CHESTER Crusader Deluxe Lathe User manual

Contents

1. GENERAL DESCRIPTION OF THE MACHINE

General Description

Basic Technical Data

2. DESCRIPTION OF THE MAIN UNITS

Gearbox

Quadrant

Feed Box

Carriage Group

Thread Indicator

Tail Stock

Rests

3. MACHINE INSTALLATION

Unpacking

Handling

Preparation

Mounting, Foundation and Levelling

Connection to the Electrical Supply

Putting into Operation

4. MACHINE SERVICE

Lubrication

Recommended Lubricants

5. MACHINE OPERATION

Putting into Operation

Cutting of Threads and Feeds

Fretted Parts

6. MECHANISMS ADJUSTMENT

7. SAFETY

8. MACHINE CARE AND MAINTENANCE

9. TRANSMISSION SYSTEM & PARTS

10. BEARING DISTRIBUTION

1. GENERAL DESCRIPTION OF THE MACHINE

1.1General Data

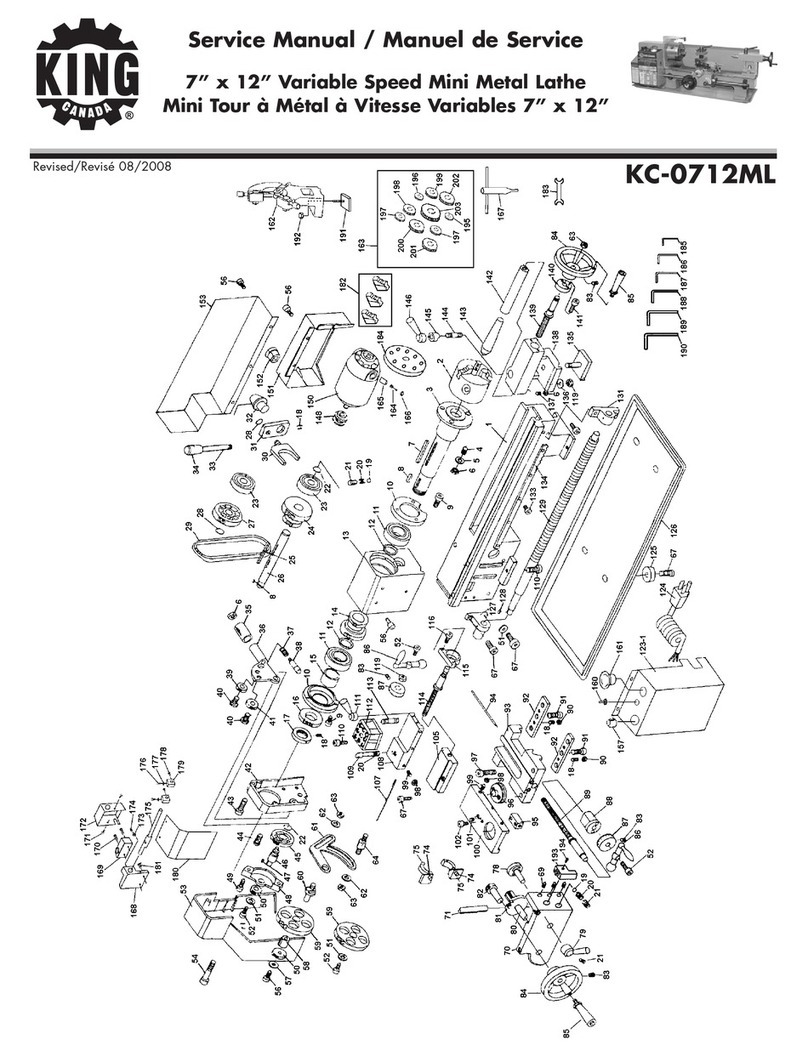

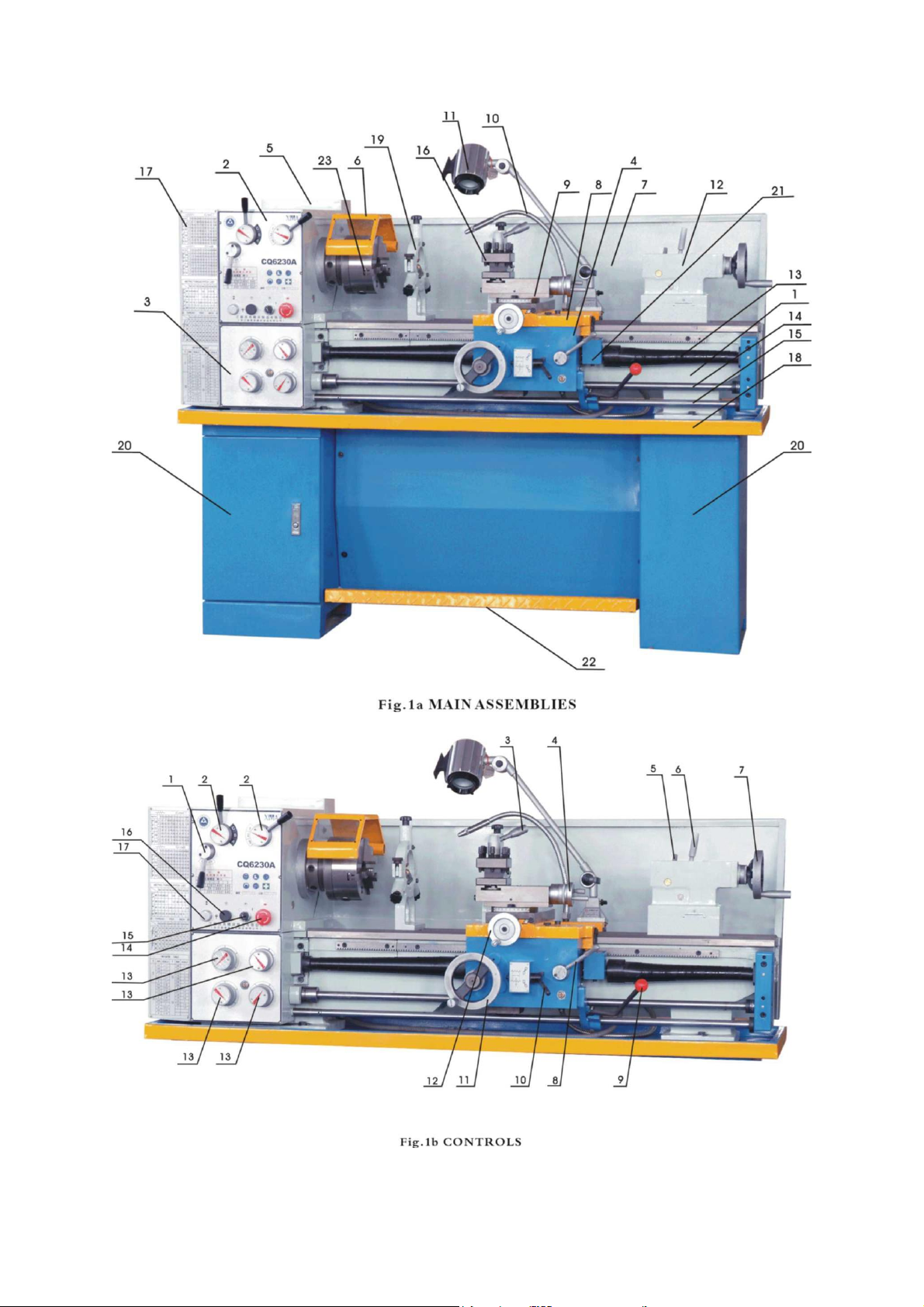

Main Assemblies (see fig 1a)

1. Bed way 13. Lead screw (with guard)

2. Headstock 14. Feed rod

3. Feed box 15. Switch rod

4. Carriage box 16. Tool holder

