ESDEC Panelclaw clawFR Dual User manual

9910046 RevG April 2021

Table of Contents

clawFR Dual Tilt 10 Degree

Installation Manual

ANSI/UL 2703

System Fire Class Rating: Class A for low slope roofs with Type 1, 2, 16, 19, 22, 25, 29 and 30 Modules

Mechanical Load Rating: See Appendix A: UL 2703 Grounding

Introduction & Safety Overview 2

Storage, Array Construction, and

O&M considerations

3

System Components 4

Accessories 5

Tools, Torque, & Construction Aid 6

Construction Aid Setup 7

Build Assemblies 8

Build East Edge Row 9

Build Remaining Rows 10

Place Ballast 11

Install Module Low Side 13

Install Module High Side 15

Continue Installing Modules 16

Cam & Lock Claw Inspection 17

Electrical Grounding 18

Appendix 19

Scan here for

installation

videos

9910046 RevG April 2021

Introduction

The clawFR DT 10 Degree flat roof mounting system is comprised

of four major components that intuitively assemble into a support

structure for photovoltaic (PV) modules.

This installation manual explains how to build a PV array using

clawFR DT 10 Degree.

PAGE 2

A CORROSION INSPECTION ONE YEAR AFTER INSTALLATION

AND ONCE EVERY THREE YEARS THEREAFTER IS REQUIRED

TO MAINTAIN THE PRODUCT WARRANTY. VISIBLE SURFACE

RED RUST ON STEEL COMPONENTS MUST BE LOCALLY

COATED WITH A COMMERCIALLY AVAILABLE GALVANIZED

PAINT OR COATING TO MAINTAIN PRODUCT WARRANTY.

EXCEPT FOR DEFLECTORS, ALL RACKING COMPONENTS IN

EACH SUBARRAY AND THEIR CONNECTIONS, BALLAST, AND

MECHANICAL ATTACHMENTS (IF ANY IN DESIGN) MUST BE

INSTALLED BEFORE MOUNTING MODULES. WHEN

FORECASTED WIND GUSTS EXCEED 25%OF THE WIND

SPEED LISTED IN THE SITE CRITERIA TABLE OF THE RACKING

CONSTRUCTION SET, DEFLECTORS MUST BE INSTALLED ON

ALL MOUNTED MODULES TO AVOID POSSIBLE SYSTEM

DAMAGE.

Safety Overview

Safety is an essential part of every PV installation and every

construction site. It is imperative to plan ahead for any safety

concerns and hazards to promote safe work practices during

installation. This section does not claim to address or support all

safety concerns that may arise during the installation of PanelClaw

mounting systems or any other aspect of the work being

performed. Before beginning work, installers should refer to all

local and federal safety, health, and regulatory requirements to

assure compliance. Refer to OSHA Part 1926 and its related

Subparts for federal construction related regulations and

standards.

Appendix J: Safety outlines some of the major hazards to be aware

of during the installation of PanelClaw products.

PRIOR TO INSTALLATION, READ THE SAFETY PROVISIONS

ATTACHED IN Appendix J: Safety AND REVIEW THIS

INSTALLATION MANUAL IN ITS ENTIRETY.

9910046 RevG April 2021 PAGE 3

Storage Considerations

PanelClaw recommends installing the racking components shortly

after delivery to the project site. If clawFR components are not

deployed immediately, they should be stored in a well-ventilated,

dry location. Otherwise, moisture can form between the packed

components which may cause staining and/or white rust.

Significant white rust formation may decrease the coating service

life and, in extreme cases, the component performance.

If storage onsite is unavoidable, remove the plastic and/or

carboard wrapping from the exterior of the packaging and cover

with canvas or place components under an open sided tent. Note

the use of a plastic cover does more harm than good as it prevents

the product from breathing and causes condensation. Storing parts

in any other manner is at the customer’s own risk. PanelClaw is not

liable for claims related to improper storage and any such claims

are not covered by the product warranty. Operations & Maintenance

See O&M Manual, available upon request, for initial inspection

recommendations including steps that can be performed only

during construction.

Sub Array Dimensions

Each PV system is unique and is frequently made up of multiple

sub arrays. The Racking Construction Set, which must be onsite at

all times during construction, details sub array dimensions and

location on the roof. Review the Racking Construction Set in its

entirety to prevent unnecessary rework during site construction.

The furthest extent of the racking components or modules of

adjacent sub arrays, whichever defines the outermost array

boundaries, must be separated by at least the minimum

dimensions documented in the Racking Construction Set. Refer to

the general notes and the Minimum Clearance Requirements

table, if present, within the Racking Construction Set.

