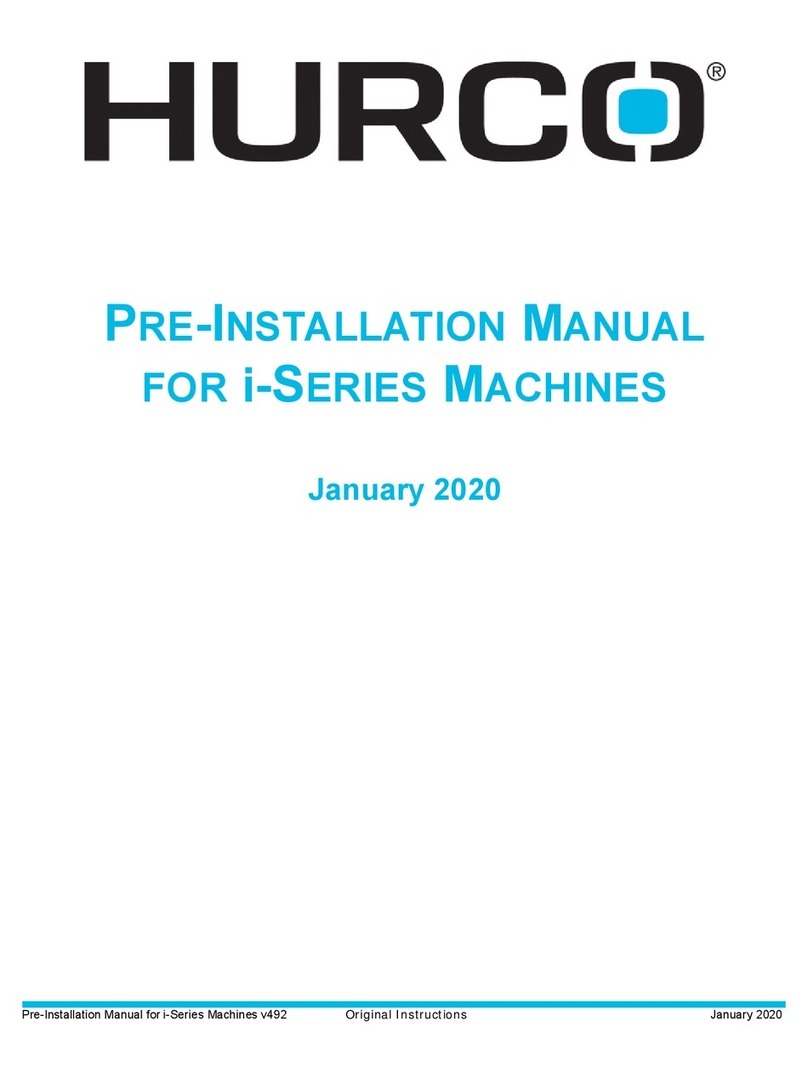

Fig. 3 Punching and profiling segment – profiling ....................................................... 12

Fig. 4 Punching and profiling segment – offsetting ..................................................... 12

Fig. 5 Punching and profiling segment – cross-section............................................... 13

