ESP Safety IPES-IR/UV User manual

IPES-IR/UV Flame Detector

Operating Manual

80010-001 R07

IPES-IR/UV Flame Detector

Operating Manual

80010-001 R07

ESPSafety,Inc.

555NorthFirstStreet

SanJose,CA95112

408‐886‐9746

March2013

RevisionHistory:80010‐001

DateRevisionDescriptionApproved

12/09/0901InitialDraftJ.Lorelli

1/10/1002TechnicalcontentreformattedJ.Lorelli

3/12/1003Corrections;FMchangesJ.Lorelli

3/30/1004Corrections;RevT5markingK.Bernstein

2/22/1105IECEx/ATEXrevisionsK.Bernstein

4/4/1206CorrectionsYaroslavMiloserdov

3/21/1307Addition;AppendixCWarranty&

ReturnPolicy

A. Burgos

IPES-IR/UV Flame Detector

80010-001 R07 Operating Manual

Page ii

Revised 10/21/2013

TableofContents

1.0Introduction......................................................................................................................................................................1

OurMission...............................................................................................................................................................................1

ESPSafetyIncContactInformation..........................................................................................................................................1

2.0Description........................................................................................................................................................................2

Application................................................................................................................................................................................2

Specifications............................................................................................................................................................................2

3.0SafetyConsiderations........................................................................................................................................................3

Guidelines.................................................................................................................................................................................3

ExplosionProtectionMeans.....................................................................................................................................................3

AdditionalConsiderations.........................................................................................................................................................4

FMCompliance.......................................................................................................................................................................4

IPES‐IR/UV.................................................................................................................................................................................4

4.0PerformanceCharacteristics..............................................................................................................................................6

Appearance...............................................................................................................................................................................7

ResponseTime..........................................................................................................................................................................7

GenerationofAlarmSignals.....................................................................................................................................................7

EliminationofFalseAlarms.......................................................................................................................................................7

Serviceability.............................................................................................................................................................................8

LED............................................................................................................................................................................................8

OpticalIntegrity........................................................................................................................................................................8

AnalogSignal...........................................................................................................................................................................10

DigitalSignal...........................................................................................................................................................................10

RelayDryContactSignal.........................................................................................................................................................10

OperatingModes....................................................................................................................................................................10

5.0Installation.......................................................................................................................................................................11

ComponentPartsandDeliverySet.........................................................................................................................................11

VisualExamination..................................................................................................................................................................11

Pre‐InstallationSteps..............................................................................................................................................................11

Installation..............................................................................................................................................................................11

CompletingtheInstallation.....................................................................................................................................................19

ArrangementandFunctionofMountingConnectionTerminals............................................................................................14

6.0StartupandOperation......................................................................................................................................................16

Startup........................................................................................................................................Error!Bookmarknotdefined.

Operation................................................................................................................................................................................18

7.0Troubleshooting...............................................................................................................................................................18

TroubleshootingTable............................................................................................................................................................18

8.0Maintenance....................................................................................................................................................................19

IPES-IR/UV Flame Detector

80010-001 R07 Operating Manual

Page iii

Revised 10/21/2013

MaintenanceActivities...........................................................................................................................................................19

DailyMaintenance..................................................................................................................................................................19

EverySixMonths.....................................................................................................................................................................20

AutomaticTesting...................................................................................................................................................................20

9.0TransportationandStorage..............................................................................................................................................20

Transportation........................................................................................................................................................................20

Storage....................................................................................................................................................................................20

10.0Warranties......................................................................................................................................................................21

ExpectedServiceLifeofUnit..................................................................................................................................................21

11.0RepairandReturn...........................................................................................................................................................22

FieldRepair.............................................................................................................................................................................22

ReturnMaterialAuthorization(RMA)Number.......................................................................................................................22

12.0PartsOrderingInformation.............................................................................................................................................22

13.0Certifications..................................................................................................................................................................23

FM(U.S.&Canada).................................................................................................................................................................23

HazardousLocations...............................................................................................................................................................23

ABS..........................................................................................................................................................................................23

ATEX/......................................................................................................................................................................................23

CE............................................................................................................................................................................................23

IEC/.........................................................................................................................................................................................23

IECEx.......................................................................................................................................................................................24

IngressProtection...................................................................................................................................................................24

AppendixA1:IPES‐IR/UVExplosionProtectionMeans...........................................................................................................25

AppendixA‐2:IPES‐IR/UVInstallation....................................................................................................................................26

AppendixB:IPESDigitalCommunicationsProtocol................................................................................................................28

IPESCommands......................................................................................................................................................................28

SettingAddress/BaudRateCommand...................................................................................................................................28

PollStatusCommand..............................................................................................................................................................29

Itisimportantthatthisentiremanualbethoroughlyreadand

understoodpriortoinstallingoroperatingtheIPES‐IR/UV.Any

deviationfromtherecommendationsinthismanualmayimpair

systemperformanceandcompromisesafety.

IPES-IR/UV Flame Detector

80010-001 R07 Operating Manual

Page 1 of 29

Revised 10/21/2013

1.0Introduction

IntroductionTheIPES‐IR/UVflamedetector’sadvanceddetectiontechnologyincorporatesoptical

filtersconfiguredformaximumsensitivitytoradiationproducedbyflameorfireand

ensuresrapidflamerecognitionandalarmsignaling.TheIPES‐IR/UVhasafieldofview

ofnotlessthan90degrees.Uponfirerecognition,itsignalsachangeinstatefrom

normaloperationtofireinanyoriginalequipmentmanufacturersOEMorproprietary

alarmandresponsesystem.

