Essilor Pro-E 700 edger User manual

User Manual

CONTENTS

INTRODUCTION 7

I. FIRST STEPS WIT PRO-E 9

1. Descriptive diagrams 11

2. Using the edger 13

a. Turning on the edger 13

b. Switching off the edger 13

c. Using the touch screen and keypads 14

d. Edging screen 15

II. EDGING A LENS 17

1. Edger working environment 19

a. Menu screen 20

b. Calling up a shape 22

c. Lens set-up and feeling 22

2. Perform a Beveling 24

a. Automatic beveling 25

b. Legend screen for customized bevels 26

c. Customized beveling 27

d. Modifying the bevel curve 29

e. Modifying the bevel curve at a particular point 30

f. Displacing the bevel curve 31

3. Perform a high-base bevel 32

a. Captioned screens 33

b. igh-base beveling 34

4. Perform a Step bevel 40

a. Captioned screens 41

b. Perform a Step bevel 42

5. Grooving 49

a. Automatic grooving 50

b. Customized groove legend screen 51

c. Customised grooving 52

d. Modifying the groove curve 54

e. Modifying a point in the groove curve 55

f. Displacement of the groove curve 56

6. Produce a Flat-edge finish 56

7. Do a mixed job 57

a. Legend screens 58

b. Configuring the mixed finish 60

8. Perform a Drilled job 62

a. Automatic drilling 63

b. Legend screen for customized drilling 64

c. Customized drilling 65

9. Perform a Polishing 67

10. Chamfering 67

11. Perform a Retouching 68

USER MANUAL> CONTENTS

12. Perform a “Super Chamfer” (Pro-E 700) 70

13. Perform a Chemistrie TM job (Pro-E 700) 72

a. Prerequisites 72

b. Preparing a Chemistrie TM job 73

c. Prepare the Chemistrie TM lenses 77

d. Cut a Chemistrie lens 78

14. Carry out a alf Jacket job (Pro-E 700) 81

a. Outline the step bevel trajectory on a alf Jacket shape 81

b. Finalize the step bevel settings in “front surface follow-up” mode 94

c. Modify the shape on Essibox 96

15. M’EYE Sign feature (Pro-E 700) 100

a. To prepare the engraving 100

b. Performing engraving 112

c. Setting up the favorites 116

16. M’EYE Touch feature (Pro-E 700) 117

a. On Essibox 118

b. On the edger 125

III. PREPARING A DRILLED JOB 127

1. Menu screen 129

2. Configuring a drilling point 130

a. Creating a drilling point 131

b. Dimensioning a drilling point 131

c. Adjusting the position of a drilling point 132

IV. CONFIGURING T E EDGER 137

1. Configure the edger 139

a. Time, date and language 139

b. Connections 140

c. Screensaver 141

2. Adjusting the precision of the edger 141

a. Adjusting the diameter of the finished lenses 141

b. Adjusting the position of the bevel and groove 142

c. Adjusting the diameter of drill-holes 143

d. Adjusting the chamfer 144

e. Adjusting the groove 145

f. To adjust the engraving 146

g. Adjust the position of high-base bevel 147

h. Adjust the position of the step bevel 149

3. Restore the factory settings 150

V. MAINTENANCE & SERVICING 151

1. Carrying out the autotests 153

2. Calibrating the touch screen 154

3. Consulting the preventive maintenance screen of the “small tools” module 155

4. Changing or cleaning the edger tools 158

a. Changing or cleaning the drill bit 159

b. Changing or cleaning the mill bit 162

c. Changing the chamfering wheel 165

d. Install and change the step bevel ++ tool 168

e. Installing and changing the engraving tip 171

USER MANUAL> CONTENTS

5. Statistics and technical log 174

a. Edger cycles 174

b. Technical log and errors 175

6. Maintaining and cleaning the edger 176

a. Precautions required 176

b. Clean the door, the “small tools” module and the wheels 176

c. Dress the wheels 178

TEC NICAL DATA 181

1. Edger 183

2. Environment 185

GENERAL INFORMATION 187

1. Symbols 189

2. Modifications 189

3. Declaration of conformity 190

4. Copyright 190

5. Materials and products 190

6. Safety instructions: 190

7. Electromagnetic waves 191

8. License agreement for M’EYE Sign™ (Engraving) software 191

a. General information 191

b. Accepted use of the Software and restrictions 192

c. Liability 192

d. Disclaimer of warranties 192

e. Limited liability 192

f. Termination 192

g. Applicable law 193

h. Entirety of the agreement; authentic language 193

GLOSSARY 195

USER MANUAL> CONTENTS

INTRODUCTION

To take full advantage of the features on your Pro-E 600 edger, we encourage you to read through the entire

manual.

