ESMI EB-6500R User manual

I56-3881-001EB200-01-02 1

DEUTSCH

ESPAÑOL

ENGLISH ITALIANO

GENERAL

The model EB-6500R is a conventional long range projected beam smoke

detector designed to provide open area protection. It consists of a combined

transmitter/receiver unit and a reector. Smoke entering the area between

the two components causes a reduction in the signal returned to the receiver.

When the obscuration reaches alarm thresholds, selected at the transmitter/

receiver unit, the detector generates an alarm signal. Complete blockage of

the beam causes a fault signal. Slow changes in obscuration due to a build

up of dirt or dust on the lens of the detector are compensated for by a micro-

controller that continuously monitors the signal strength and periodically

updates the alarm and fault thresholds. When the self-compensation circuit

reaches its limit, the detector generates a fault signal, indicating the need for

service. After local testing is complete, the yellow LED will blink a pattern to

indicate the level of drift compensation employed during the test (see Blinks

Output by Yellow LED table at back of manual).

The model EB-6500RS includes an integral servo controlled calibrated test

lter, which allows automatic remote alarm testing.

SPECIFICATIONS:

General

Range: 5to70m

70mto100musingoptional6500-

LRK/BEAMLRK

Sensitivity: Level 1: 25% Obscuration

Level 2: 30% Obscuration

Level 3: 40% Obscuration

Level 4: 50% Obscuration

Level 5: 30% to 50%

Adjusting (Acclimate)

Level 6: 40% to 50%

Adjusting (Acclimate)

Maximum angular misalignment: Detector: ± 0.5°

Reector: ± 10°

Environmental

Temperature Range: -30°C to 55°C

Humidity: 10% to 95% Relative Humidity

(Non-condensing)

Mechanical

Dimensions (Without Faceplate): 229mm x 178mm x 84mm

Dimensions (With Faceplate): 253mm x 193mm x 84mm

Wiring: 0.3mm² to 3.2mm²

Adjustment Angle: ±10° Horizontal and Vertical

Electrical

Voltage Range: EB-6500R: 10.2 to 32 VDC

EB-6500RS: 15 to 32VDC

Avg. Standby Current: 17mA at 24 VDC

Max. Alarm Current: 38.5mA at 24VDC

Max. Fault Current: 8.5mA at 24 VDC

EB-6500RS Test Mode: 500mA peak

Relay Contact Ratings: 0.5A at 30 VDC

Remote Output (Alarm): Voltage: 15 to 32VDC

dependantonsupply

Current: 6mAto15mA,

Limited by 2.2KΩ Resistor

PARTS LIST

Description Quantity

Transmitter/ReceiverUnit 1

PaintableTrimRing 1

Reector (6500REFL) 1

Pluginterminalblocks 5

Instruction Manual 1

Orange Alignment Assistance Label 1

Alarm 0 ohm Shunt 1

Alarm Limiting Resistor 470 ohm 1

Alarm Limiting Resistor 680 ohm 1

Alarm Limiting Resistor 1000 ohm 1

Schottky Diode 1

APPROVED ACCESSORIES

6500-LRK/BEAMLRK

Long Range Kit comprising three additional 20cm x 20cm reectors, which

may be mounted in a square with the supplied reector, permitting the detector

tobeusedforrangesfrom70mto100m.

6500-MMK/BEAMMMK

Multi-Mounting Kit allowing the EB-6500 to be mounted to ceilings, or to

walls where the detector and reector cannot be mounted within 10° of one

another. One kit mounts either the transmitter/receiver unit or reector. If

the transmitter/receiver is mounted on the 6500-MMK/BEAMMMK, then the

6500-SMK/BEAMSMK must be used. Note that only a single 20cm x 20cm

reector can be mounted using the MMKs: The 6500-LRK/BEAMLRK is not

compatible with the MMKs.

6500-SMK/BEAMSMK

Surface Mounting Kit for the transmitter receiver (also used in combination

with the MMK) to give an additional 43mm depth to assist surface mounting

andtopermitsideentrycabling.