Viaintegratedinfrared(IR)andultraviolet(UV)sensorstheIPES‐IR/UVmonitorsin

specificregionsofbothspectralranges.Intheinfraredspectrum,thedeviceis

configuredforsensitivitytowavelengthsintherangeof4.2to4.6microns,allowing

optimalsensitivitytohydrocarbonfires,andothertypessuchasmetalfireswhile

rejectingfalsesignalsfromincandescentlamps,sunlightandhotobjects.Forultraviolet

radiation,thedeviceisconfiguredforsensitivityintherangeof180to250nanometers,

makingthesensor“blind”tosunlightandradiationfromheatedobjectsbutstillableto

“see”theUVradiationemittedbyaflame.Withthesesettings,theIPES‐IR/UVselects

andalarmsfromthosecharacteristicwavelengthemissionsfromtheIR‐to‐UVspectrum

thatindicateactualflameorfire.

ThecombinationofmultiplesensorsandwavelengthrangesettingsmakestheIPES‐

IR/UVanexcellentchoiceforeliminationoffalsepositiveindicatorscausedbynon‐flame

sourcesofradiationsuchasartificiallighting,directandindirectsunlight,lightning,arc

weldingandmetalgrinding.

OurMissionESPSafety,Inc.’smissionistoprovidecompleteturn‐keyprotectionsolutionsbeginning

withthedesignstage,throughsysteminstallationandcommissioning,andon‐goingfield

serviceinhazardousenvironments.Ourlineofindustry‐leadingproducts,services,and

systemsbenefitssociety,saveslives,andpreservescapitalresources.

ESPSafety,Inc.Contact

Information

Telephone:408‐886‐9746

FAX:408‐886‐9757

Address:555NorthFirstStreet,SanJose,CA95112

IPES-IR/UV Flame Detector

80010-001 R07 Operating Manual

Page 2 of 29

Revised 10/21/2013

2.0Description

ApplicationTheIPES‐IR/UV’sdesignandexplosion‐proofratingsmakeitanexcellentchoicefor

indoorandoutdoorapplications,including:

Drillingandproductionplatforms

Shippingtankers,freighters,andothervessels

Fuelloadingfacilities

Refineries,bulkterminals,andtankfarms

LNG/LPGprocessingandstoragefacilities

Compressorstationsandpipelinefacilities

Petrochemical,paint,andfertilizerplants

Powerplantsandgasturbinefacilities

Transportationfacilities(airportsandsubways)

Oilandgasfiredboilers/furnaces

Aircrafthangars

SpecificationsTheIPES‐IR/UVmeetsindustrycertificationsandrequirementsforHazardousLocations.

DetectionType:Optical

DetectionMethod:IRandUVradiation

SpectralRange:4.2to4.6micron(IR);180to250nm(UV)

PowerSupply:18to32VDC

PowerConsumption:StandBy:2Wmax;AlarmState:3Wmax

FireRelayOutputs:Singlepolecontact,normallyopen,rated5A@30VDC;normally

closedcontactisavailableonrequest*

*NormallyclosedconfigurationisnotcompliantwithNFPA72,ULC/ORD–C386and

FM.

FaultRelayOutputs:Singlepolecontact,normallyopen,rated5A@30VDC;closedin

normalwork,openonfaultdetectionorlossofpower

Communications:

Analogoutput:4‐20mA

Digitalsignal:RS‐485withModbusprotocol

Wiring:14AWG(2.08mm2)or16AWG(1.31mm2).Shieldedcableisrecommended.

OperatingTemperature:‐40°Fto+185°F(‐40°Cto+85°C)

StorageTemperature:‐76°Fto+185°F(‐60°Cto+85°C)

Humidity:95%,non‐condensing

HazardousLocationClassification:Pleaserefertosection13.0Certifications

IPES-IR/UV Flame Detector

80010-001 R07 Operating Manual

Page 3 of 29

Revised 10/21/2013

ConduitEntry:¾”NPTapprovedHazLocbushing

EnclosureMaterials:316SSor6061Aluminum

EnclosureScrews:Pleaserefertosection13.0Certifications

Weight:SS=11lbs(5.0kg);Aluminum=5.5lbs(2.5kg)

3.0SafetyConsiderations

BeforeinstallingandoperatingtheIPES‐IR/UV,besuretoread

thisentiremanual.Failuretofollowtheseguidelinescouldresult

inimpairedproductperformanceandsafetyhazards.

GuidelinesFormaximumsafety:

Onlypersonswhohavethoroughlyreadandunderstoodthismanual,aretrainedin

safetytechniques,andhaveelectric‐safetycertificatesarepermittedtoinstalland

operatetheIPES‐IR/UV.

NeveroperatetheIPES‐IR/UVifthecasingisdamaged.

DonotseparatetheIPES‐IR/UVwhenenergized.

RefertotheAppendicesanddiagramsinthismanualtoensurethatthewiringisin

compliancewithlocalordinancesandtheNEC.

PerformregulartestingandmaintenanceasoutlinedintheMaintenancesection.

Ensurethatfire‐alarmandfire‐extinguishingsystemsandcontrolsareswitchedoff

beforeanytestingormaintenancetoavoidunwantedoperationofalarmsandfire‐

extinguishingequipment.

Alsoseetheindividualsectionsinthismanualforrelevantspecificsafetyguidelines.

