Ersted RI-407 User manual

TIME DOMAIN REFLECTOMETER

Model: RI-407

USER MANUAL

Saint-Petersburg

2016 г.

Safety Information

Implemented Measurement Methods

Time Domain Reflectometer RI-407 User Manual Page 2 of 67

Safety Information

ATTENTION!

Before you start please check out the User Manual carefully

DANGER: - High Voltage!

The device should only be used by a

qualified personnel

The operator of the device must comply with all safety precautions listed in this User Manual

in order to ensure own safety and the safety of other people in the work area immediate vicinity.

Mishandling can result in serious injury or death.

The device has an open inputs.

When you connect the RI-407, make sure that there is no

voltage on the line.

Software User Manual to communicate RI-407 with the PC can be found on the CD.

Designations and Contractions

Implemented Measurement Methods

Time Domain Reflectometer RI-407 User Manual Page 3 of 67

1. Designations and Contractions

HVPG - high-voltage pulse generator

PF – Propagation Factor

HVL - High-voltage testing laboratory

PC – personal computer

UM – User Manual

TC – technical conditions

MC – measuring channel

MEC – memory channel

Introduction

Implemented Measurement Methods

Time Domain Reflectometer RI-407 User Manual Page 4 of 67

2. Introduction

This UM is a document certifying guaranteed by the manufacturer the basic parameters and

technical characteristics of the time domain reflectometer RI-407 (hereinafter the RI-407).

UM is intended for acquaintance with the RI-407 device and the principle of operation and

sets the operating rules, compliance with which maintains the device in constant readiness for action.

Persons with secondary technical education are admitted to work with the device, with

experience in electrical appliances for general purposes.

Application Area

Implemented Measurement Methods

Time Domain Reflectometer RI-407 User Manual Page 5 of 67

3. Application Area

RI-407 is intended for the following measurements on balanced and unbalanced cables:

cable length measurement and cable continuity tests;

measurement of the distance to the heterogeneity of the cable impedance or low-resistance fault,

using the pulse (TDR) method;

measurement of the distance to the high-resistance fault, using the Arc Reflection Method (ARM)

in complex with the high-voltage pulse generator (HVPG) (Arc Discharge Generator ADG-200

or similar generator from the high-voltage test laboratory);

measurement of the distance to the high resistivity fault, using the Impulse Current Method

(ICM) or Decay Method in complex with the high-voltage pulse generator (HVPG) (Arc

Discharge Generator ADG-200 or similar generator from the high-voltage test laboratory);

measurement of the velocity factor of the line at a known length;

determination of fault’s nature;

recording into internal storage and playback of at least 300 waveforms for subsequent processing

in stationary conditions;

Specifications and Characteristics

Implemented Measurement Methods

Time Domain Reflectometer RI-407 User Manual Page 6 of 67

4. Specifications and Characteristics

Measurement results are displayed on the color TFT screen with a resolution of 640 x 480

pixels.

Distance measuring range (time delay) from 0 to 128000 m (from 0 to 1280 µs).

Measuring sub-ranges:

0 – 62,5 m (0 – 0,625 µs); 0 – 125 m (0 – 1,25 µs); 0 - 250 m (0 – 2,5 µs);

0 - 500 m (0 -5 µs); 0 - 1000 m (0 - 10 µs); 0 - 2000 m (0 - 20 µs);

0 - 4000 m (0 - 40 µs); 0 - 8000 m (0 - 80 µs); 0 - 16000 m (0 - 160 µs);

0 - 32000 m (0 - 320 µs); 0 - 64000 m (0 - 640 µs), 0 - 128000 m (0 - 1280 µs).

Measurement permissible relative error of the distance (time delay) in the normal range of

temperatures from 15 °C to 25 °C are ± 0.2% of the sub-range value.

Measurement permissible relative error of the distance (time delay) in the operating range of

temperatures from -20 to 15 °С and from 25 to 40 °С are ± 0,4 % of the sub- range value.

Probing pulse parameters with positive polarity are shown in Table 2-1.

Table 2-1

Probing pulse

parameters

Pulse

10 ns

20 ns

50 ns

100 ns

200 ns

500 ns

1 µs

2 µs

5 µs

10 µs

20 µs

50 µs

100 µs

τи, µs

≤ 0,01

≤ 0,02

≤ 0,05

0,1 ±

0,01

0,2 ±

0,02

0,5 ±

0,05

1,0 ±

0,01

2 ±

0,2

5 ±

0,5

10 ±

1,0

20 ±

2,0

50 ±

5,0

100 ±

10,0

Τн, ns,

no more than

10

10

15

15

20

20

25

30

30

30

30

30

30

U1, В, not less than

9,0

9,0

9,0

9,0

9,0

9,0

9,0

9,0

9,0

9,0

9,0

9,0

9,0

U2, В, not less than

*

43,0

43,0

43,0

43,0

43,0

43,0

43,0

43,0

43,0

43,0

43,0

*

* Note: The parameters of the probe pulse in U2 mode, with durations 10 ns and 100 µs are not

standardized.

