- 2 -

Safety warning.

Safety warning.Safety warning.

Safety warning.

The following symbols shown beside a paragraph represent danger warnings associated to the

failure to comply with the corresponding instructions.

DANGER!

DANGER!DANGER!

DANGER!

Risk of

Risk ofRisk of

Risk of

electrocution.

electrocution.electrocution.

electrocution.

Not observing this precaution involves a risk of electrocution.

DANGER!

DANGER!DANGER!

DANGER!

Warns that not observing the precaution involves a risk of damage to people

and/or materials.

WARNING

WARNINGWARNING

WARNING

Warns that not observing the precaution involves a risk of damage to the pump

or the installation.

TABLE OF CONTENTS

TABLE OF CONTENTSTABLE OF CONTENTS

TABLE OF CONTENTS

1) GENERAL INFORMATION....................................................................................................................................3

2) TECHNICAL SPECIFICATIONS..............................................................................................................................3

2.1) Models. .....................................................................................................................................................3

2.2) Dimensions. ..............................................................................................................................................3

2.3) Features. ...................................................................................................................................................3

3) INSTALLATION. .................................................................................................................................................4

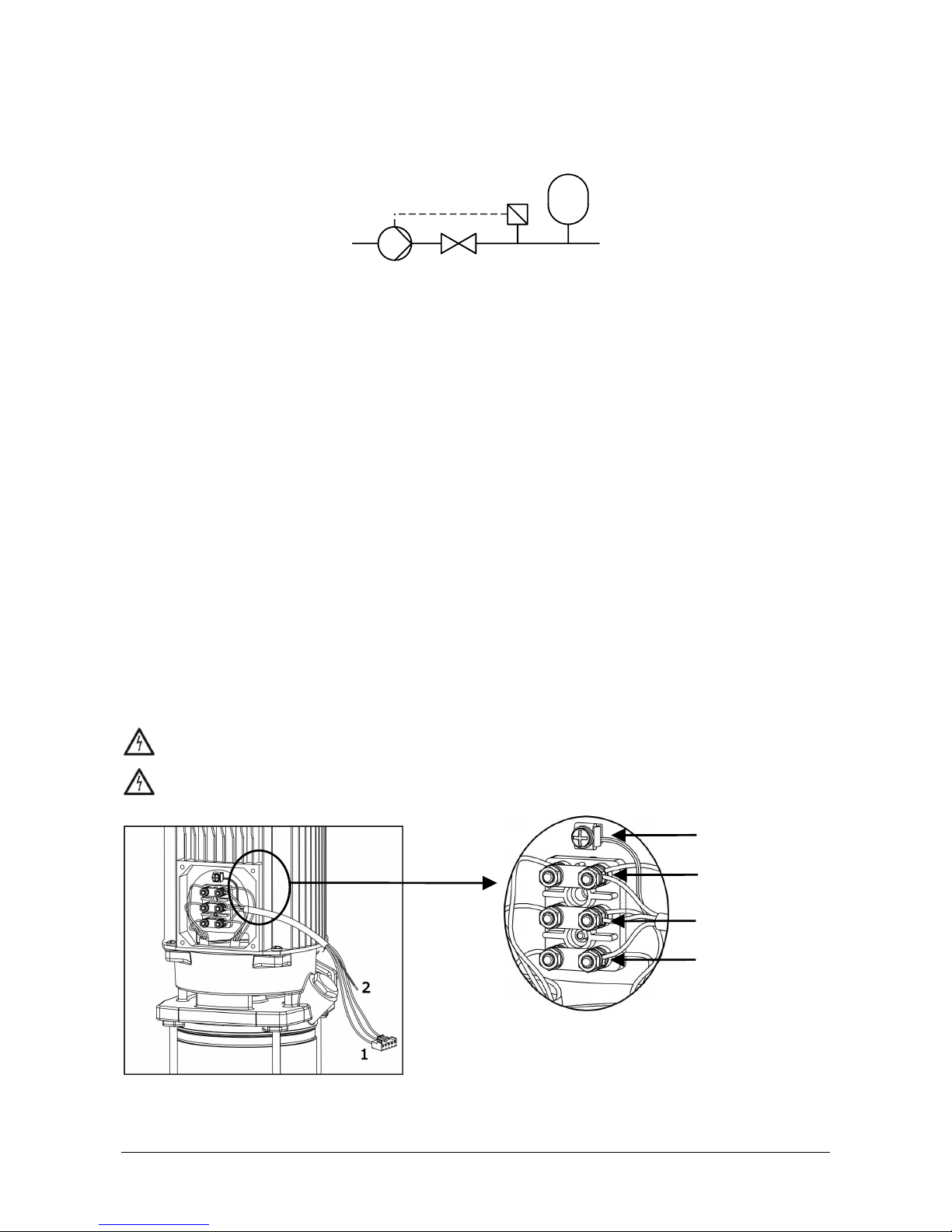

3.1) Hydraulic installation.................................................................................................................................4

