The JA-110ST Bus combined smoke and heat detector

The JA-110ST Bus combined smoke and heat detector 2 / 2 MLW51612

When connecting the module to the bus,

always switch the system’s power off.

4. Proceed according to the control panel installation manual.

Standard procedure:

a. When the device is powered, the yellow LED starts flashing

repeatedly to indicate that the module has not been enrolled

into the system.

b. Go to the F-Link program, select the required position in the

Devices tab and enter the Enrollment mode by clicking on

the Enroll button.

c. Click on “Scan/add new BUS devices”, select the detector from

the list and double-click on it to confirm your selection.

The yellow LED light will stop flashing.

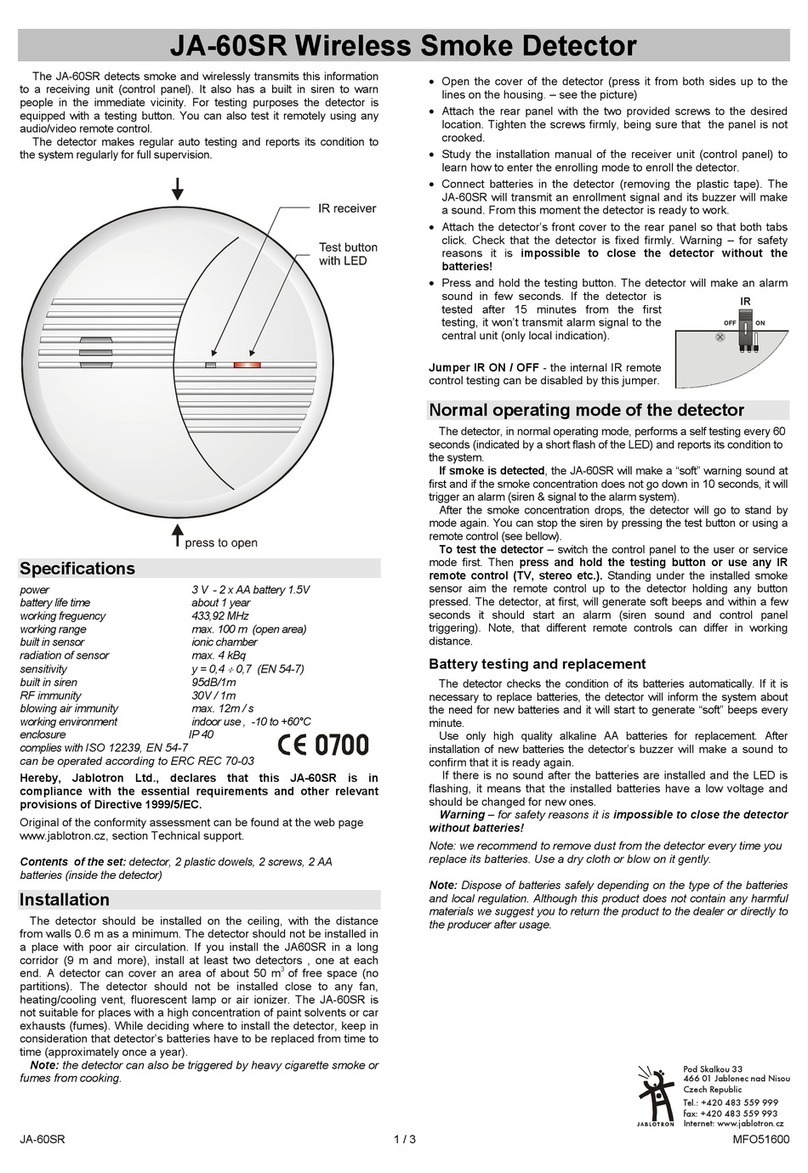