9910046 RevG April 2021

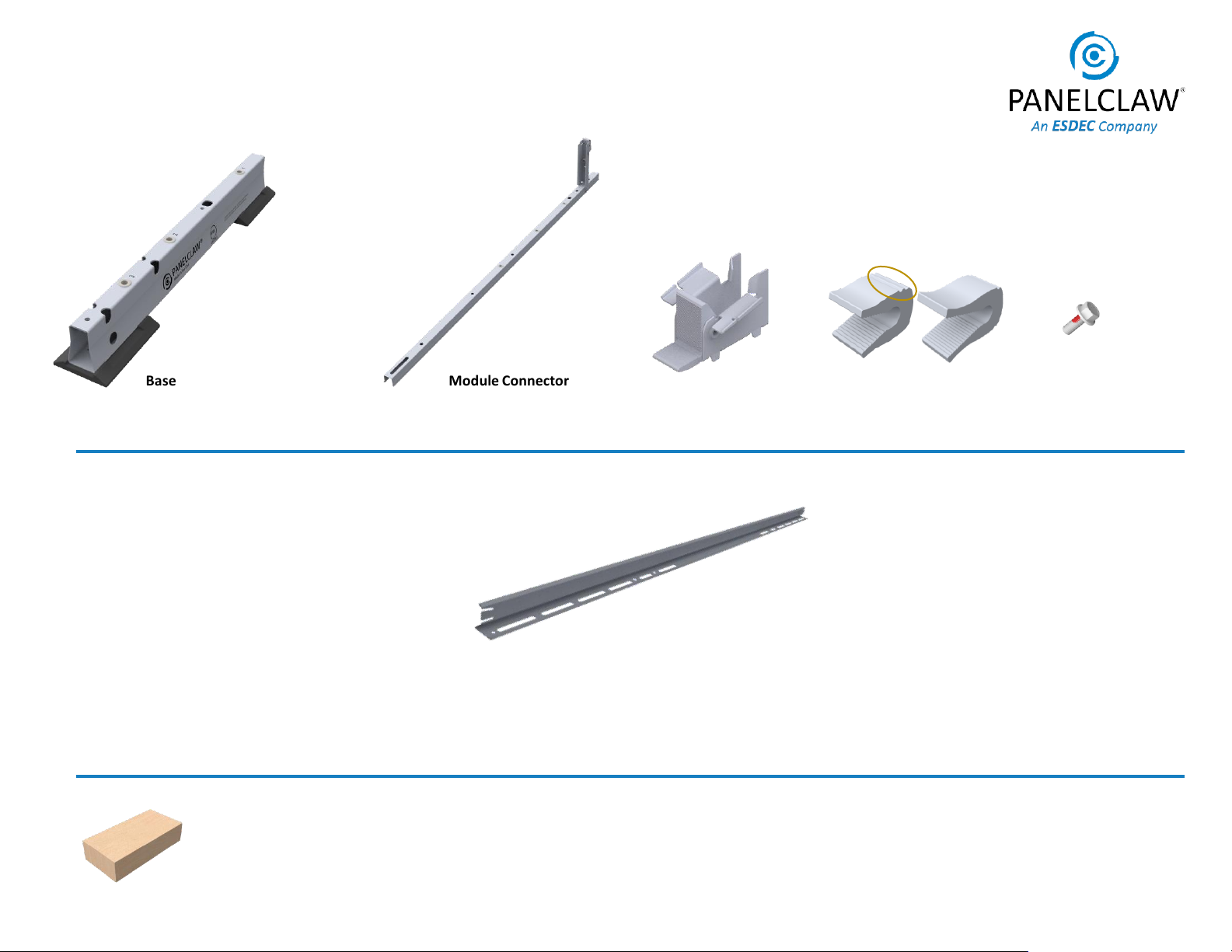

System Components

PAGE 4

M6x16mm Bolt

2000697

Module Connector

5000507XX

Base

500050201

Rail

2000695/2000895

Cam Claw*

2000673 (1 pair of grooves)

2000815 (1 groove)

Pair of grooves

*Both SKUs are shown here. Check the Racking Construction Set to verify correct Cam Claw is received

Cam

5000500

Ballast Block: Solid cap concrete roof paver, conforms to ASTM C1491 or C1884 standard and manufactured for

freeze-thaw resistance where applicable. See Appendix E for more details

9910046 RevG April 2021

Accessories

PAGE 5

Note: Use of non-UL listed accessories, including non-metallic components, does not affect the system ANSI/UL 2703 certification.

See: Appendices D-H

Shim Pad

5000228

Optimizer Attachment

5000509

Wire Router

5000225XX

Base Pad

2000678

Wire Clip

5000226

Lock Claw Clip

2000819

Wire Management Accessories

See: 9910053-Wire Management Manual

Mechanical Attachment Strut

2000830/2000930

Mechanical Hardware Kit

500022301/5000423

Ground Lug Kit

5000494

WM Homerun

200082302

and 2000828

WM Homerun

Clip

WM Homerun

Cover

9910046 RevG April 2021

Torque Setting

*

Fastening Operation

6 ft

-lb (8.1 Nm)

All System connections

except

Special Cases

Spacer Stick

Construction Aids

Drill with Inline-Torque Limiter or Torque Wrench

10 mm Magnetic Nut Driver

ALERT: NO IMPACT DRIVERS

Tools

Cam Spacer / Lock Claw Insertion Depth Gauge

*+/-4% allowable during installation

PAGE 6

Spacer Stick and Cam Spacer Kit

5000510/5000610

2000761 may be required

Note: Additional tools may be required when installing

accessories.

Bolts which are installed into a pre-installed nut

are tightened to 6 ft-lb

9910046 RevG April 2021

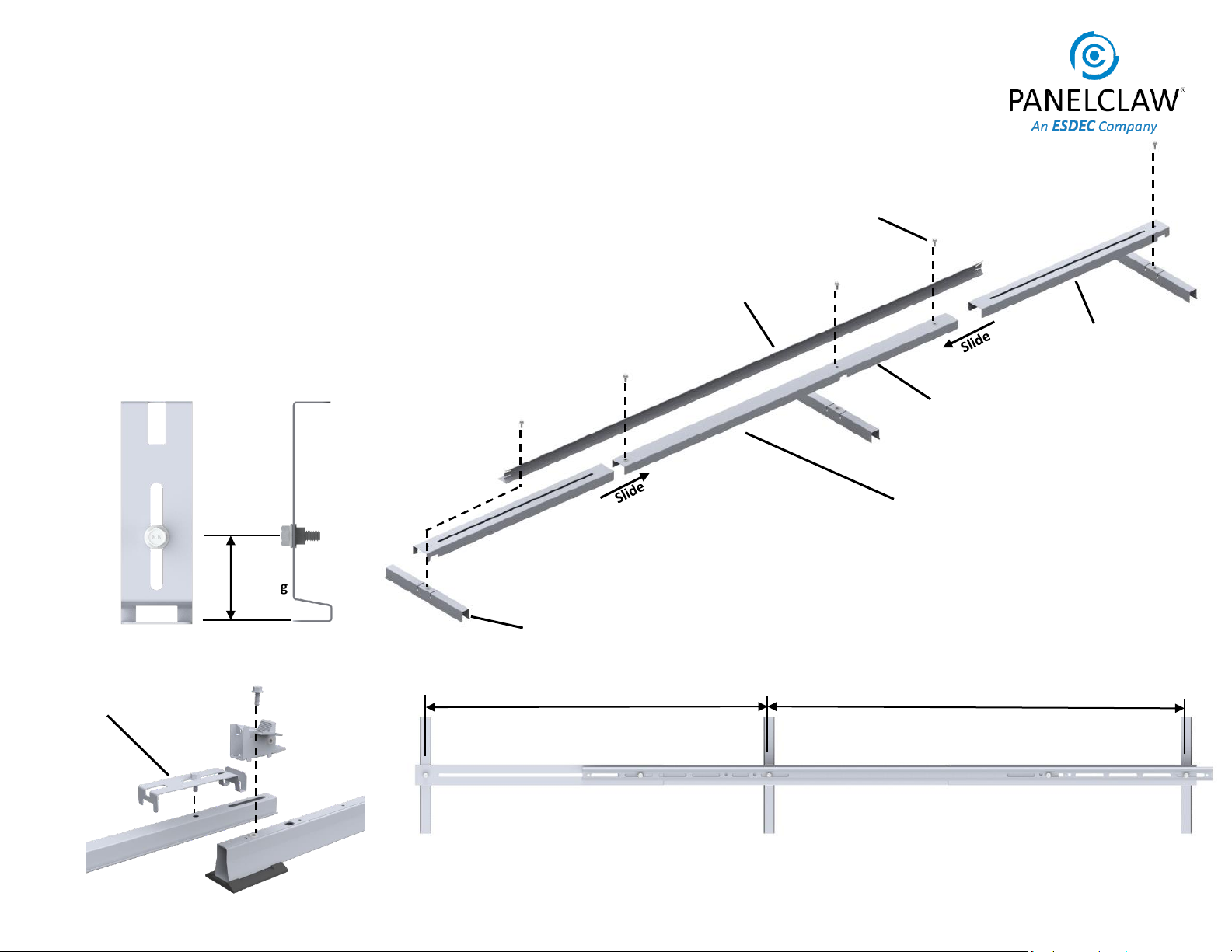

1. Construction Aid Setup

2X

3X

1X

5X

Tip: L, S, and Cam Spacer dimensions are found in the

Racking Construction Set. See Sheet Title: Typical Array

Dimensions.