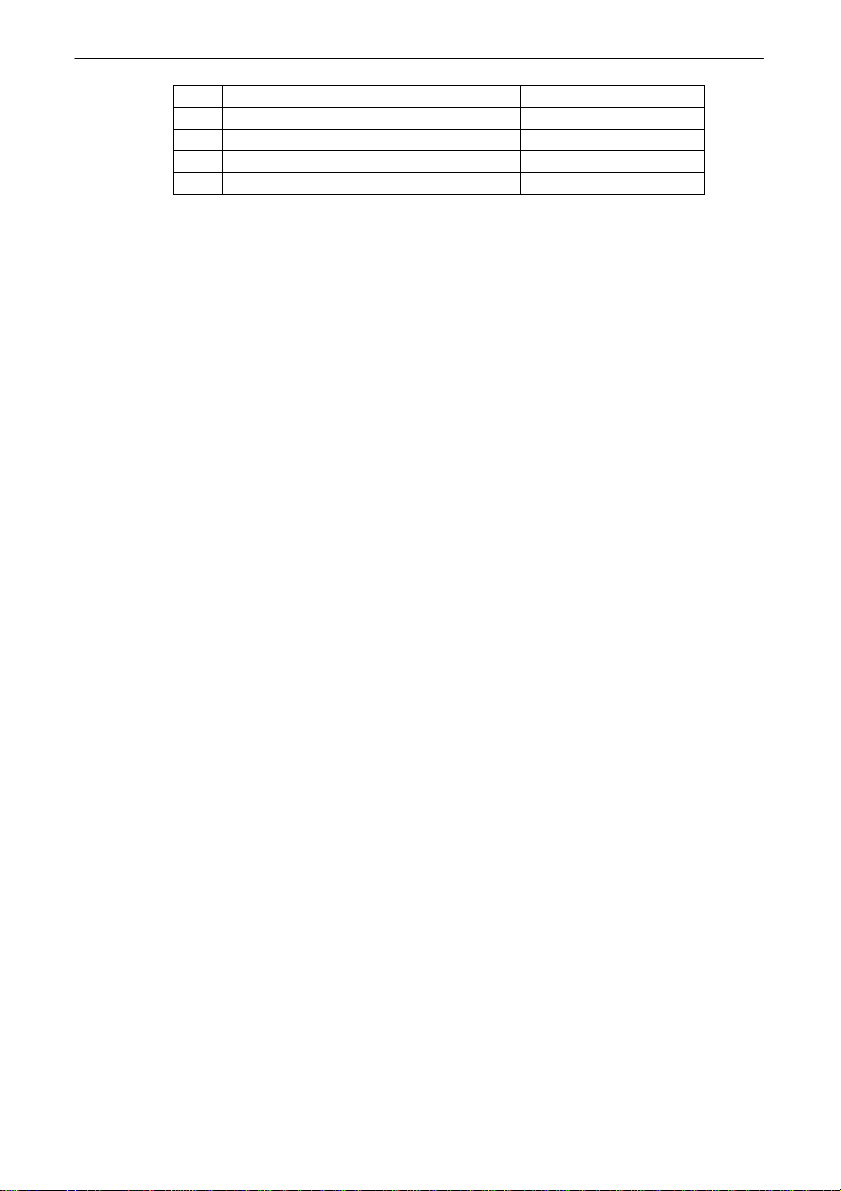

Fig. 6 Cutter – cross-section ....................................................................................... 14

Please read the operational and work safety

and hygiene manuals prior to operation!

ERKO company reserves the right to technical changes improving/modernizing its products.

4

1. Technical specification

- working pressure 680 bar

- working pressure at die outlet 680 bar

- power supply 3 x 380V, 1.1 kW

- operation 24V

- busway machining (Cu, Al) (thickness x width) max. 12 x 125 mm

2. Operation

2.1 Elements

A workshop table is a complete working station for conducting the operations of

cutting, punching holes and profiling copper and aluminium bars.

A standard table includes the following elements:

1. Cutter for cutting bars HC-120 (1) 1 pc

2. Punching and profiling segment (2) 1 pc

- punching holes for screws from M6 to M20 6 sets (dies and punches)

- punching oval holes for screws from M6 to M16 5 sets (dies and punches)

- Profiling – range from 0 to 90˚1 set (pins and profiling insertion)

3. External die terminal (3) 1 pc (terminate in a fast terminal

PM type)

Equipment that could be additionally connected:

- Die GU 120 – terminal clamps at conductors 10-120 mm2, reshaping sector wires

- Die GU 300 – terminal clamps at conductors 150 – 300 mm2, reshaping sector

wires

- Die GO 300 – terminal clamps at conductors 6 – 300 mm2, reshaping sector

wires

- Die GU 625 – terminal clamps at conductors 300 – 625 mm2

- Die GW – punching holes in cubicles walls

- Die GC 50 N, GC 100 – cutting wires and conductors

- Trimmer GL-6 – cutting assembly bars

- Conductor-rail type GP horizontal bending machine

ERKO company reserves the right to technical changes improving/modernizing its products.

