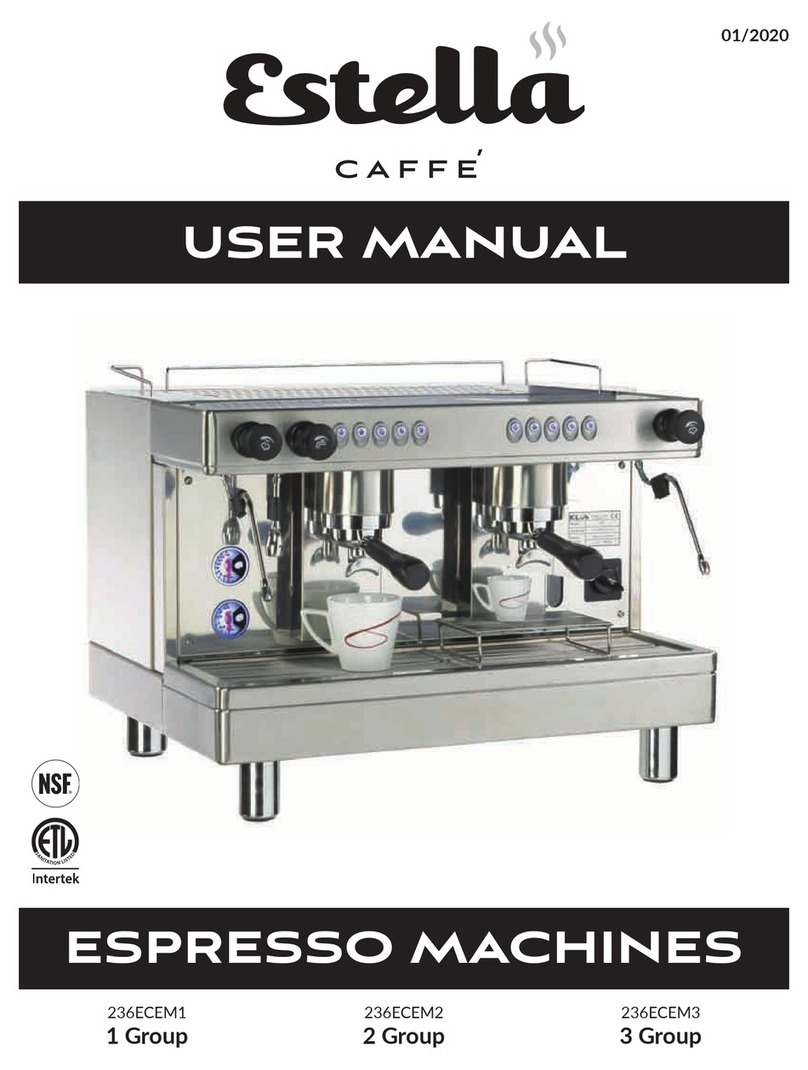

Estella 236ECEM1 User manual

USER MANUAL

www.EstellaEquipment.com

ESPRESSO MACHINES

01/2023

#236ECEM1 • 1 Group

#236ECEM2 • 2 Group

#236ECEM3 • 3 Group

www.EstellaEquipment.com2

3058215

General ........................................................2-3

Specifications ................................................ 3

Installation ...................................................... 4

Setup ........................................................... 4-5

Operation ....................................................... 5

Cleaning & Maintenance .........................6-7

Parts Diagram................................................ 8

Wiring Diagram (236ECEM1)...................... 9

Wiring Diagram (236ECEM2)....................10

Wiring Diagram (236ECEM3).....................11

1. This manual specifies important operation, maintenance, and safety information. Please read carefully.

2. After unpacking, please check to ensure your machine has not been damaged during shipping.

Please notify a qualified technician regarding all questions or concerns before installing. Please note that

the machine's packaging material, including plastic bag and Styrofoam, can be dangerous and should be

kept out of reach of children.

3. There is an identification label on the unit. Before operating, please check to ensure the power source

corresponds to the rating shown on the identification label. The manufacturer is not responsible for issues

resulting from improper installation and usage.

4. Make sure to use a power source that corresponds with the unit's power rating.

5. Please use No Fuse Breaker (NFB) that conforms to the safety regulation separately. Do NOT use a socket.

The NFB should have a minimum contact space of 3 mm and provide electrical spike and drain protection.

The ampere must be sucient for providing the required electric current to this machine.

6. Be sure to use a grounded power source to prevent electric shock and ensure the safety of this machine

and its operators.

7. The machine must be used in accordance with its original design. Additional use is inappropriate and

dangerous.

8. The steam wand, hot water wand, and brewing group can reach very hot temperatures. Use caution while

operating.

9. Please follow all cleaning and maintenance instructions specified in this manual in order to ensure peak

operating eciency.

10. If the machine breaks down or functions abnormally, please turn o machine,

disconnect the power source, and notify a qualified service technician to fix.