1.1 Assemble the Spacer Stick and adjust to L & S dimensions.

All dimensions are measured from the Base centerlines.

Tip: To stiffen the Spacer Stick, place one Rail

2000695/2000895 on the assembly as shown, shift the

Rail to find a location which allows for attachment with

the specified bolts. Tighten the bolts.

1.2 Insert the bolt and adjust the Cam Spacer to the Cam

Spacing dimension.

Adjust Spacer Stick

Spacing S

Spacing L

PAGE 7

Typical Cam

Spacer Usage

1X Rail 2000695/2000895

The optional 2000761 center

piece is used only if 5000610 is

shipped and the Racking

Construction set calls for

750mm “S” spacing.

Cam Spacer / Lock Claw

Insertion Depth Gauge

Cam

Spacing

9910046 RevG April 2021

Hole 2

West Module

Assembly

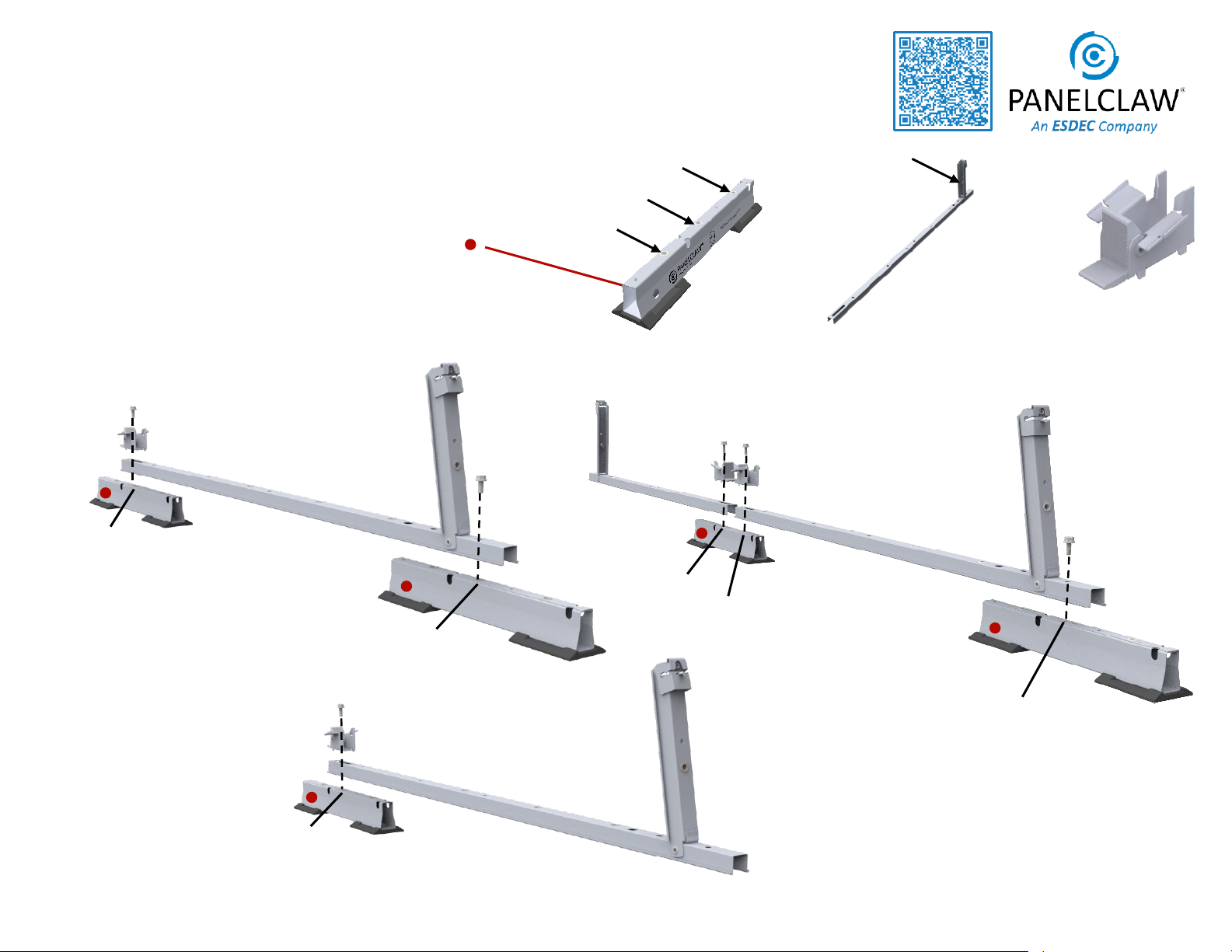

2. Build Assemblies

PAGE 8

2.1 Position components as required per assembly type and loosely

assemble the Cam, Module Connector and Base.

ALERT: Note location of orientation marker on Base “ ”

Tip: Immediately tighten bolts to 6 ft-lb which are at the Tilt Arm

end of the assembly.

2.2 Use the Cam Spacer tool to correctly locate the Module Connector.

Tighten bolt to 6 ft-lb.

Middle Valley

Assembly

Hole 2

Hole 1

Hole 2

Hole 2

East Module

Assembly

Hole 2

+ +

Base

(qty 1 or 2) Module Connector Cam

Hole 1

Hole 3

Hole 2

Tilt Arm

Scan here for

Assembly Jig

Manual

9910046 RevG April 2021 PAGE 9

3. Build East Edge Row

S

LSpacer Stick

S

LALERT: To ensure system

alignment, use the Spacer Stick

to align Module Connectors

before securing Rails.

Place East Module Assemblies with the Base Pads

along the East Edge line. The first and last East

Module Assemblies should be placed with the edge

of the Base Pads on the Base Edge line.

Tip: Raise Tilt Arms after securement of assembly.

3.2

Place a Rail on all “S” spacings (module centered).

Rails at row ends should be flush with array edge

when “S” spacings permits.

Place a Rail on all “L” spacings (between modules) on

top of and overlapping the Rails on the “S” spacing.

Install bolt and tighten to 6ft-lb.

S

L

3.3

Base edge

measured to

Pad edge

Tip: Base Edge

is in line with

Base Pad

Tip: “S” spacings are module centered

“L” spacings are between modules.

Tip: L, S, R and AEBE dimensions

are found in the Racking

Construction Set. See Sheet

Title: Typical Array Dimensions.

Snap East Edge, Array Edge, and Base Edge lines.

Tip: Snap Array Edge lines on one or both array

edges (row ends) and snap Base Edge line on the

edge where module mounting will begin.

3.1

See Sheet Title Page: Typical

Array Dimensions in the Racking

Construction Set for AEBE

dimension.