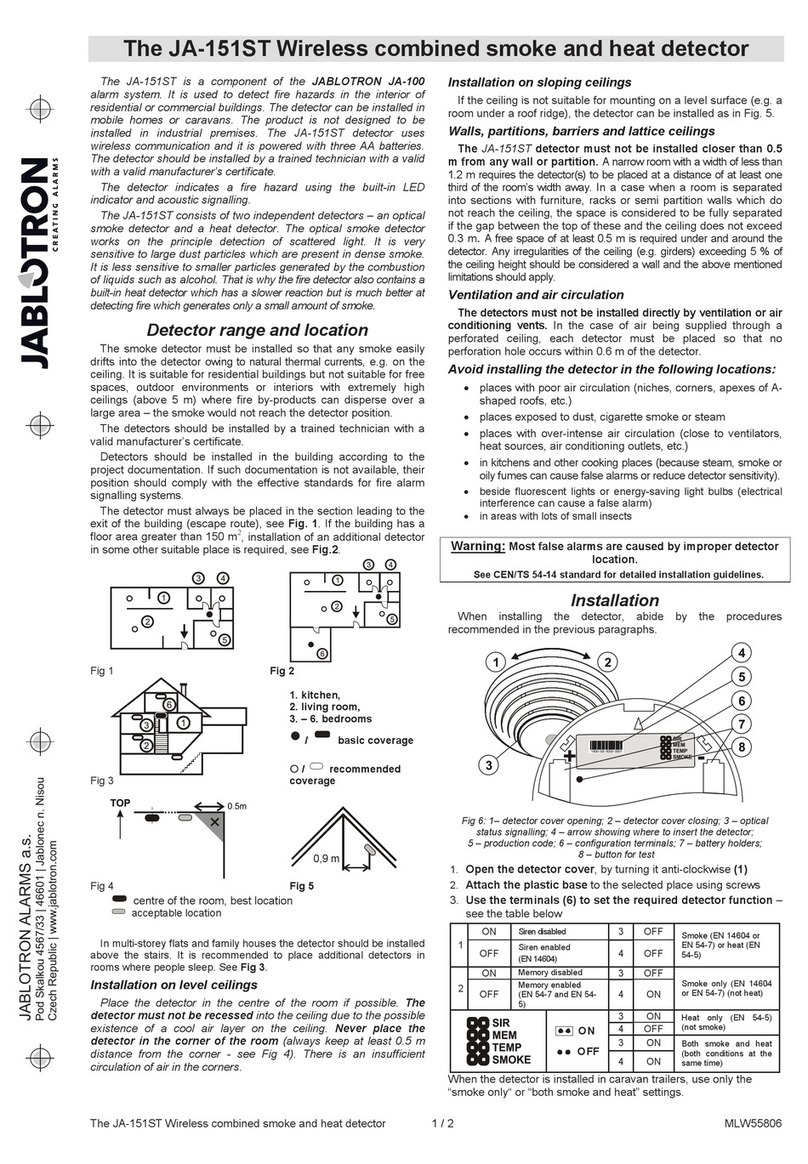

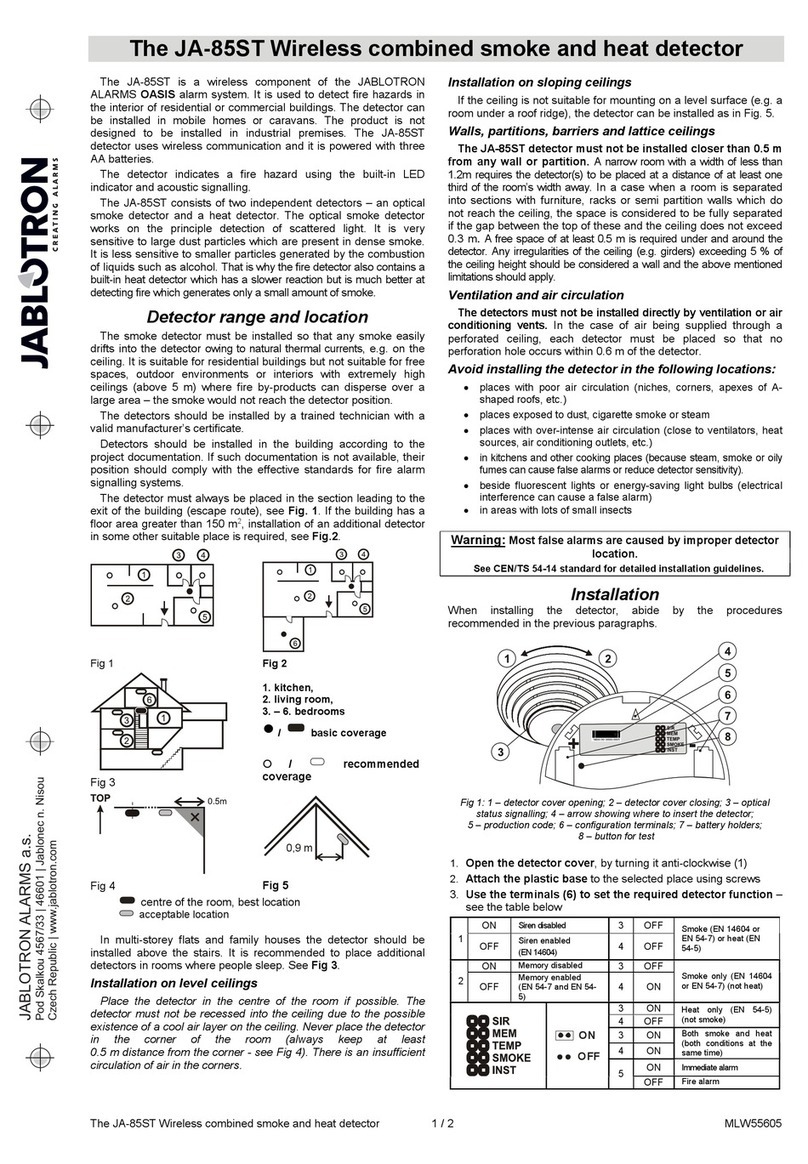

5. Insert the detector into the plastic base. It can only be inserted in

the position marked with arrows (4) on both plastic parts. Close the

detector by turning it clockwise (2). When the detector is fully

secured to the base, a control LED lights up (3), which indicates an

automatic detector test. During this period of time, the detector

won’t detect anything. The test ends when the LED shuts down (3)

and the detector becomes fully operational. A possible detector

fault may be indicated. See the Fault indication chapter.

Notes:

In order to facilitate identification when enrolling the detector

in F-Link, we recommend removing the sticker with a serial code

