ESL 429 Series User manual

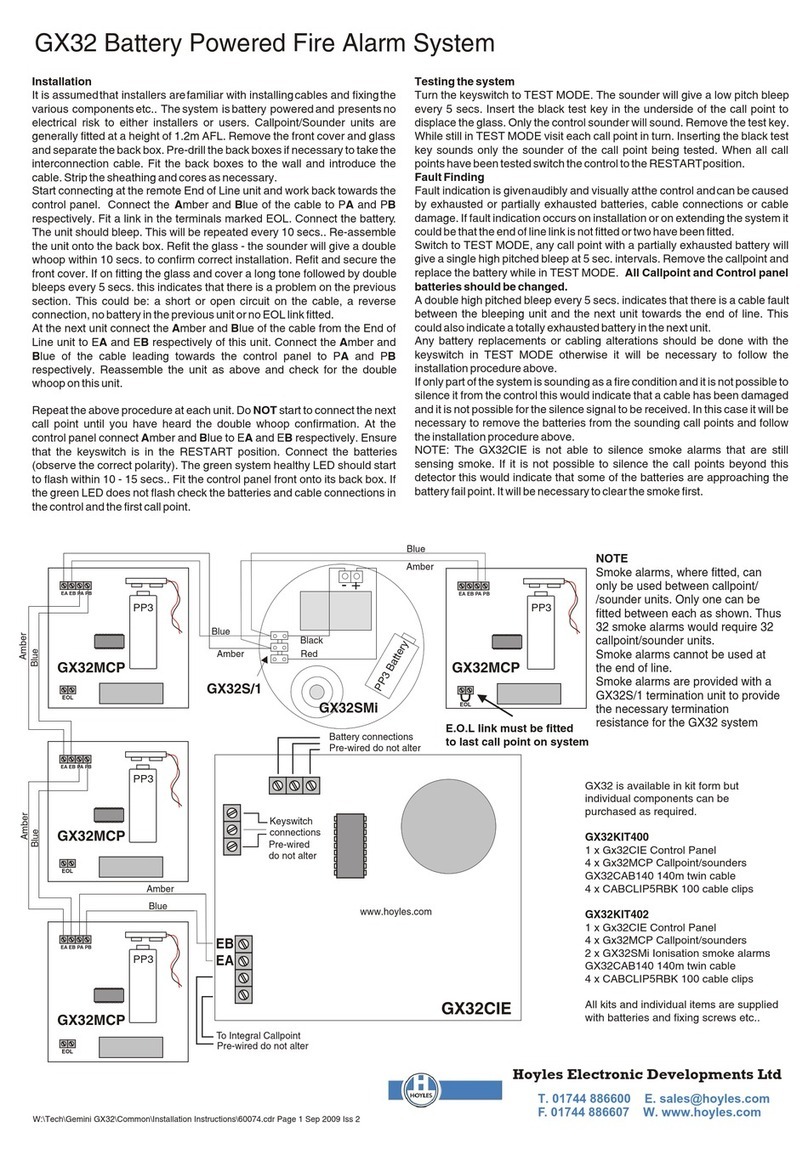

Two-Wire Compatibility

The ESL 429 Series two-wire, smoke detectors

offer the widest range of two-wire compatibility

in the industry. Refer to ESL’s Compatibility

Index for compatible control panel listings.

+

–

fire

alarm

initiating

circuit

models 429AT, 429C, 429CT,

429CST, 429CSST model 429CRT

END OF LINE

DEVICE

COMPATIBLE

LISTED

CONTROL UNIT*

first

detector last

detector

power

++--

auxiliary

contacts power

+

+

--

not used

429 & 428 Series Wiring Diagram

Diagram 2

GENERAL DESCRIPTION

TheESL429/449and428/448Serieslow-profile,self-diagnostic,two-

andfour-wiresmokedetectorsworkonthelightscatteringprinciple.A

pulsed infrared light-emitting diode serves as the light source, and a

high-speed photo-diode as the sensing element. This design has

superior protection against false alarms caused by dust, insects, RF

and ambient-light.