Scan here for

rail installation

video

ALERT: Rail on “L” Spacing is ALWAYS on

top of Rail on “S” Spacing. This

installation sequence is critical to system

performance.

Tip: Rail has two holes. Consult Sheet

Title: Typical Array Dimensions in the

Racking Construction Set for appropriate

hole use.

9910046 RevG April 2021

4.2 Install Rails throughout the array using the same

steps described on the previous page. Alternating

between “S” and “ L” Spacings. Install bolt and

tighten to 6 ft-lb.

ALERT: To ensure system alignment, use the Spacer

Stick to align Module Connectors before securing

Rails.

PAGE 10

4. Build Remaining Rows

Place Middle Valley or West assemblies onto

assemblies from previous row and bolt to 6 ft-lb.

Tip: Sheet Title: Assemblies in the Racking

Construction Set clearly indicates hole selection.

Using the wrong hole will result in an array which

does not match site plan.

4.1

Note

Orientation

ALERT: Eastern and Western Edge Rails face the

opposite direction; bolts securing these rails are

tightened to 6ft-lb.

Hole 1

Hole 1

Rail are required at Eastern

and Western Array Edges

ALERT: Installation of Eastern and Western Array

Edge Rails is critical to system performance.

ALERT: Tighten fasteners prior to moving spacer

stick to next position.

Spacer Stick

L

Tip: Raise Tilt Arms after

bolting assemblies in

preparation for Rail

installation.

S

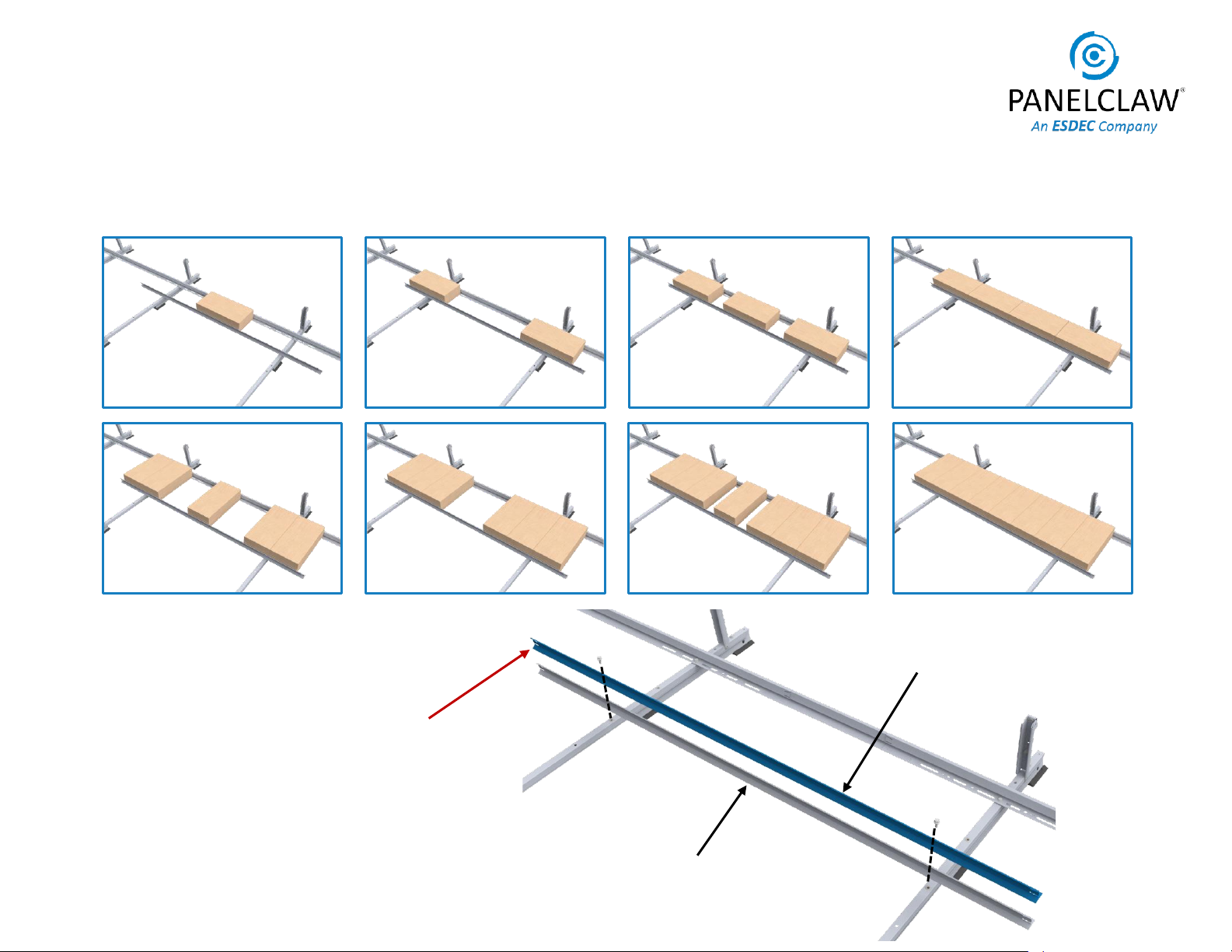

9910046 RevG April 2021

ALERT: Do not step

on ballast blocks

Attach Rail to

location closest

to Cam.

Rail Position for 5-8 Ballast blocks

PAGE 11

5. Place Ballast

Tip: Installing the east edge row ballast blocks helps keep the

racking structure from moving as the rest of the array is built.

Tip: Sheet Title: Ballast Layout –XX in the Racking Construction

Set identifies where Ballast is to be installed. Mark the roof with

chalk to speed up installation.

5.1 Install a Rail onto array in locations where Ballast is required.

Bolt to both Module Connectors and tighten to 6 ft-lb.

ALERT: Every Rail must be fastened to two Module Connector

assemblies.

Tip: Ballast and Rails are only placed on “S” spacings. Center

them on the “S” spacing for equal ballast distribution.

5.2 Place Ballast onto Rails. If rapid cyclic movement of system is

expected e.g. due to seismic activity or building vibration from

activities within or nearby the structure, bend the Rail tabs to

secure Ballast.

ALERT: Install Mechanical Attachments before going to next

step. See Appendix D

Rail Position for 1-4 Ballast blocks

Attach Rail to

location closest to

Tilt Arm.

Bend tabs at ends of Rail.

(See 5.2 to determine if required)

Bend Tabs to

capture Ballast

as required.

1

2

5

8

4

Ballast Quantity

S

3

7

6

9910046 RevG April 2021 PAGE 12

5. Place Ballast (Continued)

1 2 3 4

5 6 7* 8*

*ALERT: Modules longer than 2100 mm with

7 or 8 ballast blocks require two (2) Rails.

Install Rail 2 on top of Rail 1 and tighten to

6ft-lb.