You need to have at least memory version:

•V 3 for Pro-E 600,

•V 3 for Pro-E 700.

USER MANUAL> INTRODUCTION

7

Pro-E 600_Pro-E 700 > v1 -10.18

I. FIRST STEPS WIT PRO-E

Pro-E 600_Pro-E 700 > v1 -10.18

10

USER MANUAL> I. FIRST STEPS WIT PRO-E

This chapter contains all the information relating to the first use of the edger:

•Description of the edger (F p.11)

•Using the device (F p.13)

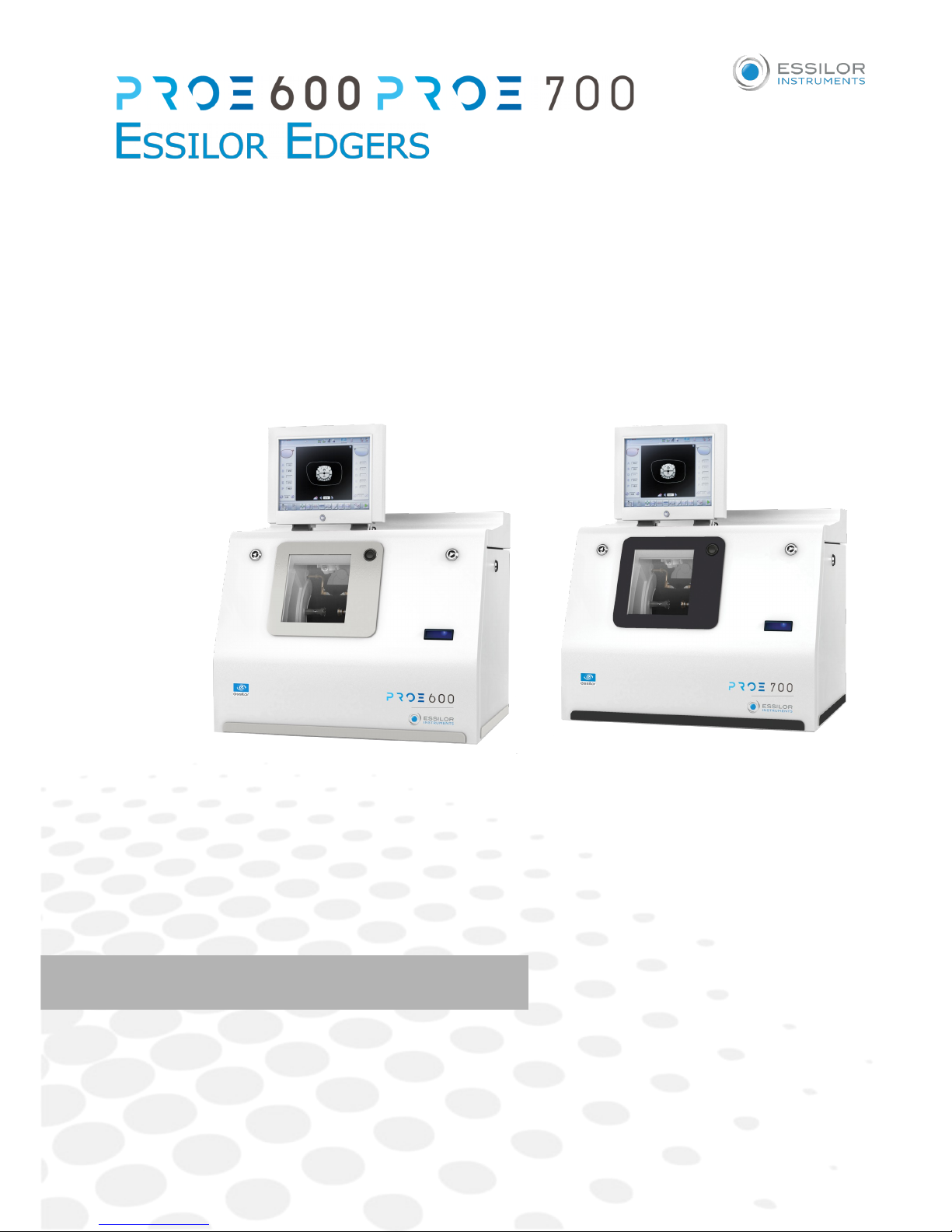

1. DESCRIPTIVE DIAGRAMS

This section consists of descriptions and lists of accessories.

1. USB plug

2. Trough

3. Screen

4. ON/OFF button

5. Cycle start/stop button

6. Barcode reader

7. Screen t lt buttons

8. Fans

9. Manufacturer plate

10. Ma n sw tch

Connectors

USER MANUAL> I. FIRST STEPS WIT PRO-E

11

Pro-E 600_Pro-E 700 > v1 -10.18

1. Power socket

2. Soleno d valve socket

3. Pump socket (tank + pump) / Soleno d valve socket (town)

Accessories

Stylus

Posiblock removal pliers

Triangular key

White dressing stone for finishing wheel

Square dressing stone for polishing wheel

Transport wedges to be kept

Accessory box

Use :

•22 mm posiblock holder

•18 x 14 mm posiblock holder

•22 mm stop

•18 x 14 mm stop

•Mill/drill bit replacement tool (blocking key)

•Ø 1.0 mm drill bit (quantity 2, including one mounted on the module)

•Ø 0.8 mm drill bit (quantity 2)

•Ø 1.5 mm edging mill bit (quantity 2, including one mounted on the module)

•Ø 20 mm grooving wheel

•Chamfering wheel

•Step bevel wheel

•Torque wrench

•igh-base edging wheel

•Metal ruler

•Modeling clay

•Description pamphlet of the accessories box

Maintenance

•Blocking key for tool changes (drill bit/mill bit)

•Adjustable wrench for tool changes (drill bit/mill bit)

•Accessory for Step bevel wheel assembly/dismantling

•Adjustable wrench for tool changes (drill bit, mill bit, chamfering wheel)

Options

