EPM205-MRS - Technical reference - Preliminary Page 3

Advanced Printing Systems

TABLE OF CONTENTS

Sec. Page

1. INTRODUCTION 5

1.1 EPM205-MRS FEATURES...................................................................................................................................... 6

2. GENERAL SPECIFICATIONS................................................................................................................................. 7

3. PRINTER DEVICE INTERCONNECTION ................................................................................................................. 8

3.1 POWER SUPPLY CONNECTOR .................................................................................................................................. 8

3.2 SERIAL COMMUNICATION CONNECTOR ...................................................................................................................... 9

3.3 KEYBOARD CONNECTOR....................................................................................................................................... 10

3.4 PARALLEL COMMUNICATION CONNECTOR ................................................................................................................ 11

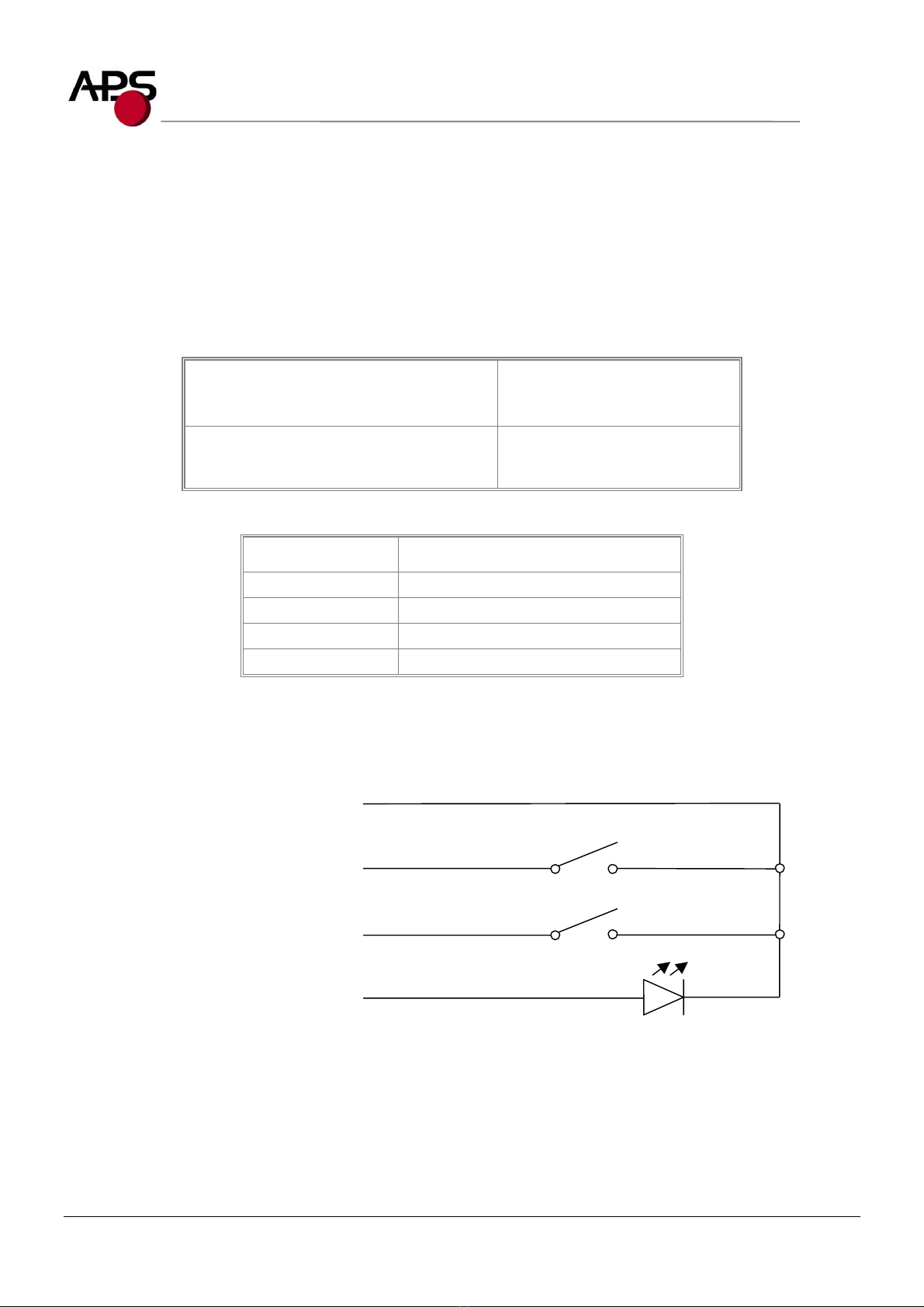

3.5 SLEEP MODE DISABLE CONNECTOR ........................................................................................................................ 11