Rail 1

Rail 2

5.3 Ballast must be placed as shown. Ballast quantity affects the Ballast placement on the Rails

and in some cases additional Rails are required as noted below.

9910046 RevG April 2021

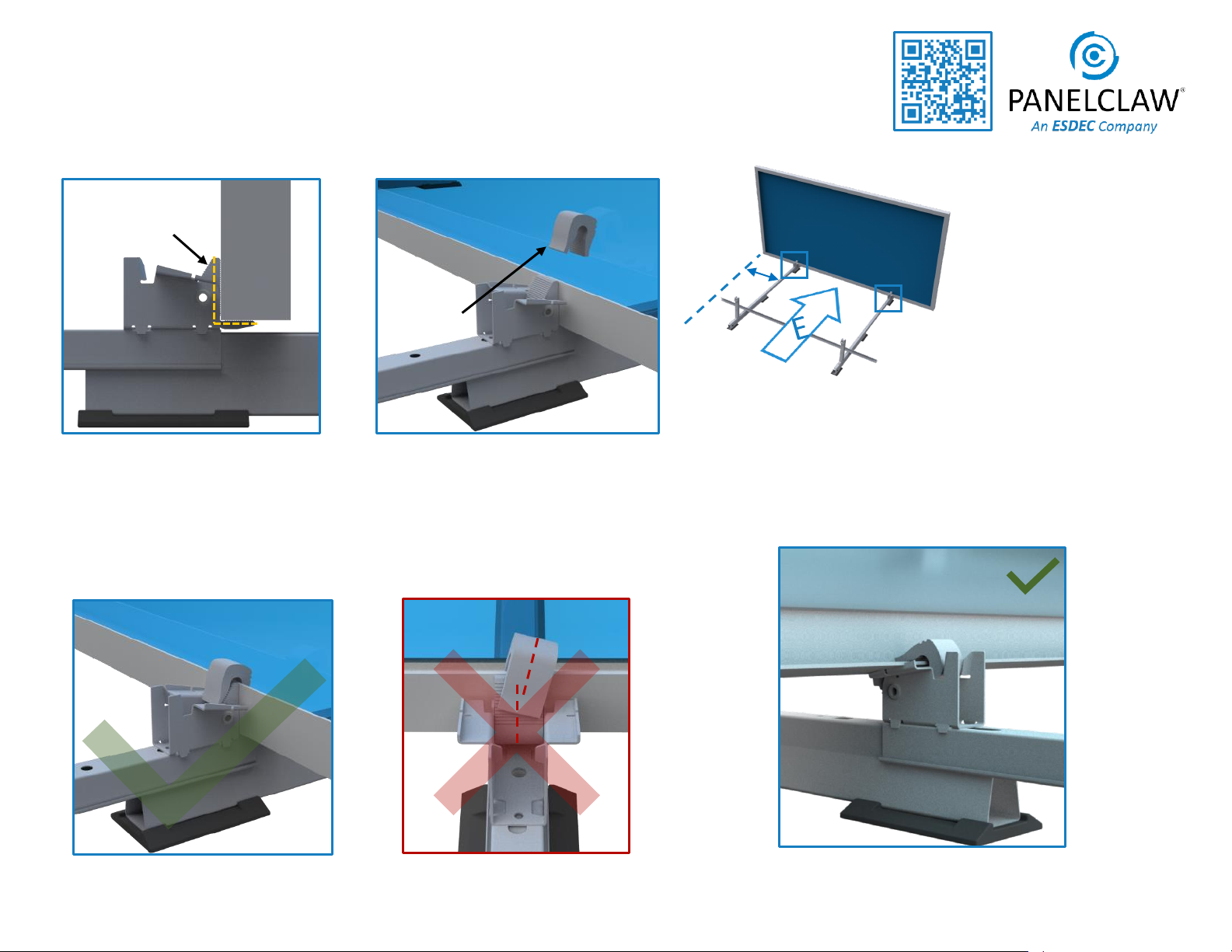

6. Install Module Low Side

PAGE 13

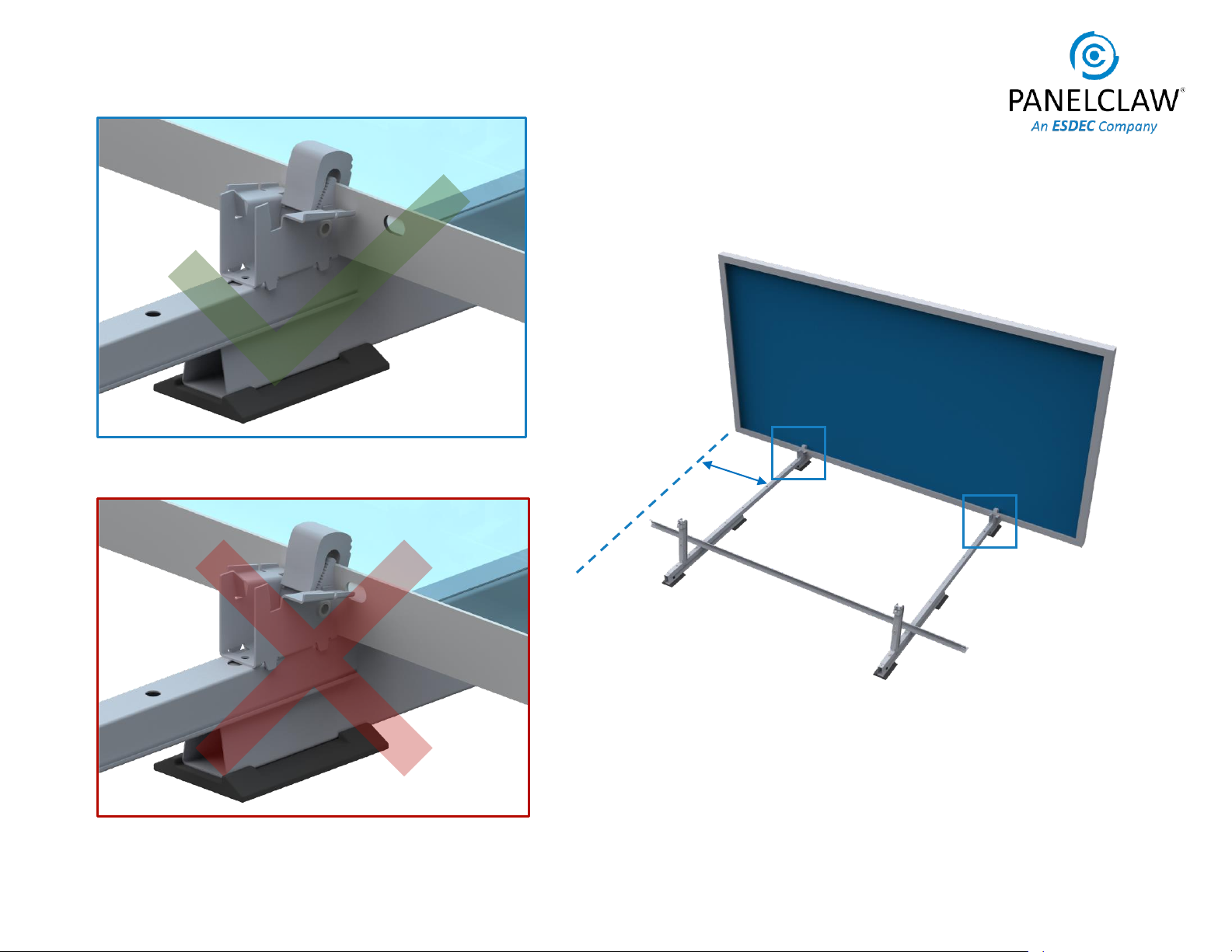

Cam Claw aligned

6.1

Cam Seat

Place module on Cam Seat and

align with Array Edge.