ExplosionProtection

Means

ThetablebelowdescribesdesignfeaturesthatprotecttheIPES‐IR/UVagainstexplosions:

FeatureProtectionMeans

EnclosureofCurrent

CarryingParts

Thecasingincludesspigotjointswithcontrolledgapstomeet

explosion‐proofrequirementsforinstallationinClassI,DivisionI,

GroupB,CandD,andT5locations.

CaseMechanicalStrengthThehighmechanicalstrengthofthecaseisabletowithstandhigh

explosivepressureswithoutruptureorfailuresofmechanicalparts.

ThecasedesignisinaccordancewithFM3600andFM3615.

ManufacturingControlOf

Casing

RefertoAppendixA1formanufacturingdetails.Important

parametersinclude:

Maximumwidthandminimumlengthofspigotjoints

Surfaceroughnessofthejoinedparts

Thenumberofcompleteintactthreadsattheconduitentry

point

IPES-IR/UV Flame Detector

80010-001 R07 Operating Manual

Page 4 of 29

Revised 10/21/2013

FeatureProtectionMeans

IgnitionTemperatureTheignitiontemperatureofthesurroundingenvironmentislimited

bytheoutsidesurfacetemperatureofthehousing,whichdoesnot

exceed275°F(135°C).

SecuringofBolts,Joints

andGrounding

Springwashers,lockwashers,andlocknutsmaintaintheintegrityof

theboltedconnectionsbypreventinglooseningofthebolts.

JoinedPartsProtectionAnti‐seizelubricantisappliedonthecriticaljointsasdescribedon

AppendixA1.

CasingIngressProtectionThedesignofthecasingisprotectionclassIP66inaccordancewith

IEC60529‐004.

SealingCablesatConduit

Entry

Useapprovedhazardouslocationsealedconduitfittings.Foroutdoor

installations,ensuresealingmeetsIP66requirements.

Additional

Considerations

Itisimportanttoidentifyfalsealarmsourcesandanyconditionsthatcouldpreventthe

IPES‐IR/UVfromrespondingappropriatelytoafire.Thefollowingshouldbeconsidered:

FalseAlarm

Prevention

ArcWeldingandGasWelding

DonotperformarcorgasweldingwithinthefieldofviewoftheIPES‐IR/UV.Systembypass

ismandatoryforgasweldingandishighlyrecommendedforallweldingactivity.Referto

thesectiononFMCompliancebelowforresultsoftestingwithfalsestimuli.

Walkie‐Talkies

OwingtopotentialEMIandRFIinterference,walkie‐talkiesshouldnotbeusedwithin1foot

oftheIPES‐IR/UV.

FireTypesTheIPES‐IR/UVcandetecthydrocarbonfiresfrompetrochemicalsources,metalfires,and

firesfromwoodandpaperproducts.Inaddition,thedetectorisFM‐approvedfordetecting

methane,propane,n‐Heptane,JP4,andmethanolfires.

FMCompliance

IPES‐IR/UVMeetsFM(USandCanada)certificationsandrequirementsforHazardousLocation

classification:ClassI,DivisionI,GroupB,CandDandT5CasedesignaccordswithFM3600

andFM3615.Ta=‐40oCto+85oC(‐40oFto+185oF)IP66

IPES-IR/UV Flame Detector

80010-001 R07 Operating Manual

Page 5 of 29

Revised 10/21/2013

Standards

FlameResponse

Sensitivity

TITLEAUTHOR‐NUMBERDATE

NationalFireAlarmCodeANSI/NFPA722002

RadiantEnergy‐SensingFire

DetectorsforAutomaticFire

AlarmSignaling

ANSI/FM‐32602004

RadiantEnergy‐SensingFire

DetectorsforAutomaticFire

AlarmSignaling

FMApprovals‐32602000

ElectricalEquipmentForUseIn

Hazardous(Classified)Locations–

GeneralRequirements

FMApprovals–36001998

ExplosionproofElectrical

Equipment–General

Requirements

FMApprovals–36152006

FlameDetectorsULC/ORD‐C3861990

StandardforSmokeDetectorsfor

FireAlarmSystems

CAN/ULC‐S5292002

ThreadedConduitEntriesCSAC22.2No.0.5

(Reaffirmed)

1982

(1999)

Explosion‐ProofEnclosuresfor

UseinClassIHazardousLocations

CSAC22.2No.30

(Reaffirmed)

1986

(2003)

DegreesofProtectionProvidedby

Enclosures(IPCode)

ANSI/IEC60529

CSA‐C22.2No.60529

2004

2005

ExplosiveAtmospheres,General

Requirements

ANSI/ISA60079‐02009

ExplosiveAtmospheres,

Equipmentprotectionby

flameproof“d”enclosures

ANSI/ISA60079‐12009

WhenanIPES‐IR/UVdetectorisexposedtoaseriesoftestfiresalongthecenterlineofthe

sensorasdescribedinthetablebelow,thealarmresponseoftheIPES‐IR/UVisbelowthe

30‐secondresponsetimerequiredunderFMStandard3260.

FuelDistanceFireSizeAverageTime

n‐Heptane82ft.(25m.)1ft.x1ft.(32.5cm.)pan4.52sec.

Denaturedethyl

alcohol(85.4%)

82ft.(25m.)1ft.x1ft.(32.5cm.)4.9sec.