5

3. Operation manual

Note:

1. White diode (L5) indicates that the engine has been switched on.

2. Green diodes (L1, L2, L3, L4) indicate selected mode of machining.

Cutting

1. Position the horizontal rulers [4] with the use of the hand wheel [15] so the

cutters knife axis is positioned in the centre of the material;

2. Start the machine [W1];

3. Select machining mode with the selector [W3] to cutting;

4. Press pedal [W2] to start cutting;

5. After the material has been cut, depress pedal [W2] and the cutter knife will

return to its initial position.

Fig.1 illustrates the particular elements.

Note: Prevent knife fittings pressing action on the material or cutting knives. Do not

manipulate with the extreme position switch.

Punching circles

1. Select a required whole punch [9] and die [10];

2. Set the punching and profiling segment [2] at a required height with the use of

the crank [6] according to the ruler [7];

3. With the vertical ruler [8] set the hole distance from the bar end [8];

4. Start the machine [W1];

5. Select machining mode with the selector [W3] to punching; punching is not

allowed in the profiling position;

6. Press pedal [W2] to initiate punching holes;

7. Continue the punching process until the sensor [W6] lights – (erratic running);

8. After the hole has been punched, depress pedal [W2] and the punch will

return to its initial position.

Fig. 1 and Fig. 2 illustrate particular elements.

Punching ovals

1. Insert the pin positioning the die [10a];

2. Select a required punch [9] and die [10];

3. Fit the die and the punch;

4. Set the punching and profiling segment [2] at a required height with the use of

the crank [6] according to the ruler [7];

5. With the vertical ruler [8] set the hole distance from the bar end [8];

6. Start the machine [W1];

ERKO company reserves the right to technical changes improving/modernizing its products.

6

7. Select machining mode with the selector [W3] to punching; punching is not

allowed in the profiling position;

8. Press pedal [W2] to initiate punching holes;

9. Continue the punching process until the sensor [W6] lights – (erratic running);

10. After the hole has been punched, depress pedal [W2] and the punch will

return to its initial position.

Fig. 1 and Fig. 2 illustrate particular elements.

Profiling

1. Insert the pin [11] and the profiling insertion [12];

2. Set the punching and profiling segment [2] with the use of the crank [6] so the

middle part of the profiling bar was positioned with the segment servo-motor

axis [2];

3. Set a required profiling angle at the scale [13] by releasing and clamping [14];

4. Start the machine [W1];

5. Select machining mode with the selector [W3] to profiling;

6. Press pedal [W2] to initiate profiling action;

7. Continue the profiling process until the extreme position selector [W4] lights –

(erratic running);

9. After the bar has been profiled, depress pedal [W2] and the profiling insertion

[12] will return to its initial position.

Fig. 1 and Fig. 3 illustrate particular elements.

Offsetting

1. Fit the offsetting insertion [17];

2. Set the punching and profiling segment [2] with the use of the crank [6] so the

middle part of the profiling bar was positioned with the segment servo-motor

axis [2];

3. Start the machine [W1];

4. Select machining mode with the selector [W3] to profiling;

5. Press pedal [W2] to initiate profiling action;

6. Continue the profiling process until the bar has been profiled;

7. After the bar has been profiled, depress pedal [W2] and the profiling insertion

[12] will return to its initial position.

Note: the offsetting insertion is not equipped with a run cycle switch. Offsetting

should be carried out only on the oval elements of the insertion. Prevent the bar

from pressing the flat element of the insertion.

Fig. 1 and Fig. 4 illustrate particular elements.

Working with an external die

1. Fit the external conductor [3] with a required die and fittings;

2. Start the machine [W1];

3. Select machining mode with the selector [W3] to external die;

ERKO company reserves the right to technical changes improving/modernizing its products.

