EsiWelma Sensigas UCE18 User manual

EsiWelma® s.r.l. E191.604_En Rev. 4 dated 30/11/2018 Pag. 1/4

EsiWelma® s.r.l.

E191.604_En

it

Istruzioni di installazione Centralina rivelazione fughe gas Sensigas®

UCE18

en

Installation instructions Gas leak detection system

fr

Instruction de installation Système de détection de fuite de gaz

en

English

These instructions must be kept together with the device.

General Information

The installation, the periodical inspections, or the devices

replacement must be done by qualified technicians.

The installation of a gas leak detection system for methane or

liquid petroleum gas (LPG), do not exempt from the compliance

to the safety rules and to all the laws in force concerning the

installation and the use of gas-operating-devices, for the

ventilation of the rooms and for the discharge of flue gases.

Installation

Mounting position

Check that environmental specifications of the installation place are

compatible with the values listed on Technical Data.

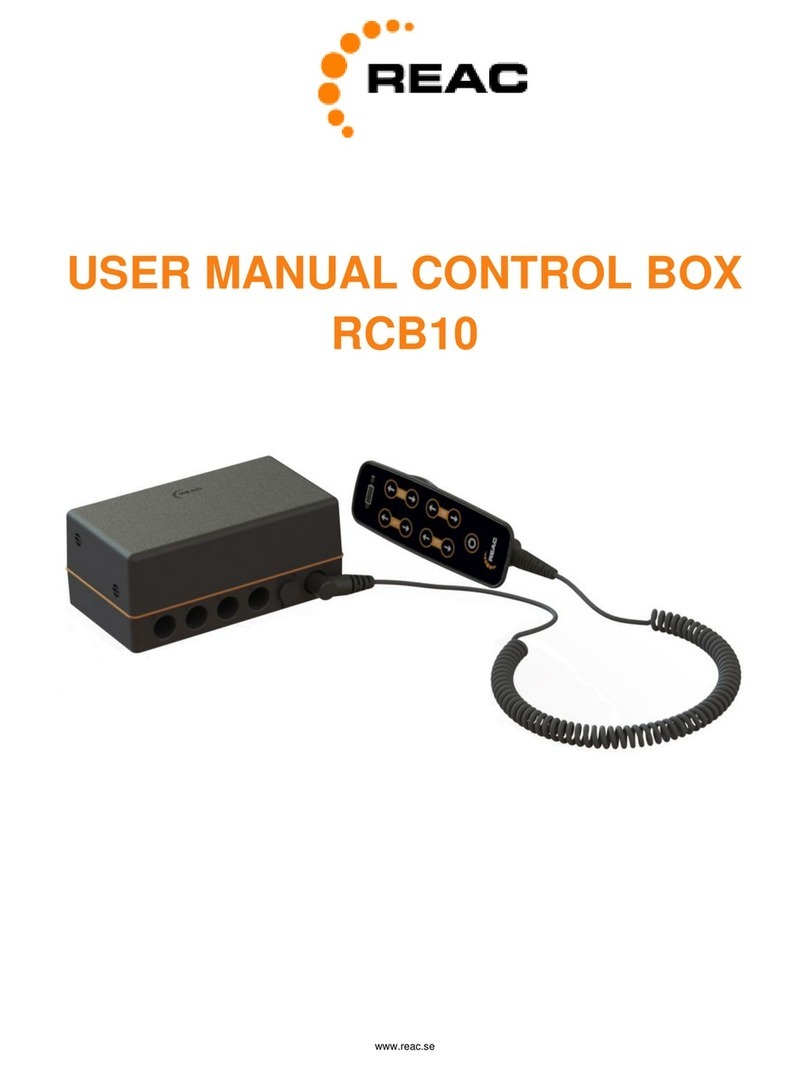

Control Unit UCE18

A on DIN bar (EN50022-35 x 7.5) min length 170mm

B on wall, with 2 screws

C on panel front end using a DIN bar length 195mm,

n°2 50mm spacers, screws and washers

A B C

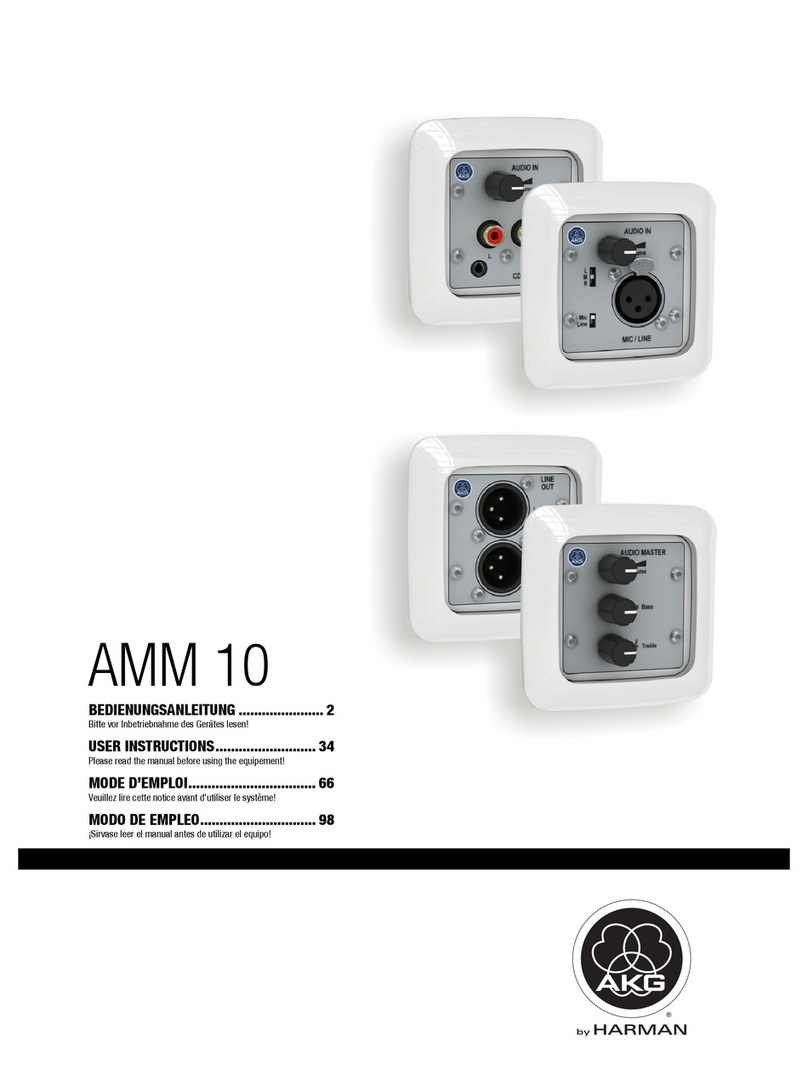

Sensors UR.13/A

On wall in an area subject to natural air circulation.

Never close to water jets, suction grids, windows, openings,

etc.

At a suitable distance from gas devices in order to avoid

unexpected system actions due to functional losses.

In an accessible position for controls and inspections.

Respect the correct mount orientation

in order to ensure the normal

convection air flow inside the sensor.

URG13/A: High, 20…30cm from the ceiling, to detect light gases

like methane, etc.

URG13.P/A: Low, 20…30cm from the floor, to detect heavy gases

like LPG, propane, butane etc.

URO13/A: At about 1,5m from the floor, to detect carbon

monoxide (CO)

NOTE for sensor installation

In case of a new plant the sensors should be installed as latest as