JP482ft.(25m.)2ft.x2ft.(60cm.)panInstantaneously

IPES-IR/UV Flame Detector

80010-001 R07 Operating Manual

Page 6 of 29

Revised 10/21/2013

FalseStimuli

Exposure

WhentheIPES‐IR/UVisexposedtothefiresspecifiedabove,andareinthepresenceofthe

followingfalsestimulisources–modulatedatapproximately1.5Hz,andun‐modulated–no

falsealarmactivationorinstabilityoccursattheminimumdistanceslistedbelow.

SourceDistance

Heater12inches(30.48cm.)

Arcwelder9.8feet(3m.)

Fluorescent6inches(15.24cm.)

Halogen6inches(15.24cm.)

Incandescent6inches(15.24cm.)

DirectsunlightDetectorsnotaffectedbyfrequencyrangeof

visiblelight

IndirectsunlightDetectorsnotaffectedbyfrequencyrangeof

visiblelight

FieldofViewTheIPES‐IR/UV’sviewingangleisvariedfromthecenterlineup,down,leftandright.The

detectorisexposedtoeachofthetestfiresdescribedin“FlameResponseSensitivity”above

atadistancedescribedinthetablebelow.

FuelHorizontal

(Left)

Horizontal

(Right)

Vertical

(Up)

Vertical

(Down)

Min,

Distance

Avg.Time

n‐Heptane45o45o45o45o56.1ft.(17.1

m.)4.61sec.

Denaturedethyl

alcohol85.4%45o45o45o45o41ft.(12.5

m.)4.55sec.

JP445o45o45o45o82ft.

(25m.)Instantaneously

4.0PerformanceCharacteristics

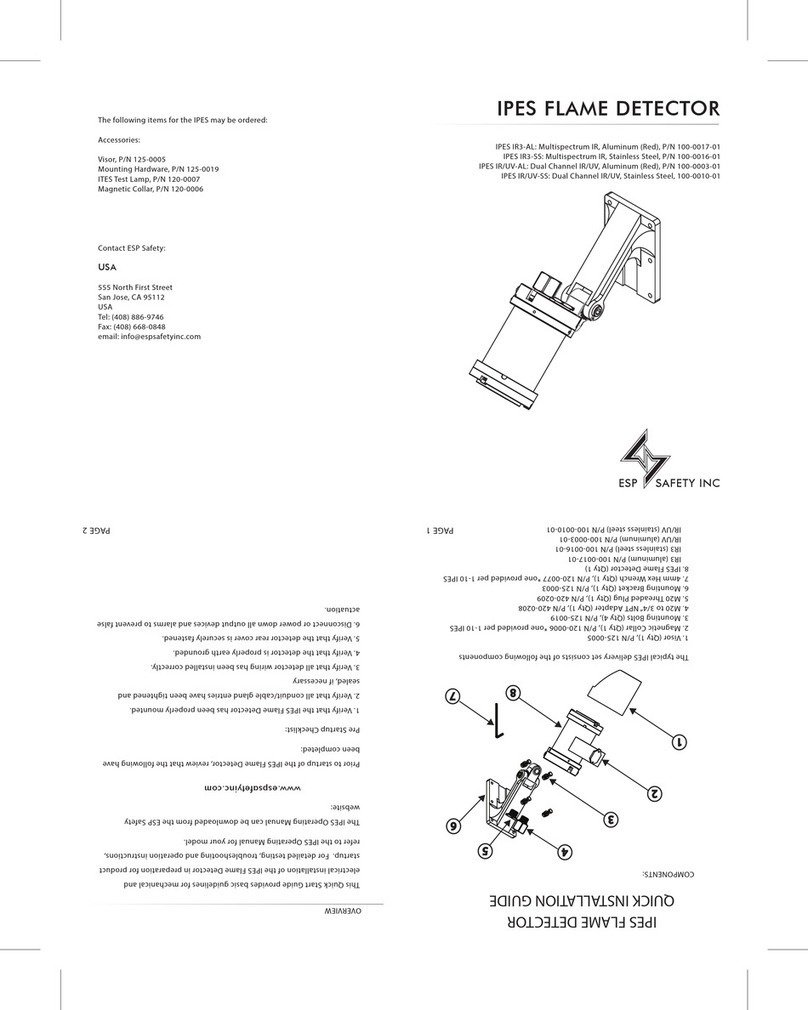

AppearanceTheIPES‐IR/UVconsistsofanexplosion‐proofcasingcontainingsensorswhichconvert

EarthGroundAttachmentPoint

MountingBase

OpticalWindowwithIR

&UVDetectors&

OperationalStatusLEDs

FrontCover

RearCover(removefor

wireinstallation)

Figure 4

-

1: Appearance of the IPES

-

IR/UV

Tilt&PanSwivelAdjustments

IPES-IR/UV Flame Detector

80010-001 R07 Operating Manual

Page 7 of 29

Revised 10/21/2013

electromagneticradiationfromflamesintoelectricalsignalsbyuseofelectronicamplifiers

andfilters,digital‐analogconverters,amicroprocessor,andLEDindicators.

ResponseTimeTheIPES‐IR/UVresponsetimetodetectingradiationemittedbytestsourcesofn‐Heptane

combustionina12”x12”(0.3mby0.3m)pan,andethylalcoholcombustionina12”x12”

(0.3mby0.3m)pan,atadistanceof82feet(25meters)doesnotexceed30seconds.

ThesensitivityandresponsetimecanbevariedinordertoreducethenoisewhentheIPES‐

IR/UVidentifiesafire,orthedistancetotheprobableplaceoffireisshort(“near/far”and

“slow/fast”modes).CanbesetusingtheESPCommanderprogram.