5. Electrical box 17. Quadrant

6. Chuck protection box 18. Oil tray

7. Splash guard 19. Steady rest

8. Lower carriage 20. Foot stand

9. Top carriage 21. Thread indicator

10.Cooling 22. Foot brake

11.Working Light 23. 3 jaw chuck

12.Tailstock

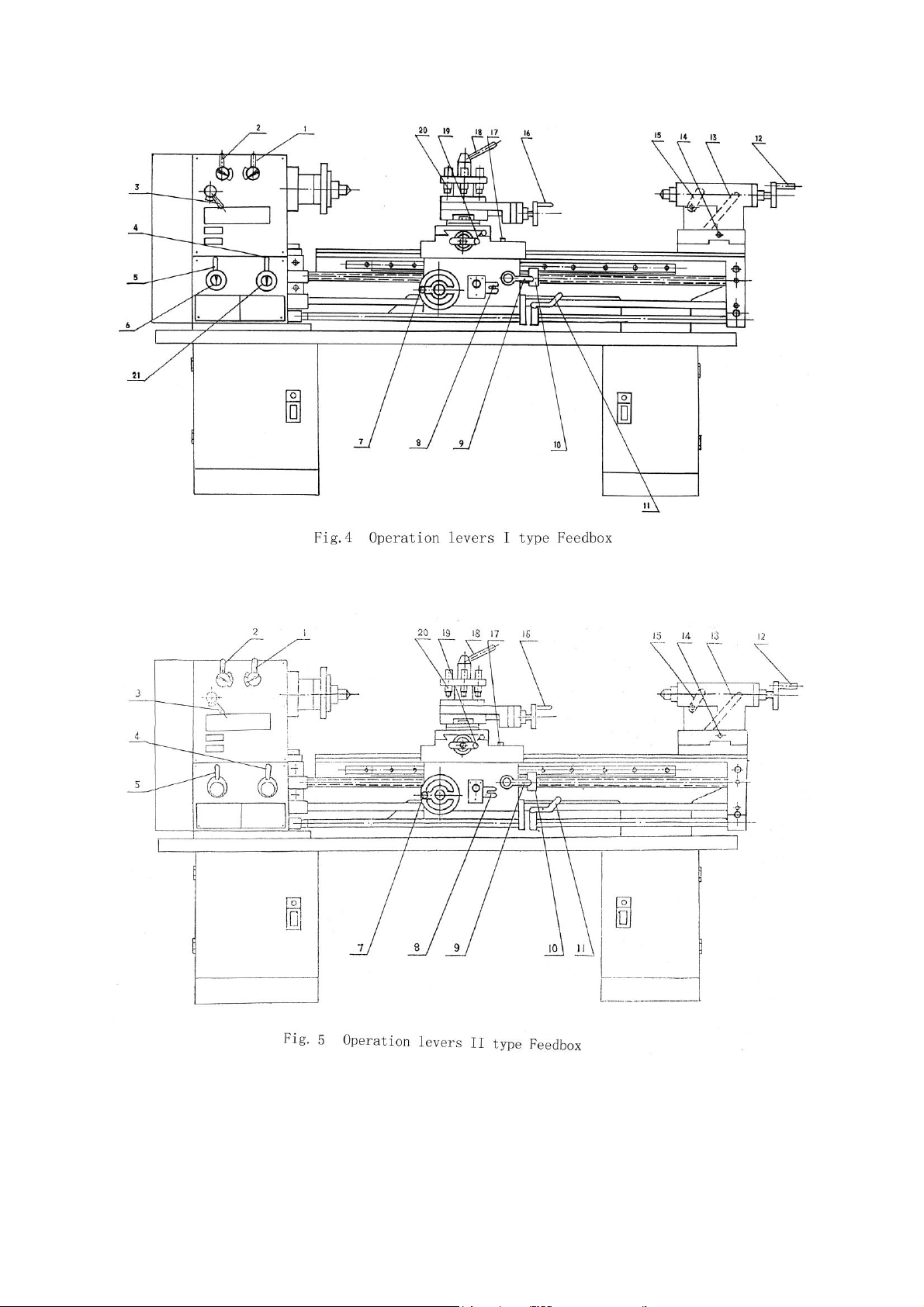

Controls (see fig 1b)

1. Lever for starting, stopping and reversing the carriage feed movement while

threading

2. Lever for spindle speed stages

3. Wrench for the tool holder

4. Flywheel for the shifting the tool holder slide

5. Handle for the tail spindle fixing

6. Handle for the tailstock fixing

7. Flywheel for the tail spindle shifting

8. Handle for the starting and stopping of the carriage longitudinal shifting while

threading

9. Lever for starting the spindle in forward or reverse stroke and its stopping.

When shifted in the forward direction, the spindle will turn counter-clockwise,

and when shifted in the backward direction, the spindle will turn clockwise.

