ESTERS ELEKTRONIK GDR 1530-0000-0000 User manual

P

=

Speed Pressure Flow Rate Temperature

Rev.-Nr.: IM 326-00 E V0.4-2023-08-11, FW G12.02

Instruction Manual IM 326-00 E

Page 1

Phone: +49 6021- 45 807 - 0

Fax: +49 6021- 45 807 - 20

Esters Elektronik GmbH

Hafenrandstr. 14 · D-63741 Aschaffenburg

Internet: http://www.esters.de

INSTRUCTION MANUAL IM 326-00 E

Device: Flow Computer GDR 1530-0000-0000

Content: Instruction manual

Rev. No.: IM 326-00 E V0.4-2023-08-11, FW G12.02

P

=

Speed Pressure Flow Rate Temperature

Rev.-Nr.: IM 326-00 E V0.4-2023-08-11, FW G12.02

Instruction Manual IM 326-00 E

Page 2

Phone: +49 6021- 45 807 - 0

Fax: +49 6021- 45 807 - 20

Esters Elektronik GmbH

Hafenrandstr. 14 · D-63741 Aschaffenburg

Internet: http://www.esters.de

User information

- Read the operating instructions completely before installing or operating the device for the first time.

- Pay attention to all important notes and warnings in this document.

- Please refer to the nameplate for the serial number of the device, which you will need to order spare parts,

and the correct voltage supply. You will find it on the outside of the device.

- Installation, commissioning, operation and maintenance may only be carried out by a qualified electrician.

The guidelines applicable at the installation site must be observed.

- For reasons of personal safety, maintenance work may only be carried out when the device is de-energized.

- To ensure operational safety, only original spare parts from the manufacturer may be installed.

- If the device is not used for its intended purpose, any claims under warranty and product liability become

invalid. In particular, improper use is deemed to have occurred if the information in the operating

instructions was not observed during installation, commissioning, operation and maintenance.

- The device must be integrated into the lightning protection concept of the system operator.

Please note that the device must always be used in accordance with the operating

instructions. Any deviations will invalidate the operating safety.

Technical developments may result in deviations from this document. If you require further information or if

special problems arise which are not dealt with in detail in these operating instructions, you can obtain

information at the following address:

Imprint

Esters Elektronik GmbH

Hafenrandstr. 14

D-63741 Aschaffenburg

Tel.: +49 (0)6021 –45 807 - 0

Fax: +49 (0)6021 –45 807 - 20

Internet: www.esters.de, www.fluidistor.de

Copyright

This manual is copyrighted.

Duplication and distribution are not permitted without written permission.

© Esters Elektronik GmbH, Aschaffenburg

P

=

Speed Pressure Flow Rate Temperature

Rev.-Nr.: IM 326-00 E V0.4-2023-08-11, FW G12.02

Instruction Manual IM 326-00 E

Page 3

Phone: +49 6021- 45 807 - 0

Fax: +49 6021- 45 807 - 20

Esters Elektronik GmbH

Hafenrandstr. 14 · D-63741 Aschaffenburg

Internet: http://www.esters.de

Table of Contents

User information ____________________________________________________________________________2

Imprint ____________________________________________________________________________________2

Copyright __________________________________________________________________________________2

Table of Contents____________________________________________________________________________3

Index of Figure ______________________________________________________________________________4

Index of Tables______________________________________________________________________________4

List of abbreviations__________________________________________________________________________4

1Common ____________________________________________________________________________5

2Technical data ________________________________________________________________________5

2.1 Input _______________________________________________________________________5

2.2 Output ______________________________________________________________________6

2.3 Relays_______________________________________________________________________6

2.4 Electrical values _______________________________________________________________6

2.5 Environmental influences _______________________________________________________6

2.6 Display, housing, weight ________________________________________________________7

2.7 Housing _____________________________________________________________________7

3Device codes _________________________________________________________________________8