GenerationofAlarm

Signals

TheIPES‐IR/UVincorporatesopticalfiltersconfiguredformaximumsensitivitytoradiation

producedbyflameorfire,ensuringrapidflamerecognitionandalarmsignaling.Uponfire

recognitionwithinits90‐degreefieldofview,theIPES‐IR/UVsignalsachangeinstatefrom

normaltofireinanyOriginalEquipmentManufacturers(OEM)orproprietaryalarmand

responsesystem.

Inaddition,viaintegratedinfrared(IR)andultraviolet(UV)sensors,theIPES‐IR/UVmonitors

inspecificregionsofbothspectralranges.Intheinfraredspectrum,thedeviceisconfigured

forsensitivitytowavelengthsintherangeof4.2to4.6microns,allowingoptimalsensitivityto

combustiblegasfireswhilerejectingfalsesignalsfromincandescentlamps,sunlightandhot

objects.Forultravioletradiation,thedeviceisconfiguredforsensitivitytowavelengthsinthe

rangeof180to250nanometers,makingthesensor“blind”tosunlightandradiationfrom

heatedobjectsbutstillableto“see”theUVradiationemittedbyaflame.Withthesesettings,

theIPES‐IR/UVselectsandalarmsfromthosecharacteristicwavelengthemissionsfromtheIR‐

to‐UVspectrumthatindicateactualflameorfire.

Theanalogsignalsfromthesensorsarefiltered,amplified,andthenconvertedtodigital

signalswhicharethenprocessedinamicrocontrollerviaaspecialalgorithm.Thisensuresthe

reliabilityofthealarmsignals.

TheIPES–IR/UVtakesthefollowingparametersintoconsiderationwhengeneratinganalarm

signal:

Magnitudeofsignalsfromdifferentopticalchannels

Ratiosbetweenthesignalamplitudesofdifferentchannels

Signalmodulationfrequency

Phaserelationshipsamongthechannels

IPES-IR/UV Flame Detector

80010-001 R07 Operating Manual

Page 8 of 29

Revised 10/21/2013

EliminationofFalse

Alarms

ThecombinationofmultiplesensorsandwavelengthrangesettingsmakestheIPES‐IR/UVan

excellentchoiceforeliminationoffalsepositiveindicatorscausedbynon‐flamesourcesof

radiationsuchasartificiallighting,directandindirectsunlight,lightning,arcweldingand

metalgrinding.

Seeadditionalimportantconsiderationsforeliminatingfalsealarmsinsection3.0Safety.

AnAlarmconditionwillnormallyoverrideaFaultconditionunlessalossofoperatingpower

impairsthedetector’sabilitytogenerateormaintainanalarm.TheIPES‐IR/UVreportsboth

FaultandAlarmconditionsexclusiveofeachother.ThismeansbothaFireandFaultcanbe

reportedatthesametimeiftheyoccursimultaneously.

Serviceability

TheIPES‐IR/UVremainsserviceableinnon‐heatedroomsorundershedsattemperatures

from–40°Fto+185°F(–40°to+85°C).

LEDNormal,FireandFaultconditionsareindicatedbytworedLEDslocatedonthecover.Referto

Table4‐1:DeterminingLEDConditions,below.

OpticalIntegrityTomaintainreliabilityoftheIPES,theopticaldevicesareautomaticallyself‐testedfor

radiationtransmissionevery25to45minutes.Thisroutinetestdoesnotrequiretheuseofa

testlamp.Thistestdetermineswhetheranydustorothercontaminationhasformedonthe

detectingwindowswhichwouldscattertheinfraredradiation.

UVLEDINDICATOR

IRLEDINDICATOR

UVDETECTOR

IRDETECTOR

Figure 4-2: IR & UV Detectors and LED Indicators

Page 9 of 29 Revised 10/21/2012

Table4‐1:DeterminingLEDConditions

Aftercompletingallinstallationsteps,refertotheillustrationandLEDindicatortablebelowtodetermineLEDconditions.

NIPESstatusFirerelaydrycontactsconditionFault

relaydry

contacts

condition

Output

signal,mA

IndicatorLEDcondition

NormallyclosedNormallyopen

1Nopowersupply

voltage

Closedopenopen0Off

2Faultoroptical

interference(dust)

Closedopenopen2Every25to45secondstwoLEDsblinkwiththefollowing

frequencies:thefirstLEDblinks5timeswithaperiodof0.5seconds,

thesecondoneblinks3timeswithaperiodof1second.BothLEDs

areoffduringthepausebetweenblinking.

3Normal(nofaultsor

firesduringoperation)

Closedopenclosed4Whennoradiationispresent:

Every25to40secondsthetwoLEDsblinkalternately3timeswitha

periodof1second.BothLEDsareoffduringthepausebetween

blinking.

WhenonlyIRradiationispresent:

TheIRLEDindicator(seefigure4‐2)willbeoncontinuously,theUV

LEDindicatorwillbeoff.

WhenonlyUVradiationispresent:

TheUVLEDindicator(seefigure4‐2)willbeoncontinuously,theIR

LEDindicatorwillbeoff.

4Fire,noFaultOpenclosedclosed18BothLEDslightcontinuously.

5Fire,withFaultOpenclosedopen18BothLEDslightcontinuously.

6Testmode(magnetic

collarison)

Closedopenopen2Magneticcollarison.firerelayisblocked.