possible so that typical working-place activities (particularly welding,

painting, etc.) cannot damage the sensors (particularly their sensing

element). In any case the installation must be completed before gas

devices and gas appliances are activated.

Wiring

Common electric cables can be used. However, when installing in

places subject to high electromagnetic interference, use of shielded

cables is recommended.

The UCE18 must be permanently powered at 24VAC.

There is no protection against accidental connection with

230V on the 24V side.

Use double insulation safety transformers; they should be sized for

continuous operation at rated power (refer to Technical Data).

Comply with all current regulations for wiring

Connections must be done in accordance with the diagrams

reported in the following operating instructions

Conform to indicated cable length and cross section

Connect only valves at 12VDC with power not greater than 13W

each (total max 26W) to EV output

Internal relays with positive logic operation that is always

energized contact in case of alarm or fault absence.

Never touch for any reason the sensing element or

electronic circuit. Any tampering might compromise

the correct system operation.

Commissioning

UCE18 does not require any programming or parameterization.

Check that sensors are suitable for the gas type to be detected:

URG13/A = Methane sensor

URG13.P/A = LPG sensor

URO13/A = Carbon Monoxide (CO) sensor

Check that power absorbed by any devices connected to relay

terminals is lower than or equal to contacts maximum ratings

(please refer to Technical Data).

Make certain that termination resistors R=18Kohm 1/4W, factory

supplied, are disconnected from used sensor inputs, while they

must be connected to any unused sensor inputs (terminals C-

S).

If no valve should be connected to EV output, insert a valve

termination Rv 1.8Kohm 1/2W (factory supplied) in the EV ter-

minal. This will avoid any wrong valve fault signal.

s

QAG13/A

METHANE GAS METANO

Pag. 2/4 E191.604_En Rev. 4 dated 30/11/2018 EsiWelma® s.r.l.