Measurement relative error of the Propagation Factor (PF) ± 0,4% in the range of PF value

from 1.000 to 3.000.

Receiver sensitivity in all sub-bands of at least 10 mV (provided that signal level is twice

noise level)

Asynchronous noise suppression - averaging 1 to 64.

Non-volatile memory capacity - traces of at least 300, at least 500 velocity factors.

Measuring input impedance TDR - 75 ohms (fixed).

Operation mode setup time less than 15 seconds.

Specifications and Characteristics

Implemented Measurement Methods

Time Domain Reflectometer RI-407 User Manual Page 7 of 67

Continuous running RI-407 from the battery ACC1 at least 6 hours (or at least 10 hours from

the battery ACC2) and depends on the condition of the battery. Continuous running via AC

adapter is not limited.

Maximum electric power consumed by the RI-407 while charging the battery, not more than

40 W.

Overall dimensions of the RI-407 is not more than:

length - 363 mm

width - 295 mm

height - 170 mm

Weight of RI-407 with built-in battery no more than 3.5 kg

RI-407 is a compact device designed to work in indoor and outdoor conditions. RI-407 meets

climatic conditions Group 4 GOST 22261:

operating temperature range from -20 to 40 °C;

relative humidity 98%, at 25 °C;

transportation and storage conditions from -50 to 50 °C.

RI-407 is stable and resistant to the sinusoidal vibration in frequency range from 10 Hz to 55

Hz. RI-407 meets conditions Group 4 GOST 22261.

RI-407 is powered by the built-in Li-Ion battery (7,2 ± 0,7)V 7,0A. The design of the RI-407

provides control of battery discharge and automatic device shut down in 2, 4, 8, 32 or 64

minutes of idle time.

RI-407 does not emit toxic gases and audio noise.

Reliability:

MTBF - at least 6000 hours.

Service life - at least 5 years.

Delivery Contents

Implemented Measurement Methods

Time Domain Reflectometer RI-407 User Manual Page 8 of 67

5. Delivery Contents

The set of RI-407 includes:

Quantity

Time Domain Reflectometer RI-407 (tech. spec. 4221-009-23133821-15)

1 item

AC Adapter 12 V

1 item

Connecting cable 75 Ohm, 3 m, BNC.M - «Alligator» with a working width

of 25.4 mm

1 item

Connecting cable 75 Ohm, 1 m, BNC.M-BNC.M

2 items

User Manual (tech. spec. 4221-009-23133821-15)

1 item

CD-ROM with software

1 item

Accessories bag

1 item

Design And Implemented Measurement Methods

Implemented Measurement Methods

Time Domain Reflectometer RI-407 User Manual Page 9 of 67

6. Design And Implemented Measurement Methods

6.1. Implemented Measurement Methods

6.1.1. Time Domain Reflectometry (TDR) Method

The instrument uses a Time Domain Reflectometry method (TDR), which is based on the

phenomenon of a partial reflection of electromagnetic waves by the impedance irregularities in the

line. When applying the TDR method a rectangular probe pulse generated by the pulse generator is

sent into the line. Probe pulse propagating through the cable line, completely or partly reflected from

the fault area in the line (impedance irregularities) and returns to the receiver input. Reflection

waveform is observed on the screen and allows to determine the type of the fault (see Table 6-2) and

the distance to it. The reflected pulses are returned to the device after a certain time from the moment

of sending the probe pulse.

Knowing the speed of electromagnetic wave propagation along the line, and the time delay of

the reflected signal (measured by the device), we can calculate the distance to the impedance

irregularity.

here,

L – Distance to the impedance irregularity, m.

v – Propagation speed of electromagnetic wave in the line, m/µs;

PF – Propagation Factor, c/v

VoP – Velocity of Propagation , (v/c)*100%

td – Measured time delay of the reflected signal, µs;

с – Speed of light is equal to 299,8 m/µs;

Impedance irregularities are the result of violations manufacturing technology of cables as

well as a consequence of mechanical and electrical hazards during the construction and operation of

the cable lines. Any cable device (couple, split, joint, Pupin coil, etc.) cause irregularity of the line

impedance.