When in the center position, the spindle will stop.

10.Lever starting and stopping the carriage in transverse and longitudinal shifting

11.Flywheel for manual shifting of the carriage in longitudinal direction

12.Flywheel for feeding the cross slide

13.Drum (handle) for selection of “feed” or “thread”

14.Button-emergency stop

15.Switch-coolant pump

16.Button-test bottom for the main electric motor

17.Signal lamp. It glows when the main electric motor is switched on

1.2 Basic Technical Data

Crusader Deluxe Lathe

Max swing over bed

300mm

Max swing over gap

430mm

Max swing over cross slide

180mm

Distance between centers

810mm

Spindle bore

38mm

Range of spindle speed

18 steps: 65-1810rpm

Taper of spindle bore

M.T.5

Taper of tailstock spindle

M.T.3

Max travel of carriage

600mm

Max travel of cross slide

160mm

Max travel of top slide

85mm

Max travel of tailstock spindle

100mm

Motor power

1.1kW

2. DESCRIPTION OF THE MAIN UNITS

Gear Box

The gear box is mounted on the machine corp. The rotation motion to this gear

box is transferred though v-belts and belt pulleys from an electric motor mounted

on the guide way.

Quadrant

The quadrant is designed to transfer the motion from the gear box to the feed box

through the change gears. It is mounted in the quadrant box. The latter is closed

by a cover.

Feed Box

The feed box is foxed to the face side of the machine corp –just below the gear

box. It includes allthe mechanisms, by thehelp of which iseffected the adjustment

for selection of the feed or thread pitches.

Required adjustments for the different values of the feed or thread pitch are

realized by the help of respective drums, located in the front part of the feed box.

Carriage Group and its Mechanisms

The carriage group is designed for fixing and driving the cutting tool. It includes

five basic parts: carriage box, carriage board, lower slide, cross piece and upper

(top) slide.

1. Carriage box

The carriage box ismounted on the carriage board. It contains the mechanisms

that are used for driving the carriage longitudinal and cross feeds, as well as

the mechanism for the engagement of the nut to the lead screw while threading

and the mechanism for manual feed of the carriage.

2. Carriage Board

The carriage board is mounted on the corp guide ways. All the rest parts of the

carriage group are fixed to this carriage board.

3. Lower Slide

The lower slide moves on the guide ways of the carriage board in a transverse

direction. This movement may be effected automatically or manually.

4. Cross Piece

When short cones have to be turned by hand, the cross piece may be swiveled

at 90° towards the lower slide in both directions and be fixed in the required

position by the help of suitable bolts and nuts.

5. Upper (Top) Slide

The top slide on which the four position tool holder is mounted, can be shifted

only by hand in the direction of the cross piece.

Thus you may obtain longitudinal, cross and combined feed for the cutting tool.

Thread Indicator

This device is mounted to the carriage box (disengaged to the driving screw) for

getting into the thread pitch.

Tail Stock

The tail stock is clamped to the corp guide ways. It is designed for working piece

clamping during machining between centers for drilling operations with manual

feed of the tool.

Rests

In response to the special request of the client, the lathe may be packed

additionally with a steady and a follow rest.

The two types are with sliding quills. The steady rest is fixed to the corp guide

ways and the follow rest to the carriage board.

3. MACHINE INSTALLATION

Unpacking

After the machine has been unpacked, check carefully its general condition as well

as the condition of all the accessories.

Handling

The unpacked machine shall be moved onlyby the help of a suitable crane. Before

passing the ropes over the specified places, see fig 2, pull out the tail stock and

carriage and fix them in the rear hand position so that when lifting the machine you

will obtain the required balance. When moving the machine, never strike or hit it

sharply as this may affect the machines accuracy irrespective of whether or not

there is any visible defects.

Since the paint on some parts of the machine maybe damaged duringthis process,

place protective pads of fabric or other suitable material on the respective places.

Preparation

Before placing the machine in the predetermined position, clean it carefully from

the protective oil. The machine surfaces should be cleaned with pure naphtha or

benzine.

Do not use hard objects or any solvent that could damage the metal surfaces or

the paint of the machine. Use dry cloths to dry any damp surfaces of the machine

and coat with machine oil to help protect the clean surfaces. Remove the end gear

cover and clean all components of the end gear assembly and coat all the gears

with heavy non-slinging grease.

Mounting, Foundations and Levelling

To obtain accurate, durable and trouble-free operation of the machine, mount it

only on a suitable foundation and level the machine carefully. The foundation is to

be prepared in advance with concrete with a thickness from 200 to 300mm

according to the soil type.

The unpacked machine is lifted by crane according to the specified method and

after the anchor and leveling bolts are in place, lower the machine onto the

foundation so that anchor bolts enter into the respective holes in the machine base.

The guide way should be checked horizontally in the longitudinal and transverse

direction towards the machine axis by the help of a spirit level with an accuracy of

+/- 0.02/1000mm and +/- 0.04/1000mm. After this initial levelling has been carried

out, pout cement putty into the space below the machine legs around the anchor

bolts.

After the cement has set (3-4 days), tighten the nuts of the anchor bolts carefully

and evenly. Check the machines level again and if necessary correct using the

leveling bolts.

Connection to the Electrical Supply

Check that the data on the electrical panel scheme (voltage and frequency of the

supply source) correspond to the power supply available.

