Estella 235ECB2D User manual

08/2020

Decanter Brewers

235ECB2D, 236ECB3D2U,

236ECB3D3L

Airpot Brewers

236ECBAP1 236ECSB1

COFFEE BREWERS

USER MANUAL

1

Warnings .........................................................2

Specificaons .....................................................2

Setup .............................................................3

Installaon .......................................................4

Cleaning ..........................................................5

Programming .....................................................6

Calibraon .......................................................7

Quick Recipes ....................................................8

Draining ..........................................................9

Parts Diagrams & Parts Lists.................................10-16

Troubleshoong .............................................17-18

Brewing Tips ....................................................19

Warranty ........................................................20

INDEX

NOTE: Save these instrucons for future reference.

Prop 65 Warning

WARNING: This product can expose you to chemicals including lead, which are known to

the State of California to cause cancer, birth defects, or other reproductive harm. For more

information, go to www.p65warnings.ca.gov

! !

2

WARNINGS

In case of overflow, turn the power switch

“OFF” immediately to stop the process.

Carefully unpack the coffee brewer and inspect

for damage and missing parts.

Read and understand all instructions before

using the appliance. CAUTION! HOT SURFACE!

•

•

•

•

•

•

•

•

•

•

•

•

!

!

!

SPECIFICATIONS

2 3 3 --- ---

Server Decanter Decanter Decanter Airpot Shule

120V 120V 120V 120V 120V

1700W 1800W 1800W 1500W 1800W

3

SETUP

[1] Display screen

[2] Seng & Service menu

[3] Recipe: A/B/C (Gray color for seng opon)

[4] Enable brew on/off switch

[5] On/Off switch for lower warmer/Half batch

[6] On/Off switch for front upper warmer/ Full batch

[7] On/Off switch for rear upper warmer

[8] Brew switch (Pressing and releasing)

[9] Hot water faucet

[10] Main Power Switch

[11] Power cord

[12] Solenoid/water inlet fing

[13] Ground connector terminal

Tea Brew Basket

(3.0 mm hole)

Coffee Brew Basket

(4.2-5.0 mm holes)

CONTROL PANEL

REAR COVER

INCLUDED ACCESSORIES

* Wire Rack must always insert into the

boom of brew basket.

Due to different water pressure in different

area, it is necessary to calibrate water volume

before brewing coffee or tea.

!

4

Check the brew basket is assembled correctly. The wire rack must wedge firmly at the

boom of the brew basket.

1. Place the brewer on a dry, firm and horizontal surface with plenty of room above to

allow easy and safe connecon to the water source.

2. The coffee maker must be connected to a cold water system. Plumbing one side of inlet

tube into the water source and the other side of tube connects to the solenoid. Then,

switch on the water source step by step.

3.

4. Place an empty server at the correct posion under the brew basket.

5. Plug the machine to the power source and turn on the main power switch on the rear

cover for 236ECSB1 model. (some models do not have main power switch on the rear

6.

7. Wait approximately 15 ~ 20 minutes for the water in the tank to heat and reach the

seng temperature, the screen display will show “Ready to Brew, watertemp.: ºF’’

when the tank has reached operang temperature. Some water will drip from the

sprinkler holder during this period because of thermal expansion and contracon

temperature. (When facing this issue, please place a small container under the faucet

working again.)

8. The coffee maker is now ready for use.

9. During above operaon, it is normal to hear some brewing, pumping sounds and see

some water vapor coming out of the machine.

CONDITION MINIMUM MAXIMUM

Total Dissolved Solids 50 PPM 125 PPM

Total Hardness 3 GPG 5 GPG

pH 6.5 pH 7.5 pH

Free Chlorine --- 0.5 PPM

Total Chlorine --- 1 PPM

INSTALLATION

A qualified water filter or softer water must be

used or the warranty will be voided.

!

WATER GUIDELINES

5

CLEANING

Regular cleaning ensures long life. For dirt or smudges on the brewer’s exterior, a damp

used. Be sure to unplug the appliance before cleaning.

DIRECTIONS FOR CLEANING GLASS DECANTERS

Use daily for best results.

1. Shake bole. Apply 3-4 squirts (approx. 1/4 oz. Per 1 gal. of liquid) Klearly Koffee into

the decanters (not included). Add very hot water (not boiling).

2. Use a carafe brush for best results on tough stains.

3. Empty soluon and rinse vessel thoroughly with clean, warm water. Air dry or wipe

clean before next use.

THE IMPORTANCE OF DELIMING

To prolong your coffee brewer’s life and maintain a consistent, quality product, regular

deliming is recommended. When hard water is heated, minerals are le behind which can

inhibit opmum performance. You should perform the following deliming process at least

every 6 months. If your water is extremely hard, monthly deliming is recommended.

