esera automation ESERA-Station 200 User manual

Art. No. 19200

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH, ESERA-Automation 2020

www.esera.de 19200 V2.0 R1.0 Manual Page 1 of 10

User Guide

ESERA-Station 200

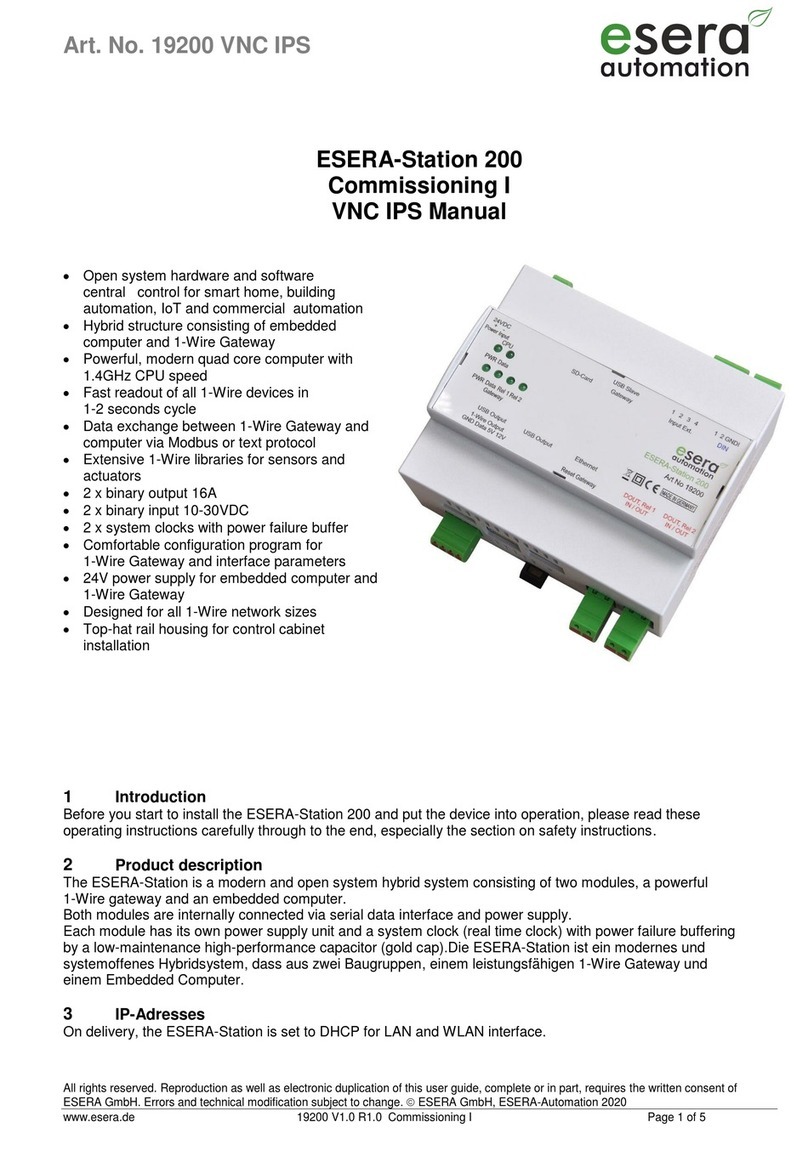

Central hard- and software control (system-open)

for smart home, building automation, IoT and

commercial automation

Hybrid construction consisting of Embedded

Computer and 1-Wire Gateway

Powerful, modern quad core computer with 1.4GHz

CPU speed

Fast reading of all 1-Wire devices within 1-2

seconds

Data exchange among 1-Wire Gateway and

computer via Modbus or text protocol

Large 1-wire libraries for sensors and actuators

2 x binary output 16A

2 x binary input 10-30VDC

2 x System clocks with power-failure buffering

Convenient configuration program for 1-Wire

Gateway and interface parameters

24V power supply for Embedded Computer and

1-Wire gateway

Designed for all sizes of 1-Wire Networks

Top-hat rail case for switchboard assembly

1 Introduction

Before you start assembling the ESERA-Station 200 and before you take the device into operation, please

read this assembly and operating instruction carefully to the end, especially the section referring to the safety

notes.

2 Product description

The ESERA-Station 200 is a modern and system-open hybrid system consisting of two modules, a powerful

1-Wire gateway and an Embedded Computer.

Both modules are internally connected by a serial data interface and the power supply.