21002

1

2ddd t

VoP

c

t

PF

c

t

L

Design And Implemented Measurement Methods

Implemented Measurement Methods

Time Domain Reflectometer RI-407 User Manual Page 10 of 67

The impedance irregularities may be caused by any cable devices (couple, joint, Pupin coil,

etc.) or faults (open, short, partial open, partial shot, wetting core of the cable, leaks to the ground,

split pairs, etc.). TDR method allows to fix multiple irregularities both lumped and lengthy,

depending on the ratio of their length and the minimal wavelength of the spectrum of the probe

pulse.

The instrument generate a probe pulse with positive polarity amplitude is not less than 10V

(U1 mode), or not less than 45V (U2 mode) (see Table 4-1). The probe pulse width is automatically

adjusted according to the selected sub-range (see Table 6-1). Furthermore, pulse width can be set

manually by the user.

RI-407 automatically calculates the distance, according to the velocity factor and

measurement cursors positions on the screen. The distance measurement error is determined by the

sampling step of the instrument and by the velocity factor setting error.

Sampling step for each sub-range is set by default in such a way that the viewing window got

whole sub-range used by (see. Table 6-1). Sampling step can be adjusted (reduced or increased)

manually by the operator to minimize the instrumental error.

The velocity factor value is depends of the type of cable.

here,

PF – Propagation Factor;

v – Propagation speed of electromagnetic wave in the line, m/µs;

с – Speed of light is equal to 299,8 m/µs;

ε – Dielectric constant of the cable insulation.

Propagation speed can be determined experimentally, knowing in advance the distance (L) to

any irregularity (e.g., cable length or distance before the coupling). In this case, the inverse problem

is solved that way:

v

с

PF

3

2t

L

с

PF

3

2tL

Design And Implemented Measurement Methods

Implemented Measurement Methods

Time Domain Reflectometer RI-407 User Manual Page 11 of 67

Additional errors are due to the distortion of the reflected signal in the lines with a frequency-

dependent losses. The measurement error affects the nature of irregularity, its value, the existence of

several irregularities in the line.

Table 6-1 Sub-bands-measurement range

Sub-range, m

Default pulse width, ns

Sampling step, m

PF=1.5 (VOP=66%)

Minimal sampling step, m

PF=1.5 (VOP=66%)