before inserting the detector into the plastic base. Paste it onto

a piece of paper and write down the location of the detector.

The detector can be also enrolled by entering the Enrollment

mode and inserting the detector into the plastic base.

Alternatively the detector can be enrolled by entering its serial

number (5) in the F-Link program. All numbers stated under the bar

code shall be entered (1400-00-0000-0001).

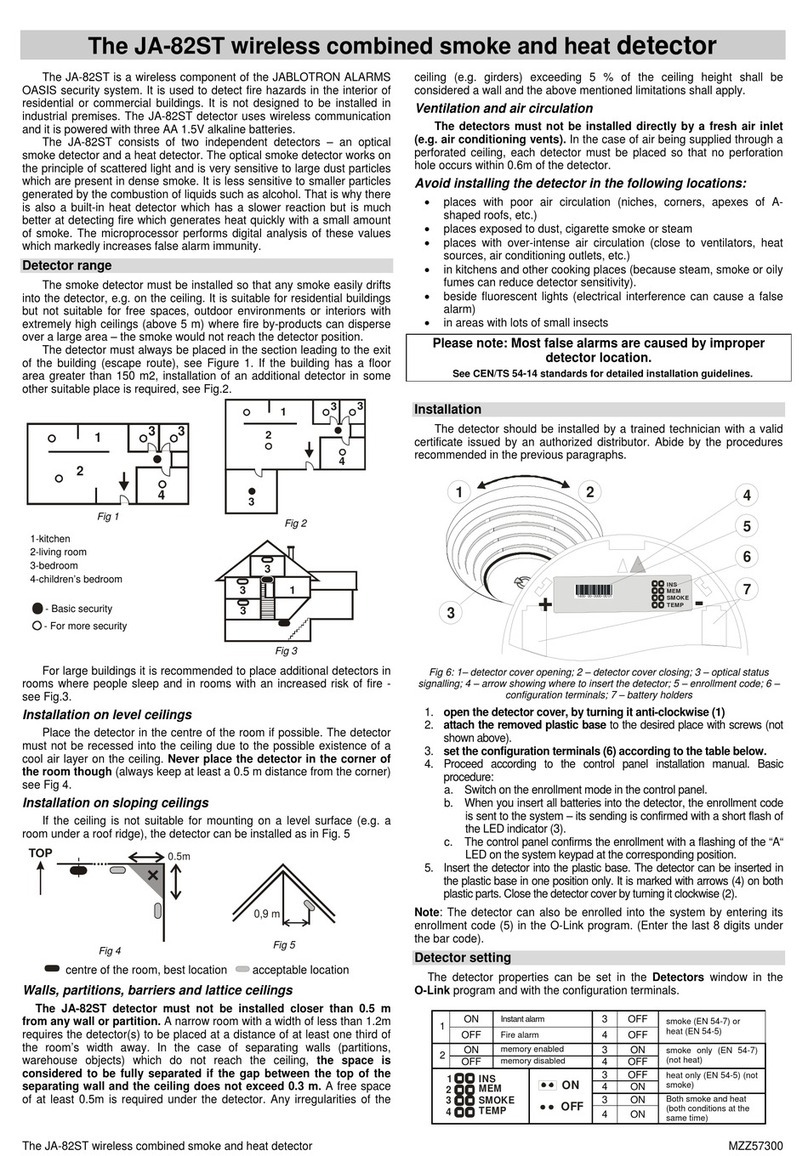

Detector settings

Go to the Devices window in the F-Link program. When you are at

the detector’s position, use the Internal settings option to open

a dialog window where you can set:

Reaction: it’s possible to choose whether the detector will react

to smoke, heat, smoke or heat or smoke and heat at the same

time.