•Open or closed circuit spraying kit

•Milling chip recovery tray

•Posiblock holder and “Weco” posiblock stop accessory kit

•M’Eye Sign Box

•Essibox

Connection accessories

•220 V power cable

•RJ45 cable for the tracer-edger connection

•Essibox connection cable

Pro-E 600_Pro-E 700 > v1 -10.18

12

USER MANUAL> I. FIRST STEPS WIT PRO-E

•Wastewater evacuation pipe with attachment ring

•2 connectors to clip onto two internal water pipes and connect to the rinsing kit

2. USING T E EDGER

In this section, you will find all the information concerning the following:

•Turning on (F p.13) andoff (F p.13) the edger,

•the use of the touch screen and the keyboards (F p.14),

•the description of the work screens of the edger (F p.15).

a. T rning on the edger

Press the main switch, located behind the edger on the left, to power it up.

Press the ON/OFF button located under the touch screen.

The edger will initialise.

On the edger screen, press on the “cycle start” button on the front surface or on the icon to end the

initialization phase.

A beep indicates that initialization was successful.

The edger is ready for use when the initial screen is displayed.

b. Switching off the edger

Before switching off the edger:

•Check that there is no glass in the trough

•Check that the lens clamp shafts are loosened and that the trough door is open

•Go to the edging screen.

Press the ON/OFF button for a short time located under the touch screen or press / ,

then .

Do not press the ON/OFF button for several seconds. This would result in shut-down of the

machine and an error message would be displayed at the next switch-on.

A confirmation message is displayed on the screen.

Press to confirm.

>

>

>

1

2

3

1

2

3

USER MANUAL> I. FIRST STEPS WIT PRO-E

13

Pro-E 600_Pro-E 700 > v1 -10.18

The edger will switch off.