0 – 62,5

10

0,125

0,125

0 – 125

10

0,250

0,125

0 – 250

20

0,500

0,125

0 – 500

50

1,000

0,125

0 – 1000

100

2,000

0,250

0 – 2000

200

4,000

0,500

0 – 4000

500

8,000

1,000

0 – 8000

1000

16,000

2,000

0 – 16000

2000

32,000

4,000

0 – 32000

5000

64,000

8,000

0 – 64000

10000

128,000

16,000

0 - 128000

20000

256,000

32,000

Design And Implemented Measurement Methods

Implemented Measurement Methods

Time Domain Reflectometer RI-407 User Manual Page 12 of 67

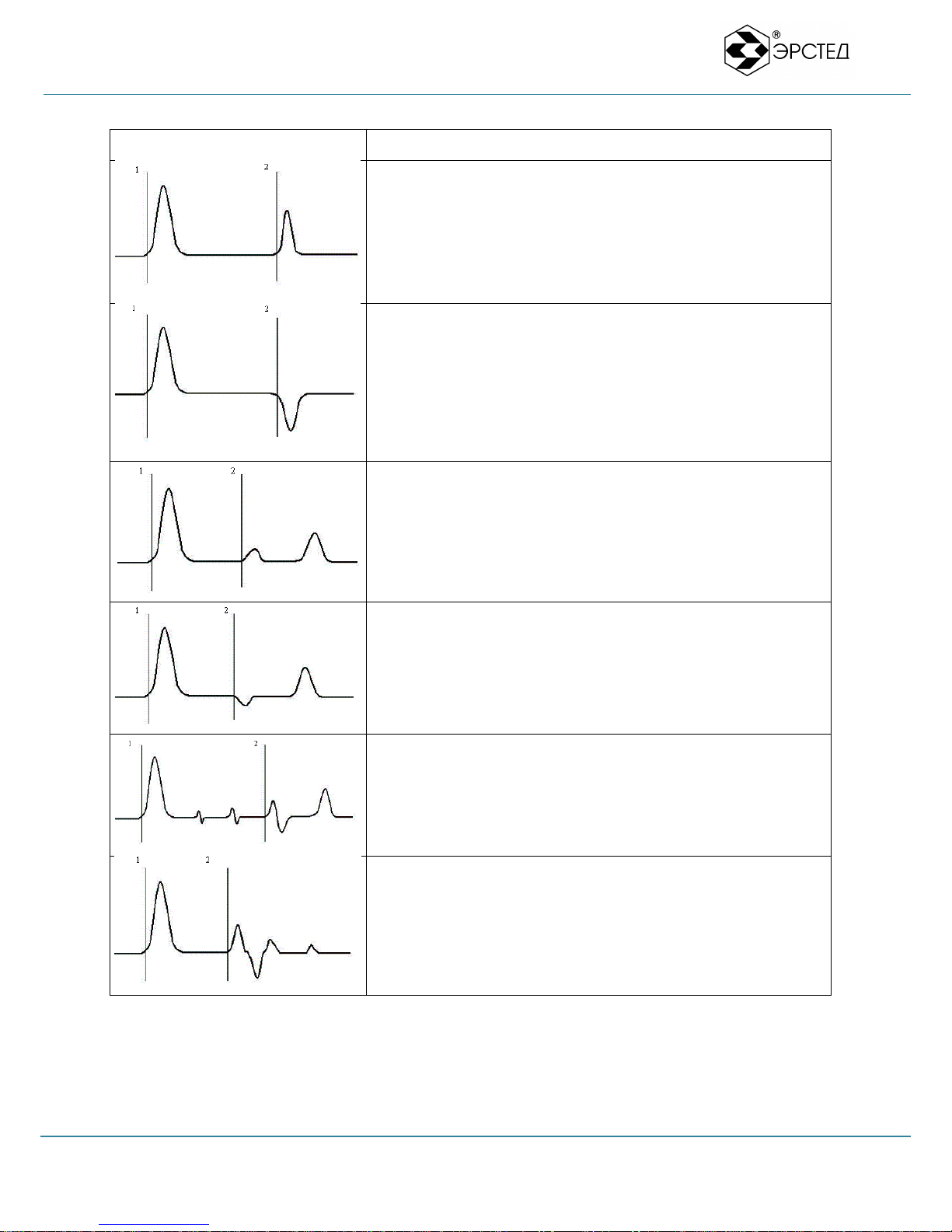

Table 6-2 Waveforms of the typical irregularities.

Waveform

Description

The first cursor points to the probe pulse.

The second cursor points to the reflection from irregularity with

high impedance, which corresponds to the cable break

(COMPLIT OPEN).

The first cursor points to the probe pulse.

The second cursor points to the reflection from irregularity with

low impedance (reflection with inversed signal polarity), which

corresponds to a short circuit in the cable (DEAD SHORT).

The first cursor points to the probe pulse.

The second cursor points to the reflection from irregularity with

increased impedance, followed by a complete cable break.

(PARTIAL OPEN)

The first cursor points to the probe pulse.

The second cursor points to the reflection from irregularity with

decreased impedance, followed by a complete cable break

(PARTIAL SHORT).

The first cursor points to the probe pulse.

The current waveform shows three joints on a cable. A joint,

marked by the second cursor is defective, it can be clearly seen

on the level of reflection.

The presence of a faulty amplifier in the line results an increased

reflection from the amplifier. The signal must terminate on the

amp, but it’s possible an additional reflection (phantom) of the

amplifier.

Design And Implemented Measurement Methods

Implemented Measurement Methods

Time Domain Reflectometer RI-407 User Manual Page 13 of 67

Couplers in the cable can cause measurement errors due to

multiple reflections. On the waveform cursor marks the coupler.

Two differently directed reflected signals indicate the two

segments of the coupler.

Additional resistance or weld rise to an S-shaped reflection on the

trace. Reflection from increased impedance followed by

reflection from decreased impedance.

Well matched cable including cable terminator fully absorbs

signal reflections. This waveform guarantees the normal cable

terminator choice, which does not cause reflection.

Wet cable is recognized as an area with the random reflection. The

beginning of this area shows a second cursor corresponds to the

beginning of the wet region.

Increasing humidity in the cables leads to the appearance of the noises

in the waveform.

Note to Table 6-2: The amplitudes of the pulses are given in the appropriate proportions at the

same amplification.

Design And Implemented Measurement Methods

Implemented Measurement Methods

Time Domain Reflectometer RI-407 User Manual Page 14 of 67

6.1.2. Arc Reflection Method (ARM)

Localization of the cable faults with a high transient resistance (R>10 kOhm) is usually

difficult when using low-voltage TDR method. One of the ways for localization such defects in

power cables is an Arc Reflection Method (ARM).

