TABLE OF CONTENTS

0463 331 001 © ESAB AB 2015

1 SAFETY ................................................................................................................ 4

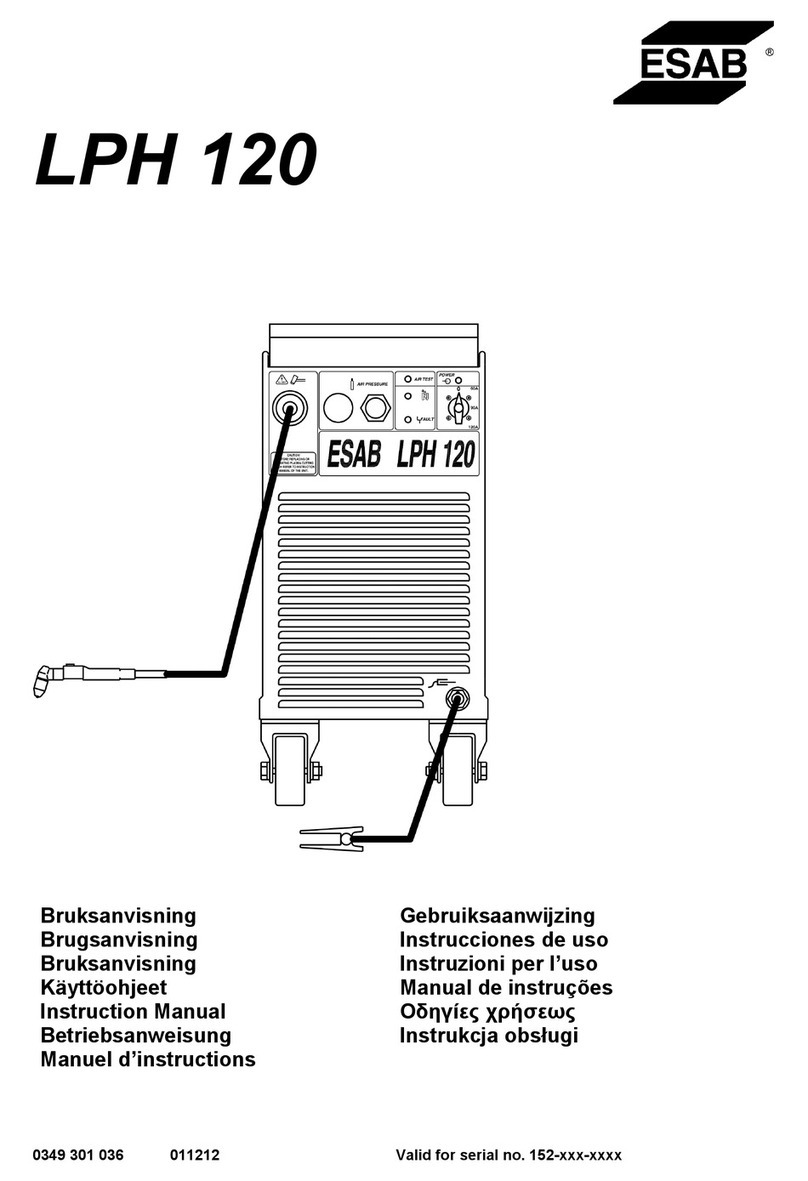

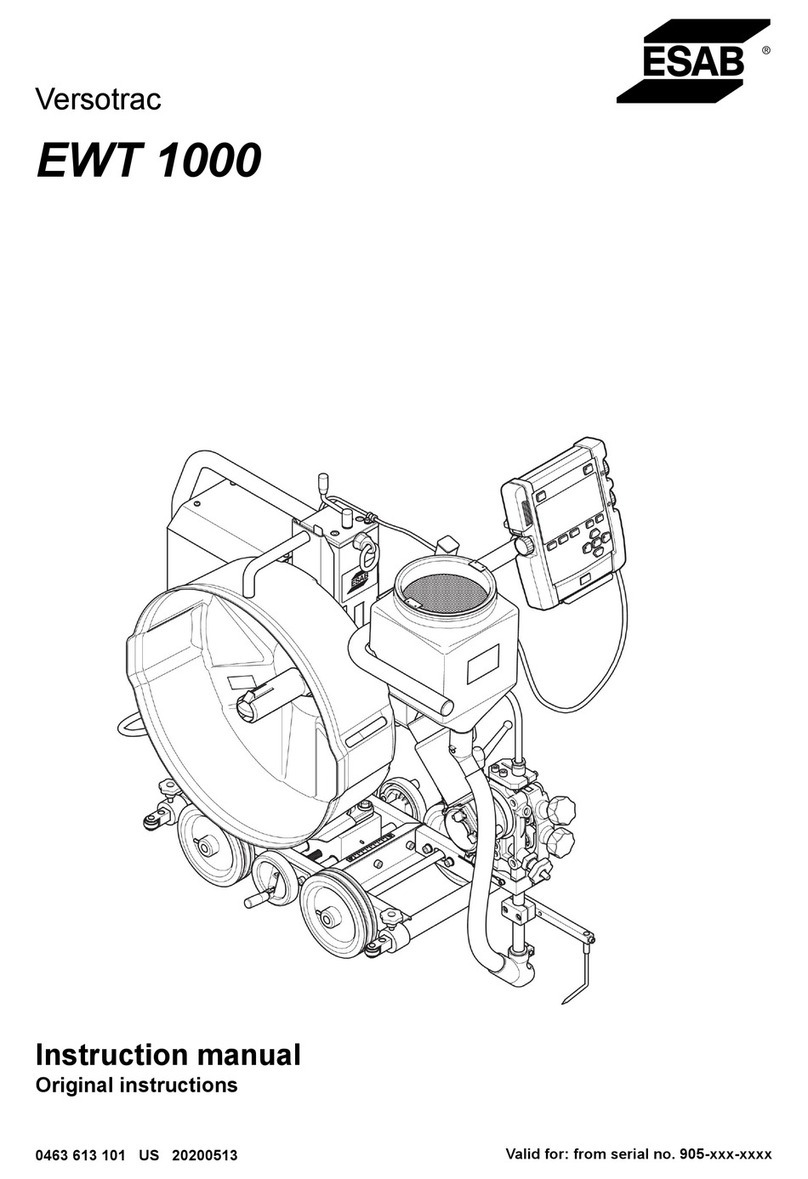

2 INTRODUCTION................................................................................................... 7

2.1 Equipment............................................................................................................. 7

3 TECHNICAL DATA ............................................................................................... 8

4 INSTALLATION................................................................................................... 10

4.1 Location .............................................................................................................. 10

4.2 Lifting instruction............................................................................................... 10

4.3 Mains supply ...................................................................................................... 11

5 OPERATION ....................................................................................................... 14

5.1 Connections and control devices.....................................................................15

5.2 Symbols .............................................................................................................. 15

5.3 Connection of welding and return cable..........................................................15

5.4 Turning the power source on/off ......................................................................15