DELIMING PROCEDURE

• Mix 10 oz. of fresh or condensed lemon juice with 32 oz. of water.

• Place brew basket in proper locaon.

• Place and empty container at the correct posion under the brew basket.

• Connect to the solenoid valve with an external bole water pump that substutes for

the water source. Then, pump the lemon juice mixture into the water tank by following

the brewing procedure.

• Let stand for 10 minutes and repeat 2-3 mes for best descaling results.

• Connect back to the water source and run the brewing cycle several mes with clean

water to rinse out the lemon soluon. Turn off the power and wait unl the water cools

down inside the boiler. Finally, use the drain pipe to release all remaining water in the

If the brewer suddenly stops working during a normal brewing cycle, deliming may be

necessary.

Klearly

Klearly Klearly Koffee is a simple, easy-to-use product that should be

used daily to remove or prevent oil residue and mineral build-up,

which turns rancid, causing bitter tasting coffee or tea.

pour-over coffee makers to loosen lime deposits. Made of

stainless steel. Sold Separately.

20" Deliming Spring 3591901033

6

PROGRAMMING

1. Turn on the power

2. Within the first 3 seconds of powering the unit on,

press and hold on A & C buons at the same me.

3. Select the Language

4. Select Temperature unit (C/F)

5. Select Volume unit (Liter/Ounce)

Recipe A, B, C and Hiding

Recipe

Grey Arrow = Back, Yes/+, No/-

Turn warmer plates On/Off Plates correspond to the relevant graphics.

Brew half or full batch Batches correspond to the relevant graphics.

1. Seng

2. Service Menu

3. Hiding Recipe

1. Seng buon includes seng

temperature, watervolume, pulse me,

water out manner and safety interval…

etc.

2. Press and hold on 3 seconds to access

menu mode. This is used to access into the

program mode and step forward through

the menu.

3. A hidden recipe for tesng purpose

1. Brewing cycle

2. Lights up

3. Blinking

1. Press once to begin brewing (indicator

lights up).

2. Press again to pause brewing (indicator

blinking).

3. Press again to resume brewing cycle.

Press and hold to turn off cycle.

1. Standby switch

2. On/Off

3. Interrupt

1. Power/Standby switch.

2. Press to turn on and off.

3. Interrupt the brew cycle

Press power switch on the back of machine for #236ECSB1

enable brew buon. Press Enable brew buon for all other units.

Before Status

1. Aer Status 1.

2. Heang... Water temp. XXX

BUTTON FUNCTIONS

7

CALIBRATION

program is the second to last opon in the funcon sengs.

ACTUAL CALIBRATION VOLUME

Follow the screen indicaon, measuring the water volume output for 4 minutes. Then, input

the actual measuring value. Aer measuring, convert the volume to oz per minute and

remember this parameter to facilitate future adjustment.

INPUT CALIBRATION DATA

standard value is approximately 1.1L per minute.

A container, measuring cup and electric scale

are required to complete the calibration

procedure.

Execute the calibration procedure once a week

to ensure brew volume accuracy.

!

!

8

DECANTER & AIRPOT BREWERS

SHUTTLE BREWERS

There are three quick recipes of [A] [B] [C] which are built-into the factory default sengs

seng up recipies without selecng [A] , [B] or [C], you can consider recipe [D]. Users may

set different recipes such as water temperature, volume, immerse volume, immerse me

and Pulse Brew cycle.

Users may change the parameters for the recipe [A], [B], [C] or [D] as needed. Select [A], [B]

or [C] and press and hold on for 3 seconds. The system will enter the Seng Menu.

Follow the indicaons on the screen to set various brewing parameters as needed.

The new seng parameters will replace the factory default seng aer compleng above

procedure.

The hidden recipe can also be programmed by pressing and and holding for 3 seconds,

but without [A], [B] or [C] selected.

QUICK RECIPIES

RECIPE DESCRIPTION INPUTS

[A] 190 °F Non-Stop dripping

with 63 oz. brew volume.

[B] 198 °F Non-Stop dripping

with 63 oz. brew volume.

[C] 203 °F Non-Stop dripping

with 63 oz. brew volume.

[D] 185 °F Non-Stop dripping

with 63 oz. brew volume

RECIPE DESCRIPTION INPUTS

[A] 190 °F Non-Stop dripping

with 202 oz. brew volume.

[B] 198 °F Non-Stop dripping

with 125 oz. brew volume.

[C] 203 °F Non-Stop dripping

with 101 oz. brew volume.

[D] 185 °F Non-Stop dripping

with 125 oz. brew volume

(select nothing)

(select nothing)

9

DRAINING

When the brewer needs to moved, repaired, de-scaled, or emped for extended storage,

the remaining water in the boiler tank can be released following the steps below:

1. Unplug the power cord from the electrical socket and let the brewer cool down for at

least 40 minutes to avoid any burn injuries.