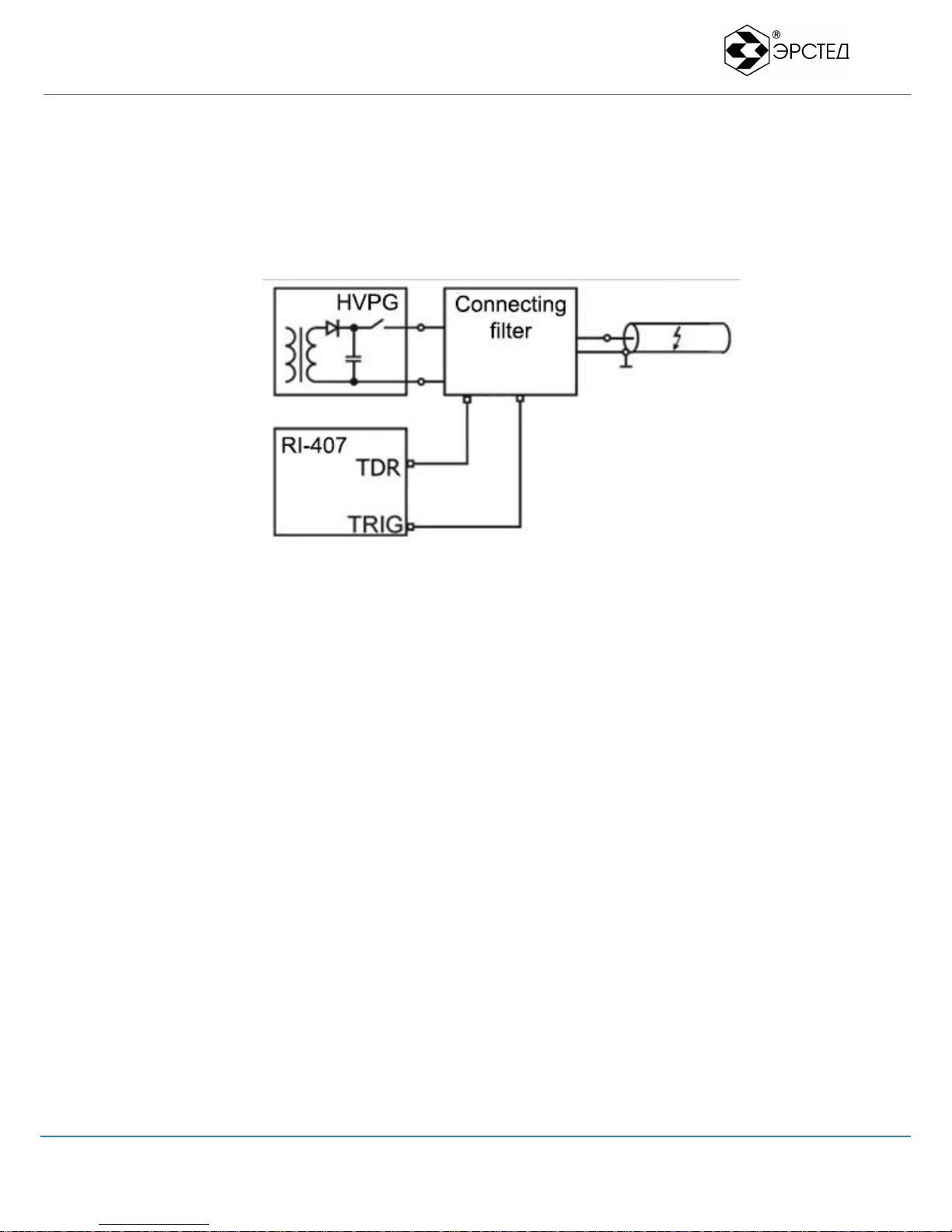

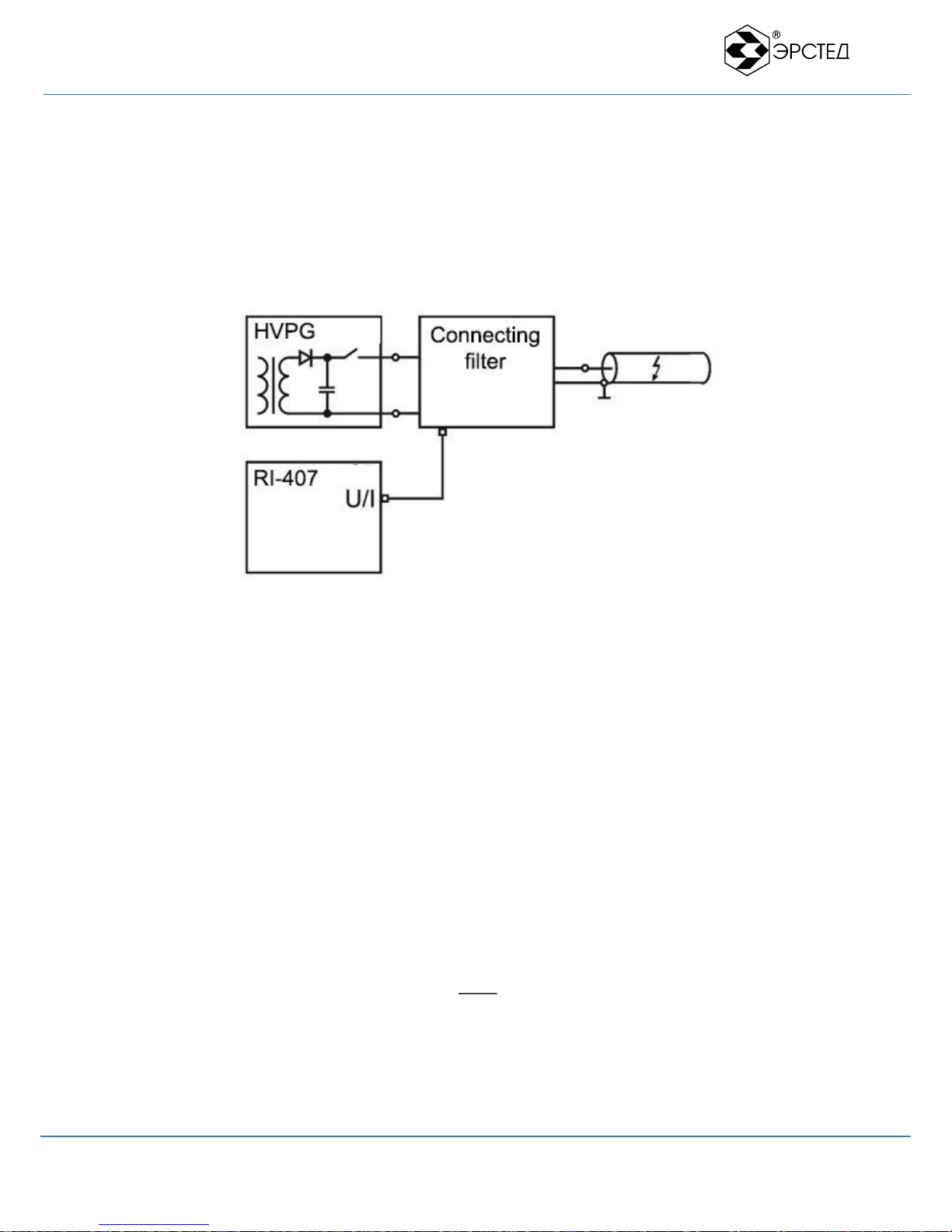

Picture 6.1 Diagram of the implementation of an Arc Reflection Method

Implementation of ARM method is carried out with the additional equipment: high-voltage

pulse generator (HVPG) and the special connecting device (as an external unit or internal HVPG

unit).

The essence of the ARM method is in creating conditions (using HPVG) for the occurrence

electric arc (breakdown) for a short time (few milliseconds) in the point of the fault. Synchronously

with the burning arc (sync signal obtained from HPVG) reflectometer performs sensing. The TDR’s

probe pulse is reflected from a low resistance of the arc with inverted polarity (like shorted circuit).

For easy identification of the fault location, waveform without breakdown (high transient

resistance at the point of the defect) and waveform during breakdown (low transient resistance at the

point of the defect) are compared.

Design And Implemented Measurement Methods

Implemented Measurement Methods

Time Domain Reflectometer RI-407 User Manual Page 15 of 67

6.1.3. Oscillatory Discharge Methods (ODM)

Localization of the cable faults caused self-healing insulation breakdown is usually difficult

when using low-voltage TDR method. One of the ways for localization such defects in power cables

is an Oscillatory Discharge Methods (ODM): Impulse Current Method (ICE) and Decay travelling

wave method (DECAY).

Picture 6.2 Diagram of the implementation of an Oscillatory Discharge method

The methods of oscillatory discharge (ICE, DECAY) are based on the measuring period of

oscillatory processes occurring in the breakdown of the charged cable. Implementation of the

methods is carried out using the optional equipment: the high-voltage pulse generator (HVPG) and a

special connecting device (as an external block or internal HVPG unit).

The essence of the method is: HVPG raises voltage in the cable until the breakdown

occurred. The defect causes a breakdown of the insulation at the site of the fault, causing a spark,

which has low resistance and the oscillatory discharge in the cable occurs. Knowing the speed of

electromagnetic wave propagation (v) in the line and the period of oscillation process (Top), we can

calculate the distance to the breakdown (L):

To achieve the highest accuracy only the first oscillation period is selected.

2

op

T

L

Design And Implemented Measurement Methods

Product View

Time Domain Reflectometer RI-407 User Manual Page 16 of 67

6.2. Product View

The product view is provided on the Figure 6-3.