IPES-IR/UV Flame Detector

80010-001 R07 Operating Manual

Page 10 of 29

Revised 10/21/2013

AnalogSignal

Analogsignal(4‐20mA)

Signallevel DetectorState

(±0.1)mACircuitopening

(2±0.1)mAFault

(4±0.1)mANormal

(18±0.1)mAFire

(2±0.1)mATest

DigitalSignalInformationaldigitalsignalsarestandardRS‐485communicationwithModbus:

Hardwareself‐testFault

OpticalinterferenceFault

Firedetected

(ThedigitalchannelprotocolModbusRTUisdescribedinAppendixB.)

RelayDryContact

Signal

Relaydrycontactsignal:

OperationofthenormallyopenFirerelaydrycontacts*

oFIRErelay–two‐directionalsingle‐polecontact,whichallowsthestatetobe

changedattheoutputtonormallyclosedornormallyopenbyusingtheESP

Commanderprogram.Thecontactrelayisratedforcurrentsrangingfrom10mA

to5AatDCvoltageof30V.

Theoutputsignal“Fire”canbeclearedaftereliminatingthesourceofthealarm

signal.

*AnormallyclosedconditionoftheFirerelaycontactsdoesnotcomplywiththe

requirementsofNFPA72orULC/ORD–C386andisnotapprovedbyFMapprovals.

OperationofthenormallyopenFaultrelaydrycontacts

oFAULTrelay–single‐directionpolecontactwhichisnormallyopen.Therelayis

designedtohandlecurrentsof10mAto5AatDCvoltageof30V.

RefertoTable4‐1:DeterminingLEDConditionsabove.

OperatingModesPossibledetectorconfigurationsusingESPCommander

TheIPES–IR/UVhasthefollowingdetectoroperatingmodes:

“Near/far”and“slow/fast”modes–Toprovidemaximumsensitivity.

“Latching/non‐latchingmode”–Toselecteitherlatchingornon‐latchingfunctionalityof

thefirerelay,whichprovideslatchingalarmstateforthefire‐alarmrelayincompliance

withNFPA72andULC/ORD–C386.

Themanufacturer’sdefaultsettingscorrespondtofarandfast.Tochangethemanufacturer’s

settingsconnecttheflamedetectortothecomputerandusetheESPCommanderprogram.

IPES-IR/UV Flame Detector

80010-001 R07 Operating Manual

Page 11 of 29

Revised 10/21/2013

5.0 Installation

ComponentParts

andDeliverySet

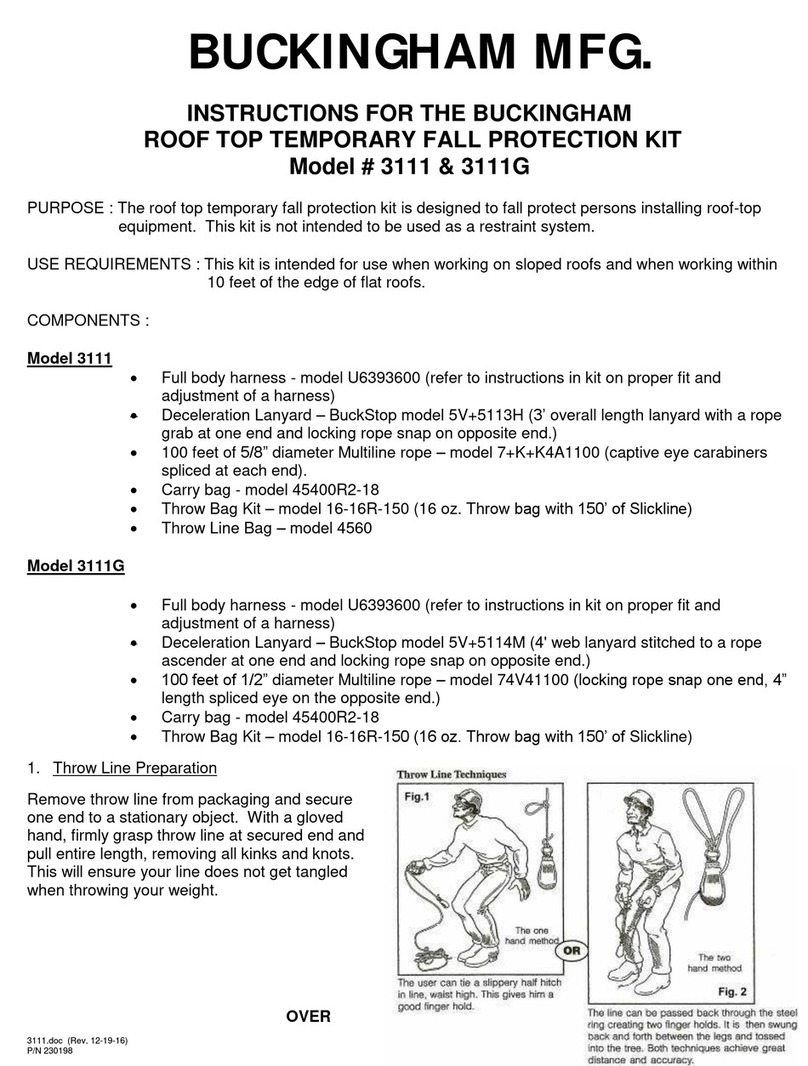

TheIPES‐IR/UVdetectorcomponentpartsanddeliverysetconsistsofthefollowing:

OneIPES‐IR/UVDetectorwithonemountingbase.

(10010‐001/10011‐001StainlessSteelor10010‐002/10011‐002Aluminum)

OneOperatingManual80010‐001

AccessoryKit(bolts,nuts,washers,etc.).RefertoAppendixA‐1,Drawing80025‐001,for

furtherdetails.