The controlling level should remain in the middle and also press the power switch

down to keep the machine switched off.

Make sure that the machine is properly grounded.

Putting into Operation

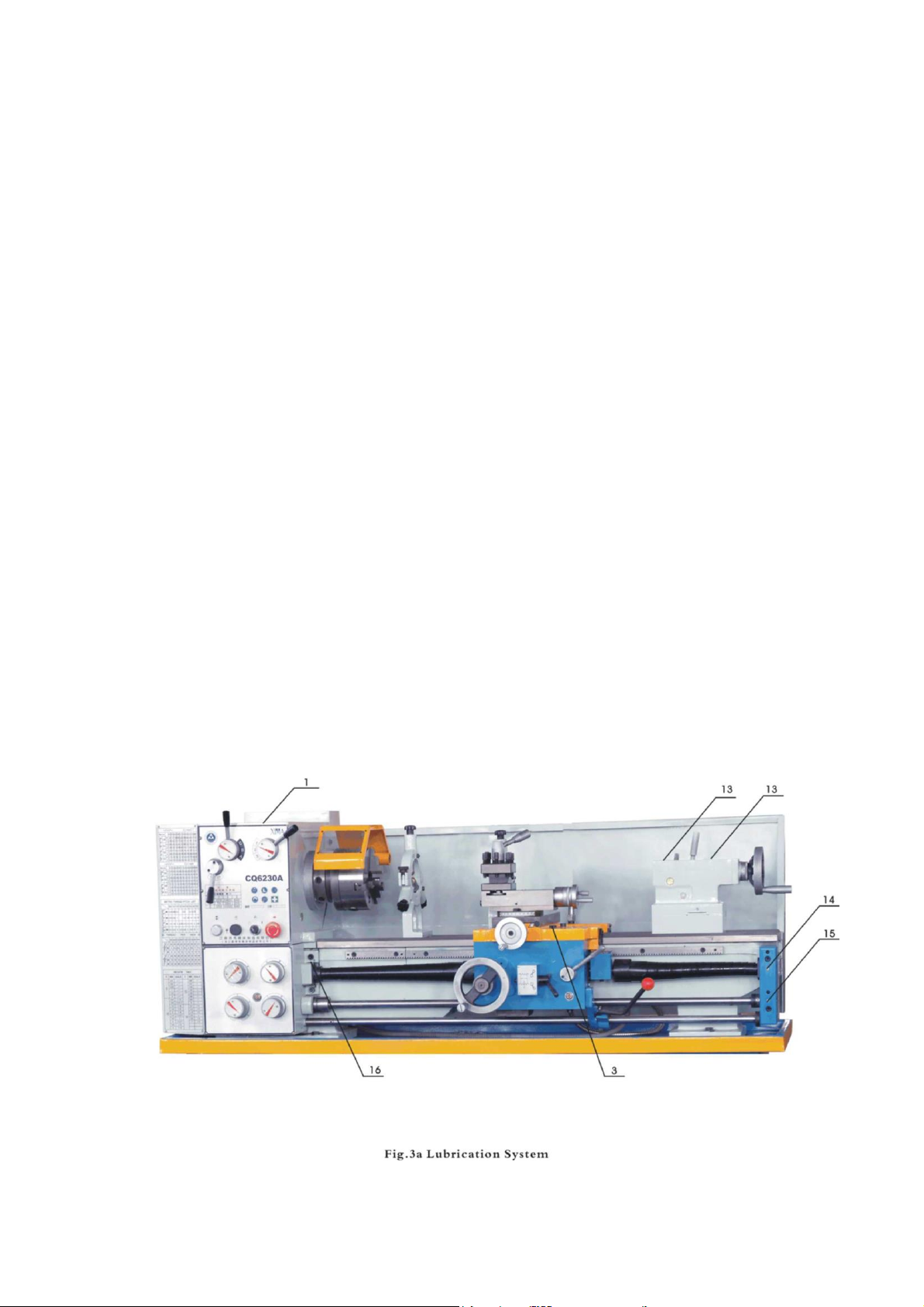

Before starting the machine, clean it once again and lubricate according to the

diagram, see fig 3a, 3b and 3c.

Check the V-belt from the motor to the gear box and make sure that it is not too

tight or too loose. If the belt is too tight, it could damage the bearings, if the belt is

too loose, it will slip. Adjust must be adjusted to the correct tension.

Starting is effected in the following order:

Check manually the movements of all the components. It should be smooth.

Check all the controls are operating correctly.

Fill the tank of the coolant system with the specified coolant (optional accessory

order separately). Switch on the main electric motor.

After one hour check the oil levels in the tanks and, if necessary, add the oil

quantity required.

After two shifts of operation, check the V-belts for excessive play.

4. MACHINE SERVICE

Lubricant

The trouble-free operation of the lathe depends on careful servicing, especially the

regular lubrication of all machine operating parts with the recommended lubricants,

see fig 3a, 3b and 3c.

The headstock is lubricated by the splashing of oil. The oil may be poured into

headstock after the removal of the cap (1) from the oil vent with the oil filler located in

the headstock cover. The oil is drained by unscrewing the plug (1-1) to the oil draining

tube. If the oil has be replaced, clean the headstock with pure naphtha carefully.

When refilling with new, the level must be to the middle of the oil sight glass. The disk

couplers and the main spindle front bearing are lubricated by an oil collecting groove.

The feed box is lubricated through a hole (2) located on its left hand side. The oil

quantity required must reach the middle of the sight glass. The oil is drained through

the plug (2-2).

The change gear sleeve for the quadrant should be lubricated with grease once per

day with a suitable oiler. The change gears should be lubricated with oil once per day.

The carriage box is lubricated through a common hole (3) where the oil is fed into a

tank which is common for the whole box. Using suitable grooves, the oil is fed to the

respective bearing as a portion of the oil drops on the bottom of the box from where

the gears are oiled. The oil is drained from a plug (3-3).