Each module has an own power supply and a system clock (real time clock) with power-failure buffering by a low-

maintenance, high-performance capacitor (Goldcap).

2.1 Embedded Computer

The ESERA-Station 200 includes a standardized and powerful computer that comes with a

Quad Core CPU with 1400MHz. This CPU provides enormous power reserves by low power consumption. Given

to its 1024 MB RAM memory, even large automation projects can be implemented.

All modern interfaces such as LAN, WLAN with 2.4GHz and 5GHz, as well as Bluetooth with standard 4.2 are

available for connection with the "outside world".

The Embedded Computer also has 3 external and one internal USB 2.0 interfaces.

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH, ESERA-Automation 2020

www.esera.de 19200 V2.0 R1.0 Manual Page 2 of 10

2.2 1-Wire Gateway

In addition to the Embedded Computer, the ESERA-Station 200 has an extremely powerful and reliable 1-Wire

interface, the 1-Wire Gateway developed by ESERA.

The 1-Wire Gateway is internally connected to the Embedded Computer by serial interface. Via an USB slave

interface, the 1-Wire Gateway can also be accessed directly, without an Embedded Computer. Once you use the

USB interface, the internal communication to the Embedded Computer is interrupted. The Embedded Computer

is only able to receive data.

Standard Modbus TCP protocol

You can work with your industrial controller, e.g. SPS to communicate with the 1-Wire Gateway 20 via

standard Modbus TCP protocol. The addressing is structured in a way that is comparable to many other

Modbus systems. Addresses for system and sensor or actuator data are available.

An address overview with all available data points is available at the article download section of our website.

Independent administration

The ESERA-Station 200 is intended for self-sufficient management of 1-Wire networks. You no longer have

to worry about 1-Wire commands or formulas for evaluating sensor data. The ESERA-Station 200

independently scans the 1-Wire network for new sensors and actuators and makes them available, in plain

text by using Modbus protocol, depending on the modules found and the corresponding data converted.

Formatted data output

The ESERA-Station 200 provides plausibility checked sensor and actuator data in a ready to use format. E.g.

temperature sensor provides values in Celsius degrees with 2 decimal places. You only need to divide this

number by 100. Within the 1-Wire Gateway a product specific transformation table is available for all 1-Wire

sensor and actuator products offered by ESERA.

Designed for all 1-Wire Networks

The 1-Wire interface of the ESERA-Station 200 is specially designed to securely support all sizes of 1-Wire

networks, even for huge cable length. 1-Wire sensor devices can be operated in parasitic or normal mode at

the same time.

The latest available most powerful 1-Wire interface for a maximum level of data security has been used. This

includes complex network structures as well.

1-Wire Gateway configuration

Free configuration software (Config-Tool 3) is provided. When using Config-Tool 3, the latest documentation

is available at any time hence it automatically updates via internet. This software is available for download on

our webpage. Communication to Modbus TCP is parallel with no switching.

System time / real time clock

No real time clock with battery buffering available in your system? No problem at all. ESERA-Station 200 is

providing time and date as real time clock including an integrated backup battery. Data plausibility check is

possible at any time.

Power supply

The ESERA-Station 200 is supplied with the industrial 24V voltage.

Connection

Standard connectors are provided for USB and Ethernet connections. All other connectors are designed in

modern screwless push-in technology for rigid and fine-stranded cables with cross sections up to 1.5 or

2.5qmm.

Input voltage for the ESERA-Station 200 is 16 –30 VDC. Therefore it can be used for 24 VDC (industrial

applications). Appropriate hat-rail mounted power supplies or power plugs can be found in our webshop.

3 Auto-E-Connect® Support

The ESERA Auto-E-Connect® 1-Wire Plug and Play system will be used for the

1-Wire Bus supported. This enables fully automatic configurations of 1-Wire sensors

and actuators on the 1-Wire bus. It is optimized for industrial applications and

enables significant added value beyond the sensor and chip data.

Art. No. 19200

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH, ESERA-Automation 2020

www.esera.de 19200 V2.0 R1.0 Manual Page 3 of 10

The Auto-E-Connect function automatically recognizes ESERA chips, sensors and actuators, starts suitable

libraries and outputs fully formatted data.

The Auto-E-Connect functionality will be available from mid-2020 via 1-Wire Controllers, 1-Wire Gateways and

1-Wire ECO from ESERA available.