These Series of smoke detectors are especially suited for residential

occupancies,includinghotels,motelsanddormitories,aswellasother

commercial and industrial fire-system applications. This Series is

designedfor2-wire and 4-wireconnection,respectively, to 6-24VDC

fire alarm control panels, UL Listed for commercial or household fire

protection.

Plug-in terminal block

Diagram 1

ESL 429/449 & 428/448 SERIES

Self-Diagnostic Photoelectric

Smoke Detectors

Installation Instructions

Part Number 14153

California State Fire Marshal Approved

MEA (New York City) Approved

UL

LISTED

429/449

U

N

D

E

R

W

R

I

T

E

R

S

L

A

B

O

R

A

T

O

R

I

E

S

O

F

C

A

N

A

D

A

L

I

S

T

E

D

B

Y

428/448

+

–

DC

power

circuit

fire

alarm

initiating

circuit

models 449 & 448

AT, C, CT, CST, CSST

alarm

contact power

++--

models 449 & 448

CRT, CSRT, CLT, CSLT

auxiliary

contacts

(low temp output

CLT, SCLT) power

+

+

--

LISTED

CONTROL

UNIT

first

detector

alarm

contacts

model 448CSH*

power

+

+

--

heat sensor

contacts

model 449 & 448*

CSRH

local non-

latching

smoke alarm

contacts power

++

--

heat sensor

contacts

red

black

brown brown

POWER

SUPERVISION

UNIT

last

detector

Diagram 3

449 & 448 Series Wiring Diagram

*448CSH and 448CSRH are smoke alarms.

SMARTHOME™ 1-800-SMART-HOME 949-221-9200

http://www.smarthome.com Order #7309

firealarmresources.com

Optional Features

This Series includes a wide range of options, as shown in the Product

Selection Guide (Diagram 9) on back page. These options include a

built in sounder, an auxiliary relay, an integral heat detector, and an

isolated heat detector, to meet almost any application.

Self-Diagnostics Includes Automatic

Sensitivity Testing

Eachdetector in theSeriescontinually monitorsitsown sensitivity and

operational status. Once a day it performs a full diagnostic test that

includes dynamically testing the sensing chamber and internal elec-

tronics. If a detector drifts out of its UL Listed sensitivity range or fails

internal diagnostics, the alarm LED will flash once every second to

indicate trouble. This meets NFPA 72 field sensitivity testing require-

ments without the need for external meters.

NOTE: Connect to a power supply that will not automatically reset.

Since the self-diagnostics only indicate trouble after 27 hours, if the

power supply automatically resets every 24 hours the self-diagnostic

indication will never be signaled. (The smoke detector will still signal

alarm correctly.)

INSTALLATION

This Series of detectors mount to standard single-gang electrical

boxes, four-inch octagonal or four-inch square electrical boxes, or on

WIREMOLD No. 5739 fixture boxes. These detectors may also be

mounted directly to walls or ceilings where local codes/jurisdictions

permit.

First, pull wire through the electrical box and connect to the plug-in

terminal block supplied, one wire per terminal (see Diagrams 1, 2 and

3). Second, dress wiring neatly and snap the terminal block into the

back of the detector. Note: The detector cover must be closed com-

pletely, to support the circuit board, while installing the terminal block.

Now,openthecoverandmountthedetector,usingthemountingholes

provided (see Diagram 5).

All ESL smoke detectors are shipped with a plastic dust cover for use

inareaswhereconstruction is on-going.Smokedetectorswillnotwork

with the dust cover in place. Remove the dust cover when installation

is completed, prior to testing.