Optionalmagneticcollar(deliveredonlybyspecialrequest).

Comparethecontentsofthesettothepackinglisttobesureallitemswerereceived.Ifany

itemsaremissing,contactESPSafetyInc.

VisualExaminationBeforeinstallingtheIPES‐IR/UV,examinethedetectortobesurethat:

Thenameplatesandwarninglabelsareinplace.

Theexternalsurfacesoftheelementsandjoinedsurfacesofthecasingarefreeofdents

ordamage.(RefertoAppendixA1,Drawing80033‐001,andAppendixA2,Drawing

80025‐001.)

Thetamper‐proofscrewisintactonthefrontcover(SeeAppendixA2,Drawing80025‐

001.)

Pre‐Installation

Steps

Makesureallremovablepartsarejoinedtothecasingastightlyaspossible.

Warning:Donotopen,separateordisassemblecasingwhen

energized!Separatingthecasingcanresultinseriousdamageto

thedetectorwhichcouldgoundetected,resultinginfailureto

detectfires.

InstallationPositioningtheDetector

1. Positionthedetectortoprovideanunobstructedviewoftheareatobeprotected.The

detector’s90°viewingangleismostsensitivealongthecentralaxis;therefore,position

thecentralaxissothatithasthebestunobstructedviewoftheplaceofprobablefire.

Uselineofsightorlaserlevelformoreprecisetargeting.

2. Identifyallhighriskfiresources,todeterminethenumberofdetectorsneededfor

adequatecoverage.

3. Locatethedetector(s)foreaseofcleaningandservicing.Ensurethatprobablefire

sourcesarewithinthedetector(s)fieldofviewanddetectionrange.

4. Wheninstallingmultipledetectorsinthesamearea,beawareofoverlappingfieldsof

viewanddetectorhierarchy.Overlappingfieldsofviewcanbeusedtoprovideadditional

protectionagainstfalsepositivesorfalsenegatives,dependingonthecontrolsystem

logicconnectedtothedetectors.

Note:Tomitigatefalsepositives,positionthedetectorsothatitsfieldofviewdoesnot

coveranyareasoutsidethehazardousarea.

5. Mountthedetectoronarigidsurfacewhichminimizesvibrations.Usethemounting

hardwareprovidedalongwiththerubberbushingstofurtherisolatethedetectorfrom

IPES-IR/UV Flame Detector

80010-001 R07 Operating Manual

Page 12 of 29

Revised 10/21/2013

vibrations(seeAppendixA‐2,Drawing80025‐001,Sheet1).

Note:ESPSafetyInc.recommendsboltingthemountingbaseplatetothemounting

surface.Ifboltingisnotpossible,themountingplatecanbeweldedtothemounting

surfaceifitisasimilarmetal(either316StainlessSteelor6061aluminum).Before

welding,besuretoremovethedetectorfromthebaseplatebeforeattemptinganyweld

operation.

MoistureDamageProtection

Itistheresponsibilityoftheinstallertotakeproperprecautionsduringinstallationto

protecttheelectricalconnectionsandcomponentsfrommoisture.

Anti‐seizelubricantisprovidedforeasyassemblyandcorrosionprotectionofthejoints

betweentheenclosure/coverandenclosure/base.Afterdisassembly,wipethese

surfacescleanwithasoftcottonorwoolclothandthenre‐applyathinlayeroflubricant

priortoassembly.SeeAppendixA2(Drawing80025‐001,Sheet1).

Ifinstallingwiringcableinconduit,donotuseconduitforwiringtootherequipment.

Careshouldbetakentonotinstallthedetectorwhereheavycondensate,rain,orfogcan

coverthelensandreducethesensitivityofthedetector.

Ifpossible,conductfireteststoconfirmdetection.

Caution:Allcable/conduitentriesmustbesealedwithan

appropriateandcertifiedsealingplugandcablegland.Theuseof

industrialgrade,armoredfieldcableisrecommended.

Figure 5-1: View of IPES-IR/UV with Base Removed

IPES-IR/UV Flame Detector

80010-001 R07 Operating Manual

Page 13 of 29

Revised 10/21/2013

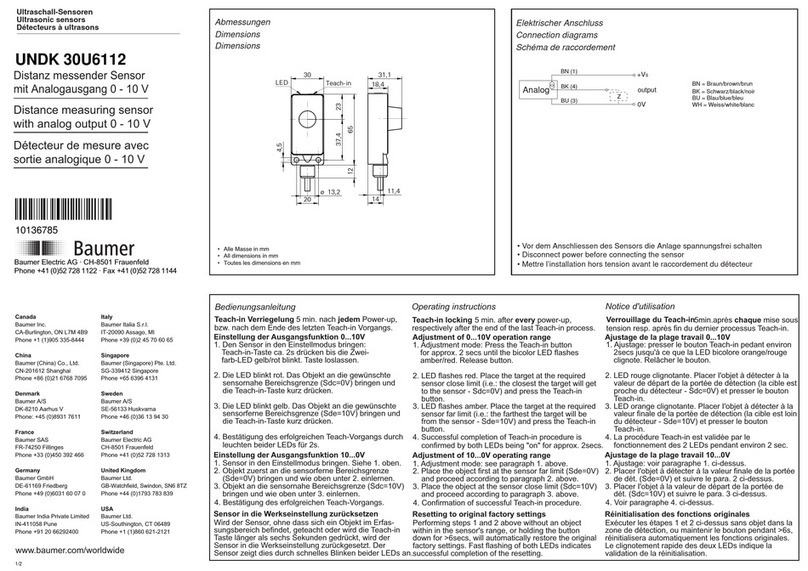

Table5‐1:ArrangementofElectricalConnections

ArrangementofElectricalConnections

ArrangetheelectricalconnectionsasdescribedinTable5‐1,Table5‐2andFigure5‐3below.