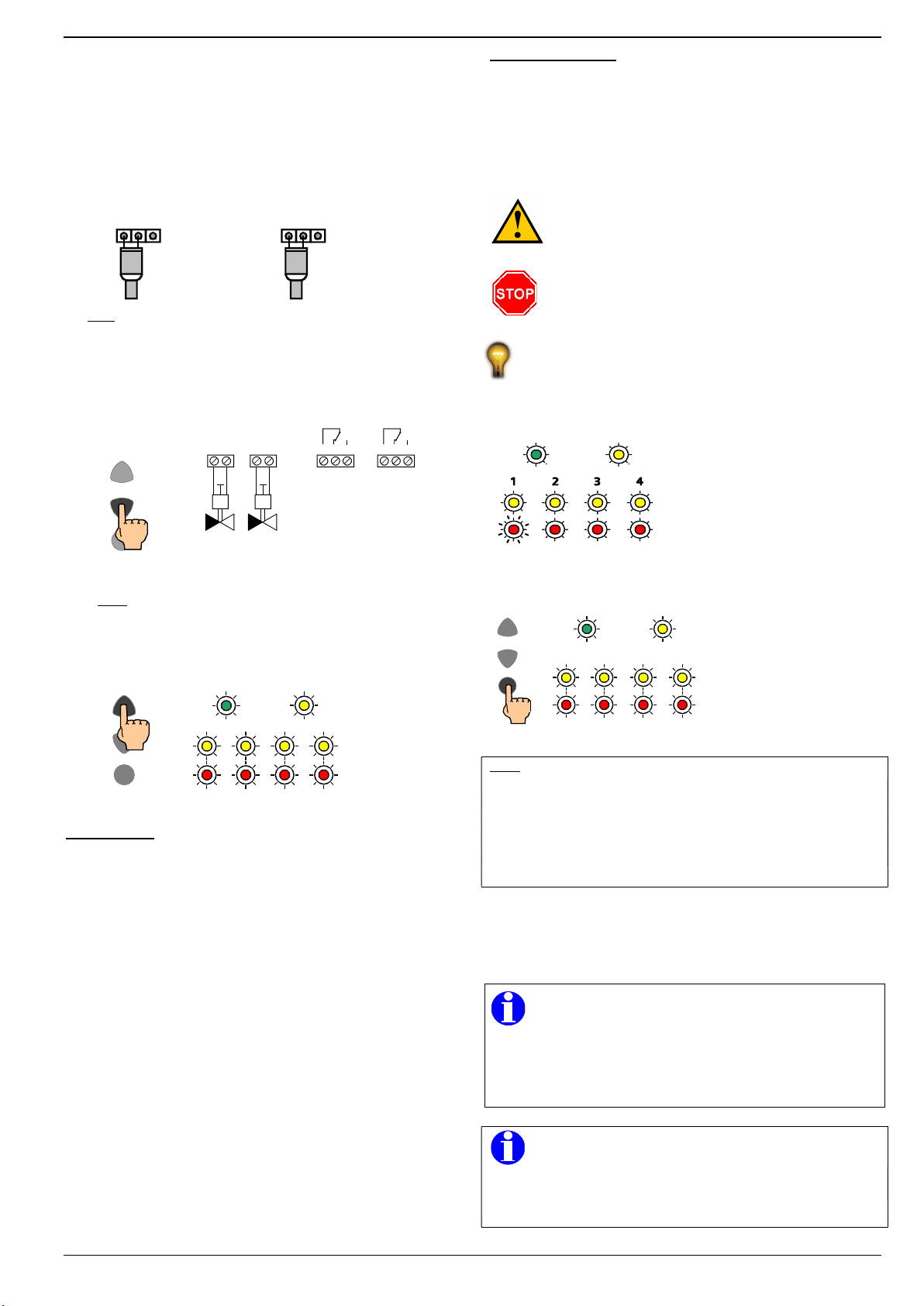

Jumper Setup

Set jumper JP2 VALVE TYPE to NC for normally closed valve type

(deliver condition) or to NO for normally open valve type.

Set jumper JP3 VALVE MODE only if normally open valve is used.

CONT position allows to set EV output constantly powered in

case of gas alarm, while PULSE position allows to set it powered

by impulses at 10s intervals.

Jumper for valve

mode selection

Jumper for valve

type selection

VALVE / TYPE

NC NO

VALVE / MODE

CONT. PULSE

NOTE: EACH CHANGE OF JUMPER SETUP MUST BE MADE UNDER POWER OFF.

Button functions

OUTPUT TEST button: if pressed for at least 5s, starting from

normal operating condition, temporarily activates all outputs

(valve + relay + hooter) in order to check regular operation of

intervention and signal devices.

LED

TEST

RESET

OUTPUT

TEST

5s

E V C NC NO

M

Relay outputs

de-energized

EV outputs

voltage absence (valve NC)

voltage presence (valve NO)

C NC NO

Alarm Fail

E V

M

Note: relay operation in positive logic

Energized relay = alarm / fault absence

De- energized relay = alarm / fault presence

LED TEST button: temporarily turns all LEDs ON in order to

check their integrity.

LED

TEST

RESET

OUTPUT

TEST

When button is

released the

LEDs go back to

their status

before the button

was pressed

Operation

When the UCE18 is powered at 24VAC preheating phase starts up

(about 1 min) while LEDs will indicate:

Green LED flashing (frequency 1Hz)

Control Unit Yellow LED steady on

Sensor Yellow LEDs steady on

Red LEDs steady on

During this phase there is no voltage at EV terminals, so it is not

possible to energize the solenoid valve(s) if NC type, while it is

possible to energize it/them if NO type. Further, the relays are not

energized.

After preheating phase, the test phase follows (3 min) while it is

possible to check sensors operation. To this purpose, all internal

timings for alarm management are zeroed.

In this phase LEDs will indicate:

Green LED flashing (frequency 2Hz)

Control Unit yellow LED steady on

Sensors Yellow LEDs steady on

Red LEDs steady on

During this phase there is voltage at NC solenoid valve(s), so it is

possible to open it/them using its manual actuator placed on the same

valve. The relays are energized.

Connect the battery to relevant terminals paying attention to polarity.

Operation test

During normal operation it is possible to simulate an alarm, in order to

check system functionality. Act as follows:

Activate test phase (if no more active after preheating) holding

down RESET button for at least 5s.

With cover fitted on approach a gas source to a sensor grid,

and let come out a small amount of gas.

CAUTION: don’t spray the gas directly on the sensor,

otherwise it will be permanently damaged. Act to

increase gradually the gas concentration close to the

sensing element.

Sensors can be permanently damaged when exposed

to high or continuous concentrations of interfering

substances (like fresh paint, ammonia based cleaning

materials, alcoholic or silicone solvents etc).

To check carbon monoxide sensor a combustion smoke can be

used.

After these operation the control unit must indicate a gas alarm status

with these effects:

- Sensor Red LED flashing

- Solenoid valve(s) driven to

closed position

- Changeover of alarm relay

contact (closed contact C -NC)

-

Piezoelectric hooter activated

(if present)

To restore normal operation, once alarm status is over, press RESET.