Smoke Detector Placement and Spacing

Ingeneralceilingmountedsmokedetectorsshouldbelocatednearthe

centeroftheroomorhallwheneverpossible,ormorethan4inches(100

mm) from any wall. When the detector is wall mounted, the top of the

detector should be 4 to 12 inches (100-300 mm) from the ceiling (see

Diagram 4). Refer to NFPA 72 for further mounting instructions.

Whenmorethanonedetectorisrequired,spacingof30feet(9.1meters)

may be used as a guide on smooth ceilings (as defined in NFPA 72).

Other spacing may be used depending on ceiling height, high air

movement, and other conditions or response requirements.

Low Temperature Output Models (CLT, CSLT Models)

Thesemodels havea separate relayoutput thatwill be energizedwhen

the ambient temperature around the detectors falls to approximately

43°F.Note:thisdetectorcontinuestohavethesameoperatingtempera-

ture range as standard models –32°F (0°C) to 120°F (50°C). Run 6

conductorfirewirefromacombinationburglar/firealarmpaneltosmoke

detector. Connect low temperature relay contact to a separate non-fire

zoneonacombinationburglar/firealarmcontrolpanel.Warning:Donot

connect low temperature output relay to fire alarm zone.

Where NOT To Place Detectors

One of the major causes of nuisance alarms is improper placement of

detectors.Avoidlocatingdetectorstooclosetokitchensorwoodstoves,

where smoke can be generated. Garages and furnace rooms are also

poor locations, due to exhaust fumes. Placing detectors too close to

bathroomscancauseproblemsfromsteamybathsorshowers.Alsodo

not install detectors where normal ambient temperature can be over

100°F(37.8°C),suchas attics. Referto NFPA72 formore information.

Supervision of System Wiring

Power wiring in four-wire systems is required by NFPA 72 to be

supervised.Thisisaccomplishedbyinstallingapowersupervisionrelay

attheend ofthedetectorpowercircuit. Thecontactsof thesupervision

relayarewiredinserieswiththesystem’salarminitiatingcircuit,andare

closedwhenenergized(seeDiagram3). Abreak inthedetectorpower

circuit or a loss of power de-energizes the power supervision relay,

opening the contacts and causing a trouble annunciation at the fire

alarm control unit.

ESL Models 204-6 V and 204-12/24 V are relays UL Listed for 4-wire

powersupervision. ESLModel204-12/24V CAN is arelayULCListed

for 4-wire power supervision. Models 449/448CTE, 449CSTE, and

449CSSTE are smoke detectors with a built-in end-of-line power

supervision relay, and can be used to supervise a circuit in place of a

powersupervision relay. The449CTE, 449CSTE, and449CSSTE will

also automatically send a trouble signal to the control panel whenever

thedetector needs maintenance. Proceed with sensitivity testing on all

detectors as outlined on next page.

Diagram 5

NOTE: Positive air pressure from wire openings, conduit, mounting boxes,

irregular mounting surfaces, or plenums causing air movement through

and away from the detector may prevent proper operation. Seal all

openings causing unwanted air flow using UL Listed expanding foam or

Duxseal.

mounting

all boxes

4" square or

WIREMOLD mounting

(No. 5739)

single gang 4"

octagon

mounting

cover release

test switch

6.1"

(15.5 cm)

1.85" (4.70 cm)

For instructions on removal

of terminal block and

circuit board call technical

services at 800-648-7424.

Diagram 4

ceiling

acceptable here

never here

4 in.

(100 mm)

4 in.

(100 mm)

minimum

12 in.

(300 mm)

maximum

top of detector

acceptable here

side

wall

NOTE:

measurements shown are to the

closest edge of the detector

Note: Measurements shown are to the closest edge of the detector.

SMARTHOME™ 1-800-SMART-HOME 949-221-9200

http://www.smarthome.com Order #7309

firealarmresources.com

without the need for external meters. In accordance with NFPA 72,

smoke detector sensitivity should be checked within one year after

installation and every alternate year thereafter, in commercial installa-

tions, or every three years in residential sites.