RTS151KEY

Remote test and annunciator accessory that enables the detector to be tested

remotely, providing test and reset functions, it has a Red LED to indicate alarm

conditions (Note: Back-box, if required, needs to be ordered separately - part

numberWM2348).

DETECTOR MOUNTING

Location

The EB-6500R(S) must be located in accordance with local standards and

guidelines, for example BS5839 part 1. For general information, refer to the

application guide for projected beam smoke detectors available on request

fromyoursupplier.

Mounting Position

Beamdetectors requirea verystable mountingsurface forproperoperation. A

surface that moves, shifts, vibrates, or warps over time may cause false alarm

or fault conditions. Initial selection of a proper mounting surface will eliminate

nuisance alarms and fault signals. Mount the detector on a stable mounting

surface such as brick, concrete, a sturdy load-bearing wall, support column,

structural beam, or other surface that is not expected to experience vibration

or movement over time. DO NOT MOUNT the beam detector on corrugated

metal walls, sheet metal walls, external building sheathing, external siding,

suspended ceilings, steel web trusses, rafters, non-structural beam, joists, or

other such surfaces. The reector has a much greater tolerance to movement

than the transmitter/receiver, hence in cases where only one stable mounting

surface as dened above can be used, the transmitter/receiver unit should be

mounted to the stable surface. See specications for maximum permissible

angular misalignment; movement outside these limits may cause nuisance

alarmsandfaults.

Mounting Considerations

• There must be a permanent clear line of vision between the detector and

the reector.

• Reective objects should be a minimum of 380mm from the line of sight

between the detector and reector to avoid compromise of the protected

area by reected light.

• Direct sunlight or strong lights into the transmitter/receiver unit should be

avoided. There should be a minimum of 10° between the paths of the light

sourceandthedetectorbeam.

• Operation of the detector through panes of glass should be avoided if

possible. If it is necessary to pass though glass, the angle between the

beam and glass should be set a minimum of 10° off perpendicular, and

operationthroughmultiplepanesshouldbeavoided.

Mounting

The transmitter/receiver unit may be mounted directly to the wall, with rear

cable entry. The detector base has four primary mounting holes, one in each

corner of the base. All four holes must be used to provide secure mounting. In

order to mount the detector to the wall, the outer cover must be removed after

unscrewing its four retaining screws.

INSTALLATION AND MAINTENANCE INSTRUCTIONS

EB-6500R AND EB-6500RS REFLECTIVE TYPE

PROJECTED BEAM SMOKE DETECTOR

I56-3881-001EB200-01-02 2

10°

10°

RTS151/KEY

1

2

3

4

5

6

T2-3

T2-4

T2-2

T2-1

OPTICAL LINE OF SIGHT

WALL

MOUNTING

SCREW X 4 COVER

SCREW

X 4

WALL

ACCEPTABLE MOUNTING

LOCATIONS FOR REFLECTOR

REFLECTOR

REFLECTOR

Figure 2a: Reflector Mounting Guidelines

Figure 2b: Reflector Mounting Guidelines

Please refer to the relevant kit instructions if the transmitter/receiver is to be

mounted onto the 6500-SMK/BEAMSMK or 6500-MMK/BEAMMMK allowing

more exibility for cable entry.

Figure 1: Transmitter/Receiver Wall Mounting

The reector is mounted directly to the wall using all four of its mounting holes,

one in each corner. The reector must be mounted such that the plane of the

reector is perpendicular to the optical line of sight to the transmitter/receiver

unit. The maximum tolerance for non-perpendicular mounting locations is

10°. If this tolerance is not possible, then the MMK should be used, see MMK

instructionsformountingdetails.

10° MAXIMUM

Figure 3: Detector Terminal Connections

FAULT N.C.

FAULT COM

REMOTE TROUBLE OUT

NOT USED

REMOTE ALARM OUT

AUX (-)

TEST INPUT

RESETINPUT

POWER IN (+)

POWER IN (-)

POWER OUT (+)

POWER OUT (-)

ALARM N.O.

ALARM COM

ALARM N.O.