INDEX

GENERAL

Note: Save these instructions for future reference.

www.EstellaEquipment.com 3

11. Please use filtered and softened water. If using groundwater or tap water for brewing coee, please soften

it first. Unsoftened water will decompose dissolvable minerals and turn to limescale after boiling. The

limescale will reduce the machine’s thermal eciency and machine’s lifetime.

12. This machine fills water automatically. If the water fails to fill, the light touch panel will flash and power will

be cut o automatically in order to protect the system. To resume normal functions, turn o the machine for

2-3 seconds and turn on the machine again.

13. The heating element on this machine will not operate unless the water in the unit is at the minimum

required level. When starting the machine without any water in the tank, heating will be delayed for about

60 seconds.

14. Before operating the machine, please confirm that there is no water inside of the boiler. Temperature of

water must be kept above freezing point. The damage caused by frozen water inside the tube or boiler

won’t be covered by the manufacturer.

15. This unit is shipped from the factory with all water drained from the boiler. If you put the machine

away for storage, please ensure that all water is drained. If water were to freeze inside the unit, it could

cause damage.

16. Only place dry cups in the storage area on top of the machine. Wet cups on the machine may damage the unit.

Every machine has an identification label placed on the front of the machine. The label includes information of

model number, voltage, serial number, wattage, and its certificate. Please do not remove this label in order for

technician to check electrical information in the future.

SPECIFICATIONS

236ECEM1 236ECEM2 236ECEM3

Groups 1 2 3

Boiler Capacity 6 Qt. 13 Qt. 19 Qt.

Voltage 110-120V 220-240V 220-240V

Wattage 2000W 4700W 6500W

Weight 97 lb. 141 lb. 179 lb.

Recommended

Circuit Amperage 20A 30A 50A

Dimensions

(in) WxDxH 19½" x 21" x 22⁄" 27½" x 21" x 22⁄" 37" x 21" x 22⁄"

www.EstellaEquipment.com4

1. Check and confirm that water source is in normal working order.

2. Turn the power switch to On to initiate automatic system check. If boiler water level is not in the green zone,

wait until the automatic water replenishment process is complete before proceeding to the next step.

3. Heating will stop when boiler pressure reaches approximately 1.2 bars (factory default setting). Do not

operate machine until steam pressure gauge reading is in the green zone.

• There are two identical button suites on 2 group models

and three identical button suites on 3 group models.

• No default coee output setting is provided. Settings must

be made manually during setup.

• If you are using a multi-cup machine, settings made on the

farthest right hand side button suite will serve as default for

the others. So, start from the right hand side and work your

way to the left.

Starting the Automatic Machine

Output Volume and Frequency Setup

1. To program your machine, turn the output volume setup

switch ON (Fig. 1).

2. The output LEDs (Fig. 2) should be lit with the 5th button

flashing, indicating the machine is in setup mode.

• A cold water connection is required for this unit to function properly.

• Contact a qualified technician to ensure that your electrical and water setup are correct to the specifications

of the machine.

• This machine comes hardwired (no plug) and a qualified electrician is required for installation.

• A technician is also required to connect the existing waterline and check the filtration system before starting.

Operating with poor water conditions can void the warranty.

• Use an independent breaker for this machine which conforms to safety regulations.

• Total Dissolved Solids: Minimum 50 PPM, Maximum 125 PPM

• Total Hardness: Minimum 3 GPG, Maximum 5 GPG

• pH: 6.5~7.5

• Free Chlorine: Maximum 0.5 PPM

• Total Chlorine: Maximum 0.5 PPM

• Minimum amount of water pressure: 29-43 PSI

INSTALLATION

SETUP

Fig. 1

www.EstellaEquipment.com 5

OPERATION

3. To configure output button 1, press output button 1,

which should light LED 1 and switch o all other LEDs.

Press and hold the button until the desired output is

reached. Users can measure fluid ounces or time

dispensed for their settings.

4. At this point, LED 1 should be o and LED's 2, 3 and 4

should be lit.

5. Repeat steps 2 through 4 to set up output buttons 2, 3

and 4, respectively.

6. The left set(s) of output buttons will mirror the value

settings in the set of output buttons to its immediate right.

Repeat steps 2 through 5 if dierent output volumes are

desired for dierent groups.

7. The fifth button of each group head will remain continuous flow. This means once you press this button,

it will not turn o until pressed again.

8. After completing setup, turn the output volume setup switch OFF to return the machine to normal

operational mode.

LED

1

LED

2

LED

3

LED

4

LED

5

Fig. 2

1. Grind coee beans to a fine consistency.

2. Fill the portafilter with coee grounds and tamp.

3. Secure the portafilter to the espresso machine with a quarter turn.

4. Use any of the presets to brew or use the continuous flow button.

5. If using continuous flow, the brewing will continue until it is pressed again, stopping the brewing process.

1. Press the first and fifth buttons simultaneously to start automatic reverse flushing. Output buttons 2-4 in the

control panel will light and start automatic reverse flushing from the right output system to the left.