Figure 6-3 RI-407 Product View

Design And Implemented Measurement Methods

Interface Controls

Time Domain Reflectometer RI-407 User Manual Page 17 of 67

6.3. Interface Controls

6.3.1. Overview

All controls and connectors of the instrument are located on the front panel, shown in Figure 6-4:

a) Display (par. 6.3.3) - color TFT screen with a resolution of 640 x 480 pixels;

b) "Reset" button is designed to forcibly turn off the power of the instrument;

c) 24 -Button keypad (tab. 4-4) for controlling the device via the GUI;

d) Input / Output BNC Connectors, 3 х 75 ohm female (par. 6.3.2);

e) USB socket – provides socket for data exchange and additional devices;

f) Charge Connector – provides DC -12 V socket to the instrument charge adapter;

g) Charge Indicator – provides charging status of battery through LED indication.

Figure 6-4 RI-407 front panel.

Design And Implemented Measurement Methods

Interface Controls

Time Domain Reflectometer RI-407 User Manual Page 18 of 67

6.3.2 Connectors

All connectors of the instrument are located on the front panel:

TDR connector (input/output, 75 ohm, BNC female) - for connecting the instrument to the

cable either directly or through the appropriate HPVG socket (TDR socket on ADG-200);

TRIG connector (input, 75 ohm, BNC female) - for receiving Sync signal from the

appropriate HPVG output (TRIG socket on ADG-200), when using ARM method;

WAVE connector (input, 75 ohm, BNC female) - for receiving signal from the appropriate

HPVG output (WAVE socket on ADG-200), when using ODM methods (ICE, DECAY);

Charge Connector (DC 12 V) – provides connecting with external power supply for battery

charging;

Charge Indicator – provides charging status of the internal RI-407 battery through LED

indication;

USB-A connector to connect an external USB-flash drive for data exchange.

Design And Implemented Measurement Methods

Interface Controls

Time Domain Reflectometer RI-407 User Manual Page 19 of 67

6.3.3 Display. GUI Structure Overview

The device is equipped with a TFT-display 10'' (640x480 pixels).

The upright side of the screen of the RI-407, displays internal battery status and current date

and time. The left and bottom sides displays Screen Selectors (current function of the corresponding

key "F1"-"F10" ) which are used for set and control the operating parameters of the device. In the

central part of the screen are displayed the waveforms and measurement Cursors.

The GUI structure is shown on the figure below:

Saved waveforms

management

Window

«WAVEFORMS LIBRARY»

Cables Velocity Factor

reference list

Window «CABLES PF/V2/VoP

LIBRARY»

Adjusting common instrument

settings

Window «MENU»

Button F9

(Menu)

Window «MEASUREMENT»

Channels and measurement

modes management

Window «CHANNELS»

Adjusting measurement

parameters

Window «PARAMS»

Button F10 (PARAMS)

Button F10 (CHANNELS)

Button F8

(CABLES PF LIBRARY)

Button F8

(LIBRARY)

Button Esc Button Esc

Button F10

(MEASURE)

Figure 6-5 GUI structure

Design And Implemented Measurement Methods

Interface Controls

Time Domain Reflectometer RI-407 User Manual Page 20 of 67

6.3.4 Keyboard

The RI-407 is equipped with a context sensitive keyboard (24 keys):

Table 6-3 (part 1 of 2)

Button

Functions

Turn ON/OFF the instrument.

F1 - F10

Activate the Selector, located next to the button.

In the CHANNELS window – SHIFT UP of the selected waveform.

In the PARAMS window – INCREASE the value of the active Selector: Scale, Pulse Width,

Velocity Factor, Averaging, Gain, Offset Input Delay, Threshold.

In the WAVEFORMS LIBRARY, CABLES LIBRARY and OPTIONS windows – NAVIGATE UP

through the list.

Inserts the character to the text (for example, when specifying the name of the waveform or cable in

the LIBRARY): "Space", "=", "+", "-", "1".

In the CHANNELS window and in the PARAMS window - adjustment of the waveforms

HORIZONTAL SCALE (ZOOM IN) in the area of Active Cursor.

Inserts the character to the text (for example, when specifying the name of the waveform or cable in

the LIBRARY): "_", ".", ",", ";", "2".

In the CHANNELS window and in the PARAMS window - adjustment of the waveforms

VERTICAL SCALE.

Inserts the character to the text (for example, when specifying the name of the waveform or cable in

the LIBRARY): "3","a", "b", "c".

