07/08

General information / Storage and transportation instructions

3.6 Fire safety

Please refer to local laws and regulations before installing modules and abide by requirements on building fire protection.

The roof should be coated by a layer of fireproof materials with suitable fire protection rating for roofing installation and

make sure that the back sheet and the mounting surface are fully ventilated.

Different roof structures and installation modes will affect fireproof performance of buildings. Improper installation may

lead to the risk of fire.

To guarantee roof fire rating, the distance between module frame and roof surface must be greater than 10 cm

Please use proper module accessories such as fuses, circuit breakers and ground connectors according to local laws and

regulations.

Please do not apply modules in where exposed inflammable gases are nearby.

4.1 Considerations for module unloading

Upon arrival of the modules, please check the packaging box is in good condition, and check whether the module type and

quantity on the outer packaging are consistent with the delivery order, if anything is wrong, please contact AIKO logistics

and sales staff immediately.

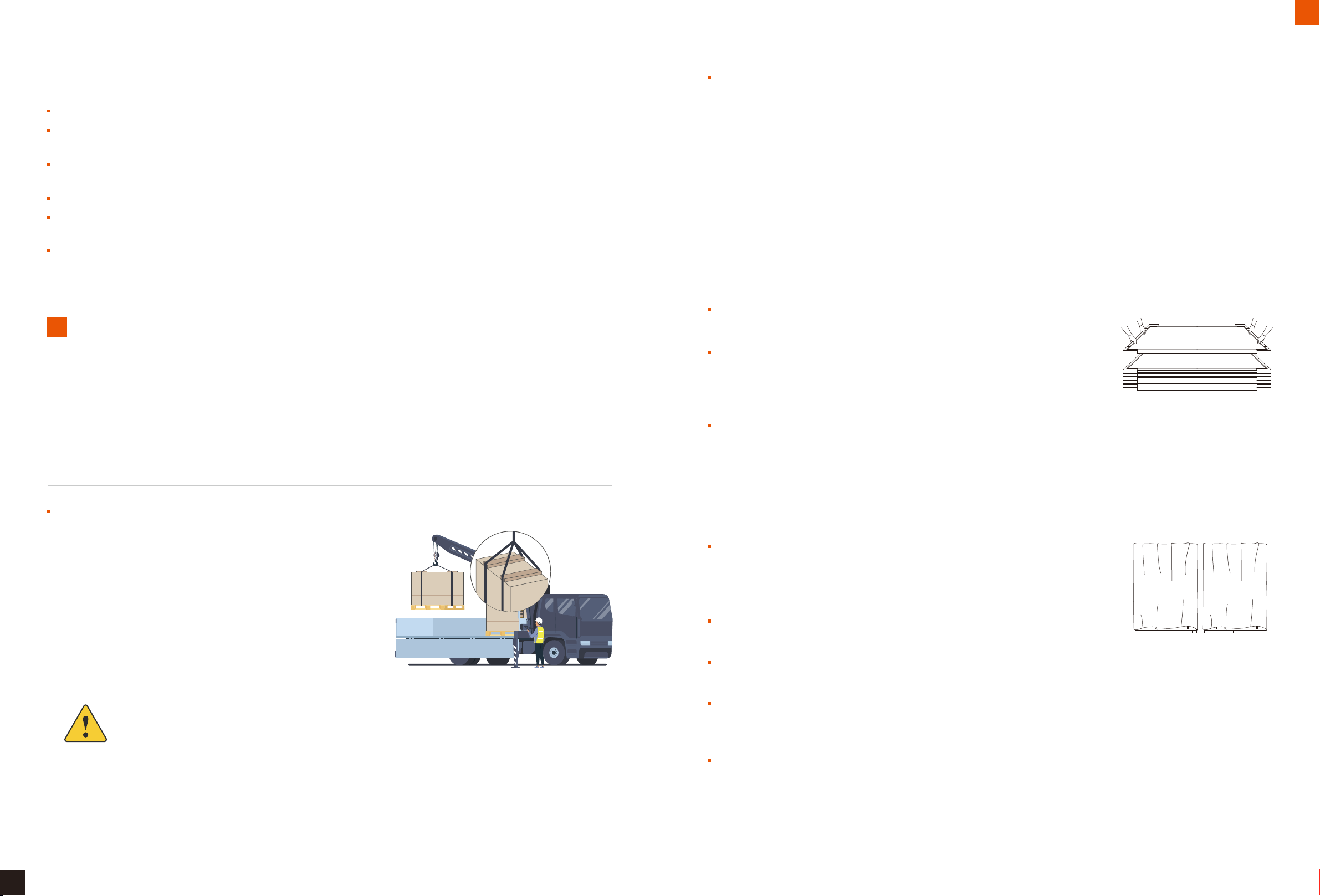

Crane unloading:

When unloading the modules by crane, please choose and use

specialized tooling according to the weight and size of the pallet.

Please adjust the position of the sling to keep the modules steady.

To ensure the safety of the module, wooden sticks, boards or other

fixtures of the same width as the outer packing cases should be

used on the upper part of the box to prevent the sling from

squeezing the pallet and damaging the modules. Please operate

the spreader at a constant speed, when the lifting is close to the

ground, place the box gently in a relatively flat ground.