7

4. Prepare the die for work;

5. Press pedal [W2] to activate the die;

6. After the work with the die has been completed, depress pedal [W2] and the

die piston will return to its initial position.

Fig. 1 illustrates particular elements.

4. Maintenance materials

1. Hydraulic unit – hydraulic oil L-HM 32 – (5 dm3);

2. Punching and profiling unit lifting bolt – lubricant ŁT – 46.

4.1 Hydraulic oil exchange and refill

1. Remove the side plate [21];

2. Oil exchange and refill should be carried out according to the instructions

included in the Technical and Operational Documentation of the hydraulic

unit.

4.2 Lubrication of lifting unit bolt

When required carry out according to the following steps:

1. Unfasten the crank [6];

2. Remove the front plate [11];

3. Lubricate the bolt.

5. Work Safety and hygiene manual

1. Only personnel familiar with the Technical and Operational Documentation

are to operate the SH/400 machining station.

2. Proper positioning of the operating elements should be checked prior to

starting the machining station SH/400.

3. The machine can be operated only when at full technical performance.

4. Prior to starting check the following:

- electrical power installation

- oil level in the hydraulic feeder tank

- state of the mobile elements

- hydraulic unit

5. Electrical power should be disconnected during daily checks and repairs in

order to prevent accidental machine starting.

6. Personnel should wear adequate protective gear while operating the

machine.

7. Use the SH/400 machining station only for its intended purpose.

ERKO company reserves the right to technical changes improving/modernizing its products.

8

8. Prevent debris collection around the machining station. In case of high dust

concentration, cover the machine.

9. Working without a shield is forbidden.

10. Starting while manipulating the machine (fitting and unfastening elements,

positioning the machining material) is forbidden.

11. Start the machine only after the preparation has been completed and when

there is no danger of body or machine damage.

6. Troubleshooting

Problem Cause Solution

1. After starting the machine the

power diode does not light

a. no power supply

b. no 1 phase

c. voltage fall to

175V/phase

Check the power

supply

2. The machine switches off

while running

a. no phase at

engine

b. engine alarm went

off

c. no power supply

Check power supply

and engine alarm

3. Loud pump running with no

servo-motor motion

d. cover not closed

e. electrovalve has

broken

Close the cover

correctly. Contact

service.

ERKO company reserves the right to technical changes improving/modernizing its products.

9

7. Electrical diagram SH/400

Z1 – bending machine coil

Z2 – cutting machine coil

Z3 – die coil

W7 – cutting extreme position

W9 – profiling extreme position

W6 – punching extreme position

W8 – shield extreme position

W5 – angle extreme position

W3 – machining mode selector

W1 – main power switch

W4 – circuit-breaker

W3 – ŁK16R-4.858/PO3

W4 – XB2-ES542

W5 – TM1306

W6 – PCID-1, 5RP-NC MB

W7 – TM1701

W8 – TM1306

W9 – PCID-1, 5RP-NC MB

L1-L5-24V/2W

Z1-Z3-24V/0.75W

S1-FA-M250 2.5-4A

S2-KM-DILEM-10(24V50Hz)

ERKO company reserves the right to technical changes improving/modernizing its products.

10

W2 – pedal

W1 – ŁK16R-2.821/PO3

W2 – XPER310

S3-R15-1012-23-1024-D

B1-0.5A

B2-1A

T1-TR363 63VA

8. Spare parts specification

No. Part No. of pcs Manufacturer Drwg. ref. no.