Tip: Ensure the module is vertical

and flush with Seat.

ALERT: Cam Claw is mis-aligned.

Cam Claw

Place Cam Claw over module flange.

Apply a small downward force to

make sure it is properly seated.

6.2

ALERT: Install Mechanical Attachments before installing modules.

See Appendix D

R

Tip: R dimension is found in

the Racking Construction Set.

See Sheet Title: Typical Array

Dimensions.

Tip: Installing all East facing

modules prior to installing

West facing modules leads to

faster system assembly.

ALERT: Do not leave modules in

vertical position, go immediately to

next installation step (high side install).

ALERT: When forecasted wind gusts exceed 25%of the wind

speed listed in the Site Criteria Table of the Racking

Construction Set, all mounted modules must be complete

pairs (Domes) to avoid system damage.

Example of a typical good Cam Claw install,

after the module has been rotated down

and high-side has been installed

Scan here for

module

installation

video

Tip: Cam Claw grooves may be

ignored for installation purposes

9910046 RevG April 2021

6. Install Module Low Side (Continued)

PAGE 14

If Cam flanges align with the module mounting holes,

Contact PanelClaw. Consult Sheet Title : Typical Array

Dimensions in the Racking Construction Set to verify that

appropriate R dimension is in use.

Cam flanges are located away from the module mounting

holes R

9910046 RevG April 2021

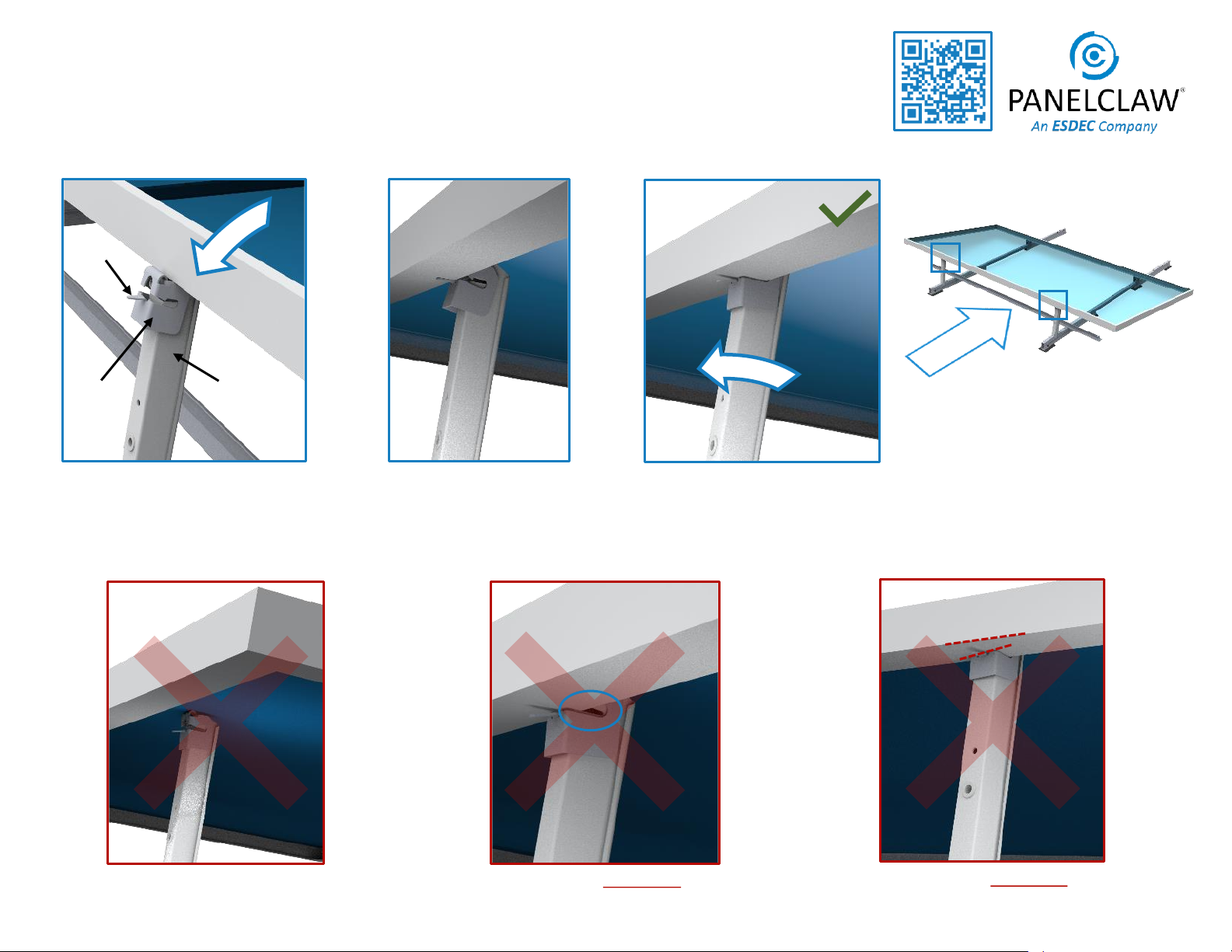

7. Install Module High Side

PAGE 15

DO NOT REST MODULE

BACKSHEET ON TILT ARM

Tip: Use two hands when engaging Lock

Claw to ensure correct installation.

LOCK CLAW UNEVENLY

ENGAGED

Tilt Arm

Tongue

Lock Claw

Rotate module down and rest the module

frame on the top of the Tilt Arms.

Tip: Make sure the Tilt Arms are fully

raised.

7.1

Support module while carefully

rotating the Tilt Arm just enough

to rest the module frame on the

Lock Claw tongue.

7.2

Pull the Tilt Arm forward until the Lock

Claw is fully engaged onto the module

frame flange.

7.3

LOCK CLAW NOT FULLY

ENGAGED

E

Tip: See Appendix I for Lock Claw

reset method.

Scan here for

module high

side installation

video

9910046 RevG April 2021 PAGE 16

7. Continue Installing Modules

ALERT: When forecasted wind gusts

exceed 25%of the wind speed listed

in the Site Criteria Table of the

Racking Construction Set, all

mounted modules must be complete

pairs (Domes) to avoid system

damage.