ALARM COM

ALARM LIMITING RESISTOR

ALARM LIMITING RESISTOR

SCHOTTKY DIODE (A)

SCHOTTKY DIODE (K)

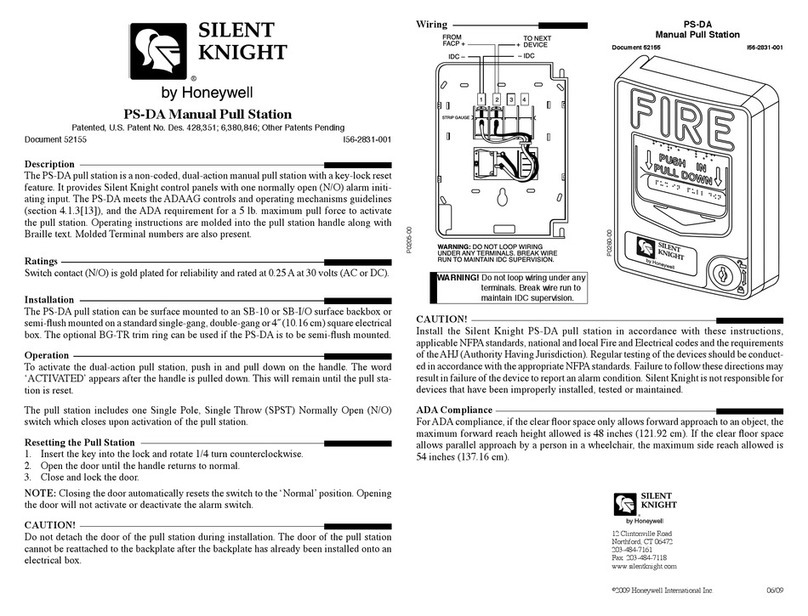

Figure 4: RTS151KEY Wiring

SEE RTS151KEY INSTALLATION INSTRUCTIONS

FOR ELECTRICAL RATINGS OF RTS151KEY

REMOTE ALARM

OUTPUT

AUX (-)

TEST INPUT

RESET INPUT

WIRING

Note: All wiring must be installed in accordance with local requirements.

Warning: Before working on the system, notify the proper authorities

that the system is undergoing maintenance and will be temporarily out of

service.

Wiring connections are made to pluggable terminal blocks, which can accept

wire sizes from 0.3mm² to 3.2mm². For best results screened cable should be

used. Refertothecontrolpanelinstructionsforcabletypelimitations

EB-6500R / EB-6500RS

1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4

T3 T2 T1 T4 T5

Signal Name Terminal Normal State Active Comment

State

Reset Input T2-4 High impedance 0V Momentarily connect

to Aux- to operate

Test Input T2-3 High impedance 0V Momentarily connect

to Aux- to operate

Aux- T2-2 0V - Internally connected to

Power -ve

Remote Alarm Out T2-1 High impedance +24V Via 2.2k ohms current

limit resistor

Remote Fault Out T3-3 High impedance +24V Via 2.2k ohms current

limit resistor

Table 0: Use of Input – Output Signals

WARNING

All INPUT and OUTPUT signal terminals are active LOW (0V)

Do not connect any other voltage to these terminals or

serious damage to the product may result.

I56-3881-001EB200-01-02 3

DEUTSCH

ESPAÑOL

ENGLISH ITALIANO

AK AK

EOL

Figure 5: Wiring Diagram

V OUT (+)

V OUT (-)

ALARM COM

V IN (+)

VIN (-)

ALARM COM

ALARM NO

ALARM NO

Figure 7: Alignment Adjustment Locations

ALIGNMENT PROCEDURE

Warning: When power is initially applied to the detector, before the alignment

procedure has been completed, it may enter fault or alarm. To prevent

unwanted alarms, disable the zone prior to applying power.

The alignment of the EB-6500R is divided into four steps: Coarse alignment,

ne adjustment, nal gain adjustment, and nal verication. It is necessary

for all four steps to be executed properly to ensure proper alignment of the

product.

Pre-Alignment Checklist

• Ensure that both the detector and reector are mounted securely to stable

surfaces.