Hole punching unit

1 Die M6 1 ERKO SH-400/02.11

2 Die M8 1 ERKO SH-400/02.11

3 Die M10 1 ERKO SH-400/02.11

4 Die M12 1 ERKO SH-400/02.11

5 Die M16 1 ERKO SH-400/02.11

6 Die M20 1 ERKO SH-400/02.11

7 Spring M16-M20 10 Pol Aston SH-400/02.14

8 Punch M6 1 ERKO SH-400/02.13

9 Punch M8 1 ERKO SH-400/02.13

10 Punch M10 1 ERKO SH-400/02.13

11 Punch M12 1 ERKO SH-400/02.13

12 Punch M16 1 ERKO SH-400/02.13

13 Punch M20 1 ERKO SH-400/02.13

14 Die 8,5/12 1 ERKO SH-404/01/02

15 Die 11/16 1 ERKO SH-404/01/02

16 Die 13/18 1 ERKO SH-404/01/02

17 Die 17/21 1 ERKO SH-404/01/02

18 Punch 8,5/12 1 ERKO SH-400/01/01

19 Punch 11/16 1 ERKO SH-400/01/01

20 Punch 13/18 1 ERKO SH-400/01/01

21 Punch 17/21 1 ERKO SH-400/01/01

22 Cover of spring PUR 10 ERKO SH-400/02/12

23 Pin 1 ERKO SH-404/01/03

Offsetting

24 Offsetting insertion pin 1 ERKO SH-400/03/00

25 Offsetting insertion punch 1 ERKO SH-400/03/00

Profiling unit

26 Profiling insertion 1 ERKO SH-400/02.02

27 Pin 1 ERKO SH-400/02.03

28 Electrical unit as in Diagram

29 Hydraulic feeder as in Annex 1

ERKO company reserves the right to technical changes improving/modernizing its products.

11

9. Figures

Conductor-rail machining station

SH/400

Fig. 1 General view

W1 W2

11

W3

L1,L2,L3L4

21

W4

L5

3

52

8

W7 1

3,

14

7

6

1

4

15

ERKO company reserves the right to technical changes improving/modernizing its products.

12

Fig. 2 Punching and profiling segment – punching holes

10

9

Fig. 3 Punching and profiling segment – profiling

Fig. 4 Punching and profiling segment – offsetting

W6

11

W5

13

14

12

ERKO company reserves the right to technical changes improving/modernizing its products.