Further information on ESERA Auto-E-Connect can be found on the ESERA website, ESERA Config-Tool 3, or in

the download area for this article in the ESERA Webshop.

4 Technical data

Embedded Computer

CPU: Quad-Core processor ARM-Cortex-A53 64Bit, 1400 MHz

Memory: RAM 1024 MB LPDDR2 memory

microSD card 8GB for operating system and software application

Operating system: Linux Debian (Raspian), software already installed

Software, option: - IP-Symcon, basic, professional or unlimited

- Codesys 3.x

External interface: LAN RJ45 10/100/1000 Mbit (Gigabit LAN by USB 2.0 with up to 300 Mbit)

- Auto negotiation (full-duplex and half-duplex)

- Support for DHCP and IP-address

- DNS support

- Auto MDI/MDIX

WLAN 802.11 b/g/n/ac (2,4 + 5,0 GHz)

Bluetooth 4.2

System clock (RTC): DS1307 with ability to bypass power failure with Goldcap for min. 24 hours

1-Wire Gateway

Data interface: Modbus RTU and ESERA ASCII text protocol

Internal interface: serial, 19200 baud 8 data bit, 1 start bit, no stop bit

Firmware update and

configuration by ESERA Config-Tool 3

1-Wire interface: 1-Wire bus (Masse/GND, 5V, 12V and data)

Protection circuits: ESD- and reverse polarity protection

Connection: Push In connector for cables up to 1.5qmm cable cross section

Output voltage: 5V max. 1A, 12VDC max. 1,2A

Overload and short circuit proof

Digital- /binary input: 2 x input 10-30VDC, max. 10mA per channel

isolated with common negative pole

Push In connector for cables up to 1.5qmm cable cross section

Digital- /binary output: 2 x output (relays) 16A switching current (NO), isolated

Push In connector for cables up to 2.5qmm cable cross section

System clock (RTC): DS1307 with ability to bypass power failure with Goldcap for min. 24 hours

Entire system

Power supply: 16 –30 VDC

Input: 3,4 –38W*

* depending on the CPU load and load on the 1-wire interface

5 Ambient conditions

Temperature, operation -10 °C up to +55 °C (extended temperature range available upon request)

Air humidity: 10 –92 % (non-condensing)

Protection system: IP20

Protection class: III

Dimensions: 35 x 90 x 70mm (WxHxD)