1 2 3 4

LED

TEST

RESET

OUTPUT

TEST

- Sensor Red LED re-

verts to steady on

- Alarm relay contact

reverts to initial position

(closed contact C - NO)

- Piezoelectric hooter

deactivated (if present)

Note:

An alarm or fault condition during test phase (3 min) causes

flashing of the relevant red or yellow LEDs at 2Hz frequency

instead of 1Hz as indicated in functional table. This latter will be

valid for events starting from normal operating condition.

Return to normal operating condition by pressing RESET button

is possible only if there aren’t any active alarms.

Open the solenoid valve(s) manually.

The control unit continuously checks connections integrity both

for sensors and valves.

The sensor will perform best if used in an area where the

only gas or vapor present, besides fresh air, is the gas or

vapor that you wish to detect.

If used in an area contaminated with relative high concentration

of different interfering substances (like fresh paint, ammonia

based cleaning materials, alcoholic or silicone solvents etc.),

false alarms may occur.

IMPORTANT

We recommend to repeat operating test at least once a year or

after a long stop period and in any case every time that a sensor

is replaced.

EsiWelma® s.r.l. E191.604_En Rev. 4 dated 30/11/2018 Pag. 3/4

Technical Data

Control Unit UCE18

Power supply voltage 24VAC +/- 10%

Frequency 50/60Hz

Power consumption 32VA max (with battery under charge)

Sensor inputs 4 x UR.13/A

Control outputs - 2 Electronic 12VDC (26W max total)

- 2 SPDT Relays 250V 5(3)A

Controlled valve type Normally Closed or

Normally Open

Operation logic positive (normally energized relays,

de-energize in case of alarm / fault)

“VALVE TYPE” Jumper

Valve type NO = Normally Open (type

NC = Normally Closed

“VALVE MODE” Jumper

Valve output mode CONT = continuous

(for NO type only) PULSE = pulses (1 pulse every 10s)

Optical signals (please refer to functional tables)

Green LED Power presence / test

Control U. Yellow LED Valve(s) / control unit fault

Sensors Yellow LEDs Sensor fault

Red LEDs Gas alarm

Sensors connection length

cable 1.5mm2 max 80m

Valve(s) connection length cable 1.5mm2 max 80m

(one cable per valve) cable 1.5mm2 max 40m (2 x 13W)

Battery protection fuse T3.15A 250V 5x20

Dimensions 174 x 106 x 56.5 mm

Protection IP20 – EN60529

Room temperature 0…50°C

Room humidity Max 90% R.H. non condensing

Sensors UR.13/A

Sensing element Tin dioxide semiconductor

Intervention threshold

URG13/A 20% LEL methane (10000ppm)

URG13.P/A 20% LEL LPG (3720ppm)

URO13/A 200 ppm CO

Protection IP44 (if correctly installed)

Average life time

5 years from installation date

Room temperature 0…50°C

Room humidity Max 90% R.H. non condensing

Built-in relay

Operation Positive logic (normally energized).

de-energizes in case of alarm / fault

Changeover contact Voltage free 250V 5(3)A

Built-in battery charger

Charge voltage 13.8VDC

Charge current 0.5A max

Battery 12V 6÷10 Ah (not supplied)

Automatic intervention and current limit

Conformity

Regulations Low Voltage 2014/35/UE

Electromagnetic Compatibility 2014/30/UE

Standards EN50194

EN50270

CAUTION

Lifetime of sensors URG13/A, URG13.P/A e URO13/A is 5

years from installation date. It is necessary to substitute

them systematically before the end of the 5th year of use.

Average lifetime of sensors has been calculated considering a typical

usage in an environment free of pollution substances (gases,

solvents, etc.). A frequent presence or high concentration of these

substances may accelerate normal oxidation process of the sensing

element and consequently shorten its decay time (lifetime).