• Ensure that all wiring is correct, and that terminal blocks are fully seated

intotheirreceptaclesonthedetector.

• Complete any wiring dressing to minimize movement to the detector once

thealignmentprocedureiscompleted.

• Ensure that the appropriate reectors are used for the installed distance.

• Ensure that the line of sight between the detector and reector is clear and

that reective objects are a minimum of 380mm from the line of sight.

• Ensure that both the detector and reector are mounted within their

operational parameters for off axis angles.

RESET

Terminals T5-1 and T5-2 provide connections used to complete the alarm circuit. A 0 ohm shunt, or current limiting resistor should be tted depending on the

application;thesearesuppliedseparately. Refertothepanelmanufacturerforcorrectcurrentlimitingresistorvalues.

Terminals T5-3 and T5-4 are used to connect the optional Schottky diode when used with active end of line monitoring; refer to panel manufacturer for details. Do

not t the diode unless it is specically required otherwise the functioning of the system will be affected. Diode polarity must be observed for correct operation.

EXTERNAL ALARM

LIMITING RESISTOR

OR SHUNT

POWER (+)

POWER (-)

INITIATING ZONE (+)

INITIATING ZONE (-)

• Disable the zone or system to prevent unwanted alarms before applying

power.

• Ensure power to the detector is “ON”.

FAULT COM

REMOTE FAULT OUTPUT

REMOTE ALARM OUTPUT

AUX (-)

TEST INPUT

RESET INPUT

Figure 6: Switch Locations

ALIGNMENT

POSITION

INDICATOR

OPTICS LOCK-DOWN

SCREWS X 2

CONTROL PANEL

ALIGNMENT

SENSITIVITY

TEST

OPTIONAL

SCHOTTKY DIODE

ALIGNMENT

MIRROR

FAULT NC FAULT NC

FAULT COM

REMOTE FAULT OUTPUT

REMOTE ALARM OUTPUT

AUX (-)

TEST INPUT

RESET INPUT

V IN (+)

VIN (-)

ALARM COM

ALARM NO

V OUT (+)

V OUT (-)

ALARM COM

ALARM NO

Step 1. Coarse Alignment

See gures 6 and 7.

1. Ensure that both of the optics lock-down screws are loosened so that the

optics will move freely.

2. Looking through the alignment mirror at both the alignment gun sight and

reector simultaneously, locate the position of the reector in the optical

sight. Note that initially this step will require some practice. An orange

sticky label is supplied, which may be temporarily mounted next to the

reector to aid initial location if the distance between the reector and the

detectorislarge.

3. Once the reector has been located, begin to adjust both the horizontal

and vertical alignment knobs so that the reector becomes centred in the

alignment mirror. Caution: If the optics are incorrectly aligned in this step,

it will not be possible to proceed with the next step.

HORIZONTAL

ADJUSTMENT

ALIGNMENT

GUN SIGHT

VERTICAL

ADJUSTMENT

DIGITAL SIGNAL

STRENGTH

READOUT

EB-6500R(S) EB-6500R(S)

ZONE

EOL

DEVICE

I56-3881-001EB200-01-02 4

Figure 8: Coarse Alignment Procedure

REFLECTOR

SCREW

LOCATIONS

Note that the alignment gun site does not give an accurate alignment. It is

sufcient only as a starting point for the next step. On completion of the ne

adjustmentprocedure, the alignment gunsitemay not appear tobecentred on

the reector.

SCREW

LOCATIONS

Figure 9: Housing Screw Locations

EYE

Step 2. Fine Adjustment

See gures 6 to 8.

1. Ensure that no objects are in the line of sight between the detector and the

reector.

2. Depress the Alignment switch once. Both the digital display and the yellow

LED should turn on indicating that alignment mode has been entered. The

display should begin reading “- -” signifying an electronic gain adjustment.

After a few moments the display will indicate a numeric value near 20.

Note: If the display reads “Lo” then the detector is not receiving enough

light from the reector. Go back and repeat the course alignment step and

verify that the proper number of reectors is used for the installed distance.