3.2) Electrical connection to the motor. .............................................................................................................4

3.3) Installation on the pump............................................................................................................................5

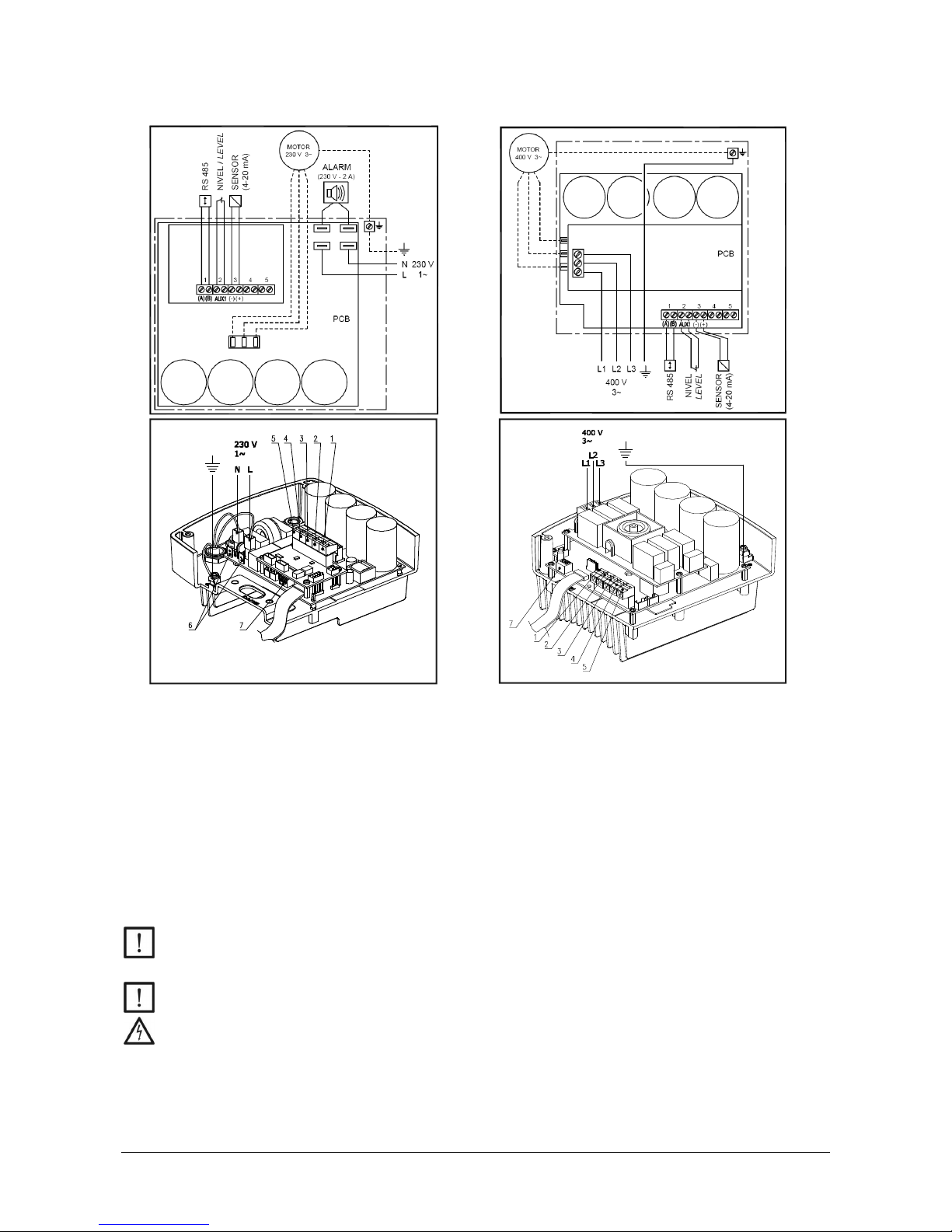

3.4) Power supply connection. ..........................................................................................................................7

3.5) Signals wires connection. ..........................................................................................................................8

4) OPERATING MODES. .........................................................................................................................................9

5) SETUP. .............................................................................................................................................................9

5.1) Definitions.................................................................................................................................................9