The carriage as well as the slide guiding surfaces are lubricated by the help of suitable

oilers (6) pressed into the carriage and cross slider (8). The electric motor bearing

should be cleaned and greased once every six months. All the friction surfaces of the

carriage, travelling stock and conic lineal should be oiled by the help of an oil holder

or oiler according to the lubrication system.

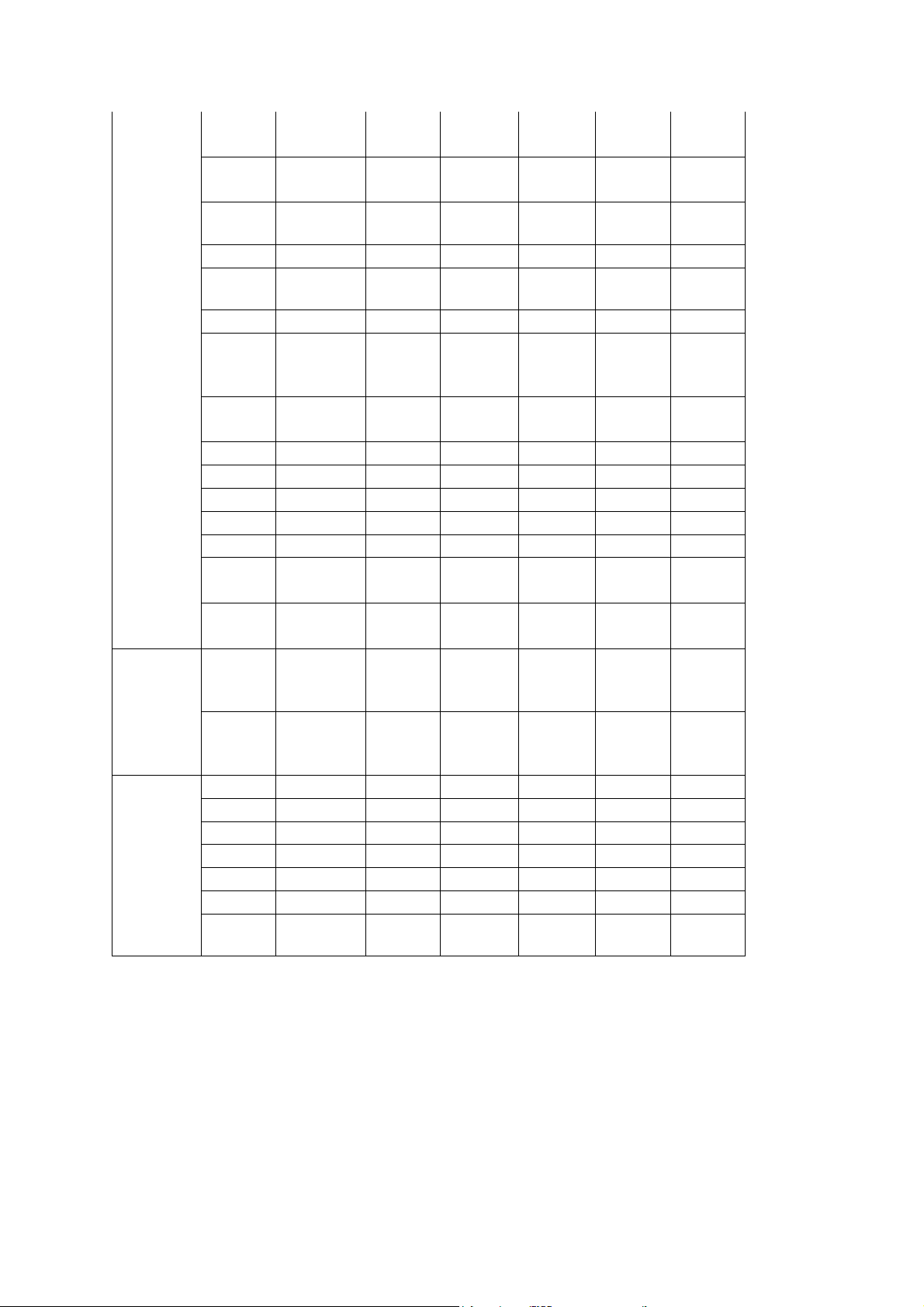

Recommended Lubricants

Assembly

Lubricating

point

Lubricating

Method

Lubricant

Lubricating

Interval

Headstock

Gears and

bearing,

Spindle fron

bearing,

Spindle rear

bearing, Belt

pulley bearing

Oil bath - by

splashing

Machine

Oil

Oil replacement:

1st time - after

10 days of

operation, 2nd

time - after 20

days of

operation, next

time - once per

each 60 days

Feed box

Gears, bearings

and all the

mechanisms

Oil bath - by

splashing

Machine

Oil

Carriage

Gears, bearings

and all the

mechanisms

Oil bath - by

splashing

Machine

Oil

Quadrant

Change gears,

Quadrant idle

axel

By Hand

Machine

Oil, Grease

"L"

Once per shift

Carriage

slide

Corp bed ways,

Slide bed ways

By Hand with

help of oilers

Machine

Oil

Once per shift

Cross

carriage

Support of the

screw in the

slide. Cross

screw for

carriage

By Hand oil tank,

located in the

carriage

Machine

Oil

Once per shift

Cross

shaped

carriage

Carriage bed

ways. Cross

shaped carriage

bed ways,

Screw of the

cross shaped

carriage, Tool

holder

By Hand

Machine

Oil

Once per shift

Tailstock

Screw support

Quill

By Hand

Machine

Oil

Once per shift

Console

Lead screw

bearing, feed

rod bearing,

switch rod

bearing

By Hand

Machine

Oil

Once per shift

5. MACHINE OPERATION

Putting into Operation

After performing the previous instruction, the machine is ready for operation, the

connection to the electric supply is effected by the help of the main interrupter.

Turning on the control lamp shows that the machine is connected to the power

supply.

All the speeds within the range 65-1810rpm at different position of the levers are

shown on the nameplate.