The display will continue to read “Lo” until the detector receives enough

light from the reector to continue with the ne adjustment step.

Note: In alignment mode (indicated by the yellow LED and the numeric

display) the sensitivity select and test switches are disabled.

3. Once the display shows a number, begin adjusting the horizontal and

vertical alignment knobs one at a time to increase signal level on the

display. Continue adjusting each axis one at a time going back and forth

between them until a peak value is indicated. If a value of 90 is achieved,

the detector will reduce its electronic gain. This will be indicated by a “- -”

reading on the display. When this happens halt any further adjustment

until the display again reads a numeric value. This process may occur

more than once during the ne adjustment step.

4. Once satised that it is not possible to achieve a higher reading on the

display depress the alignment switch to complete the ne adjustment

step. The digital display readout will turn “OFF” and the yellow LED will

remain “ON”.

5. Ensure that both of the optics lock-down screws are re-tightened.

Note: It may not be possible to achieve a gure close to 90 on the display

during the last adjustment iteration. Each time the gure 90 is reached

the gain is reduced, making it more difcult to achieve high values. Any

number is acceptable, provided it is the highest gure that can be achieved

after the nal gain adjustment.

Atthis timeitis sensible toset the sensitivityof the detectorusing the sensitivity

switch and digital display. See SENSITIVITY SELECTION for further details.

Step 3. Final Gain Adjustment

See gure 9.

In this step, the detector electronically adjusts its internal gain one nal time.

It is necessary to complete this step with the outer housing installed since the

housing will change the amount of light received from the reector.

1. Install the outer housing of the detector. The housing is installed by

tightening the four captive screws, one in each corner of the housing.

Note: The housing contains a gasket seal that protects the detector

circuitryfromcorrosionandmoisture. Toensurethat this gasket performs

correctly, it is necessary to tighten all four of the screws holding the outer

housinginplaceevenly.

2. Remove the protective lm from the front surface of the outer housing.

Note that the outer housing may require cleaning if any residue remains.

Useonlyasoft,dampcloth;donotuseanysolvents.

3. To initiate the nal electronic gain adjustment, the reset switch must be

depressed using a small screwdriver or similar tool. Once depressed the

yellow LED will begin to blink. On completion, the yellow LED will stop

blinking and the green LED will begin blinking, indicating that the gain

adjustment was successful.

Note: Use caution not to block the line of sight between the detector and

reector in this step.

4. Install the outer aesthetic ring by snapping it onto the outer housing.

Note: If the outer aesthetic ring has been painted ensure that the paint is

completely dry before proceeding with this step.

Step 4. Final Verification

This step is required to insure the detector has been setup correctly and will

detectsmokeatthepropersensitivitylevel.

1. With the detector functioning (dependant on the operation of the control

panel, this may be indicated by the green LED blinking), completely

block the reector with a non-reective opaque material, for example

this manual. After about 30 seconds, the detector should enter either the

fault or alarm condition. If the detector does not enter the fault or alarm

condition, there is a problem with the installation.

2. Complete a sensitivity test of the detector as described in SENSITIVITY

TESTING below.

SENSITIVITY SELECTION

The sensitivity of the detector can be set only when the housing is removed

and the detector is not in the ne adjustment step of the alignment mode. To

enter the selection mode, press the sensitivity button once (see gure 6). The

digital display will illuminate and read the current sensitivity setting in percent

obscuration. Press the sensitivity button again to rotate to the next setting.

Once the required setting is achieved (See table 1), the detector will exit the

sensitivity selection mode if no further switch presses occur.

In addition to the four standard sensitivity selections the detector has two

Acclimate settings. When either of these settings is chosen the detector

will automatically adjust its sensitivity using advanced software algorithms

to select the optimum sensitivity for the environment. The sensitivity will be

continuously adjusted within the ranges specied in graph 1.

Total obscuration can be converted to percent per metre assuming uniform

smoke density for the entire length of the beam. Graph 1 converts total

obscurationtopercentpermetreforallacceptablesensitivitysettings.