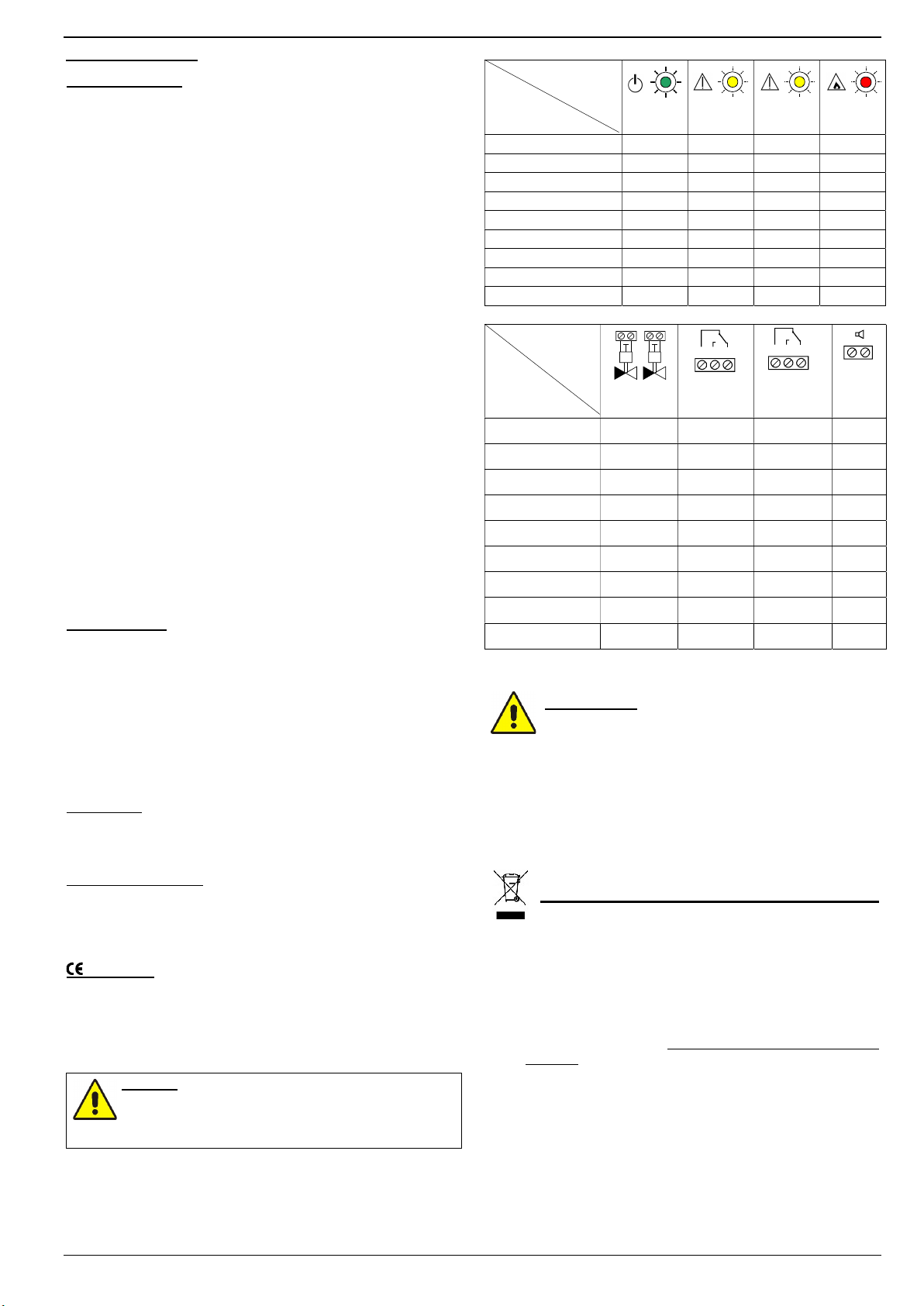

Functional tables

LEDs status

Functions

Green

LED

Control U.

yellow LED

Sensor

yellow LED

Sensor

red LEDs

Sensors preheating (1min) Flash 1Hz ON ON ON

TEST phase (3 min) Flash 2Hz ON ON ON

Normal operation ON ON ON ON

Gas alarm ON ON ON Flash 1Hz*

Valve fault ON Flash 1Hz ON ON

Sensor fault (up to 3) ON ON Flash 1Hz* OFF*

Sensor fault (all) ON OFF Flash 1Hz OFF

Ext. hooter alarm ON Flash 2Hz ON ON

General fault ON OFF OFF OFF

* for relative sensor(s) in alarm/fault

Output status

Functions

2 EV outputs

(NC valve)

Alarm relay

output

Fail relay

output

Hooter

output

Sensors preheat.(1 min) Voltage

absence De-energized De-energized Inactive

TEST phase (3 min) Voltage

presence Energized Energized Inactive

Normal operation Voltage

presence Energized Energized Inactive

Gas alarm Voltage

absence De-energized Energized Active

Valve fault Voltage

absence Energized De-energized Active

Sensor fault (up to 3) Voltage

presence Energized De-energized Active

Sensor fault (all) Voltage

absence De-energized De-energized Active

Ext hooter fault Voltage

presence Energized De-energized Active

General fault Voltage

absence De-energized De-energized Active

Simultaneousness of 2 or more events causes a combined manage-

ment of LEDs and outputs in accordance with a defined priority.

IMPORTANT

IN CASE OF ALARM FOR GAS LEAK OR CARBON

MONOXYDE PRESENCE ACT AS FOLLOWS:

Cut off all free flames and all gas-supplied devices

Do not switch-on or switch-off electrical lights or any other

electrically-supplied appliance, in order to avoid the

sparkling (cause of explosion for explosive gas)

Close the main valve of gas network or of LPG gas bottle

Open windows and doors to ventilate the rooms

Look for the cause of alarm, and eliminate it. If you are not

able to find and to eliminate the cause of the alarm, leave

the building, and, from the outside, call for emergency aids.

Environmental compatibility and disposal

This product was developed and manufactured using materials and

processes which take full account of environmental issues and which

comply with our environmental standards.

Please note the following for disposal at the end of the product life, or

in the event of its replacement:

For disposal, this product is defined as waste from electrical

and electronic equipment (“electronic waste”); do not dispose of

it as household waste. This applies particularly to the PCB

assembly.

Observe all current local laws and regulations.

Always aim for maximum re-use of the basic materials at

minimum environmental stress. Observe any notes on materials

and disposal that may be attached to individual components.

Use local depots and waste management companies, or refer

to your supplier or manufacturer to return used products or to

obtain further information on environmental compatibility and

waste disposal.

The UCE18 shipping case can be recycled. Retain it for future

use or in case of product return to the manufacturer

C NC NO C NC NO

+ -

E V

M

E V

M

Pag. 4/4 E191.604_En Rev. 4 dated 30/11/2018 EsiWelma® s.r.l.