2.

front cover. Remove the front cover.

3. A white water pipe tube and hose shutoff clamp can be seen inside of brewer. (Figure 1)

4. Fasten the white shut off clamp at the end of the drain hose. (Figure 2)

5. Look for a connector in the front of water tube clips with a metal clamp. Press down on

the metal clamp and move slightly to the end of tube. (Figure 3)

6. Place the end of the drain hose in a container that has a capacity of 3 gallons or more.

7. Release the white clamp to drain water out from the tank.

8. When the water tank is empty, move the drain hose back to the original posion. Then,

press down on the metal clamp and move it back to the original posion.

9. Check that the white shut off clamp has been loosened.

10. Replace the front panel and ghten the screws.

11.

Figure 1 Figure 2 Figure 3

10

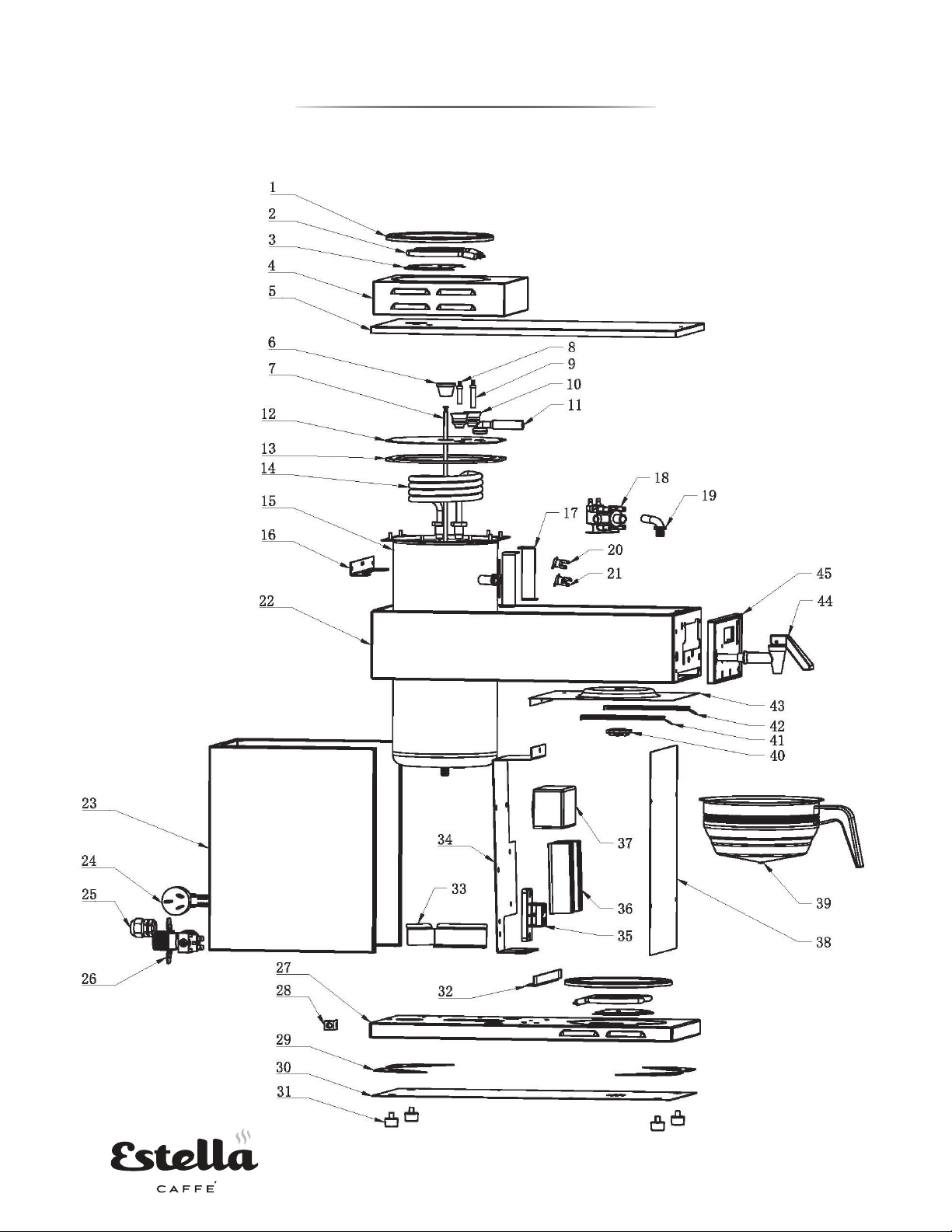

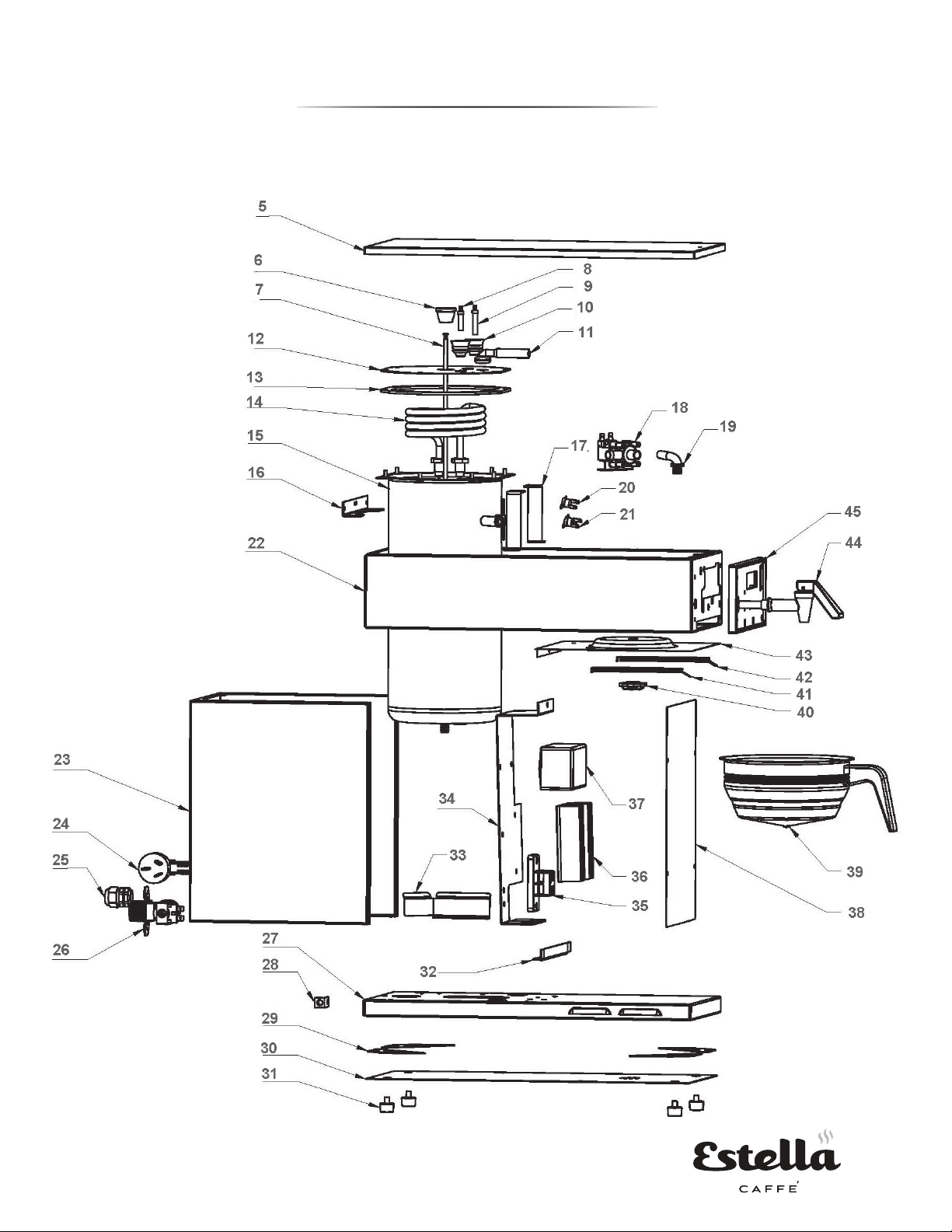

PARTS DIAGRAM

Decanter Brewer #236ECB2D