2. The default is 10 cleaning cycles.

3. If you want to stop before the completion of all 10 cleaning cycles, press button 3.

4. Flush one group after the other. You can press the third output button to skip the next output system. The

system will stop automatically after all reverse flushing is finished.

1. After cleaning the machine, remove all liquids and solid matter from the water tray.

2. Turn o the power.

3. Open steam knob to release steam flow. Do not place any liquid under the steam tube during this process

to avoid system contamination.

Brewing

Automatic Reverse Flushing

Stopping the Machine

• Reverse Flushing is recommended daily.

www.EstellaEquipment.com6

1. Wipe machine exterior with soft, slightly dampened cloth daily before starting operations.

2. If necessary, a mild, non-corrosive cleaning agent may be applied to the cloth. DO NOT spray cleaning

agents directly on the machine body to avoid corrosion and possible damage to circuits.

1. Rinse the portafilter with hot water after each brewing cycle to dissolve residual oils in the filter basket and

outlet nozzle and prevent oils from aecting the quality of coee.

2. Disassemble the portafilter and place all parts in cleaning solution (3tsp of detergent in 1 pint hot water)

for 24 hours to dissolve residual coee oils. DO NOT immerse plastic portion in cleaning solution to avoid

deterioration.

3. Rinse all components with clean water. Wipe with a soft, clean cloth only.

1. After each brewing cycle, remove the portafilter and press the manual water output button to remove all

residual coee grounds from the filter element.

2. Then attach the portafilter to the machine again.

CAUTION: DO NOT force the portafilter into the seat too tightly.

3. Press the manual water output button, shake the portafilter, and remove residual coee grounds from the

inside.

4. Place a reverse flushing silica plate in the portafilter, and apply about 2-3 grams of detergent. Attach the

portafilter onto the machine and check for tightness.

5. Next, start the auto backwashing process described in the operation section of this manual.

6. After the backwashing is complete, remove the portafilter and silica plate. Press the manual water output

button to allow residual cleaning solution in the brewing system to flow out. Turn water o after flushing for

about one minute or until the water is clear and clean.

a. During reverse flushing, remove and wash the copper plate and filter element with clean tap

water. Wipe with soft cloth.

b. If process is unable to suciently clean the plate and filter element, immerse the components

overnight in a mild cleaning solution of 3 tsp detergent in 1 pint hot water.

7. Rinse and reassemble components before restarting the espresso machine.

Machine Body

Brewing System

Portafilter and Filter Basket

CLEANING & MAINTENANCE

1. After making steamed milk, use a slightly moistened soft cloth to wipe steam tube.

2. After wiping, release a steam burst through the tube to remove any residual milk remaining in the nozzle.

3. If hardened milk residuals remain in the steam tube, disassemble and immerse tube in hot water for about

20 minutes to soften. Reassemble and repeat step (1).

Steam Tube

www.EstellaEquipment.com 7

1. Turn o the machine and remove the water tray. Wash thoroughly with cleaning solution and rinse with

water.

2. After removing the water tray, wipe and remove sediments in the discharge trough with a wet cloth or

napkin and wash with hot water to clear the discharge tube.

3. If water does not discharge properly, place a teaspoon of detergent into the discharge trough and flush

with hot water to dissolve residual oils in the tube.

4. After the discharge trough is cleaned and the tray is dry, reassemble the water tray.

To extend the serviceable life of your unit's boiler, or when you expect the machine to sit idle for a long period

of time:

1. Turn power to the machine OFF.

2. Open the steam output to discharge pressure in the boiler. Continue until the pressure gauge reading falls

to zero and steam discharge ends.

3. Once complete, empty and clean the water tray and discharge trough.

Leave the steam output setting open following steam discharge. Steam output should remain open until after

the machine is turned back on and hot water begins dripping from the steam tube.

Contact a service professional to delime the unit every 6 months.

The manufacturer recommends replacing the filter element on the resin exchange filter after processing 53

gallons of water (about 3,000 – 4,000 cups of coee). This schedule can be expected to vary based on the

quality of water used in your machine.

Water Tray and Discharge Trough

Boiler

Filter

www.EstellaEquipment.com8

2

3

3

4

5

5

14

6

13

7

12

8

11 10 10 9

1

PARTS DIAGRAM

Description

1Hot Water Knob

2Espresso Brewing Unit Control Panel

3Steam Knob

4Brewing Group

5Steam Tube

6Main Power Switch

7Drain Tray

Description

8Foot

9Sight Glass (Boiler Water Level Check Window)

10 Espresso Filter Holder

11 Cup Rack

12 Water Pressure Gauge

13 Steam Pressure Gauge

14 Hot Water Wand

www.EstellaEquipment.com 9

WIRING DIAGRAM

#236ECEM1

www.EstellaEquipment.com10

WIRING DIAGRAM

#236ECEM2

www.EstellaEquipment.com 11

WIRING DIAGRAM

#236ECEM3

Other manuals for 236ECEM1

3

This manual suits for next models

2

Table of contents

Other Estella Coffee Maker manuals