RESET SWITCH

Sensitivity Setting % Obscuration Display Reading

Level 1 25 25

Level 2 30 30

Level 3 40 40

Level 4 50 50

Acclimate Level 1 30 to 50 A1

Acclimate Level 2 40 to 50 A2

Table 1: Sensitivity Settings

I56-3881-001EB200-01-02 5

DEUTSCH

ESPAÑOL

ENGLISH ITALIANO

Test Failure Checks

If the detector fails either the sensitivity or functional test, several steps should

betaken beforereturningthe unittodetermine ifitis faulty,orsimply needstobe

re-adjusted. Thesestepsinclude:

1. Verify all wiring connections and appropriate power is applied to the

detector.

2. Verify that the optical line of sight is free from obstructions and reective

objects.

It is imperative that at least 90% of the received light is from the reector

alone, otherwise sensitivity cannot be assured.

3. Apply the maintenance procedure in this manual. Repeat the test

procedure. If the detector still fails the test procedure proceed with step 4.

4. Repeat the alignment procedure in this manual. If the alignment procedure

is successful repeat the test procedure. If the detector still fails the test it

shouldbereturnedforrepair.

EB-6500R(S) BEAM DETECTOR: SET-UP PROCEDURE SUMMARY

Beam Alignment– ensure power is on

CourseAlignment

Carryoutusingtargeteyepiece

Adjust using horizontal and vertical thumb screws

Fine Adjustment

InitiateusingAlignment Switch

Continue adjustment using horizontal and vertical thumb screws

When the adjustment is complete press the Alignment Switch

Sensitivity Setting

Select using Sensitivity Switch

Final Gain Adjustment – ensure front cover is tted

InitiateusingtheReset Switch

Completed when the green LED blinks

Final Verification

Use obscuration lters or reector test card to initiate Fire and Fault signals

MAINTENANCE

Note: Before cleaning the detector, notify the proper authorities that the

smoke detector system is undergoing maintenance, and therefore the system

will be temporarily out of service. Disable the zone or system undergoing

maintenance to prevent unwanted alarms.

1. Carefully clean the outer housing lens face. A damp soft cloth with a mild

soap may be used. Avoid products with solvents or ammonia.

2. Carefully clean the reector. A damp soft cloth with a mild soap may be

used. Avoid products with solvents or ammonia.

Functional Testing

For periodic maintenance functional testing, the detector can either be tested

using the Calibrated Test Filter method, by using the local test switch on the

transmitter receiver unit or remotely using the Remote Test Station.

The Remote Test Station, RTS151KEY, can be used with the EB-6500R(S)

beam smoke detector. The wiring diagram to connect the EB-6500R(S) to the

key is displayed on page 2 of this manual..

The EB-6500RS is equipped with an integral sensitivity test feature that

consists of a calibrated test lter attached to a servomotor inside the detector

optics. When a test is initiated using the remote test station or local test switch

the test lter is moved in the pathway of the light beam. If the correct level of

signal reduction is received the detector will enter alarm. If the proper level of

signal reduction was not achieved, indicating that the sensitivity of the detector

is out of tolerance, the detector will enter the fault condition.

Note: This test should satisfy most local periodic maintenance and testing

requirements.

If the detector fails this test, refer to the Test Failure Checks described above.

PAINTING

The outer aesthetic ring may be painted using enamel or acrylic paints either by

brushorspray.

Note: Never paint the at lens surface of the outer housing.

SENSITIVITY TESTING

NOTES:

1. Beforetesting,notifytheproperauthoritiesthatthesmokedetectorsystem

is undergoing maintenance, and therefore the system will be temporarily

out of service. Disable the zone or system undergoing maintenance to

prevent unwanted alarms.

2. Before testing the detector, check for the presence of the ashing green

LED at the receiver, making sure not to disturb or block the beam. If it does

not ash and the detector is not in fault or alarm, power has been lost to the

detector.

Detectors must be tested after installation and following periodic maintenance.

The sensitivity of the EB-6500R may be tested as follows:

Calibrated Test Filter Method

The sensitivity of the detector can be tested using an opaque material ( such

as this manual ) to cover the reector by an amount indicated by the graduated

scale on the reector, see Figure 10.