DOME

Use Cam Claw as spacer to set spacing between modules.

ALERT: Check the R

dimension every 5th

module and adjust

spacing between

modules as needed.

R

Tip: R dimension is found in the Racking Construction Set.

See Sheet Title: Typical Array Dimensions.

ALERT: If Cam Flanges are located on

Module mounting holes refer to

page 14 of the manual to verify

appropriate spacing.

9910046 RevG April 2021 PAGE 17

Lock Claw Insertion Gauge configuration and use

Place gauge against Lock Claw and underside

of module.

Select a Lock Claw which has been

confirmed to be installed correctly

through visual inspection.

The Tilt Arm and Lock Claw should

be aligned with the module frame

and the Lock Claw fully engaged

on the frame.

Mark line on gauge to finish setup.

Use gauge to confirm full Lock Claw

engagement-line must be visible.

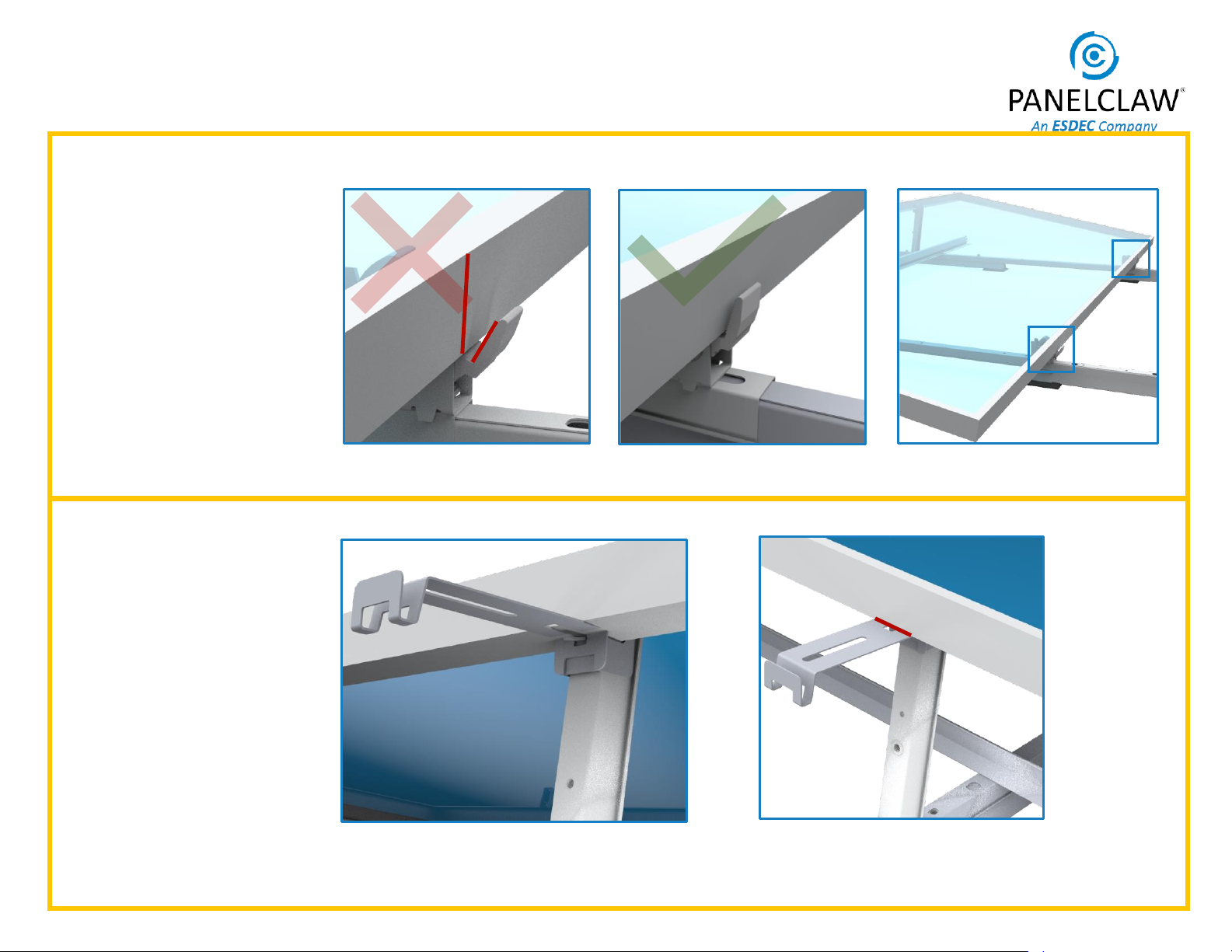

8. Cam & Lock Claw Inspection

Inspect Cam side module connection

Module and Cam are near flush.

Module and Cam have a large

non-uniform gap.

Cam installation can be quickly visually

inspected (no gauge is available or

required) by comparing a known good

installation with all other installations.

Some gap between Module and Cam

is permissible. The graphics are

representative only; actual installation

geometry varies by module vendor

and part number. If it is not clear the

module low side connection is good,

contact PanelClaw for assistance.

ALERT: Verify correct installation by

lifting up on the module near the Cam

and making sure no movement occurs.

9910046 RevG April 2021

Electrical Grounding

Please consult with national and local building code(s) for

complete grounding requirements for your installation. The

clawFR grounding method conforms to ANSI/UL 2703 and is

certified by SolarPTL for use with approved photovoltaic

modules listed under ANSI/UL 1703 and/or ANSI/UL 61730.

Installers can quickly and easily establish ANSI/UL 2703

certified electric bonds between all connected array

components, including modules and mounting system

components, without the use of additional grounding

devices, e.g. ground lugs and copper wire. At least one

ground lug must be used to ground all strings within a

physical sub-array provided the fuse rating for each string

does not exceed 40 amps. Installers may opt to use multiple

lugs per sub-array for redundancy. When grounding devices

are installed according with the approved methodology and

capacity below, the connections described above meet all

the requirements outlined in NEC 690.43.

Grounding Instructions

For modules that have been evaluated for use with clawFR Dual Tilt 10

Degree, please follow the instructions below in Appendix A: UL 2703

Grounding. Additional information regarding ANSI/UL 2703 and the

specific list of evaluated modules included in PanelClaw’s UL listing can

be found in the “clawFR UL Overview and Module Listing” document

(available at www.panelclaw.com).

For modules that have not been evaluated for use with clawFR, please

contact PanelClaw

ALERT: During grounding and bonding ensure there is separation

between bare copper and aluminum or coated steel components.

