SECTION 4 - INSTALLATION

WARNING: BEFORE PROCEEDING WITH INSTALLATION, ENSURE THAT THE

CONVEYOR BELT DRIVE AND ALL ASSOCIATED EQUIPMENT IS

FULLY ISOLATED AND LOCKED OUT.

CONTACT WITH A MOVING CONVEYOR BELT OR ITS COMPONENTS

CAN RESULT IN SERIOUS INJURY OR DEATH.

4.1 Installation Procedure

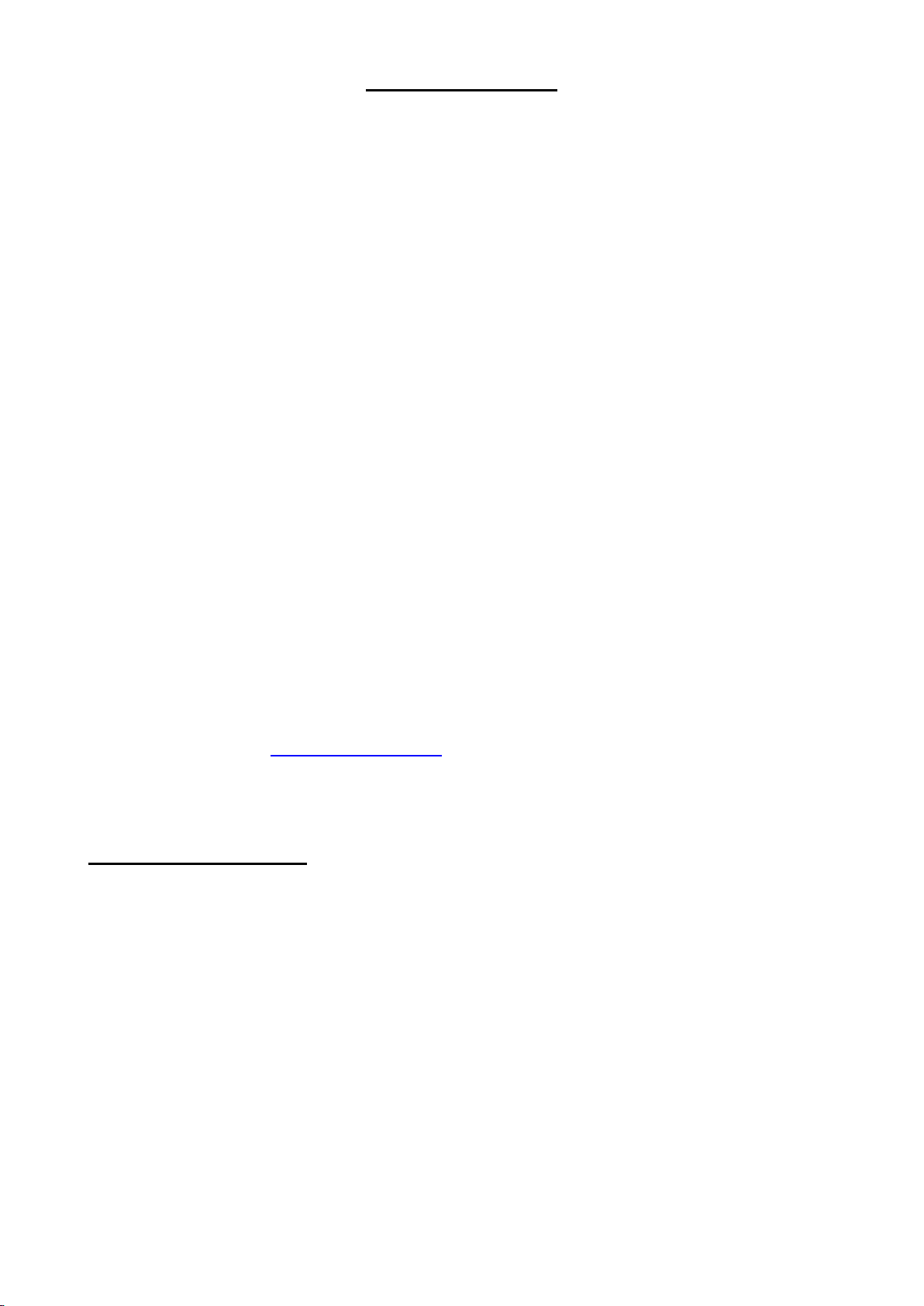

1. If the steel skirt plates are greater than dimension A (Sect 3.4) from the belt

surface, it may be necessary to extend the plates closer to the belt. A 150x10

flat bar welded to the outside of the chute or skirt side walls is an easy way to

achieve this, as long as sufficient freeboard is available outside the skirt line.

2. Take an ESS 2000 Back Plate section and position it such that the bottom edge

is uniformly dimension A (Sect 3.4) from the belt, and one end is at the required

start point of the skirt seal (preferably toward the tail end of the conveyor). The

bottom edge of the ESS 2000 must not protrude below the bottom edge of the

skirt plate or chute wall –see step 1 above.

Weld the backplate to the skirt / chute wall, using a 3mm x 25 long fillet weld at

the top above each captive wedge, and plug weld in each lower slot. Use an

appropriate welding blanket to protect the belt surface.

3. Repeat step 2 for the full skirt length, simply butting consecutive Backing Plates

against each other, maintaining dimension A from the belt. For skirt lengths that

are multiples of 600mm, and the final or closing length required is 600mm,

simply cut the backing plate in half (2 x 600mm sections), and fit the half length

of Backplate with one full Clamp Plate.

For closing lengths greater than 600mm, but less than 1200mm, cut a Backing

Plate to 600mm and install as described above. Use the following procedures

to complete the installation.