When starting the machine, check that all the gears are engaged, this is obtained

by placing the handles at their fixed positions.

The change-over of the gears shall be effected only under idling conditions.

The machine operating mode selection shall be realized from the speed indication

nameplate. When trying the machine, put the speed change lever in low speed

stage and keep the machine running for at least 20 minutes, the gradually change

the speed of the spindle up to the fasted. Every stage running over 5 minutes.

Cutting of Threads and Feeds

The feed box receives it motion from shaft V of the gearbox through a set of change

gears. If the handle (3), see fig 4, 5 and 6, is placed in its right hand position, the

lathe is set for cutting of right hand thread. If the same handle is placed in its left

hand position, the lathe is set for cutting of a left hand thread.

It is not required to place on the quadrant respective change gear set in order to

prepare the lathe for the necessary feed.

The different values for the feeds and threads are obtained by the different setting

of the quadrant and changing the position of drums/handle 4, 5, 6, 21 and handle

3.

All the quadrant setting and drums/handles different positions are shown on the

nameplate for threads and feeds.

Adjust the nut gap on the carriage, see fig 7.

Rotate the nut (1) to the satisfied saddle motion and required travel.

Chuck and faceplate mounting, see fig 8.

The connection between the spindle and the chuck or faceplate is made by a D-

Cam lock structure. When mounting, put the three pull pins of the chuck or

faceplate into the three holes on the spindle face end, then turn the three cams

with the aid of a square head wrench. When turning thecams clockwise, the chuck

will be locked, when turning the cams counter-clockwise to a certain point, the

chuck can be detached.

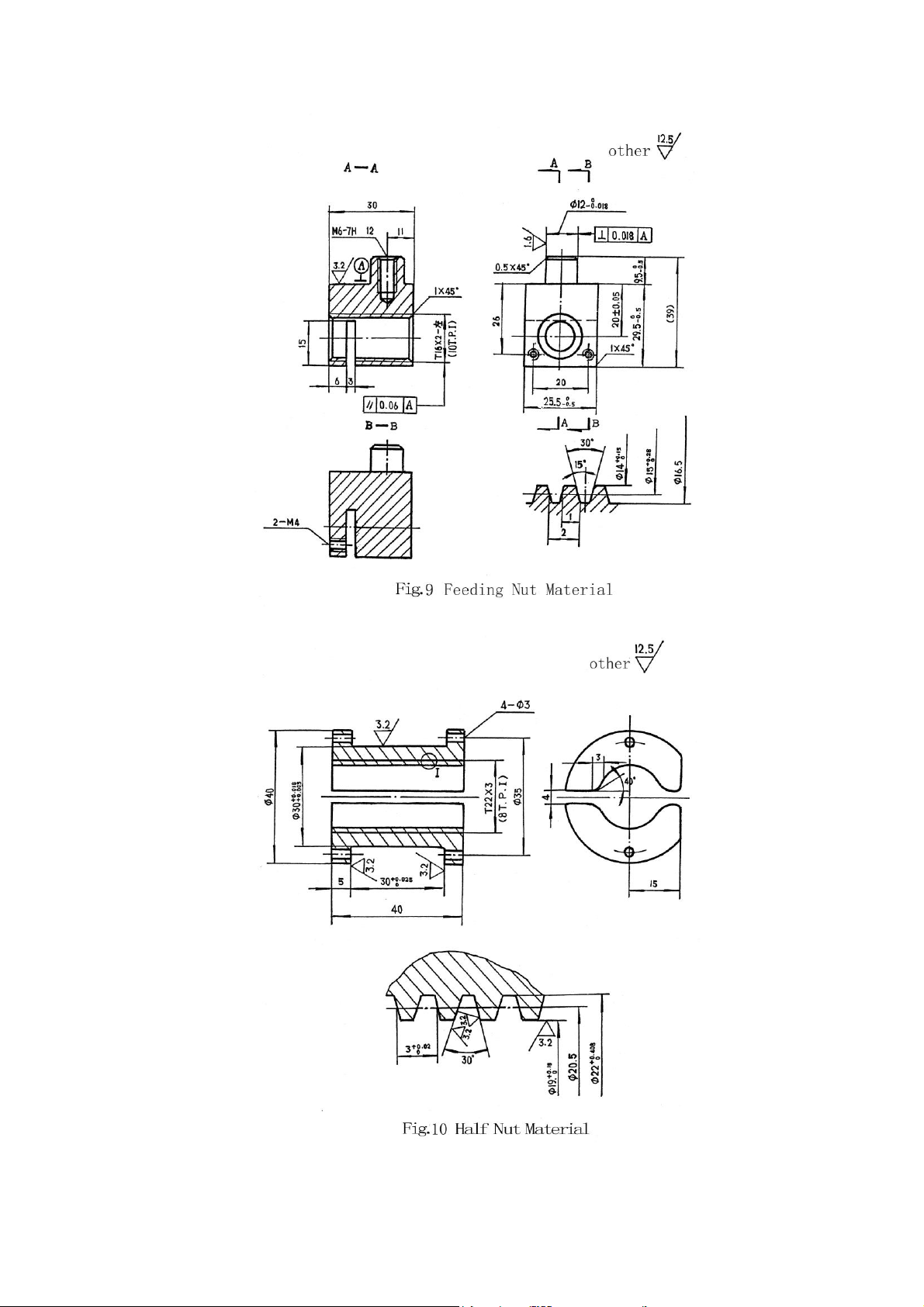

Fretted Parts

No.

Name

Material

Mount

Note

1

Feeding Nut

ZQSn6-6-3

1

CQ6230-5104

2

Half Nut

ZQSn6-6-3

1

CQ6230-4003

6. MECHANISMS ADJUSTMENT

After a period of time, some of the mechanisms will require readjustment because

of the effect of wear and tear on the friction surfaces. The adjustment and setting

of the different mechanisms shall be effected after each repair. It is recommended

that these adjustments are performed by a qualified specialist.