ToconnecttheIPES‐IR/UVtoexternaldevices,usearmoredcontrolcables4x1.5,whichare

usedinallclassesofexplosivezonesincludingindoorandoutdoorsites,channels,tunnels,

ground(trenches)withcorrosivemedium,andinzonescontainingroamingcurrents.

WiringRequirements

Thetemperatureratingofallfieldwiringconductorsshallbeatleast10oCgreaterthan

themaximumambienttemperature

Communications:14AWG(2.08mm2)or16AWG(1.31mm2)shieldedcable,twisted

pairisrecommendedtoprotectagainstEMIandRFIinterference;Power:14AWG(2.08

mm2)or16AWG(1.31mm2)wires.

Groundwireshallbe14AWG(2.08mm2)

Thewiringcolorandtypeshallcomplywithlocalcodes,ordinances,andtheNEC.Itis

recommendedthatthelocalauthoritybeconsultedincaseofdoubt.

Followthewiringinstructionsinthismanualtoensurecorrectfunctioningofthe

detector.

SettingtheModbusAddressandBaudRate

Toensurepropercommunications,auniqueaddressmustbeassignedtoeachdevice,as

duplicateaddressesarenotautomaticallydetected.Moduleswithduplicateaddresseswill

reportwiththesameaddress,confusinglatestupdates.Recordalladdressesanddevice

typesaftercompletingtheinstallation.

RefertoAppendixBforsettingtheModbusaddressandbaudrate.

Completingthe

Installation

Forthefollowing,refertotheillustrationsinAppendixA2(Drawing80025‐001,Sheets1&2).

1. UnscrewtheM5SocketHeadCapscrewsfromthebase.Removethedetectorfromthe

base.

2. DetachNPTconduitbushingfrombase.

3. Installthebaseonasuitableworkplatformandsecureusingthe4mountingscrews,

washers,nuts,andrubbergrommets.

4. Runthepower,control,andgroundwiresfromtheconduitintotheconduitbushingand

connecttothewiringterminalsinthebase.FollowFigure5‐2,Arrangementand

FunctionsofMountingConnectionTerminals,fordetails.

5. Tightentheconduitbushingto4‐1/2+‐1turnsofengagement.Sealtheconduitentry

withanapprovedhazardouslocationconduitsealant.

6. Runtheearthgroundwiretotheexternalgroundstudonthebase.

7. Aftercompletingallwiring,refertoTable4‐1toverifythefunctionalityofthefrontcover

LEDs.

8. Inspectbaseandre‐applyathinfilmofanti‐seizecompoundifrequired;re‐installthe

detectoronthebaseandevenlytightentheM5screwsto40in‐lbs.

9. Uponcompletingtheinstallation,checktheresistanceoftheearthgroundlugtoground

whichshouldnotexceed1ohm.

IPES-IR/UV Flame Detector

80010-001 R07 Operating Manual

Page 14 of 29

Revised 10/21/2013

ArrangementandFunctionof

MountingConnectionTerminals

Thearrangementandfunctionofmountingconnectionterminalsusedtoconnect

theIPES‐IR/UVtoacontrolsystemareshownbelow.

Table 5-2: Connecting Terminals

ReceptaclePinFunction

X3+24V24VDCfromsystempowersource(ExternalUserProvided)

GNDSystemGroundfromsystempowersource(ExternalUserProvided)

+4/20IndustryStandard+4‐20mAcurrentloopoutput

RS485ARS‐485MODBUS

RS485BRS‐485MODBUS

R_WORK

R_WORK

Fault/ObstructionRelayNormallyClosed(NCTypeB)WhenEnergized

X4+24VOutputtonextdeviceifrequired

GNDOutputtonextdeviceifrequired

+4/20IndustryStandard+4‐20mAcurrentloopoutput

RS485AOutputtonextdeviceifrequired

RS485BOutputtonextdeviceifrequired

R_FIRE

R_FIRE

AlarmRelayNormallyOpen(NOTypeA)WhenEnergized

X5FactoryUse

X6FactoryUse

1) WhenusinganRS‐485busconnection,itisadvisabletoconnecttheIPES‐IR/UVtothebusviatheterminalbox.To

connectthedetectortotheterminalbox,useacablenotlongerthan1.64feet(0.5m).Thecablecharacteristicsshould

meettherequirementofthecableentriesmountedontheIPES‐IR/UVcasingandthoseoftheterminalbox.

2) Arrangethepower‐supplysystemsothatthepower‐supplyvoltageacrossthedeviceterminalsrangesfrom18to32V

(takingintoaccounttheIPES‐IR/UVconsumption).

Figure 5-2: Arrangement and Functions of Mounting Connection Terminals

Table of contents

Other ESP Safety Security Sensor manuals

Popular Security Sensor manuals by other brands

RKI Instruments

RKI Instruments 35-3010RKA-03 manual

PCB Piezotronics

PCB Piezotronics ICP 353B51 Installation and operating manual

SGB

SGB VLR Series Documentation

RKI Instruments

RKI Instruments 35-3010RKA-06 manual

Inficon

Inficon D-TEK 3 operating manual

Medifab

Medifab Houdini Harness 27 Installation and user manual