In the CHANNELS window and in the PARAMS window – adjustment the position of the

ACTIVE CURSOR (LEFT)

Inserts the character to the text (for example, when specifying the name of the waveform or cable

in the LIBRARY): "4","d", "e", "f".

In the CHANNELS window and in the PARAMS window – SELECT the ACTIVE CURSOR (K1

or K2).

Inserts the character to the text (for example, when specifying the name of the waveform or cable

in the LIBRARY): "5","g", "h", "i".

In the CHANNELS window and in the PARAMS window – adjustment the position of the

ACTIVE CURSOR (RIGHT).

Inserts the character to the text (for example, when specifying the name of the waveform or cable

in the LIBRARY): "6","j", "k", "l".

In the CHANNEL window – SHIFT DOWN of the selected waveform.

In the PARAMS window – DECREASE the value of the active Selector: Scale, Pulse Width,

Velocity Factor, Averaging, Gain, Offset Input Delay, Threshold.

In the WAVEFORMS LIBRARY, CABLES LIBRARY and OPTIONS windows – NAVIGATE

Table of contents

Popular Measuring Instrument manuals by other brands

KRAFTWERK

KRAFTWERK 31006 instructions

Steinberg Systems

Steinberg Systems SBS-RL-500G user manual

Anritsu

Anritsu Spectrum Master MS2711D Programming manual

Endress+Hauser

Endress+Hauser Levelflex FMP56 operating instructions

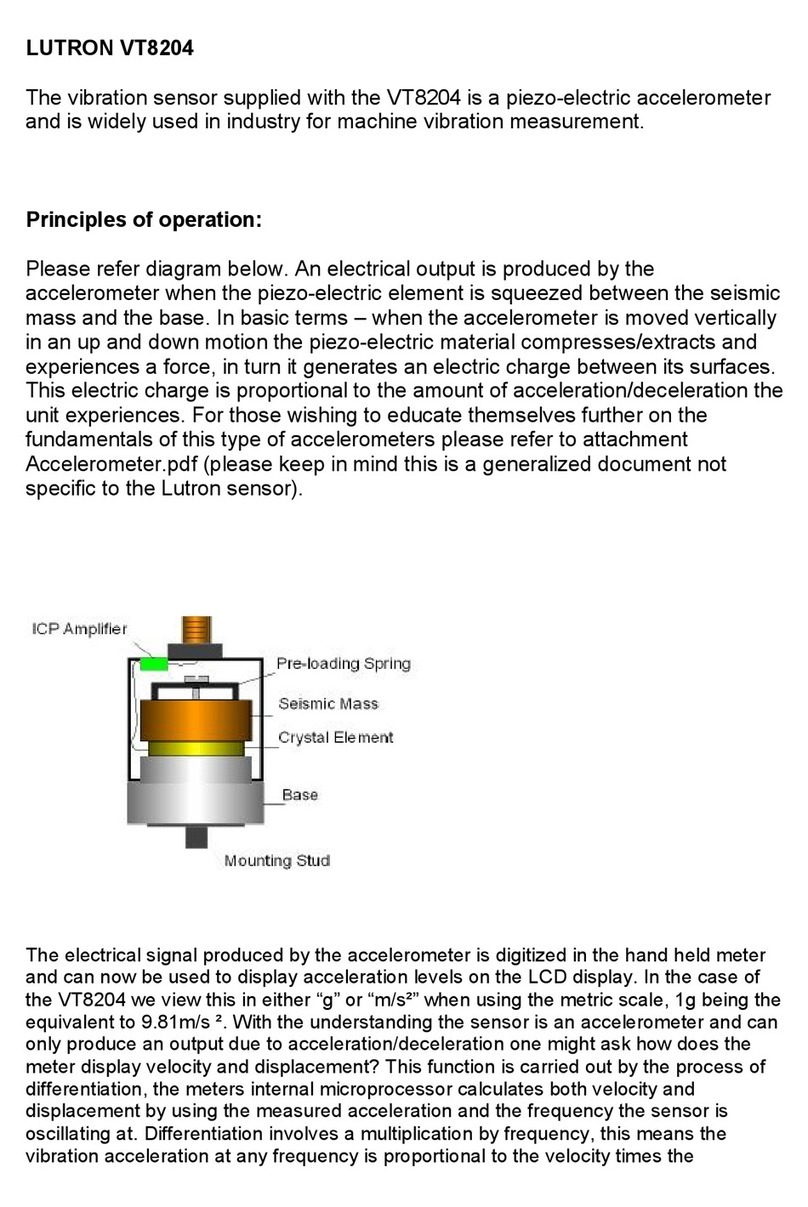

Lutron Electronics

Lutron Electronics vt-8204 user manual

Emerson

Emerson Rosemount 8800D Series Reference manual