Throubleshooting

Effect Possible cause

NC valves type do not open Valve not connected

No power

NO valve type instead of NC type

Incompatible valve type

(power absorption > 26W total)

Alarm not reset or current

Current sensor preheating phase

All sensors defective

General Fault presence

(NO) valve type

does not close

Valve not connected

Sensor not in alarm condition

Cable interrupted

RESET button does not

restore default conditions

A sensor still in alarm condition

Control unit fault

(Control unit Yellow LED OFF)

OUTPUT Test button does

not work

Current fault / alarm

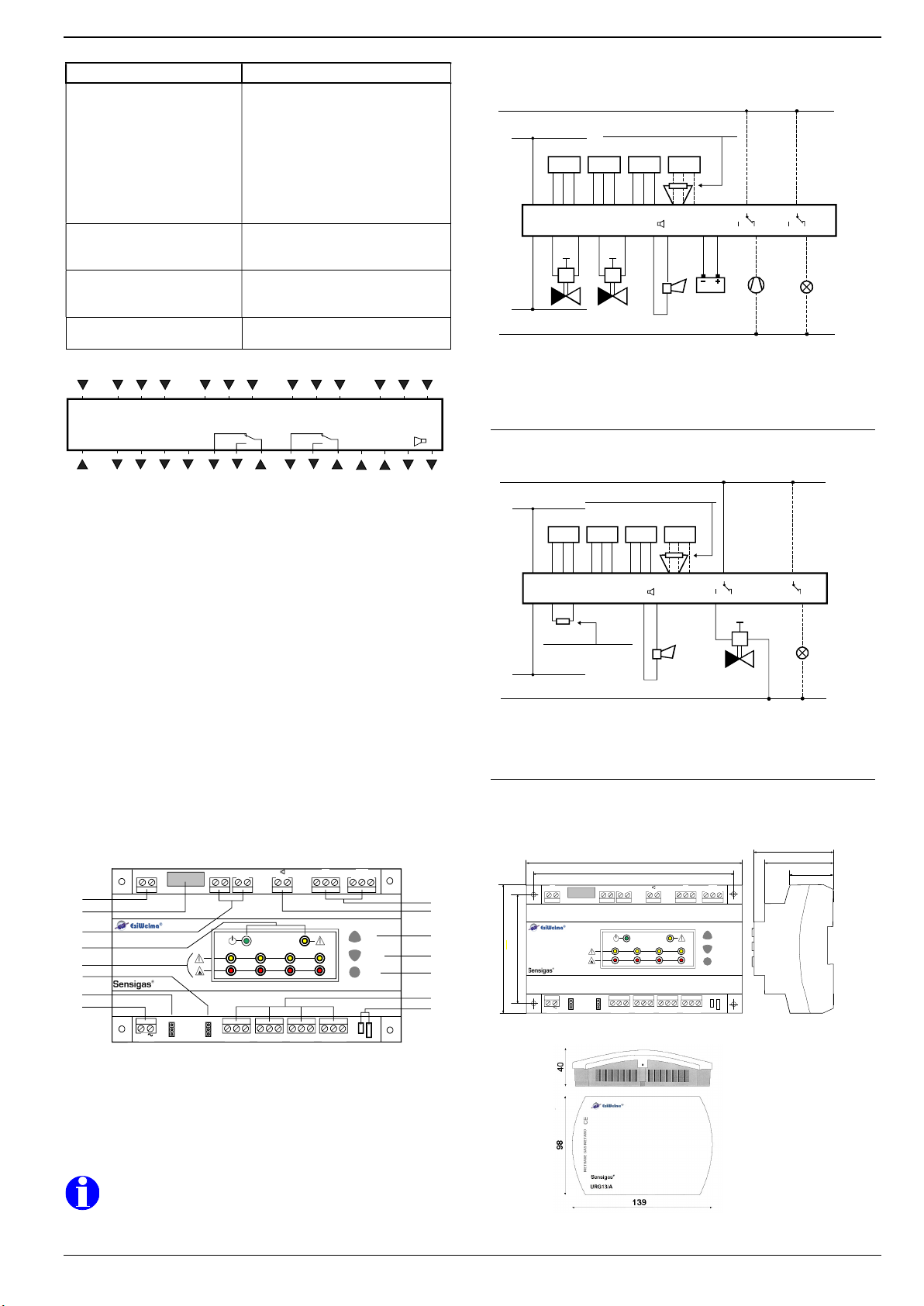

Connections

EV

G

G0

C1 S1 A1

+-

C

NC NO C

NC NO

+-

Batt

C2 S2 A2 C3 S3 A3 C4 S4 A4

EV

ALARM FAIL

G 24 V AC power supply, voltage

G0 24 V AC power supply, system neutral

C1 Sensor input 1 (common)

S1 Sensor input 1 (signal)

A1

Sensor input 1 (power)

C2 Sensor input 2 (common)

S2 Sensor input 2 (signal)

A2

Sensor input 2 (power)

C3 Sensor input 3 (common)

S3 Sensor input 3 (signal)

A3

Sensor input 3 (power)

C4 Sensor input 4 (common)

S4 Sensor input 4 (signal)

A4

Sensor input 4 (power)

E

Valve output 12VDC

V

Valve output 12VDC

C alarm

Alarm relay output (common)

NC alarm

Alarm relay output (normally closed contac

t)

NO alarm

Alarm relay output (normally open contact)

C fail Fault relay output (common)

NC fail Fault relay output (normally closed contact)

NO fail Fault relay output (normally open contact)