7. Safety

All lathe operators must be constantly aware of the safety hazards that are

associated with using the lathe and must know all the safety procedures to help

avoid accidents and injuries.

Please follow the following safety precautions:

1. Remove loose clothing and jewelry, tie back long hair and roll sleeves up above

the elbow. Do not operate whilst wearing gloves

2. Always stop the lathe before making adjustments.

3. Do not change the spindle speeds until the lathe has come to a complete stop.

4. Handle sharp cutters, centers and drills with care.

5. Remove chuck keys and wrenches before operating the machine.

6. Always wear protective eye protection.

7. Handle the chuck with care and protect the lathe guide ways with a block of

wood before replacing or installing the chuck.

8. Make sure you know where the emergency stop button is before operating the

machine.

9. Use pliers or a brush to remove chips and swarf, never use your hands.

10.Do not lean on the machine.

11.Never lay tools directly on the guide ways.

12.Keep tool overhang as short as possible.

13.Never attempt to measure work whilst the machine is running.

14.Never file lathe work unless the file has a handle.

15.Do not over reach. Maintain a balanced stance at all times so that you do not

fall or lean against blades or other moving parts.

16.Provide adequate light around the machine and keep the perimeter around the

machine dry, clean and in good order. In addition, do not place anything near

the machine; otherwise it becomes an obstacle during operation.

17.Keep machine guards in place at all times when the machine is in use. If

removed for maintenance purposes, use extreme caution and replace the

guards immediately.

18.Keep the floor around the machine clean and free of scrap material, oil and

grease.

19.Always use identical replacement parts when servicing.

8. MACHINE CARE AND MAINTENANCE

Lathes are a highly accurate machine tool designed to operate around the clock is

properly operated and maintained. Lathes must be lubricated and checked for

adjustment before operation. Improper lubrication or loose nuts and bolts can

cause excessive wear and dangerous operating conditions.

1. The lathe ways are precision ground surfaces and must not be used as a table

for other tools and should be kept clean of grit and dirt.

2. The lead screw and gears should be checked frequently for any metal chips

that could be lodged in the gearing mechanisms.

3. Check the lathe prior to operation for any missing parts or broken shear pins.

Refer to the manual before attempting to lift the lathe.

4. Newly installed machines should be properly leveled before operation to

prevent vibration or wobble.

5. When the lathe is transported out of a normal shop environment, it should be

protected from dust, excessive heat and very cold conditions.

6. Change the lubricant frequently if working in dusty conditions.

7. In hot working areas, use care to avoid overheating the motor or damaging any

seals.

8. Operate the lathe at slower speeds than normal when working in cold

environment.

9. Lubricate all slide ways lightly before using the machine daily. The change

gears and lead screws must be lightly lubricated with lithium base grease.

10.During the operation, the chips which fall on to the sliding surface should be

cleared in a timelyfashion, an inspection should be made often to prevent chips

falling between the machine tool saddle and the lathe bed guide way. Asphalt

felt should be cleaned a certain interval.

11.After the operation every day, eliminate all the chips and clean the different

parts of the machine and apply machine tool oil to prevent rusting.

12.In order to maintain the machine accuracy, take care of the center, the surface

of the machine tool for the chuck and the guide way and avoid mechanical

damage and wear due to improper operation.

13.If damage is found, maintenance must be carried out immediately.

ATTENTION: Before performing any inspection, repair or maintenance operation,

switch off the main power supply to the machine and make an additional check to

ensure that the machine is not under voltage.

Oil, grease and cleaning are pollutants and must not be disposed of through the

drains or in normal refuse. Dispose of these agents in accordance with current

legal requirements on the environment. Cleaning rags impregnated with oil,

grease and cleaning agents are easily inflammable. Collect cleaning rags or

cleaning wool in a suitable closed vessel and dispose of them in an environmentally

sound way –DO NOT put them with normal refuse.

