Essilor AKR 550 User manual

Auto kerato refractometer

Maintenance Manual

V1 –09/2016

1

Contents

1External View................................................................................................................. 2

2Internal Structural Diagram ........................................................................................ 3

3Measurement Principle ................................................................................................. 4

4Block Diagram................................................................................................................ 5

5Connection Diagram ...................................................................................................... 6

6Wiring Diagram ............................................................................................................. 8

7Troubleshooting............................................................................................................ 11

8Cleaning of Eye Lens, Measurement Window Filter and Model Eye ASSY ........... 33

9Functional Check ......................................................................................................... 34

10 Maintenance Mode ...................................................................................................... 35

11 Evaluation of Freeze Image........................................................................................ 46

12 Replacement Procedure of Each Unit........................................................................ 48

13 Rewriting procedures of the software of AKR550..................................................... 56

14 Packing mode............................................................................................................... 60

2

1External View

No.

Name

No.

Name

1

LCD monitor

12

Power plug connector

2

Touch-sensitive panel

13

Rating plate

3

Printer cover

14

Chinrest

4

Base

15

Body cover

5

Rubber leg

16

Face panel

6

Main unit slide lock knob

17

Headrest

7

Measurement start switch

18

Head cover

8

Joystick

19

Printer cover button

9

Slide base cover

20

Headrest rubber

10

Power switch

21

Chinrest knob

11

External interface connector

3

2Internal Structural Diagram

No.

Name

No.

Name

1

Optical unit

12

Joystick

2

Control board

13

Slide base cover

3

Optical cover

14

Base

4

LCD monitor

15

PD meter

5

Touch sensor board

16

Vertical unit

6

LCD relay board

17

XZ unit

7

Printer

18

Power unit

8

Printer control board

19

Bottom plate

9

Measurement window ring

20

Rubber leg

10

Main unit BKT

21

Chinrest

11

Toothed belt

22

Headrest

4

3Measurement Principle

1) Measurement of eye refraction

A measurement pattern for measurement of eye refraction is projected to an eyeground to

be measured.

The projected pattern changes its size depending on the eye’s refractive power. The reflect

light of this eyeground image is led to the sensor through the measurement system. The

detected data is stored in the frame memory and conducted pattern analysis by image

processing to calculate values of S, C and A.

Rough refractive power (temporary measurement) is calculated by the first measurement

and auto fogging operation and focusing operation of eyeground images are started based

on the data. Then, the actual measurement is started and the refractive power of the eye

to be measured is calculated and displayed.

2) Measurement of corneal curvature radius

A ring-shaped measurement pattern is projected onto a cornea of an eye to be measured.

The pattern projected on the cornea varies its size depending on the corneal curvature

radius. The projected light is led to the sensor through the cornea measurement system.

The detected data is stored in the frame memory and conducted pattern analysis by

image processing to calculate values of R1, R2 and A.

Subject’s eye

Cornea

Projected light

Corneal curvature

radius: small

Corneal curvature

radius: large

Projected patterns on the sensor

Subject’s eye

Eyeground

Cornea

Projected light

Myopia

Hyperopia

Projected pattern on the sensor

5

4Block Diagram

LCD

Motor

Motor

Operation Switch

RS-232C

Interface

Focus Motor

Position Sensor

Target Motor

Position Sensor

Potentiometer

Measurement Start Switch

Main Control

Circuit Unit

EEPROM

Printer

Printer Control Circuit Unit

CMOS Camera

CMOS Camera

Ranging Sensor

Kerato LED

Target LED

Ref LED

Ranging LED

Fuse

Power Switch

Power

Inlet

Switching Supply

Basic Insulation

Reinforced Insulation

Between Primary and

Secondary

Metallic Portion with Protective Earth (Chassis)

Reinforced Insulation

LCD Relay

Circuit Unit

Headrest

Chinrest

DC 12V (SELV)

DC 5V (SELV)