Do not unload modules under the weather conditions of wind more than 6 class (in Beaufort scale)

Storage and transportation instructions

04

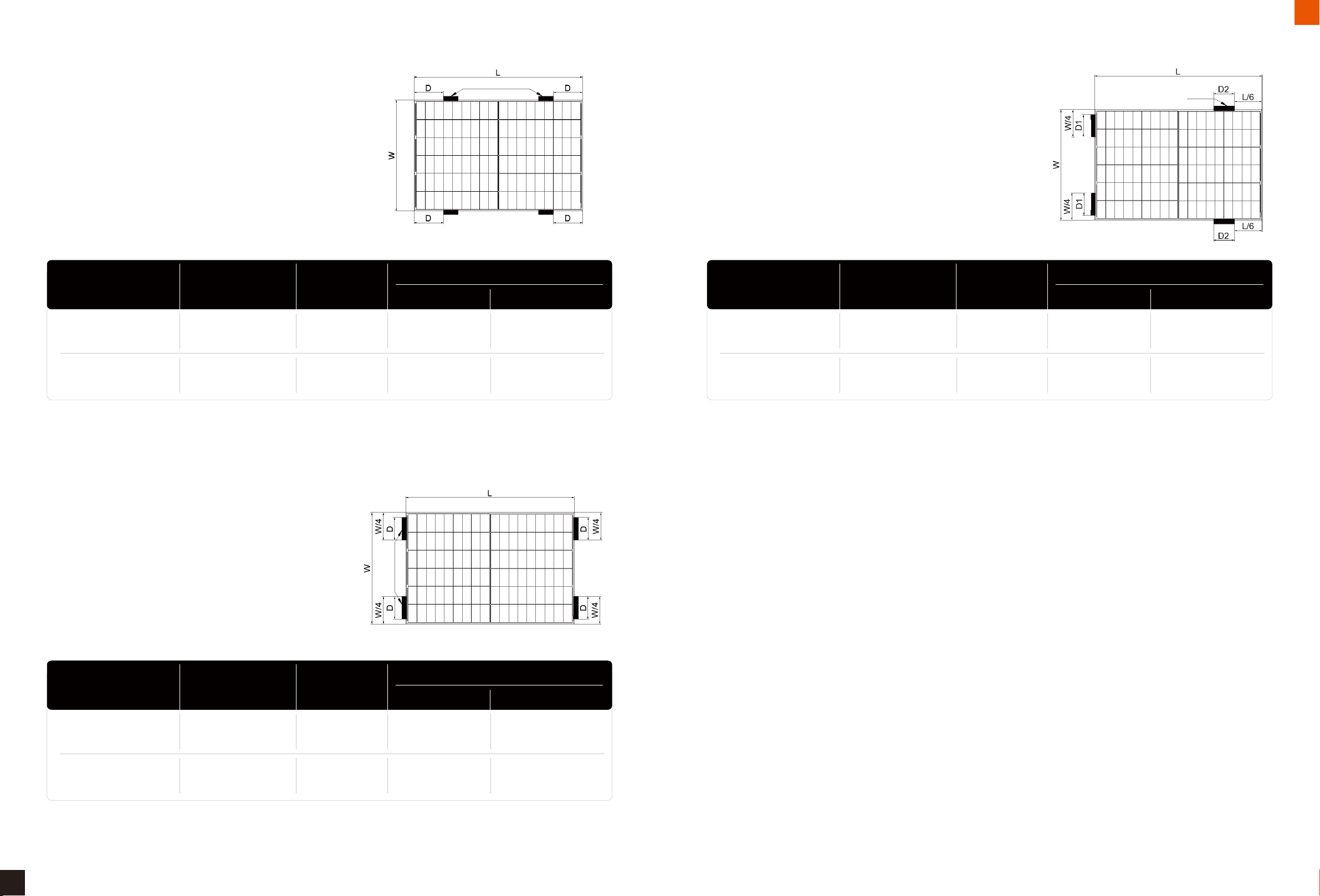

When using forklift to transport modules, please ensure that the fork length

meets the requirements to avoid module tilting due to uneven force.

When opening the packing box, please place the modules to be unpacked at a

distance of 20-30cm from the wall or another torr of modules, and then remove

the torr. After removing the cable tie of the fixed modules, slowly lean the

modules against the wall or another torr of modules to prevent them from falling.

Forklift unloading:

The loading dock should be as the same height as the underside of the carrier.

Keep the straight line speed of forklift within 5km/h and the turning speed within 3km/h. Please avoid sudden stop and

rapid start.

If the packing box blocks the sight of the forklift driver, it is recommended to drive backwards during the fork-lifting, and

arrange for special supervision and command to prevent bumping into people or items causing personal injury or damage

to the modules.

4.2 Considerations for module transportation

Please handle the installation modules gently during transportation, Do not lift the modules by pulling the junction box or

cables under any circumstances. Two or more people must hold the edges of the modules with both hands.

Please store the packing box of modules in a clean, dry place with relative

humidity below 85%. The storage temperature should be between -20 ℃ and

50 ℃ . When storing modules for a long time, do not place the two boxes of

modules on top of each other.

In any circumstances, keep the junction box and cables of the modules clean and

dry.

4.3 Considerations for module storage

Store modules in a ventilated, rainproof, dry place, If placed outdoor, please fully cover the modules and pallets with a

rain protection and take moisture-proof measures on pallets and cartons to prevent collapse and moisture ingress.

For the storage of unpacked modules, please stack the modules flat on the empty torr. The first module should be placed

with the glass side up, and the following ones placed with the glass side down. (A maximum of 25 pieces of modules for

54 types and 20 pieces of modules for 72 types can be stacked together).

For long-term storage, do not remove the original package and keep the wrapping film and carton box in a good

condition. It' s recommended to place modules in a standard warehouse for long-term storage and conduct regular

inspections. Once there is an abnormal tilt, please take enforcement measures in time.