0020140826_00 - 08/12 - Glow-worm

- 4 -

INTRODUCTION

EN

- Regulation concerning the Registration, Evaluation,

Authorisation and Restriction of Chemicals (REACH, No.

1907/2006)

In GB, the installation of the control unit must comply with the

requirements of the current issue of BS6798 and be carried out

by a competent person approved at the time by the Health and

Safety Executive and as described in the following regulations:

- The manufacturer’s instructions supplied.

- The Gas Safety (Installation and Use) Regulations.

- The appropriate Building Regulations (UK), The Building

Regulations (Scotland), The Building Regulations (Northern

Ireland).

- The Water Supply (water ttings) Regulations 1999 and water

byelaws 2000, Scotland.

- The Health and Safety at Work Act, Control of Substances

Hazardous to Health (COSHH).

- Any electrical work must conform to BS7671 and part P of the

building regulations where applicable.

Where no specic instructions are given, reference should be

made to the relevant British Standard Code of Practice.

In IE, the installation must be carried out by a competent person

approved at the time by the Health and Safety Executive and

installed in accordance with the current edition of I.S.813

“Domestic Gas Installations”, the current Building Regulations

and reference should be made to the current ETCI rules for

Electrical Installation.

GB: the following Codes of Practice apply: BS4814, BS6798,

BS5440 Part 1 and 2, BS5546 Part 1, BS5449, BS6891, BS6700,

BS7074 Part 1 and 2, BS7593, BS7671.

IE: I.S.813, BS5546, BS 5449, BS 7074, BS 7593.

NOTE: For further information, see the current issue of the

Building Regulations, approved document L1 ( in the UK) and the

following current issues of:

1) Central heating system specication (CheSS) and

2) Controls for domestic central heating system and hot water.

BRECSU.

Benchmark places responsibilities on both manufacturers

and installers. The purpose is to ensure that customers are

provided with the correct equipment for their needs, that it is

installed, commissioned and serviced in accordance with the

manufacturer’s instructions by a competent person approved at

the time by the Health and Safety Executive and that it meets the

requirements of the appropriate Building Regulations.

The Benchmark Checklist can be used to demonstrate compliance

with Building Regulations and should be provided to the

customer for future reference.

Installers are required to carry out installation, commissioning

and servicing work in accordance with the Benchmark Code

of Practice which is available from the Heating and Hotwater

Industry Council who manage and promote the Scheme.

Visit www.centralheating.co.uk for more information.

2.3.2 Domestic Hot Water

All domestic hot water circuits, connections, ttings must be

in accordance with the relevant standards and water supply

regulations.

2.3.3 Electrical Supply

The control unit MUST be earthed. All system components shall

be of an approved type and all wiring to current I.E.E. wiring

regulations. External wiring must be correctly earthed, polarised

and in accordance with the relevant standards.

In GB, this is BS 7671.

In IE, this is the current edition of ETCI rules.

The control unit MUST be connected to a permanent 230V ac,

50Hz supply.

2.4 CE label

The CE mark indicates that the products described in these

instructions are in compliance with the following directives:

- European Directive Num. 2004-108 of the European Parliament

and the Council regarding electromagnetic compatibility

- European Directive Num. 2006-95 of the European Parliament

and the Council regarding low voltage.

3 Description of the product

3.1 Product Overview

The control unit provides a system solution which permits eBUS

controllers to be combined with room thermostats, valves,

multizone heating and domestic hot water cylinder systems.

There are 2 functional modes that can be selected with the rotary

switch :

- Multizone mode (position 0) with SWC2 functions.

- Monozone mode (position 1) with SWC1 functions.

230V~ CYL.

2 1

DHW

CH1 CH2

ON

DHW

OFF

1

2

-

+

BUS NTC

0

1

Legend

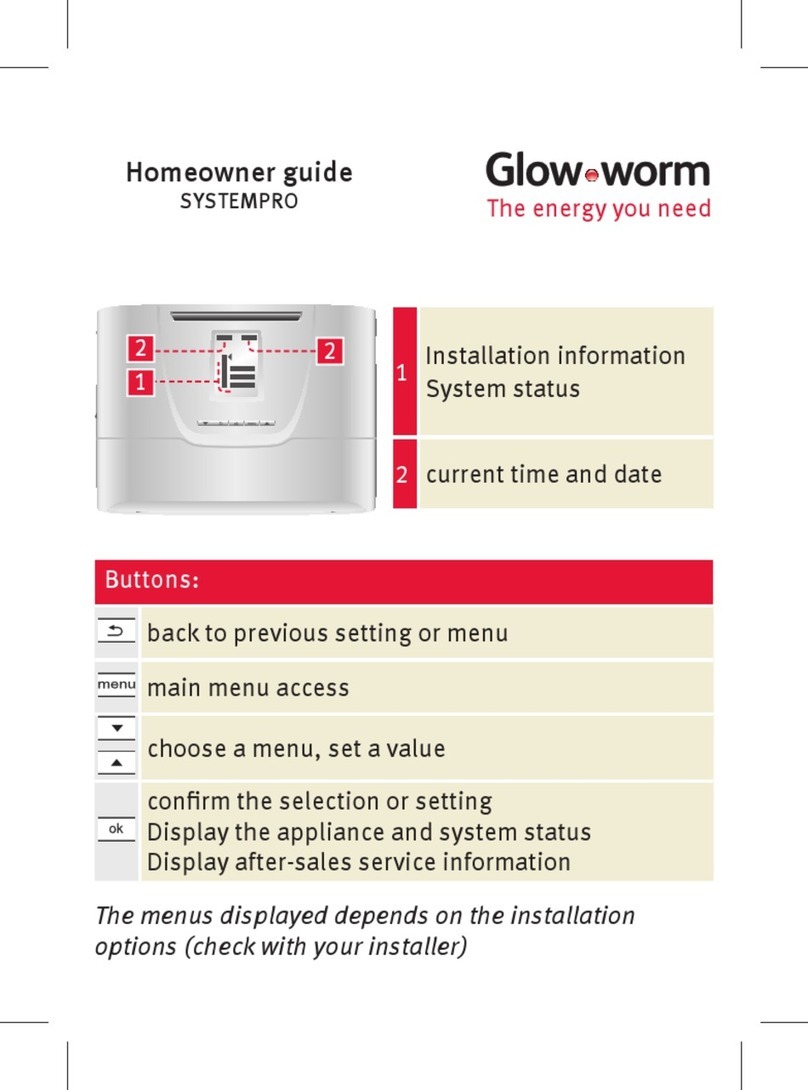

1 Rotary switch