13

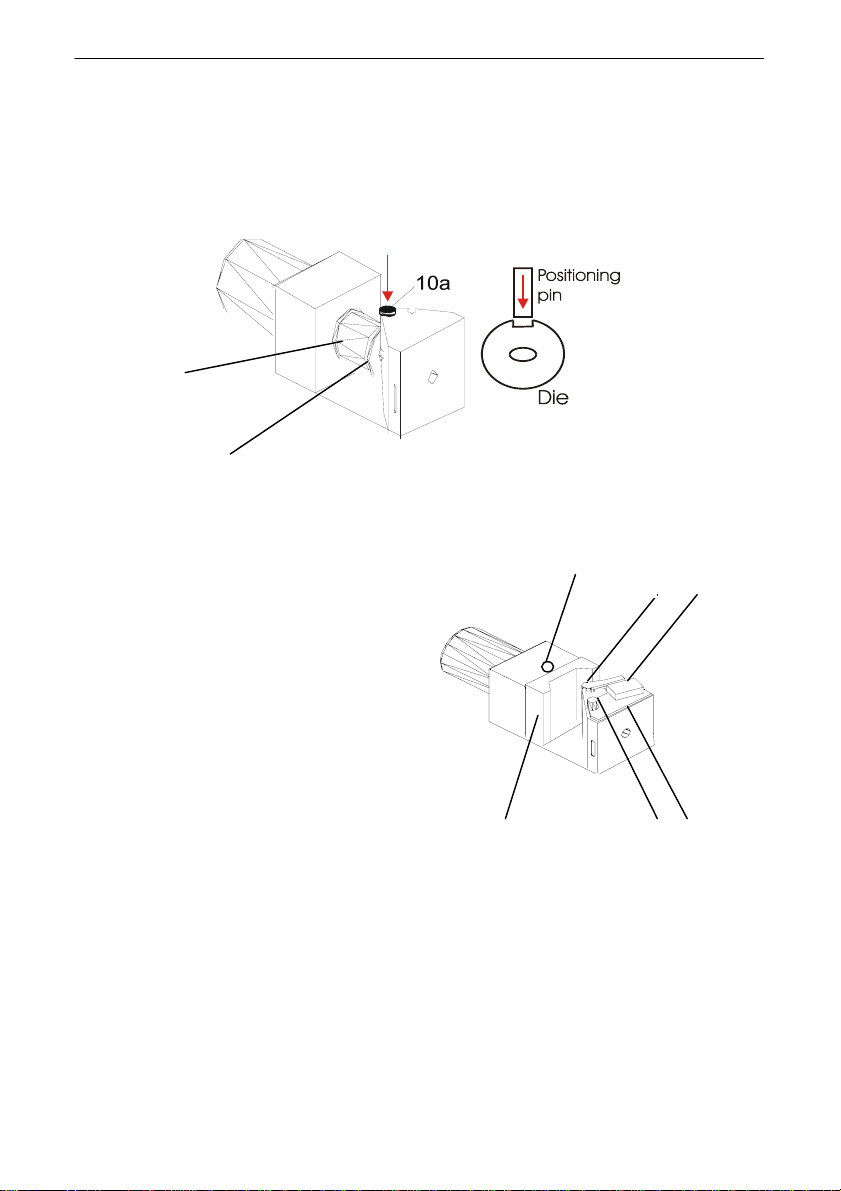

Fig. 5 Punching and profiling segment – cross-section

No. Element Drwg. ref. no.

1 Body SH-400/02.01

2 Cylinder HGD-100/01.06-A

3 Piston SIH-63/01.02

4 Spring SIH-63/01.03

5 Guiding barrel (Igus) GSM-4044

6 Insulation (Busak&Schamban) PS1400630-T46N

7 O-ring (Busak&Schamban) ORID04750

8 Guiding ring (Busak&Schamban) GP6900630-C380

17

ERKO company reserves the right to technical changes improving/modernizing its products.

14

Fig. 6 Cutter – cross-section

No. Element Drwg. ref. no.

1 Body SH-400/01.01(02)

2 Connector SH-400/01.03

3 Cylinder HGD-100/01.06-A

4 Piston SIH-63/01.02

5 Spring SIH-63/01.03

6 Insulation (Busak&Schamban) PS1400630-T46N

7 O-ring (Busak&Schamban) ORID04750

ERKO company reserves the right to technical changes improving/modernizing its products.

15

8 Guiding ring (Busak&Schamban) GP6900630-C380

9 Guiding barrel GSM-4044

10 Knife fitting SH-400/01.05

11 Mobile knife SH-400/01.04

12 Permanent knives (2pcs) SH-400/01.07

10. Hydraulic unit

Technical and Operational Documentation

10.1. Introduction

Read the following Technical Description before operating the hydraulic feeder. The

hydraulic unit can only be operated by personnel trained in work safety and hygiene as

well as in the construction and the operation of the unit.

10.2. Technical description

Technical specifications

- power output (electric engine) 1.1 kW

- max. pressure 700 bar

- nominal efficiency 1.25 l/min

- power supply voltage 380 V, 50 Hz

- operation 24 V DC

- working medium L-HM-32 (Gdańsk Refinery)

- tank capacity ~ 5 dm3

Unit construction

This compact feeder consists of an oil tank and built-in hydraulic elements.

The main elements of the feeder are: a pump system V1 (pump and engine

submerged in oil), a press-return filter and a distributor. The tank construction enables

attachment. The hydraulic system of the unit is terminated with outputs G1/4 type.

The feeder is equipped with an oil level indicator.

ERKO company reserves the right to technical changes improving/modernizing its products.