11

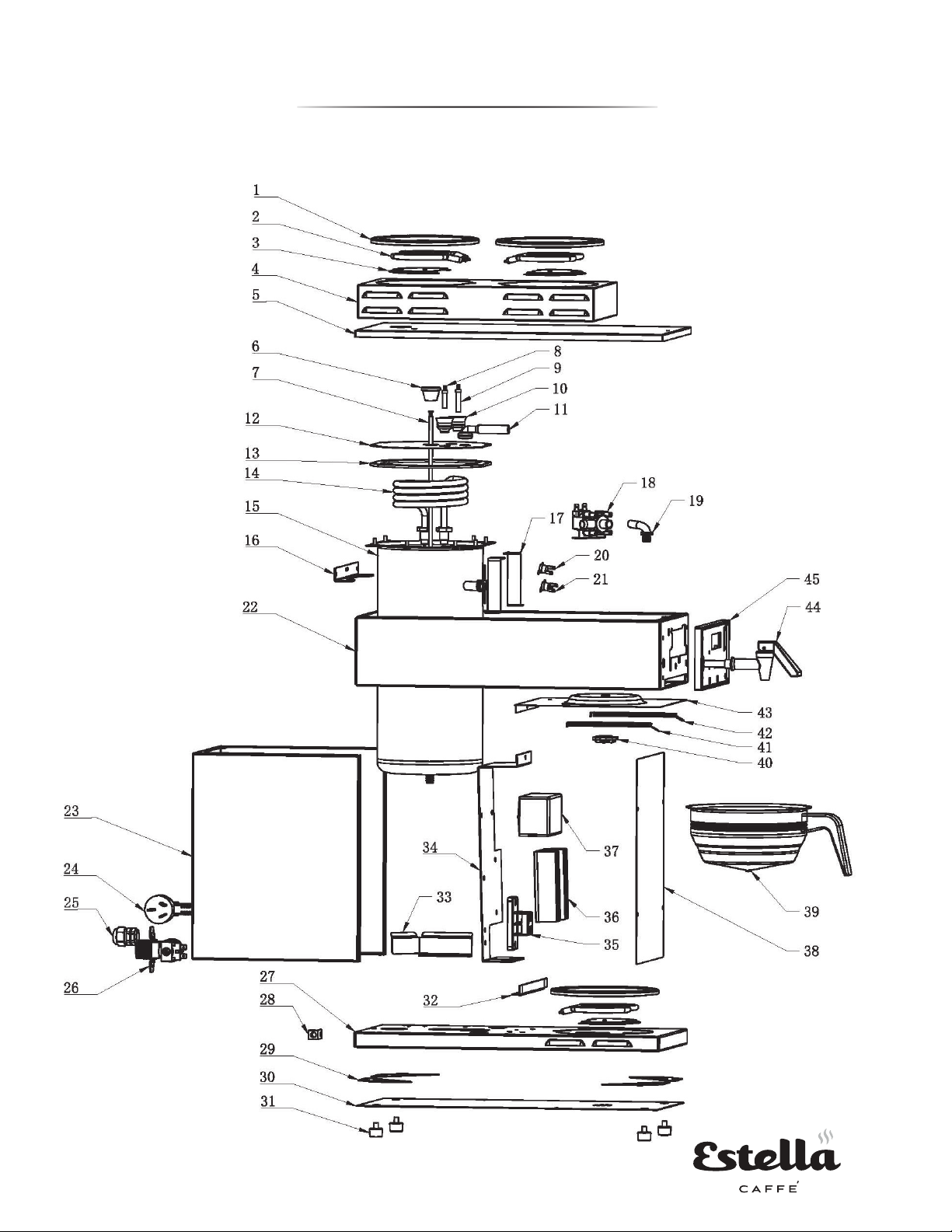

PARTS DIAGRAM

Decanter Brewer #236ECB3D2U

12

PARTS DIAGRAM

Decanter Brewer #236ECB3D3L

13

PARTS DIAGRAM

Airpot Brewer #236ECBAP1

14

# VENDOR DESCRIPTION

1 AI001 Warming Plate

2 AI002 Heang Element of

Warming Plate

3 AI003 Warming Plate Holder

4 AI004 Upper Warming Plate Frame

5 AI005 Upper Cover

6 AI006 NTC Silicone Sealing

7 AI007 NTC Temperature Probe

8 AI008 Water Level Detector

(Short)