PAGE 18

9910046 RevG April 2021

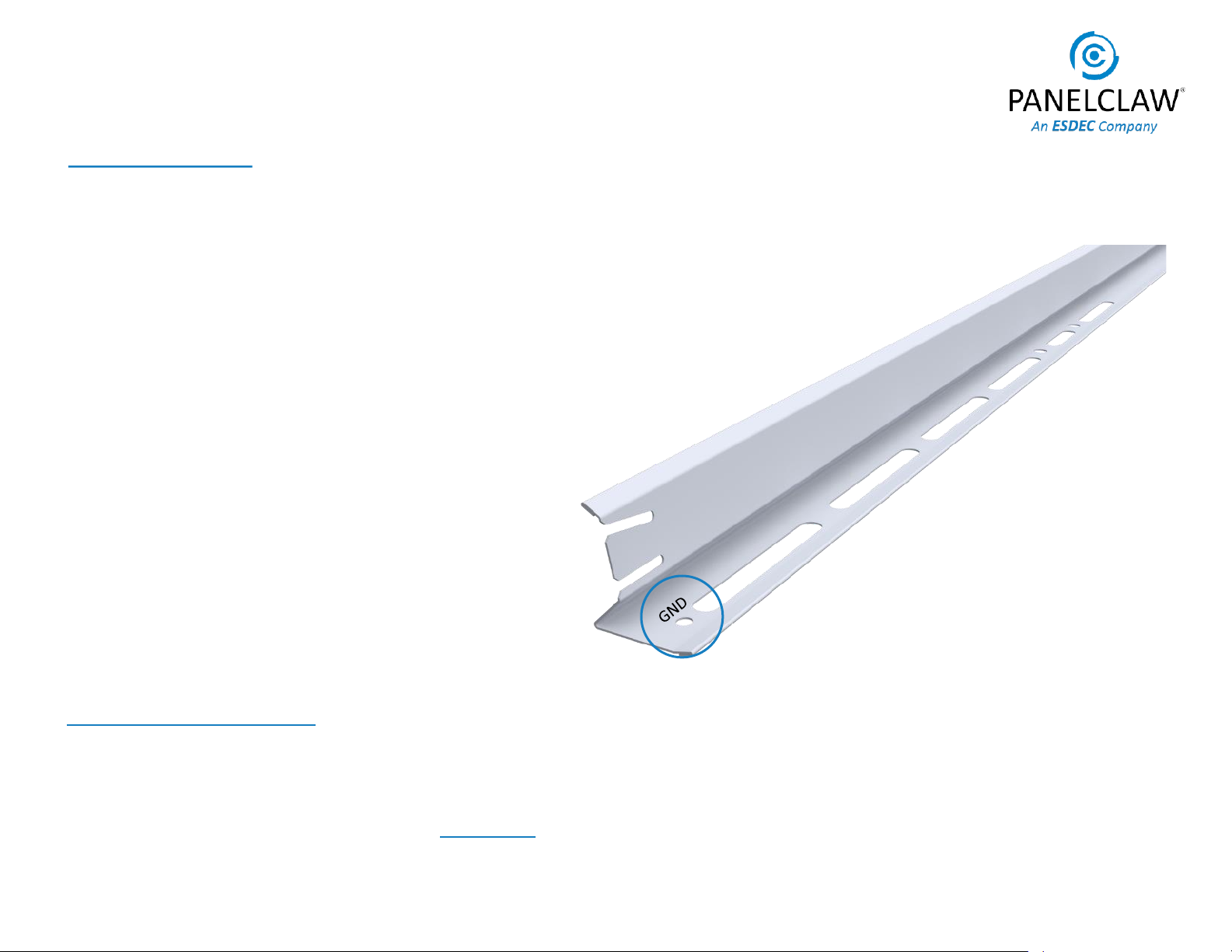

Appendix A: UL 2703 Grounding

The clawFR Dual Tilt 10 Degree flat roof

system may be used to ground and/or mount

aPV module complying with ANSI/UL 1703

or ANSI/UL 61730 only when the specific

module has been evaluated for grounding

and/or mounting in compliance with the

included instructions. For a list of modules

which have been evaluated see PanelClaw’s

“clawFR UL Overview and Module Listing”

(see www.panelclaw.com).

A periodic re-inspection of the system shall

be performed for loose components, loose

fasteners, and any corrosion. If found, they

should be immediately replaced or remedied

in accordance with the system installation

instructions.

System Ground Path

The system ground path “grid” is established throughout the array by the interconnection of system components. Specifically, in the column

direction via the Base and Module Connector connections and in the row direction via the Rail connections. A Tyco lug connected to the Rail

establishes a point of connection for the EGC at one location with a contiguous array. All modules are grounded to the system through their

Cam to Module connection.

Note: The presence of aPV module does not affect the bonding ability of the clawFR system components. More precisely, the grid provides

a means to ground PV Modules which have been evaluated for ANSI/UL 2703 grounding with clawFR.

PAGE 19

To DC

Grounding

Path

Ground Lug

Tyco #2106831-1

Row

Column

9910046 RevG April 2021

Appendix A: UL 2703 Grounding (Continued)

Tyco Grounding lug attachment:

To attach the Tyco grounding device/lug to the Rail, the mounting hex washer and threaded post end should be installed to the specified hole

in the Rail and torqued to 2.08 ft-lb (25 in-lb).Once the grounding device/lug has been attached to the Rail, a copper bonding jumper from an

acceptable DC grounded location outside of the array must be installed to the wire slot end and torqued to 3.75 ft-lb (45 in-lb). For additional

instruction regarding the installation of the Tyco solid wire grounding assembly, please refer to the Tyco Electronics instructions sheet

(document number 408-10262) via their website www.te.com.

Grounding Instructions:

PanelClaw components within the array are required to be

electrically bonded to other DC grounding paths via the use of

appropriately sized Cu wire and a UL 467 listed Tyco Solarlok

grounding assembly, part number 2106831-1, manufactured by

Tyco Electronics Corporation. The conductor size should be

selected in accordance with NEC 690.45 and NEC 250.122.1.

To ground the array, first determine the groupings of strings

whose power output wiring is grounded together at an

equipotential grounding conductor location. This could be all

the strings within a physical sub-array, or all the strings grouped

by a single combiner box. Once the groupings of strings at

equipotential have been determined, a Tyco solid wire

grounding assembly must be attached to one Rail within each

group of strings. PanelClaw’s clawFR Rails have a hole to which

this grounding device/lug can be attached. In an array that

requires multiple bonding jumpers to satisfy the equipotential

requirements, each bonding jumper should be located and

installed on a Rail within the group of strings which will be

grounded by that jumper.

ALERT: Every sub-array must include at least one grounding

device/lug.

PAGE 20

ALERT: If installing clawFR Dual Tilt 10 Degree with a module which is not on the UL2703 listing, contact PanelClaw.

Table of contents

Other ESDEC Solar Panel manuals

Popular Solar Panel manuals by other brands

Apricus

Apricus AP series Installation & operation manual

LG

LG LGxxxS1C(W installation instructions

Axi

Axi Solar panel user manual

Sanyo

Sanyo HIP-225HDE1 installation manual

Dometic

Dometic 9600010943 Installation and operating manual

Chicago Electric

Chicago Electric 44768 Assembly and operating instructions