AC100-240V

50/ 60Hz

6

5Connection Diagram

7

8

6Wiring Diagram

6-1 Front View

6-2 Side View

Printer Control Board

Power Switch

Optical Unit ASSY

Printer

Joystick

9

6-3 Rear View

6-4 Bottom View

PD ASSY

Switching Power Supply

SWPS Output Harness

SWPS Input Harness

Peripheral Relay Harness

Measurement Window Ring

Face Cover

10

6-5 Plane View

6-6 Back Side of LCD

LCD Relay Board

Operation

Switch Board

LCD Backlight Harness

LCD Signal Harness

Operation Switch Harness

Main Control Board

LCD Relay Harness

11

7Troubleshooting

7-1 General description of boards

7-2 Error message ‘RETRY’appears

7-3 Error message ‘EEPROM fault’appears

7-4 Error message ‘Target (Focus) Motor fault’appears

7-5 Error message ‘Printer Overheated’appears

7-6 Error message ‘Printer cover opened’appears

7-7 Error message ‘Paper empty’appears

7-8 Error message ‘Sub system time out’appears

7-9 Error message ‘Sub system data err’appears

7-10 Nothing is displayed when turning on

7-11 No responses when pressing measurement start switch

7-12 No responses when pressing operation switches

7-13 Measurement result is not printed out/ printout is not normal

7-14 Ref measurement LED does not light up

7-15 Cannot see target

7-16 Infrared illumination LED does not light up

7-17 Light source for Kerato/ illumination does not light up

7-18 Cannot communicate with PC or phoropter

7-19 Cannot measure PD (cannot measure PD correctly)

7-20 No power outlet

7-21 Abnormal measurement value of model eye ASSY

12

7-1 General description of boards

This product is composed mainly with the peripheral boards such as the boards and the various

types of sensors etc. as shown below.

Main functions of each board are described below.

1

Control board

: Control of CMOS camera, control of LCD, control of Motor,

Control of LED, control of each sensor, control of external

communication, image processing, calculation of

measurement value

2

Operation switch board

: Detection and control of switch operation

3

Printer control board

: Printing, control of paper feeding

4

LCD relay board

: Power generation for LCD and operation switch board

5

CMOS camera board

: Taking images

6

EEPROM board

: Retention of optical setting information and system setting

information

7

Motor sensor board

: Detection of limit position of each motor

8

Ranging LED board

: Light source for ranging

9

Ranging sensor board

: Sensor for ranging

10

Ref LED board

: Light source for ref

11

Target LED board

: Light source for target

12

Kerato/ Illumination board

: Light source for Kerato and illumination

13

7-2 Error message ‘RETRY’appears

Main causes when error message ‘RETRY’appears:

・When the image is not caught accurately because of examinee’s condition (blinking or not

looking at target etc.)

・Alignment is not achieved correctly

・Failure of control board

・Failure of optical unit

Can a model eye be measured?

NO

YES

Check the condition of subject’s eye.

Evaluate the Freeze Image.

【Refer to 11】

‘RETRY’is displayed.

Realign correctly and take

measurements again.

【Refer to ‘6.2 Alignment’ of

operation manual】

Measurement cannot be taken in

case of disorder such as cataracts etc.

If the pupil is smaller than reticle mark,

measurements might not be taken.

Darken the surround and try to take

measurements again.

Abnormal case ②

Abnormal case ①

Normal

OK

14

7-3 Error message ‘EEPROM fault’appears

Main causes when error message ‘EEPROM fault’ appears:

・Disconnection of harnesses

・Failure of control board

・Failure of EEPROM board

YES

‘EEPROM fault’is displayed.

OK

Replace the EEPROM board.

Is ‘EEPROM fault’still displayed?

Is ‘EEPROM fault’still displayed?

Replace the control board.

Is conduction of EEPROM harness normal?

YES

YES

Perform ‘Reset of setting’

of the maintenance mode.

Replace the EEPROM harness.

NO

NO

NO

15

7-4 Error message ‘Target (Focus) Motor fault’appears.

Main causes when error message ‘Target (Focus) Motor fault’appears:

・Failure of control board

・Failure of optical unit

Is ‘Focus (Target) Motor

fault’still displayed?

‘Target (Focus) Motor fault’ is displayed.

OK

Replace the optical unit ASSY.

Replace the control board.

Replace the optical unit

ASSY and control board.

Replace the harness connected to CN703

with the one connected to CN704.

Are both ‘Target Motor fault’and

‘Focus Motor fault’displayed?

YES

YES

NO

NO

16

7-5 Error message ‘Printer Overheated’appears

Main causes when error message ‘Printer Overheated’appears:

・Printer head is hot

・Failure of printer unit

・Failure of printer control board

‘Printer Overheated’is displayed.

Replace the thermal printer.

Replace the printer control board.

OK

Is ‘Printer Overheated’still displayed?

NO

YES

Wait until the printer head is cooled down.

Is ‘Printer Overheated’still displayed?

YES

NO

17

7-6 Error message ‘Printer cover opened’appears

Main causes when error message ‘Printer cover opened’appears:

・Printer cover is opened.

・Failure of printer unit

・Failure of printer control board

Is the printer cover set correctly?

NO

YES

Set the cover correctly.

‘Printer cover opened’is displayed.