4. EPM DEVICE OPERATIONS ................................................................................................................................ 12

4.1 KEYBOARD FUNCTIONS ........................................................................................................................................ 12

4.2 SELF TEST MODE................................................................................................................................................ 13

4.3 TIMING FOR PARALLEL COMMUNICATION ................................................................................................................. 14

4.3.1 COMPATIBILITY MODE TIMING (HOST WRITES TO THE PRINTER) ................................................................................... 14

4.3.2 BYTE MODE TIMING (HOST READS DATA FROM PRINTER)............................................................................................ 15

4.4 SERIAL / PARALLEL MODE SELECTION..................................................................................................................... 15

4.5 TEXT PRINTING FORMAT ...................................................................................................................................... 16

5. OPERATING CONTROL CODES .......................................................................................................................... 18

5.1 CONTROL CODES CROSS REFERENCE ..................................................................................................................... 18

5.2 SETUP AND HARDWARE CONTROL COMMANDS.......................................................................................................... 20

GS / n ........................................................................................................................................................................ 20

GS s n1 n2 ................................................................................................................................................................. 20

GS a n........................................................................................................................................................................ 20

GS D n....................................................................................................................................................................... 20

ESC @ ....................................................................................................................................................................... 21

ESC v ........................................................................................................................................................................ 21

ESC I......................................................................................................................................................................... 22

ESC S ........................................................................................................................................................................ 23

ESC A n..................................................................................................................................................................... 23

GS B n ....................................................................................................................................................................... 24

GS b n ....................................................................................................................................................................... 24

GS P n1 n2................................................................................................................................................................. 25

5.3 TEXT AND GENERAL COMMANDS ............................................................................................................................ 26

ESC % n.................................................................................................................................................................... 26

ESC R n..................................................................................................................................................................... 26

ESC 2 n ..................................................................................................................................................................... 26

ESC 3 n ..................................................................................................................................................................... 26

ESC SP n ................................................................................................................................................................... 27

ESC b n ..................................................................................................................................................................... 27

ESC c n...................................................................................................................................................................... 27

ESC C n..................................................................................................................................................................... 27

ESC ! n ...................................................................................................................................................................... 28

ESC { n...................................................................................................................................................................... 28

LF ............................................................................................................................................................................. 28

CR ............................................................................................................................................................................. 28

ESC J n ..................................................................................................................................................................... 29

ESC j n ...................................................................................................................................................................... 29

CAN .......................................................................................................................................................................... 29

5.4 GRAPHIC COMMANDS........................................................................................................................................... 30

ESC * n1 n2 n3 n4 n5 n6 <data> ................................................................................................................................ 30

ESC $ n1 n2............................................................................................................................................................... 31

ESC V n1 n2 n3 <data>.............................................................................................................................................. 31

5.5 BAR CODE COMMANDS ......................................................................................................................................... 32

GS k n [Start] <data> NUL ........................................................................................................................................ 32

GS h n ....................................................................................................................................................................... 32

GS w n....................................................................................................................................................................... 32

GS H n....................................................................................................................................................................... 32

GS R n....................................................................................................................................................................... 33

5.6 HOLE / BLACK MARK DETECTION COMMANDS ........................................................................................................... 34

GS L n ....................................................................................................................................................................... 34

GS T n1 n2 ................................................................................................................................................................ 34

GS E .......................................................................................................................................................................... 34

5.6.1 HOLE / BLACK MARK DETECTION EXAMPLES............................................................................................................. 35

6. MECHANICAL AND HOUSING ............................................................................................................................. 36

6.1 OVERALL DIMENSIONS AND FIXING POINTS .............................................................................................................. 36

6.1 MOUNTING PRECAUTIONS..................................................................................................................................... 37