Fire alarm

Optical detector: When smoke enters the detector, an alarm

is triggered, and it is signaled with a rapidly flashing red LED light

(approx. 8 times per second). The indication lasts until the detector’s

detection chamber is ventilated.

Heat detector: When the temperature rises above limit, an alarm is

triggered, and it is signaled with a rapidly flashing red LED (approx.

8 times per second). The indication lasts until the temperature drops

(e.g. when the room is ventilated).

Alarm memory: If enabled, LED alarm indication continues to flash

slowly (approx. twice per second) for further 24 hours after the alarm

stops. The indication can be terminated by unsetting the section in

which the detector is installed.

Tamper alarm: When the detector cover is opened, the detector

sends a tamper signal, unless the control panel is in Service mode.

Detector testing and maintenance

Fault indication

The detector checks its functionality. When a fault is discovered, the

LED indicator immediately flashes 3 times and then briefly 3 times

every 30 seconds. The automatic test indicates a fault the same way.

See the Installation chapter

The error found may be caused by a fault of the detection chamber,

the temperature of the environment being out of the operating

temperature range or other faults of the detector.

An operating temperature range fault will disappear the moment the

temperature of the environment turns back to normal.

Other faults found are indicated as a fault even after their cause has

gone. The fault indication can be stopped by the functionality test. The

basic functionality test is triggered by opening the detector cover (fig 6-

1), removing the lower plastic part and putting it back (fig 6-2). If this

test results in a fault again, send the detector to the repair service.

WARNING! The control panel must be switched to Service mode

otherwise a Tamper alarm will be triggered.

Technical specifications

Power from control panel digital bus 12 V (9…15 V)

Current consumption in standby mode 5 mA

Current consumption for cable selection 10 mA

Dimensions diameter 126 mm, height 50 mm

Weight 143 g

Smoke detection optical light scattering

Smoke detector sensitivity m = 0.11 - 0.13 dB/m pursuant to EN 54-7

Heat detection class A2 according to EN 54-5

Alarm temperature +60 °C to +70 °C

Operating temperature range -10 °C to +80 °C

Complies with EN 54-5, EN 54-7

EN 50130-4, EN 55022

15 1293-CPR-0507

JABLOTRON ALARMS a.s. hereby declares that the JA-110ST is in a compliance

with the relevant Union harmonisation legislation: Directives No: 2014/30/EU,

2011/65/EU. The original of the conformity assessment can be found

at www.jablotron.com - Section Downloads.

Note: Although this product does not contain any harmful

materials we suggest you return the product to the dealer or directly

to the producer after use.

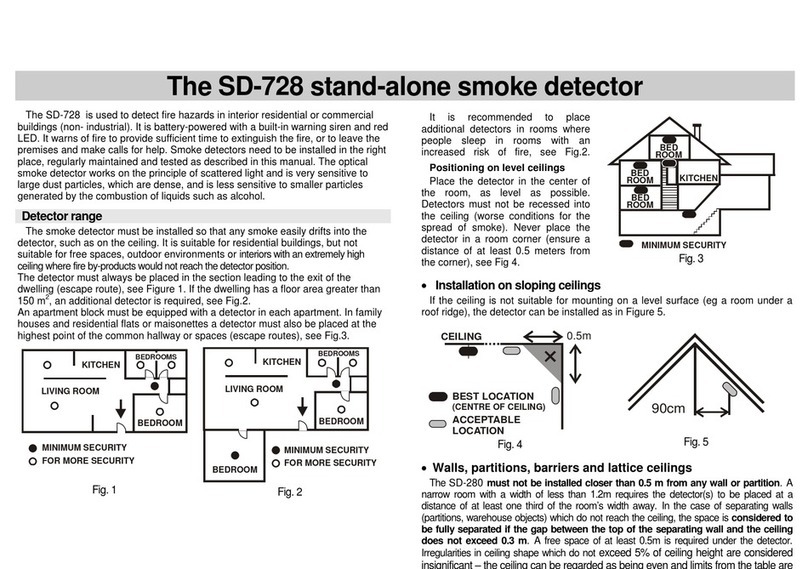

The functionality of the optical part of the detector can be tested with

a test spray. The functionality of the heat part can be tested with

a hairdryer. If the detector is configured to be triggered by both

conditions, it’s necessary to conduct both spray and hairdryer tests at

the same time. The test should be carried out once every 30 days. The

detector’s cover should be cleaned regularly from cobwebs and dust.

Test button: Pressing the test button will start the automatic

detector test. A result of this test is indicated by displaying a green

or red circle. The green circle means that the detector works

correctly. However the red circle indicates a fault of the detector. In

this case, repeat the test. If the fault appears repeatedly then it is

necessary to send the detector to the service for repair.

Warning: never test the detector with fire inside the building