5.5 Fan control.......................................................................................................... 16

5.6 Overheating protection......................................................................................16

5.7 VRD (Voltage Reducing Device) .......................................................................16

5.8 Remote control unit ...........................................................................................16

5.9 MIG/MAG and self shielded cored wire welding .............................................16

6 MAINTENANCE.................................................................................................. 17

6.1 Inspection and cleaning ....................................................................................17

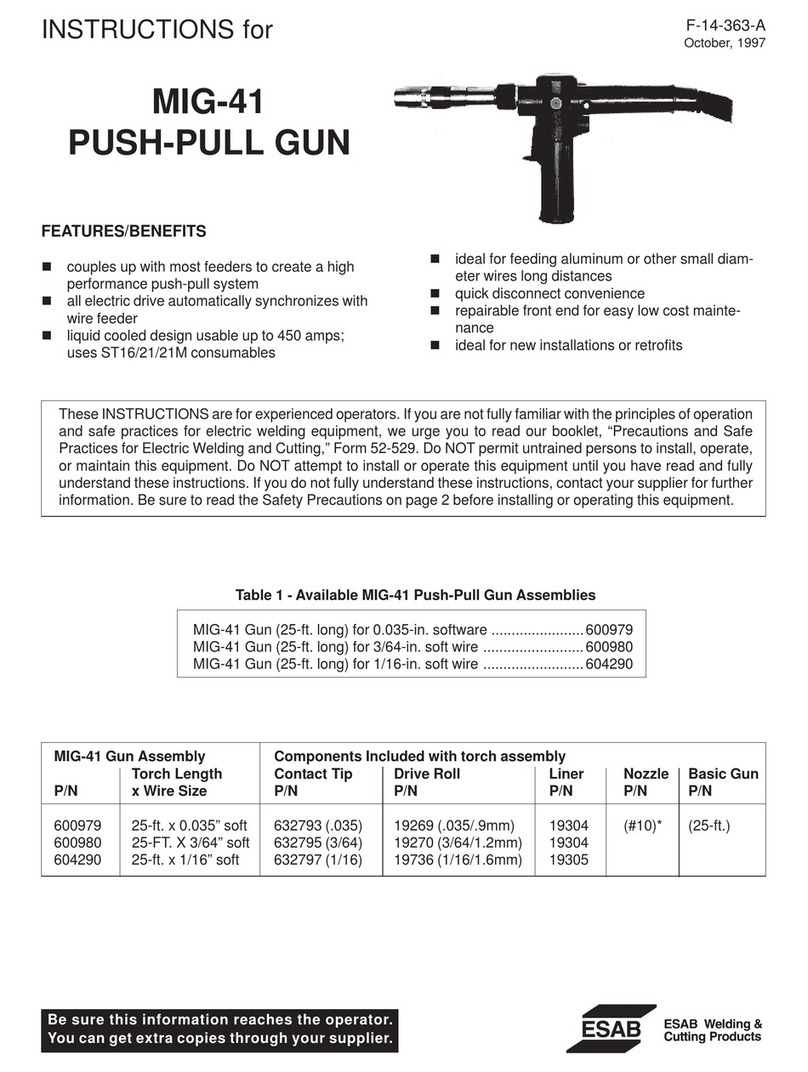

6.2 Welding torch ..................................................................................................... 17

7 FAULT TRACING................................................................................................ 18

8 ORDERING OF SPARE PARTS ......................................................................... 19

DIAGRAM ..................................................................................................................20

ORDERING NUMBERS.............................................................................................21

SPARE PARTS LIST..................................................................................................22

ACCESSORIES .........................................................................................................23

Rights reserved to alter specifications without notice.