Extended period of non- se

For a prolonged period of non-use (a few days), it is preferable to turn off the edger using the main

switch.

It must be turned off at least once a week.

c. Using the to ch screen and keypads

Using the to ch screen

Use the stylus supplied with the machine to use with the touch screen.

You can also touch the screen with your finger.

•If the screen is not sensitive enough to finger pressure, press lightly with a fingernail.

•If the response area does not correspond to the position of the key, you need to calibrate the touch

screen. For further information, refer to the section Maintenance and servicing > Check and calibrate

> Calibrate the touch screen (F p.154).

•Never press hard on the screen as this could break it.

•Never press on the screen with sharp objects such as pens, scissors, clamps, etc.

•Screen breakage is not covered by the guarantee.

On the screen, press the icon buttons to access the desired menus and job functions .

Using the keypads

When you need to enter or modify data, two types of keypads are automatically displayed, according to the

information to be entered.

•The numeric keypad is displayed for entering values.

•Reset the fields

•Go back

•Cancel and go back to the work screen

•Confirm

>

Pro-E 600_Pro-E 700 > v1 -10.18

14

USER MANUAL> I. FIRST STEPS WIT PRO-E

•The alphanumeric keypad is displayed to save or search for jobs.

•Job ID

•Job reference (alphanumeric characters)

•Collection list (when the edger is connected to a Essilor range tracer)

•Job list&

d. Edging screen

1. Work screen nd cator

2. Tool wear nd cator

3. Sett ngs

4. Dev ces connected

5. Act ve eye

USER MANUAL> I. FIRST STEPS WIT PRO-E

15

Pro-E 600_Pro-E 700 > v1 -10.18

6. Informat on on the shape

7. S ze ncrease/reduct on

8. Work area

9. Turn ng off the product/edg ng screen

or

10. Job call: Tracer menu

11. Act ons ava lable for the current screen

12. Start the edg ng cycle

Detailed f nctions

For more information, consult the section Edging a lens > Work environment of the edger > Captioned

screen. (F p.20)

Pro-E 600_Pro-E 700 > v1 -10.18

16

USER MANUAL> I. FIRST STEPS WIT PRO-E

II. EDGING A LENS

Pro-E 600_Pro-E 700 > v1 -10.18

18

USER MANUAL> II. EDGING A LENS

This chapter describes the work environment of the edger and the procedures for edging any type of lens:

•Edger working environment (F p.19)

•Perform a Beveling (F p.24)

•Beveling for a high-base frame (F p.32)

•Perform a Step bevel, (F p.40)

•Grooving (F p.49)

•Produce a Flat-edge finish (F p.57)

•Do a mixed job (F p.57)

•Perform a Drilled job (F p.62)

•Perform a Polishing (F p.67)

•Perform a Chamfering (F p.67)

•Perform a Retouching (F p.68)

•Perform a “Super Chamfer” (F p.70) (Pro-E 700)

•Perform a Chemistrie job (F p.72) TM (Pro-E 700)

•Perform a alf-Jacket job (F p.81) (Pro-E 700)

•Create an engraving or a creative shape (F p.100) (Pro-E 700)

1. EDGER WORKING ENVIRONMENT

This section describes the edger working environment and the initial stages of the edging of a lens.

•Description of the edging screen (F p.20)

•Shape call-up procedure (F p.22)

•Putting the lens in place (F p.22)

USER MANUAL> II. EDGING A LENS

19

Pro-E 600_Pro-E 700 > v1 -10.18

•

a. Men screen

1. Lens mater al

◦Plastic lens -index 1.5&

◦Polycarbonate lens

◦Medium or high index plastic lens - index > 1.5

◦Trivex lensTM

◦Tribrid lensTM

The configuration of the edging cycles depends on the type of material. An incorrect choice may result in

material damage.

The Pro-E 600 edger does not edge glass lenses.

2. Type of f n sh

◦Bevel

◦igh-base bevel

◦“Step”/“ alf-Jacket” bevel

◦Groove

Pro-E 600_Pro-E 700 > v1 -10.18

20

USER MANUAL> II. EDGING A LENS

This manual suits for next models

1

Table of contents

Other Essilor Laboratory Equipment manuals