16

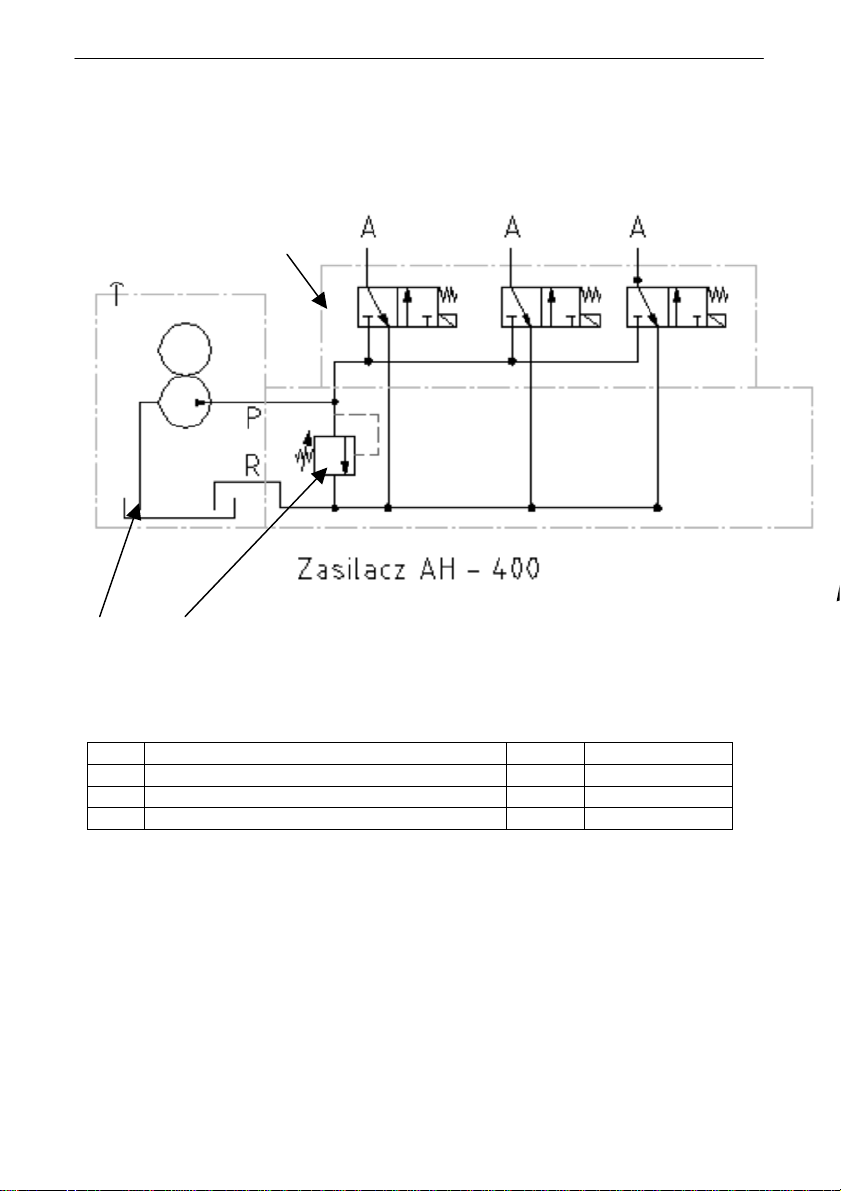

10.3. Hydraulic diagram

Feeder AH-400

3

1 2

10.4. Main parts specification

No. Part Pcs

1 Hydraulic system HC-31 HAWE 1 set

2 Emergency valve A2/700 (700 bar) HAWE 1 pc.

3 Emergency valve MVG 13 HR (400 bar) HAWE 1 pc.

10.5. Operation manual

Operation according to the Technical and Operational Documentation SH/400

The manufacturer set the maximum working pressure at the emergency valve at 400

bar or 680 bar (depending on the order) for the external die and at 680 bar for the

machining station unit. These values cannot be changed (safety leaden seals).

ERKO company reserves the right to technical changes improving/modernizing its products.

17

Caution:

- After finishing operation of the station switch off the power supply with the main

switch and cut-off from the main power supply by unplugging from power outlet.

- Switch off electrical power supply and release the hydraulic system while carrying out

any maintenance or repairs.

- The feeder generates high pressure. Operate the unit with great caution. Unit

unsealing may bring unexpected results. Entire system including the working elements

should be shielded for operator’s safety.

- Breaking leaden seals will void guarantee for the entire hydraulic system of the

machining station SH-400.