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH, ESERA-Automation 2020

www.esera.de 19200 V2.0 R1.0 Manual Page 4 of 10

6 Conformity

EN 50090-2-2

EN 61000-4-2, ESD

EN 61000-4-3, HF

EN 61000-4-4, Burst

EN 61000-4-5, Surge

EN 61000-6-1, Fault-free operation

EN 61000-6-3, Stray radiation

RoHS

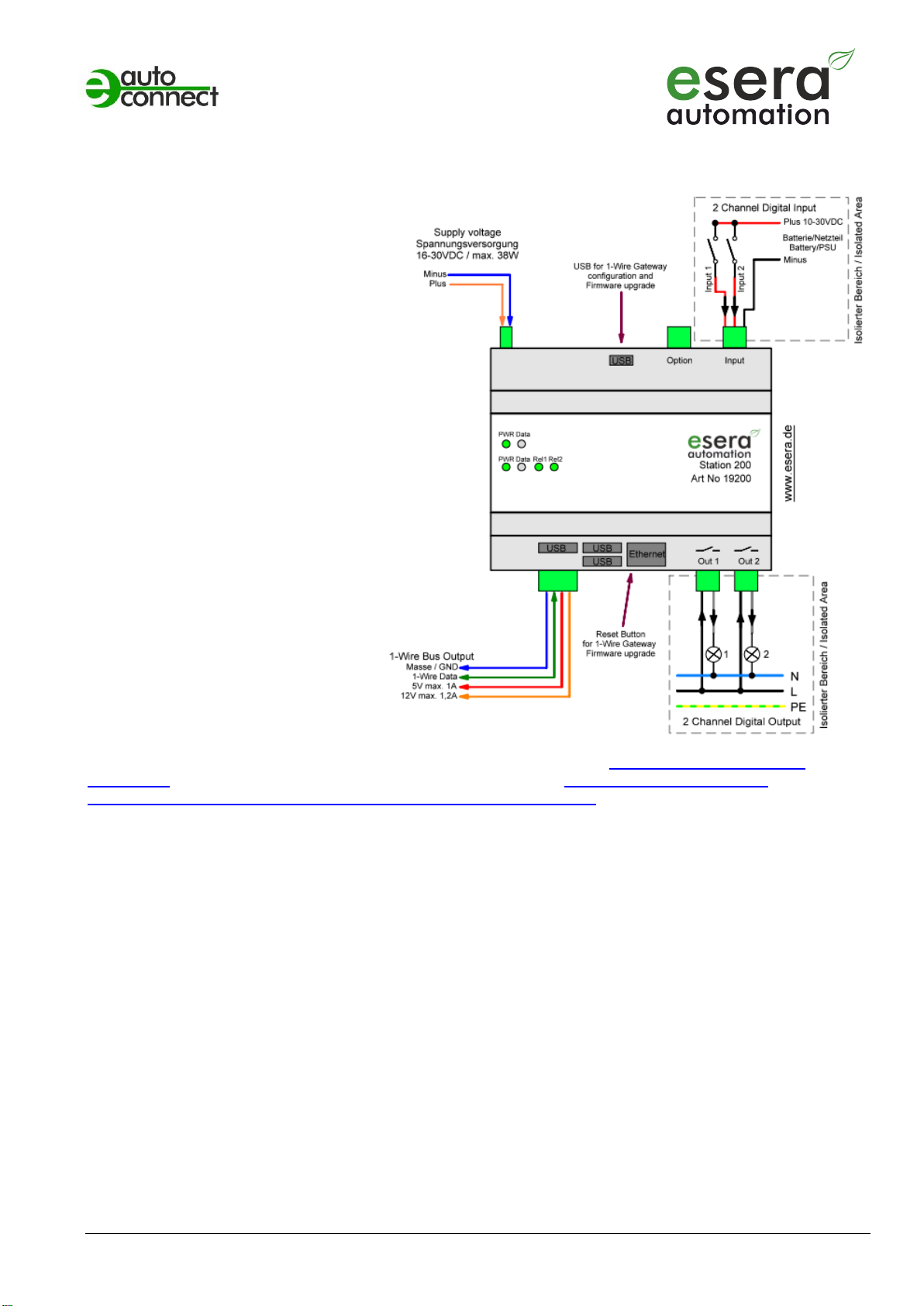

7 Block diagram

8 LED display

The ESERA-Station 200 has various display LEDs. Please refer to the following table for their functions:

LED Status

Description

Function

Embedded Computer

LED green front

PWR

Display supply voltage Embedded Computer

LED green front

DATA

LED, can be programmed for individual use (GPIO 27)

LED green Ethernet

DATA

Flashes while transferring data

LED green Ethernet

LINK

Is lit if Ethernet connection is active

1-Wire Gateway

LED green

PWR

Display supply voltage 1-Wire Gateway

LED green

DATA

LED flashes 3 times after power on

Flashes at 1-Wire activity

Flashes while transferring data by the data interface

Flashes rapidly if "KAL Receive" has been activated no

“KAL messages" received.

LED green

REL1

Output 1, is lit when relay 1 is active

LED green

REL2

Output 2, is lit when relay 1 is active

Art. No. 19200

All rights reserved. Reproduction as well as electronic duplication of this user guide, complete or in part, requires the written consent of

ESERA GmbH. Errors and technical modification subject to change. ESERA GmbH, ESERA-Automation 2020

www.esera.de 19200 V2.0 R1.0 Manual Page 5 of 10

9 Connection

Module top side (left to right)

Supply voltage 16-30VDC

USB Slave for 1-Wire Gateway

Configuration and firmware

update/upgrade

Optional input (not equipped)

2 x digital input 10-30VDC isolated

Module bottom side (left to right)

lower level

1-Wire bus output, Masse/GND, Data,

5V (max. 1A) and 12V (max. 1,2A)

Reset button for 1-Wire Gateway (inside)

Digital output 1 (max. 16A)

Digital output 2 (max. 16A)

upper level

3 x USB output (5V max. 0,5A)

Ethernet input RJ45

10/100/1000 MBit

Note: Basics and tips for 1-Wire bus systems can be found in our webshop (https://www.esera.de/1-wire-

grundlagen/) or in our e-book which is also available in our webshop (https://www.esera.de/service-

support/dokumentation/352/grundlagen-1-wire-bus-ebook?number=11901).

Other manuals for ESERA-Station 200

2

This manual suits for next models

1

Table of contents

Other esera automation Recording Equipment manuals