The replaceable sensing chamber of the 400 series photoelectric

detector unsnaps for easy field cleaning and service. Whenever the

status LED indicates cleaning is necessary, open the detector cover,

unsnap and throw away optical block chamber. Then thoroughly blow

off the optical base and snap a new optical block chamber (part #211)

back in place. NOTE: Be sure new optical block chamber is seated all

the way down. Close detector cover and verify sensitivity with the

sensitivity level test (below).

Sensitivity Level Test Mode

Each detector includes a sensitivity test mode that is activated by

holding a magnet near the integral reed switch for more than one

second (see Diagram 7). This initiates the self-diagnostic routine and

providesvisualindicationifserviceisrequired.ThealarmLEDprovides

the indication listed in Diagram 8.

Afterthesequence of blinks,ifthe sensitivity isfoundto be withinlimits

and if all other tests pass, the detector will go into alarm until reset by

the panel. If the sensitivity is not within limits, or an unserviceable

hardwarefault has been detected, the alarm LEDwill continueto flash

once per second until the detector is reset by

thepanel.Ifsensitivitytestindicatesanunacceptablelevel,takeaction

recommendedabove.Ifactiondoesnotresultinacceptablesensitivity,

replace unit.

Approvals

The smoke detector is for use in commercial fire protective signaling

systems and in household fire warning systems. (NFPA 72).

429/449 Series

Listedby UnderwritersLaboratories Inc.; California State FireMarshal

approved (Listing #7272-0447-128); MEA approved [New York City]

(Listing #MEA 64-94-E) Factory Mutual approved.

449CLT/449CSLT Series

Listed by Underwriters’Laboratories, Inc.

428/448 Series

Listed by Underwriters’Laboratories of Canada (Listing # CS205).

Testing the Installation

After all connections are complete and the wiring is checked for errors,

apply power to the system. There should be no alarm. If an alarm is

reported,determineifadetectorislatchedinalarmorifthereisaproblem

with the wiring.

Allsmokedetectorsshall be testedatleastannually in accordance with

NFPA 72. The preferred method for functional testing is with Smoke! in

a can®, available from ESL. Follow the instructions on the can carefully

to ensure proper testing. Other brands of canned smoke are not

recommended due to potential for contamination. Other acceptable

testing methods are; a smoldering punk stick or a cotton wick.

Thedetectorsamplesforsmokeaboutevery9seconds,whileflashing

its LED. If smoke is detected, the sampling increases to every 4.5

seconds. Excessive smoke must be detected in three consecutive

samplesforthealarmtoactivate. Therefore,whentestingthedetector

withsmolderingpunksorcottonwicks,holdthesmokesourcenearthe

smoke entry and gently direct smoke into the detector for 20 seconds

or until alarm is indicated. BESURETOPROPERLYEXTINGUISHTHE

SMOKE SOURCE AFTER TESTING!

This is a go/no-go test and is not a reliable indication of detector

sensitivity. If it is successful, the LED will remain lit. To reset the

detector, operate the system reset switch to remove power from the

detectors. Control unit alarm and all auxiliary functions should be

verified for a complete test of each detector.

Models with heat sensors sample for heat every 3 seconds. Test heat

sensors by using a hot air gun. Aim at heat sensor from 6-10" away.

Detector should go into alarm in less than 30 seconds. Be careful not

to melt plastics.

MAINTENANCE, CLEANING and

SENSITIVITY TESTING

Thisseriesofself-diagnosticsmokedetectorsisdesignedforeasyfield

service and maintenance. If a detector drifts beyond its approved

sensitivity range for more than 24 hours, or fails internal diagnostic

tests, the unit automatically indicates trouble by flashing its LED every

second. This meets NFPA 72 field sensitivity testing requirements

optical block cover

optical base

snap into indentation

indentation

SQUEEZE

HERE

LED

Diagram 6

Diagram 7 To activate sensitivity level test

mode, hold magnet on hinge side of

detector for more than 1 second.

magnet (for best results

position magnet slightly

off center)

Diagram 8

Approximate

obscuration Blinks Indication Action

(%/ft.)

