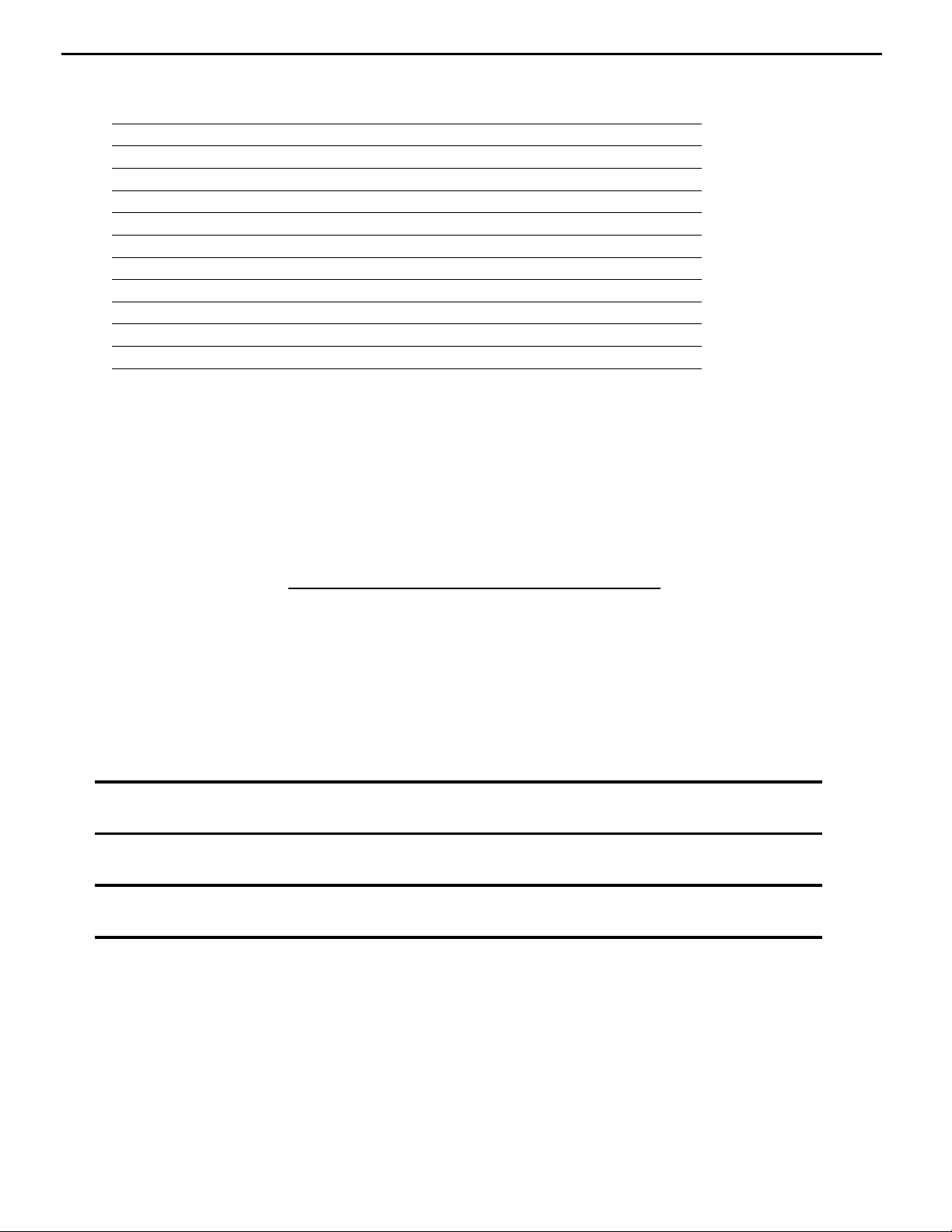

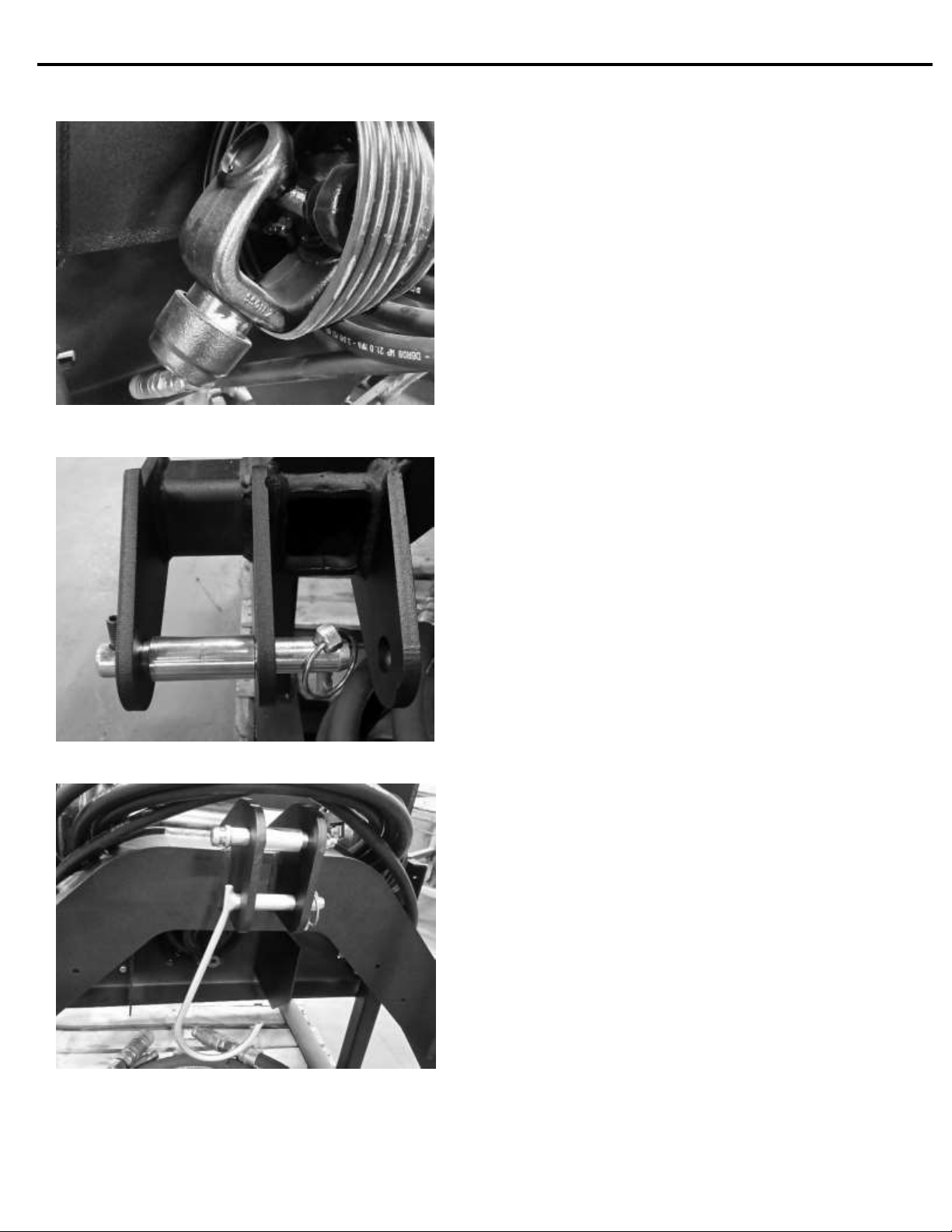

1. Mount the tank to the tractor 3-point arms

(Category II orIII). Be sure to installthe lynch pins

to secure the tank to the tractor.

2. Slide the driveline fully onto the tractor PTO shaft.

Make sure the locking collar is engaged. If the

tractor PTO shield interferes with the installation,

the shield may need to be removed or rotated up.

Always reinstall the PTO shaft

shield when the PTO pump is not connected to

the tractor. See the tractor’s operator’s

manual for instructions.

3. Check to make sure the driveline has enough

overlap and does not bottom out through the

entire range of movement of the 3-point arms. If

the driveline is too short or too long, the 3-point

mount frame can be moved fore or aft by unbolting

and sliding it. There are three different positions

available, each 2” apart.

NOTE: It may be necessary to reposition or

remove the drawbar to prevent interference with

the driveline. See the tractor’s operator’s manual

for instructions.

4. Route the lead hoses over the rear axle, underthe

tractor cab, and along the loader arms. Use

plastic cable ties to mount the hoses to the tractor

frame and loader arms.

IMPORTANT: Be sure to route the hoses near

the loader pivot points to prevent the hoses from

being stretched when the loader is raised.

NOTE: Make sure the hoses are properly routed

to fit your specific tractor. If the hoses are not

routed correctly, they may get pinched, stretched,

pulled off, or rub on tires. Be sure to check hose

routing through the full range of motion of the

loader and attachment before operating. More

than one routing may beacceptable depending on

the tractor. Use the routing that best fits your

tractor.

NOTE: Proper hose routing is the responsibility

of the owner and/or operator. Pinched, rubbed, or

stretched hoses are not covered under warranty.