9 AI009 Water Level Detector (Long)

10 AI010 Water Level Detector

Seal

11 AI011 Water Reservoir Exhaust

Tube

12 AI012 Water Reservoir Cover

13 AI013 Water Reservoir Sealing

Ring

14 AI014 Heang Element

15 AI015 Water Reservoir

16 AI016 Water Reservior Rear

Frame

17 AI017 Water Reservior Front

Frame

18 AI018 Outlet Solenoid Valve

19 AI019 L Shape Water Out Joint

Tube

20 AI020 Auto Thermostat 110°C

21 AI021 Manaul Thermostat 130°C

22 AI022 Upper Frame

23 AI023 Body Frame

# VENDOR DESCRIPTION

24 AI024 Power Cord

25 AI025 Wire Clip

26 AI026 Inlet Solenoid Valve

27 AI027 Base Frame

28 AI028 Ground Germinal

29 AI029 Reinforced Tube Of Base

Frame

30 AI030 Boom Cover

31 AI031 Foot

32 AI032 Reinforced Board Of Body

Frame

33 AI033 The Platen Of Power Cord

34 AI034 Inner Bracket

35 AI035 Terminal Block

36 AI036 Cooling Fin

37 AI037 EMI Filter

38 AI038 Front Cover

39 AI039 Brew Basket

40 AI040 Sprinkler

41 AI041 Le Track

42 AI042 Right Track

43 AI043 Sprinkler Bracket

44 AI044 Spigot

45 AI045 Control Panel

46 AI046 Sprinkler Cover

47 AI047 Sprinkler Sealing Ring

48 AI048 Reinforced Bracket of Base

Frame

49 AI049 Side Warming Plate Frame

PARTS LIST

Brewers #235ECB2D, #236ECB3D2U,

#236ECB3D3L, #236ECBAP1

15

PARTS DIAGRAM

Shuttle Brewer #236ECSB1

16

# VENDOR DESCRIPTION

5 AIS005 Upper Cover

6 AIS006 NTC Silicone Sealing

7 AIS007 NTC Temperature Probe

10 AIS010 Water Level Detector

Seal

11 AIS011 Water Reservoir Exhaust

Tube

12 AIS012 Water Reservoir Cover

13 AIS013 Water Reservoir Sealing

Ring

14 AIS014 Heang Element

15 AIS015 Water Reservoir

16 AIS016 Water Reservior Rear

Frame

17 AIS017 Water Reservior Front

Frame

18 AIS018 Outlet Solenoid Valve

(Main)

19 AIS019 L Shape Water Out Joint

Tube

20 AIS020 Auto Thermostat 110°C

21 AIS021 Manaul Thermostat 130°C

22 AIS022 Upper Frame

23 AIS023 Body Frame

24 AIS024 Power Cord

25 AIS025 Wire Clip

26 AIS026 Inlet Solenoid Valve

27 AIS027 Base Frame

28 AIS028 Ground Germinal

31 AIS031 Foot

# VENDOR DESCRIPTION

34 AIS034 Inner Bracket

35 AIS035 Terminal Block

36 AIS036 Cooling Fin

37 AIS037 EMI Filter

38 AIS038 Front Cover

39 AIS039 Brew Basket

40 AIS040 Sprinkler

41 AIS041 Le Track

42 AIS042 Right Track

43 AIS043 Sprinkler Bracket

44 AIS044 Spigot

45 AIS045 Control Panel

46 AIS046 Sprinkler Cover

47 AIS047 Sprinkler Sealing Ring

50 AIS050 Power Switch

51 AIS051 Water Level Detector

52 AIS052 Reinforced Bracket A Of

Body Frame

53 AIS053 Supporter cover of Upper

Frame

54 AIS054 Reinforced Bracket B Of

Body Frame

55 AIS055 Sealing Ring

56 AIS056 Outlet Solenoid Valve (Sec-

ondary)