+ Batt Battery output +

- Batt Battery output -

+

Hooter output +

-

Hooter output -

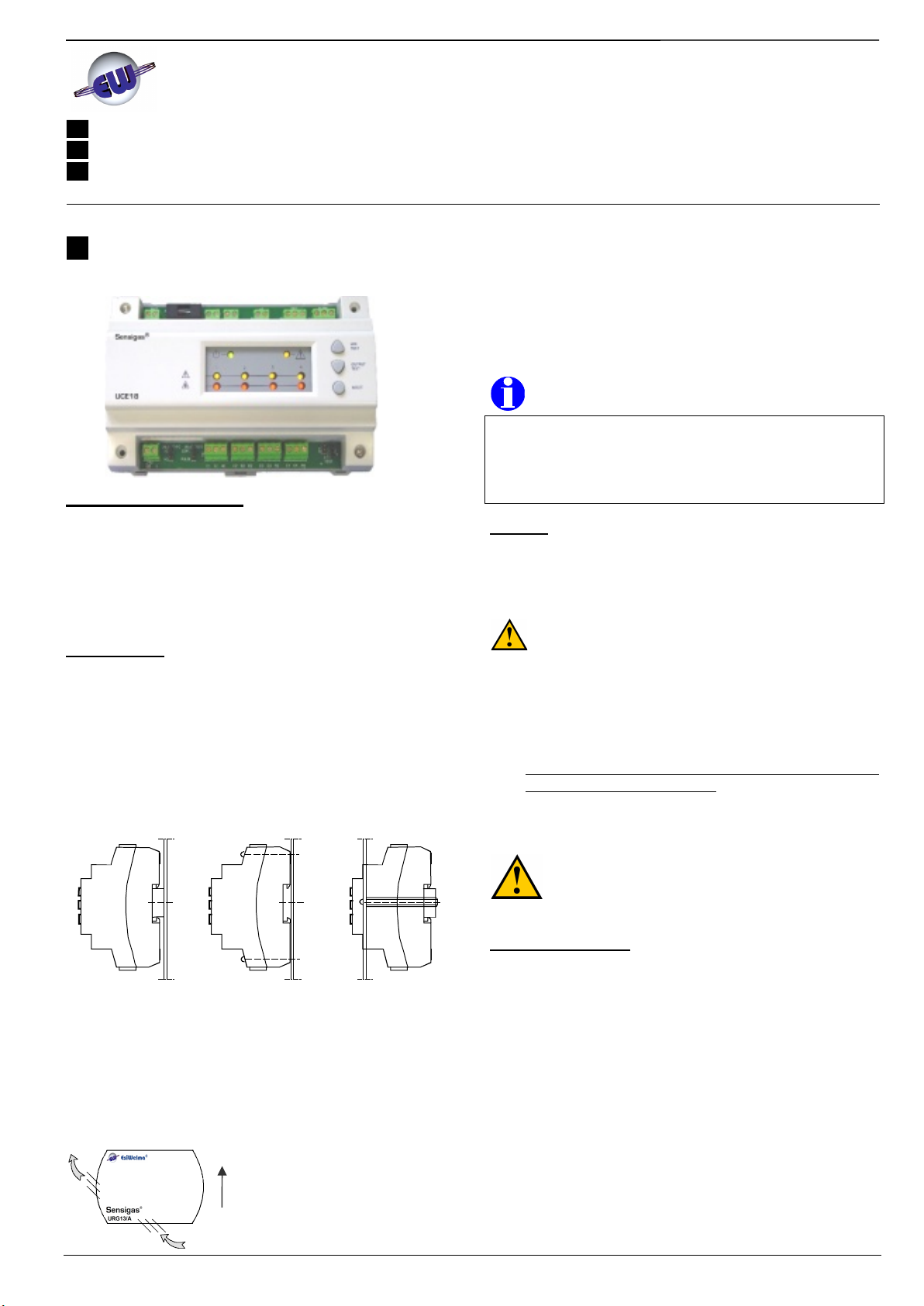

Layout

s

LYC18

LED

TEST

RESET

OUTPUT

TEST

1 2 3 4

G G0

24V

C1 S1 A1

E V C NC NO

C2 S2 A2 C3 S3 A3 C4 S4 A4

VALVE / TYPE VALVE / MODE

NC

NO

CONT.

PULSE

+ -

Batt. F1

3A

FAIL

C NC NO

ALARM

E V + -

1

2

7

8

9

10

14

15

11

12

13

3

4

5

6

1

Battery connection terminal 9

Alarm and Fail relay outputs

2

Battery protection fuse T3.15A 10

12VDC 300mA max hooter output

3

12V valve terminals 11

LED Test button

4

Control Unit status LEDs 12

OUTPUT Test button

5

Sensors status LEDs 13

RESET button

6

Valve Mode Jumper

14

Remote sensors terminals

7

Valve Type Jumper

15

Not used

8

24VAC power supply terminal

Due to our policy of continuous product improvement,

specifications are subject to change without notice.