10.6. Maintenance manual

Switch off the power supply when carrying out any maintenance jobs (by turning the

main power supply switch to “0” position and unplugging from the power supply outlet).

Electrical power installation should be maintained regularly.

Particular attention should be paid to possible oil leaks. If any, remove them

immediately.

Check the oil level in the tank with the indicator under the electrical plate. Oil should fill

the capillary vessel located at the side of the hydraulic oil tank. Oil should be

exchanged every 12 months (if operated intensively – every 6 months). A tank

cleanliness check after removing old oil and before refilling new oil is recommended.

The suction filter cleanliness should be checked as well. If required, it should be

washed or replaced with a new one. After a refill, oil should fill the capillary vessel of

the oil indicator. Use HLP class oils of ZS-32 viscosity (e.g. AZOLLA ZS-32-TOTAL,

ELFOLNA DS 32 – ELF, TELLUS OIL 32 – SHELL, HYSPIN 32 – CASTROL,

ENERGOL HLP 32 – BP, NUTO H 32 – ESSO). The manufacturer recommends L-

HM32 - Gdańsk Refinery oil.

Remove air from the pump after an oil refill. To do so, set the cutting mode and initiate

the pump with short cycles (2 sec.) until the die servo-motor reaches the extreme

position. Repeat this procedure in case of loud and non-uniform unit operation and

lack of force. Skipping this procedure will prevent obtaining high pressures and in

extreme situations will result in pump seizure.

Maintaining oil purity and periodical oil exchanges has a great effect on the durability

of the hydraulic unit elements and considerably prolongs their performance and

reliability. Required oil purity: class 9 (recommended class 8) according to the NAS

1638 norm.

System tightness, removal of any oil leaks and oil level checks should be carried out

daily when operating the unit.

In case of a unit break-down, switch off electrical power supply and consult a specialist

service representative. Repairs within the guarantee period can only be carried out by

the manufacturer or authorised representatives.

ERKO company reserves the right to technical changes improving/modernizing its products.

18

11. The warranty

1. This warranty covers product repairs on condition that it is operated in

compliance with its instructions’ manual.

2. The guarantee period is 12 months from the purchase date.

3. The manufacturer guarantees full technical support in Poland.

4. Parts and materials which are to be exchanged during the correct usage of

the product (oil, filter inputs etc.) are not under the guarantee. Parts and

materials provided by cooperating companies are guaranteed on their

conditions.

Other repairs will be performed at least 3 days after the date of complaint.

5. This warranty does not concern damages caused by improper usage,

maintenance, transportation and storage of the product.

6. The guarantee will become void if any unauthorised modification is performed

on the product.

7. This guarantee will also be void if the manufacturer’s leaden seals of unit

safety valve are broken.

8. Operational requirements also concern the purity of oil and its adequate

hydraulic level. It always has to be class 9 according to the NAS 1638 norm,

otherwise the guarantee is void.

9. In order to make a complaint it is necessary to deliver the product with the

guarantee card and detailed damage description to the manufacturer or to the

point of sales.

10. The manufacturer is not responsible for damages caused by product’s

defects. Neither these damages repairs nor expenses and lost income return

is under the guarantee.

Purchasing date: Invoice no.: Sales representative

signature:

Dear User,

Thank you for selecting this product and welcome you to the growing

family of our satisfied product owners.

Any remarks or suggestions to our products will be greatly appreciated.

ERKO®, manufacturer

ERKO® has the right to make improvements to the machine construction.

ERKO company reserves the right to technical changes improving/modernizing its products.

19

12. Guarantee certificate

Name/type: Conductor-rail Machining Station SH-400

Manufacture no.

Signature and stamp KJ:

Invoice no.:

Date sold:

Date purchased:

Sales Representative signature:

Sales Representative signature:

13. REPAIR LIST

No. Date of receipt for repair Date of repair

(return)

Repair

remarks

Signature of

serviceman

ERKO company reserves the right to technical changes improving/modernizing its products.

Table of contents