429/449 428/448

1 Unserviceable hardware fault is detected Reset unit and re-run sensitivity test, if indication remains the same,

replace unit.

2.69 3.05 2 The detector is not sensitive enough Clean per instructions. Reset unit and re-run sensitivity test, if

2.46 2.75 3 indication remains the same, replace unit.

2.23 2.50 4 Detector is within sensitivity limits None

2.00 2.15 5

1.77 1.85 6

1.54 1.50 7 Detector is too sensitive Check to be sure optical block cover is snapped down completely.

1.31 1.25 8 Clean per instructions.

1.08 0.90 9

SMARTHOME™ 1-800-SMART-HOME 949-221-9200

http://www.smarthome.com Order #7309

firealarmresources.com

Sentrol reserves the right

to change specifications

without notice.

©1999 Sentrol

12345 SW Leveton Dr., Tualatin, OR 97062

Tel.: 503.692.4052 Fax: 503.691.7566

http://www.sentrol.com

U.S. & Canada: 800.547.2556

Technical Service: 800.648.7424

FaxBack: 1.800.483.2495

SENTROL

ESL

a product of sentrol

Diagram 9

Electrical Specifications

449CSRT

Series Designator

Wire Type

Features

Power Designator

Model Designator

* 429 models draw up to a maximum of 60mA alarm current if not limited by panel.

Product Data

Sensitivity

428/448 - minimum............... 2.0 + 0.50%/Ft.

- maximum .............. 2.0 - 0.50%/Ft.

429/449 - minimum............... 2.0 + 0.37%/Ft.

- maximum .............. 2.0 - 0.39%/Ft.

Operating temp .... 32°F to 120°F (0°C to 50°C)

Operating humidity range............. 0 to 95% RH

Sounder specifications.............. 85 dB at 10 Ft.

Color............................. white cover/white base

Field wiring size......................14-24 AWG

E-3914-0999

14153 Rev. B

Model Designator

Designator Listing

449 UL

448 ULC

Product Selection Guide Model Designator

Designator Power

A 6/12 V DC

C 12/24 V DC

Wire Type

Number Description

2 Two-wire only

4 Four-wire only

Max. Ripple Typ. Ave. Stby. Typ. Alarm Cur. Typ. Ave. Pol. Alarm Relay Other Relay

Model 2-Wire 4-Wire Min.Volt. Max. Volt. (PK To PK) Cur. (12-24V) (12-24V) Rev. Cur. Contacts Contacts

(V) (uA) (mA) (mA) (A) (A)