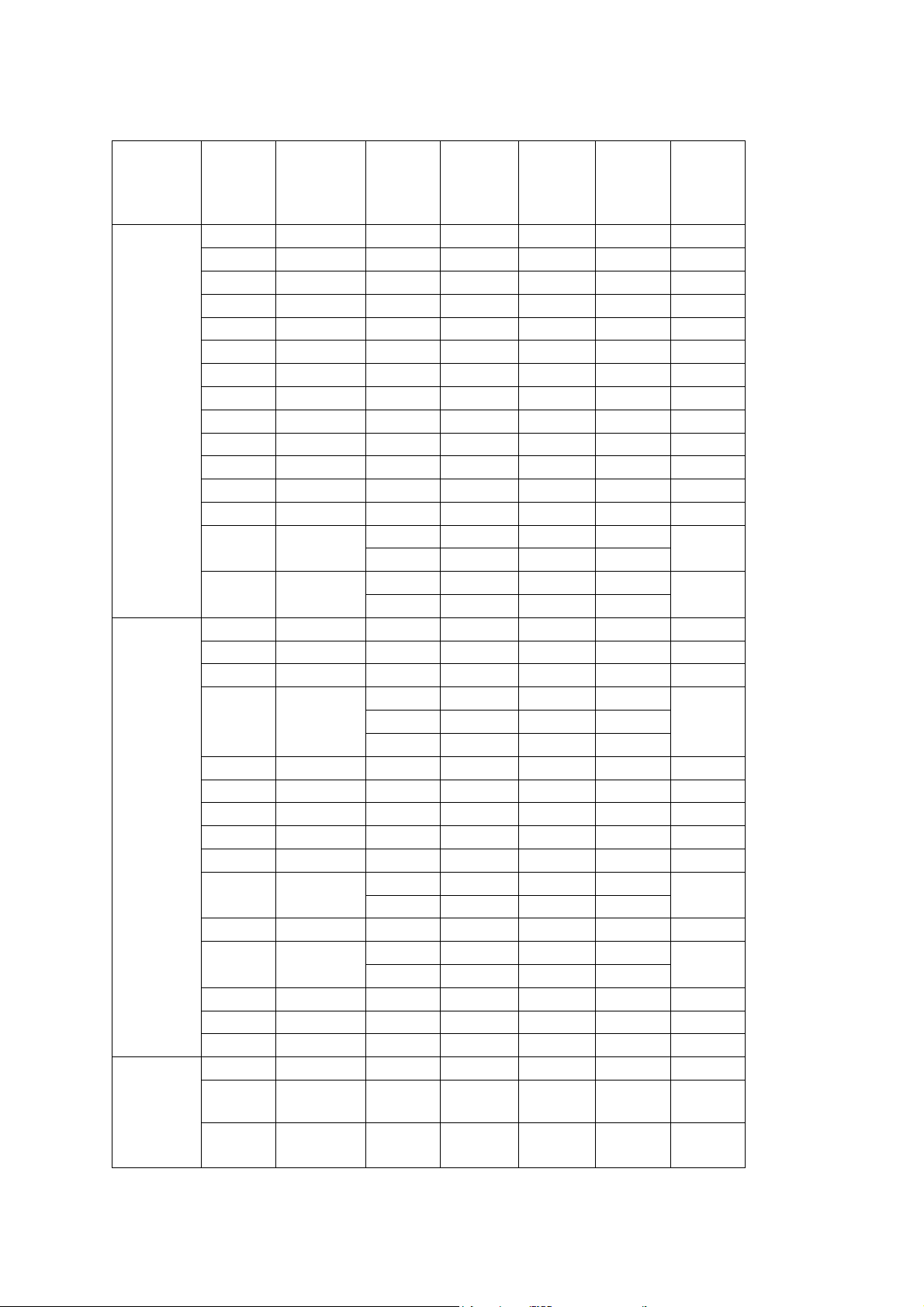

9. Transmission System & Parts

Parts

Parts

No.

Kinds

No. of

teeth

on

thread

Modulus

of pitch

Pressure

angle

Material

Notes

Headstock

1

Gear

42

M2

20°

45

2013

2

Gear

23

M2

20°

45

2018

3

Gear

47

M2

20°

45

2019

4

Gear

36

M2

20°

45

2021

5

Gear

55

M2

20°

45

2020

6

Gear

31

M2

20°

45

2022

7

Gear

45

M2

20°

45

2016

8

Gear

58

M2

20°

45

2015

9

Gear

21

M2

20°

45

2017

10

Gear

45

M2

20°

45

2008

11

Gear

59

M2

20°

45

2029

12

Gear

46

M2

20°

45

2030

13

Gear

83

M2

20°

45

2031

14

Paired

Gear

45

M2

20°

45

2026

40

M2

20°

45

15

Gear

40

M2

20°

45

2032

45

M2

20°

45

Feed Box

16

Gear

24

M2.25

20°

45

3029B

17

Gear

16

M2.25

20°

45

3031B

18

Gear

18

M2.25

20°

45

3032B

19

Triplicated

Gear

18

M2.25

20°

45

3005B

18

M2.25

20°

45

18

M2.25

20°

45

20

Gear

20

M2.25

20°

45

3003B

21

Gear

28

M2.25

20°

45

3002B

22

Gear

27

M2.25

20°

45

3027C

23

Gear

21

M2.25

20°

45

3025C

24

Gear

21

M2.25

20°

45

3018C

25

Paired

Gear

18

M2.25

20°

45

3026C

30

M2.25

20°

45

26

Gear

22

M2.25

20°

45

3007C

27

Paired

Gear

15

M2.25

20°

45

3006C

22

M2.25

20°

45

28

Gear

23

M2.25

20°

45

3009B

29

Gear

17

M2.25

20°

45

3016C

30

Gear

15

M2.25

20°

45

3014C

Apron

31

Gear

11

M2.25

20°

45

4028

32

Rack

M2.25

29° or

30°

45

33

Lead

Screw

Single

Thread

8TPI or

3mm

45

34

Halfnut

Single

Thread

MS2

20°

ZQSn6-

6-3

35

Worm

Single

Thread

MS2

20°

45

36

Worm

Gear

24

M2

20°

ZQSn6-

6-3

4017

37

Gear

15

M2

20°

45

4030

38

Gear

50

M2

20°

ZQSn6-

6-3

4029

39

Gear

25

M2

20°

45

4014

40

Nut

Single

Thread

10TPL or

2mm

ZQSn6-

6-3

Left

Hand

Thread

41

Screw

Single

Thread

10TPL or

2mm

45

42

Gear

14

M2

20°

45

4019

43

Gear

51

M2

20°

45

4013

44

Gear

43

M2

20°

45

5127

45

Gear

25

M2

20°

45

4010

46

Gear

48

M2

20°

45

4012

47

Screw

Single

Thread

10TPL or

2mm

45

48

Nut

Single

Thread

10TPL or

2mm

ZQSn6-

6-3

Tailstock

49

Rod Screw

Single

Thread

10TPL or

2mm

45

Left

Hand

Thread

50

Nut

Single

Thread

10TPL or

2mm

ZQSn6-

6-3

Left

Hand

Thread

Change

Gear

Gear

22

M1.25

20°

3076C

Gear

24

M1.25

20°

45

2002C

Gear

26

M1.25

20°

45

3075C

Gear

44

M1.25

20°

45

3077C

Gear

48

M1.25

20°

45

3039C

Gear

52

M1.25

20°

45

3039C

Paired

Gear

127

(120)

M1.25

20°

45

3078C

Table of contents

Other CHESTER Lathe manuals

CHESTER

CHESTER DB8VS User manual

CHESTER

CHESTER 920 User manual

CHESTER

CHESTER Cobra Mill User manual

CHESTER

CHESTER Crusader User manual

CHESTER

CHESTER CONQUEST SUPER LATHE User manual

CHESTER

CHESTER DB7VS User manual

CHESTER

CHESTER Craftsman User manual

CHESTER

CHESTER Centurion Series User manual

CHESTER

CHESTER Crusader VS User manual

CHESTER

CHESTER CONQUEST SUPER User manual