4

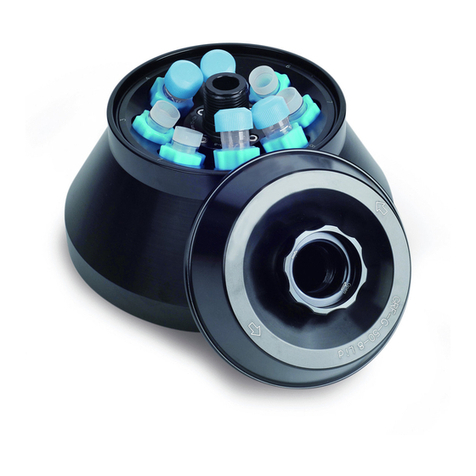

Compact Bench-Top, Refrigerated Centrifuge 624R

CONTENTS

Page #

1. Meanings of Symbols & Safety Precautions................................................................................4

1-1. Meanings of Symbols.................................................................................................................5

1-2. Safety Precautions......................................................................................................................5

2. Product Description & Technical Specifications .....................................................................8

2-1. Product Description....................................................................................................................8

2-2. Technical Specifications............................................................................................................8

3. Unpacking..............................................................................................................................................9

4. Installation........................................................................................................................................10

4-1. Power On/Off and Lid Release...............................................................................................10

4-2. Rotor Coupling and Disassembling......................................................................................11

5. Operation..........................................................................................................................................13

5-1. Key Functions of Control Panel.............................................................................................13

5-2. Setting the RPM/RCF Value.....................................................................................................14

5-3. Setting the Time Value .............................................................................................................14

5-4. Setting Temperature and Fast Cool......................................................................................15

5-5. Acceleration / Deceleration.....................................................................................................16

5-6. Program Saving & Recalling...................................................................................................17

5-7. Start/Stop.....................................................................................................................................18

5-8. Repeat Account and Sound Pitch of End Alarm ...............................................................18

5-9. Pulse .............................................................................................................................................19

5-10. Emergency Lid-Lock Release...............................................................................................19

6. Maintenance........................................................................................................................................20

6-1. Outer part of Instrument..........................................................................................................20

6-2. Chamber.......................................................................................................................................20

6-3. Shaft..............................................................................................................................................20

6-4. Rotor .............................................................................................................................................20

6-5. Transportation of Instrument .................................................................................................20

7. Trouble Shooting...............................................................................................................................21

7-1. Check List....................................................................................................................................21

7-2. Error Code...................................................................................................................................21

8. CE

...........................................................................................................................................................24