57 AIS057 Posion Fixed Pillar

58 AIS058 Foot Supporter

PARTS LIST

Shuttle Brewer #236ECSB1

17

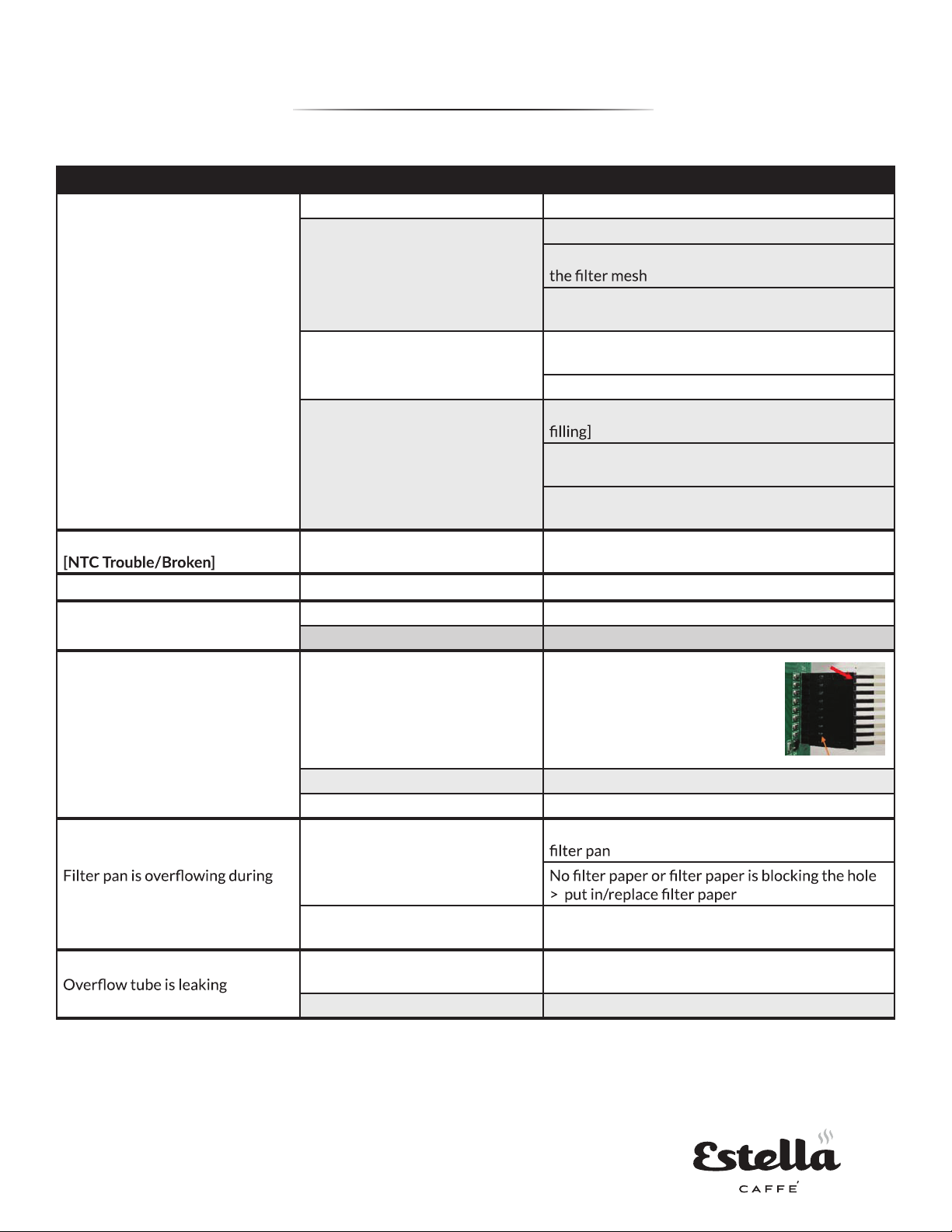

TROUBLESHOOTING

PROBLEM CAUSE ACTION / REMEDY

Filling me is too long

No water out Check the water source

Inlet solenoid block up

Turn off the water source

Disassemble the inlet solenoid and clean

Reinstall back to machines and turn on the

water source

The pressure of water source is

too low.

Water pressure is lower than working

pressure 1.0kg/cm2

Install another pressurized motor

Inlet solenoid failure or circuit

board failure

The screen displays [Please wait, tank

Inlet solenoid with working pressure >

solenoid abnormal > replace solenoid

Inlet solenoid without working pressure >

circuit board abnormal > replace circuit board

Screen displays Temperature sensor failure Check/replace

Temperature is too high Temperature sensor failure Check/replace

Power is ON, Screen is not

displaying

No power input Check the power source

Circuit board malfuncon Replace circut board

Screen displays normal,

but touch inputs are not working

Control board strip not properly

connected

Check all touch buons.

Check if the control board strip

is inserted correct or not.

Check if the control board strip

pin and the drop-out line is

connected incorrectly.