429AT, 428AT •6.5 20 10% 70 *see S09A –––

429C, 428C •8.5 33 10% 70 *see S10A –––

429CT, 428CT •8.5 33 10% 70 *see S10A –––

429CRT •8.5 33 10% 70 *see S11A ––2

429CST, 428CST,429CSST •8.5 33 10% 70 *see S11A 10 ––

449C, 448C •8.5 33 10% 70 15 –0.5 –

449CT, 448CT •8.5 33 10% 70 15 –0.5 –

449CRT •8.5 33 10% 70 31 –0.5 2

449CLT, 448CLT •8.5 33 10% 70 15 –0.5

449AT, 448AT •5.1 27 10% 70 15 –0.5 –

449CST, 448CST •8.5 33 10% 70 40 10 0.5 –

449CSRT •8.5 33 10% 70 51 10 0.5 2

449CSLT, 448CSLT •8.5 33 10% 70 40 10 0.5 –

449CSRH •8.5 33 10% 70 51 10 0.5 2

449CSST •8.5 33 10% 70 40 10 0.5 –

449CSTE, 449CSSTE •8.5 33 10% 23mA 51 33 0.5 2

449CTE, 448CTE •8.5 33 10% 23mA 31 23 0.5 2

448CSH** •8.5 33 10% 70 51 10 0.5 –

448CSRH** •8.5 33 10% 70 51 10 0.5 2

Power Supervision Units

204-6V (UL Listed) 5.1 15 –33 mA @ 6V DC ––0.5 –

14 mA @ 12V DC

204-12/24V (UL Listed) 8.5 33 –28mA @ 24V DC ––0.5 –

14 mA @ 12V DC

204-12/24V CAN (ULC Listed) 8.5 33 –28mA @ 24V DC ––0.5 –

Features

Built-in end-of-line relay that also acts as a sensitivity status output. For four wire only. Fail-safe relay trips upon loss of power or if

smoke detector is outside the approved sensitivity range for more than one day. End of line resistor is easily connected to terminal

with no extra wiring, or relay contacts can be connected to a separate trouble loop.

Isolated fixed 135°F (57°C) and rate of rise heat detector, independently trips the LED and alarm relay output. Smoke detector

activates internal sounder (local alarm) and auxiliary relay, but does not latch. Approved as both single station smoke alarm and

system heat detector. Ideal for hotel, motel and dormitory rooms where smoking is allowed.

Used to activate other devices such as elevator recall, door hangers, etc. UL Listed for releasing services.

85db built-in sounder alarms when smoke is detected or when power wiring polarity is reversed.

85db built-in sounder alarms when smoke is detected or when power wiring polarity is reversed. Also, chirps when unit goes outside

the approved sensitivity range for more than one day. Resetting detector will silence chirp for one day, until unity is restored to

proper sensitivity.

Integrated fixed 135°F (57°C) temperature and rate of rise head detector offers double protection. Either heat detector or smoke

detector can trip and latch LED and alarm relay outputs.

Non latching, low temperature output for temperatures below 43°F ±5°F (°C).

End-of-Line Power

Supervisory and Sensitivity

Status Relay

Isolated Fixed Temp. and

Rate of Rise Heat Detector

Auxiliary Relay

Built-in Sounder

Built-in Sounder with

Sensitivity Status Output

Integrated Fixed Temp. and

Rate of Rise Heat Detector

Low-Temperature Output

E

H

R

S

SS

T

L

Designator Feature Description

Heat detector specifications...fixed temperature - 135°F, 50 ft. spacing

rate of rise - 15°F/min. & > 105°F (8.3°C/min. & > 40.6°C)

Low temp specifications.........43°F (°C) ±5°F (°C)

Auxiliary relay contacts ..........2A @ 28 V DC or 120 V AC (resistive)

Alarm contacts .......................500 mA @ 36 V DC (resistive)

Detector size ..........................6.1 in. (15.5 cm) x D 1.85 in. (4.69 cm) x 8.8 oz. (0.25kg)W

Packaging ..............................10 detectors are packed in a carton

Self-diagnostic indication .......typically 27 hours after reset (do not connect to power

supply that resets every 24 hours)

©1999 Sentrol. Certain items in the Installation Instructions are protected under one or more of the following patents:5,546,074;

5,708,414; 5,798,701; 5,821,866; 5,936,533.

SMARTHOME™ 1-800-SMART-HOME 949-221-9200

http://www.smarthome.com Order #7309

firealarmresources.com

This manual suits for next models

35

Other ESL Smoke Alarm manuals

Popular Smoke Alarm manuals by other brands

ESYLUX

ESYLUX PROTECTOR K 10 PLUS Installation and operating instructions

System Sensor

System Sensor 2951 Installation and maintenance instructions

Gasmate

Gasmate GM160-018 manual

System Sensor

System Sensor FAAST FL0111E-HS Quick installation guide

Securiton

Securiton ASD 535 Application guidelines

System Sensor

System Sensor OSI-RE-SS Installation and maintenance instructions