Is ‘Printer cover opened’still displayed?

Replace the printer control board.

OK

YES

NO

Replace the thermal printer.

18

7-7 Error message ‘Paper empty’appears

Main causes when error message ‘Paper empty’appears:

・No printer papers in printer

・Failure of printer unit

・Failure of printer control board

‘Paper empty’is displayed.

Is ‘Paper empty’still displayed?

Are printer papers set properly?

YES

NO

Is dust or dirt attached on the

sensor unit of printer?

NO

YES

Remove the dust or dirt.

Are there any papers in the printer?

Set the papers.

Set the printer papers properly.

Replace the printer control board.

NO

NO

YES

OK

YES

Replace the thermal printer.

19

7-8 Error message ‘Sub system time out’appears.

Main causes when error message ‘Sub system time out’appears:

・Disconnection of printer harness

・Failure of printer control board

・Failure of control board

OK

Replace the control board.

‘Sub system time out’is displayed.

Is conduction of the

printer harness normal?

Replace the printer harness.

Replace the printer control board.

NO

YES

NO

YES

Is ‘Sub system time out’still displayed?

Other manuals for AKR 550

1

Table of contents

Other Essilor Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

LW Scientific

LW Scientific ZIPspin instruction manual

Hanna Instruments

Hanna Instruments HI 180 instruction manual

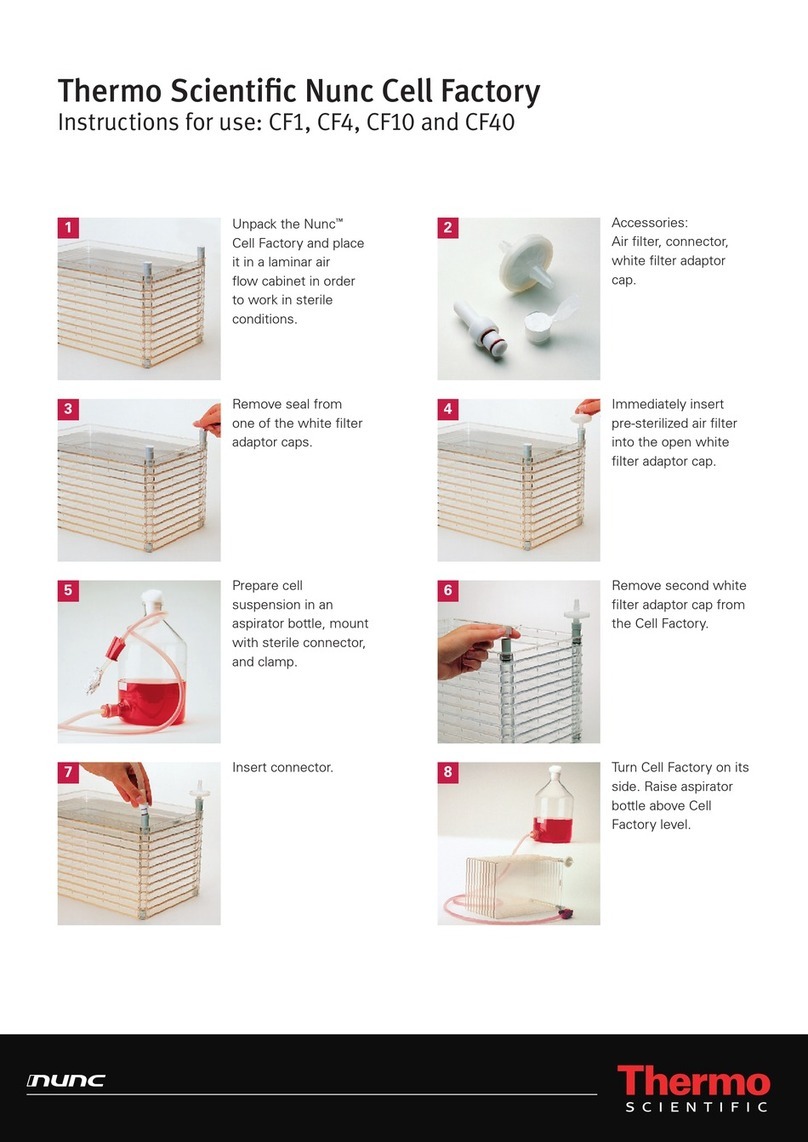

Thermo Scientific

Thermo Scientific Nunc Cell Factory CF1 Instructions for use

MIHM-VOGT

MIHM-VOGT KM Working instructions

Integra

Integra PIPETBOY pro operating instructions

Delsys

Delsys NeuroMap quick start guide