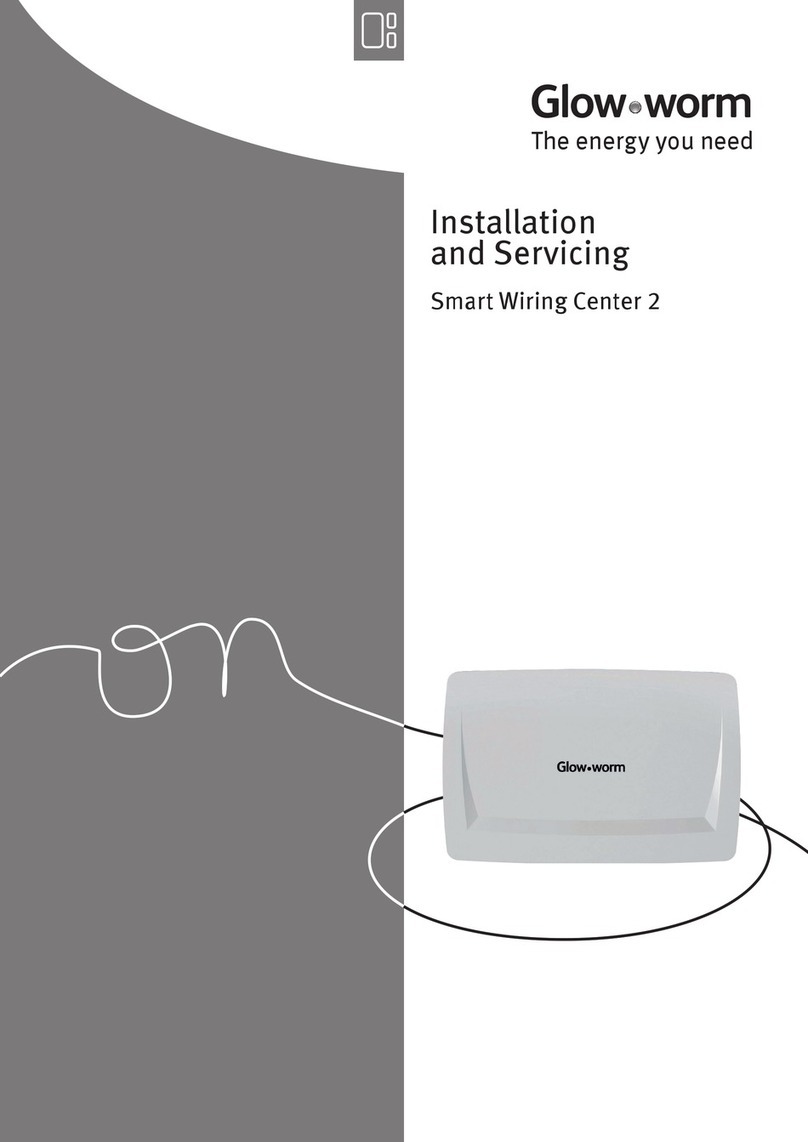

Wiring diagrams

Control unit UCE18 with 4 sensors and n.2 12VDC solenoid valves. 12V buffer

battery and external hooter. Optional devices (lamps, extractors).

Y1

24V AC

G

G0

G

G0 E V

B1

C S A

C1 S1 A1

+-

NO N C

C

M1V1

230V AC

L

N

BATT.

N1

C S A C S A C S A

B2 B3 B4

Y2 L1

N O N C

C

alarm fail

C2 S2 A2C3 S3 A3C4 S4 A4

+-

H1

M

E V

M

R

18Kohm 1/4W termination resistor

to be used in place of sensor

N1 Control unit UCE18

B1 ÷ B4 Sensors UR.13/A

Y1 ÷ Y2 Solenoid valves 12VDC

H1 External hooter 12VDC 300mA max

V1

Battery 12V 6÷10Ah (not supplied)

M1 - L1

Auxiliary devices (lamps, extractors, etc

.).

Control unit UCE18 with con 4 sensors and 230VAC solenoid valve. External

hooter 12V. Control of optional auxiliary devices (signal lamps etc).

Y1

24V AC

G

G0

G

G0 E V

B1

C S A

C1 S1 A1

+-

NO N C

C

230V AC

L

N

BATT.

N1

C S A C S A C S A

B2 B3 B4

L1

N O N C

C

alarm fail

C2 S2 A2C3 S3 A3C4 S4 A4

+-

H1

M

E V

Rv

R

18Kohm 1/4W termination resistor

to be used in place of sensor

1.8Kohm 1/2W termination

resistor to be used in place

of solenoid valve

N1 Control unit UCE18 Rv Factory supplied

B1 ÷ B4 Sensors UR.13/A

Y1 Solenoid valve 230VAC

H1 External hooter 12VDC 300mA max

L1

A

uxiliary devices (signal lamps, etc.).

Dimensions

UCE18

155

106

89

174

56.5

47.9

31

s

LYC18

LED

TEST

RESET

OUTPUT

TEST

1 2 3 4

G G0

24V C1 S1 A1

E V C NC NO

C2 S2 A2 C3 S3 A3 C4 S4 A4

VALVE / TYPE VALVE / MODE

NC

NO

CONT.

PULSE

+ -

Batt. F1

3A

FAIL C NC NO

ALARM

E V + -

UR.13/A

Dimensions in mm

UCE18

UCE18

Popular Control Unit manuals by other brands

Glowworm

Glowworm Smart Wiring Center 2 Installation and servicing

Smith & Nephew

Smith & Nephew 450P Operation & service manual

Heath Zenith

Heath Zenith DUAL BRITE SL-5318 user manual

alphainnoTec

alphainnoTec HMD 1 operating manual

Blackbe;rry

Blackbe;rry ITB100-1 installation guide

InWin

InWin Cobra IW-RS424-07 user manual

red lion

red lion Graphite GMDIO installation guide

Alarmcom

Alarmcom ADC-480Q user guide

Oriental motor

Oriental motor MSS W Series operating manual

seeed studio

seeed studio Grove-125KHz RFID Reader manual

Ublox

Ublox SARA-R4 Series System integration manual

Tripp Lite

Tripp Lite Power Accessory Module PAM-3 instruction sheet