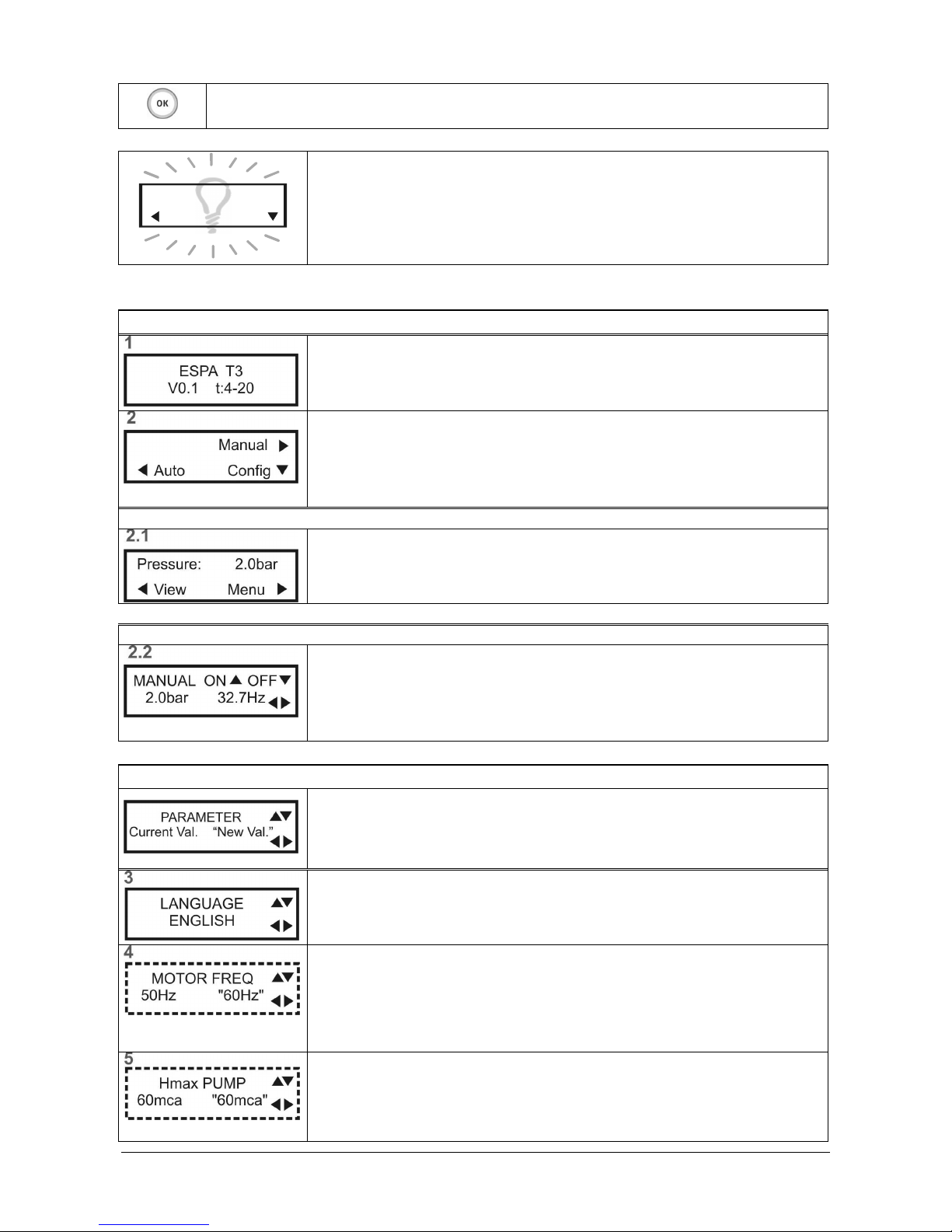

5.2) Browsing. ..................................................................................................................................................9

5.3) Description of the menus. ........................................................................................................................10

6) PROTECTION AND ERRORS. .............................................................................................................................15

ELECTRONIC CIRCUIT FAILURE..........................................................................................................................16

7) MULTIPLE OPERATION.....................................................................................................................................16

7.1) Booster set with "On-Off" auxiliary pumps ...............................................................................................16

7.2) Booster set with inverter regulated auxiliary pumps. ................................................................................17

8) MAIN COMPONENTS .......................................................................................................................................20

9) EVIDENCE OF CONFORMITY .............................................................................................................................20

9.1) LOW VOLTAGE..........................................................................................................................................20

9.2) ELECTROMAGNETIC COMPATIBILITY. .........................................................................................................20

9.3) OTHER INSTALLATIONS.............................................................................................................................20

10) MENU DIAGRAM............................................................................................................................................21