Control board malfuncon Replace control board

Circuit board malfuncon Replace circuit board

brew cycles

Filter pan is blocked up

Lack of springs > insert the springs to the

The interval of pulse me is not

enough Set the proper interval of pulse me

Water pressure is higher than

working pressure Add addional pressure reduce valve

Inlet solenoid failure Check/replace

18

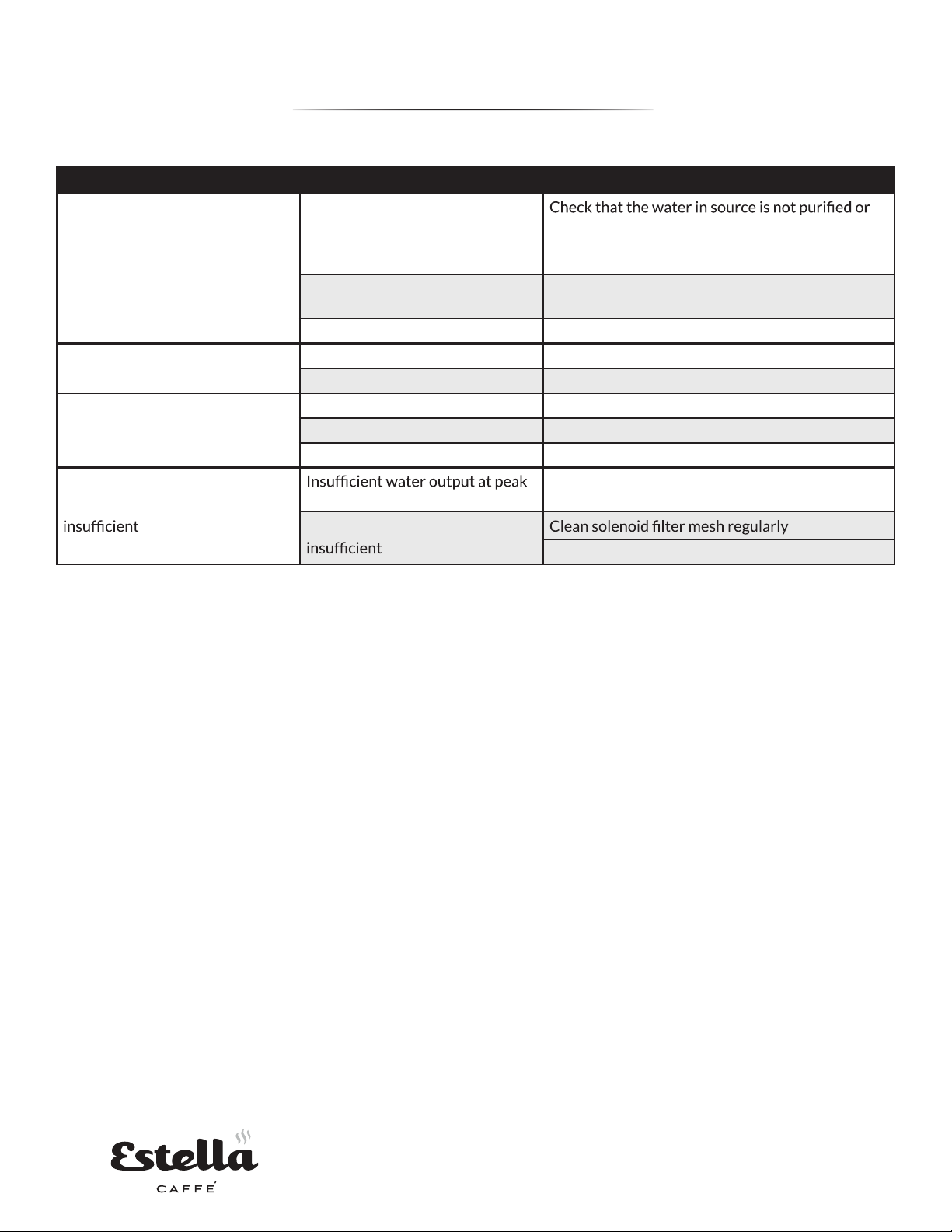

TROUBLESHOOTING

PROBLEM CAUSE ACTION / REMEDY

Power is On, nonstop

dripping from main and

sub spray head

Water quality abnormal treated with reverse osmosis. The units will not be

able to detect water level properly without typical

mineral balance. Use a different water source.

The water level detector pin is

inserted incorrectly Check and re-insert to the correct posion

Circuit board malfuncon Replace circuit board

Sustained warming up Temperature probe failure Replace temperature probe

Circuit board malfuncon Replace circuit board

Water does not heat to

proper temperature

Limit thermostat abnormal Check/replace thermostat

Heang element failure Replace heang element

Circuit board malfuncon Replace circuit board

Water out volume is usage

Connect to a lone water source or add a constant

water pressure regulator

Normal water output volume is

Calibrate the water volume

19

BREWING TIPS

Fresh and good-tasng water is essenal since it makes up more than 98% of a cup of

coffee or tea. The brewing, pulse, extracon or pouring water me is primarily determined

by the ground size.

If the ground size is coarser, it causes under extracon and tasteless coffee. If the ground

size is too fine, it causes over-extracon and a bier taste. To get the best flavors from a

coffee, we suggest a medium grind (5-grain size).

**Not exact recipes, for reference only

**Not exact recipes, for reference only

ITEM BEANS TO

WATER TEMP. SOAK TIME PULSE BREW

Breakfast Coffee 1 : 16 92°C / 197°F 10-20 sec. ---

Specialty Coffee 1 : 15 90°C / 194°F 10-20 sec. 10 sec. / 5 sec.

Ice Coffeee 1 : 13 94°C / 201°F 20-30 sec. 10 sec. / 5 sec.

< 2.5 Liter Brew 1: 18 92°C / 197°F 20-30 sec. 1 sec. / 5 sec.

ITEM BREW

RATIO TEMP. INITIAL DRIP SOAK

TIME PULSE BREW

Coffee 1 : 17 92°C / 197°F 60 sec. 20 sec. ---

Tea, < 5 Liter 1 : 40 94°C / 201°F 60 sec. 3-5 mins. 18 sec. / 20 sec.

Tea, > 4 Liter 1 : 40 94°C / 201°F 30 sec. 3 mins. 18 sec. / 20 sec.

Brish Tea 1 : 40 96°C / 205°F 60 sec. 5 mins. 10 sec. / 10 sec.

Oolong Tea 1 : 40 96°C / 205°F 60 sec. 5 mins. 10 sec. / 10 sec.

Green Tea 1 : 40 88°C / 190°F 60 sec. 5 mins. 10 sec. / 10 sec.

Jasmine Tea 1 : 40 88°C / 190°F 60 sec. 5 mins. 10 sec. / 10 sec.

DECANTER & AIRPOT BREWERS

SHUTTLE BREWERS

This manual suits for next models

4

Table of contents

Other Estella Coffee Maker manuals