1. Verify the sensitivity setting of the detector in % obscuration. See the

Sensitivity Selection section of this manual for sensitivity determination if

sensitivity is unknown.

2. Place the blocking material over the reector, lining it up with the graduated

marks that are 10 less than the detector setting in % obscuration. The

detector should not alarm or fault. Keep the material in place for a minimum

of1minute.

3. Place the blocking material over the reector lining it up with the graduated

marks that are 10 more than the detector setting in % obscuration. The

detector should enter alarm within 1 minute.

4. The detector can be reset with the reset switch on the detector unit or

remotereset.

Figure 10. Reflector Test Card Procedure

LINE UP EDGE OF BLOCKING MATERIAL WITH

APPROPRIATE OBSCURATION LEVEL

MOVE BLOCKING MATERIAL TO

DESIRED AMOUNT OF OBSCURATION

7

GRAPH 1: SENSITIVITY (%M vs DISTANCE)

(Assuming Uniform Smoke Distribution)

5

6

Level 1

4

5

(%/Metre)

Level 2

Level 3

2

3

b

scuration

Level 4

1

O

b

0

0 10 20 30 40 50 60 70 80 90 100

Distance (Metres)

I56-3881-001EB200-01-02 6

OPERATION MODES AND TROUBLESHOOTING GUIDE

Schneider Electric Fire and Security Oy, Sokerilinnantie 11 C, 02600 Espoo, Finland

Percent the

detector has

drifted

<10%

<20%

<30%

<40%

<50%

<60%

<70%

<80%

<90%

<100%

Number

of blinks

output

None

1

2

3

4

5

6

7

8

9

Blinks Output byYellow

LED once the Device has

Passed a Local Test

Modes Red Yellow Green Dual Digital Display

Readout

Initiating Means Alarm Contacts Fault Contacts Comments and

Troubleshooting Tips

Alarm Remote Fault Remote

Normal Off Off BlinkOff Successful completion of

initialisation or detector reset

Open Off Close Off

Alignment Off On Off On, relative amount of

signal 0-99, or “- -“ if

auto gain resetting, or

“Lo” if signal too low

Alignment Switch Open Off Open On

Alarm On Off Off Off Smoke, Test Filter, RTS151

KEY

Close On Close Off

Fault - Drift Comp

Limit Reached

Off 3 Quick

Blinks

BlinkOff Long term drift reference out

of range

Open Off Open On Clean detector and reflector

Fault Signal – Over

Range

Off 2 Quick

Blinks

BlinkOff Increase of reflected signal Open Off Open On

Inspect line of sight between

detector and reflector for

reflective objects in path

Sunlight into detector or

reflector

Fault - Beam

Blockage Response

Off 4 Quick

Blinks

Off Off Beam Blockage Open Off Open On Remove Blockage

Faulty Unit

Initialisation – Power

On

Off Blink until

complete

BlinkOff Apply Power from discharged

state

Open Off Close Off

Initialisation-

Alignment Exit

Off Blink until

complete

BlinkOff Depressing RESET switch

after alignment

Open Off Close Off

Local Test

Pass result

(R & RS Versions)

On Blinks out

amount of

drift used

Off Off RTS151KEY Close On Close Off Detector remains in alarm until

reset

Local Test

Fail result

(RS Version)

Off On until

reset of

timeout

BlinkOff RTS151KEY Open Off Open On Detector remains in fault until

reset or timeout

Local Test

Fail Result

(R Version)

Off As fault

mode

BlinkOff RTS151KEY Open Off Open On If local test fails will already be in

fault

0832 13

EB-6500R - DOP-LBP013

EB-6500RS - DOP-LBP014

EN54-12: 2002

Optical Beam Smoke Detector

Intended for use in re detection and re

alarmsystems in and around buildings

System Sensor Europe

Pittway Tecnologica Srl, Via

Caboto 19/3, 34147 TRIESTE, Italy

This manual suits for next models

1

Table of contents

Other ESMI Smoke Alarm manuals