4Operating overview ___________________________________________________________________9

4.1 Touch keypad_________________________________________________________________9

4.2 Display: Device start ___________________________________________________________9

4.3 Display: LIVE screen___________________________________________________________10

4.4 Display: ERROR Screens (Error messages)__________________________________________11

4.5 Display: PARAMETER screen (settings menu) and navigation __________________________11

5.2 Menu structure: Language _____________________________________________________16

5.3 Menu structure: Device info (#1100) _____________________________________________17

5.4 Menu structure: Inputs (#1500) _________________________________________________18

5.5 Menu structure: Outputs (#2400)________________________________________________23

5.6 Menu structure: Limits (#2900)__________________________________________________26

5.7 Menu structure: System (#1200) ________________________________________________27

5.8 Menu structure: Wizards (#1900)________________________________________________29

5.9 Menu structure: Access rights (#1950) ____________________________________________30

5.10 Menu structure: Counter values (#1300) __________________________________________30

6Error codes list ______________________________________________________________________31

7Appendix ___________________________________________________________________________32

7.1 Overview of nameplates GD 300 (Ex) and GD 100 ___________________________________32

7.2 Factory calibration certificate for gas flow meter____________________________________33

P

=

Speed Pressure Flow Rate Temperature

Rev.-Nr.: IM 326-00 E V0.4-2023-08-11, FW G12.02

Instruction Manual IM 326-00 E

Page 4

Phone: +49 6021- 45 807 - 0

Fax: +49 6021- 45 807 - 20

Esters Elektronik GmbH

Hafenrandstr. 14 · D-63741 Aschaffenburg

Internet: http://www.esters.de

Index of Figure

Figure 1: Touch keypad________________________________________________________________________ 9

Figure 2: Display device start ___________________________________________________________________ 9

Figure 3: Meter reading ______________________________________________________________________ 10

Figure 4: Measurement value flow rate__________________________________________________________ 10

Figure 5: Measurement value temperature_______________________________________________________ 10

Figure 6: Measurement value pressure __________________________________________________________ 10

Figure 7: Internal barometric pressure __________________________________________________________ 10

Figure 8: mA output _________________________________________________________________________ 10

Figure 9: Limit value _________________________________________________________________________ 10

Figure 10: Relay ____________________________________________________________________________ 10

Figure 11: System status______________________________________________________________________ 10

Figure 12: Error screen _______________________________________________________________________ 11

Figure 13: Main menu (PARAMETER screen) _____________________________________________________ 11

Figure 14: Displaying the hierarchy level when opening the PARAMETER screen _________________________ 11

Figure 15: Enumeration parameter (EP) _________________________________________________________ 13

Figure 16: Numerical parameter (NP) ___________________________________________________________ 13

Figure 17: Language setting for new devices______________________________________________________ 16

Figure 18: Overview nameplates GD 300 (Ex) und GD 100 ___________________________________________ 32

Figure 19: Factory calibration certificate for gas flow meter__________________________________________ 33

Index of Tables

Table 1: Device codes _________________________________________________________________________ 8

Table 2: Error codes _________________________________________________________________________ 31

List of abbreviations

EP

Enumeration parameters

NP

Numerical parameters

FS

Factory settings

P

=

Speed Pressure Flow Rate Temperature

Rev.-Nr.: IM 326-00 E V0.4-2023-08-11, FW G12.02

Instruction Manual IM 326-00 E

Page 5

Phone: +49 6021- 45 807 - 0

Fax: +49 6021- 45 807 - 20

Esters Elektronik GmbH

Hafenrandstr. 14 · D-63741 Aschaffenburg

Internet: http://www.esters.de

1Common

The actual gas quantity of the gas flow meter GD 300 (Ex) / GD 500 (Ex) is calculated by the 1-channel flow

computer GDR 1530.

On an hourly or minutely basis, the current gas quantity can be displayed in cubic meters or liters. The totalizer of

the total quantity can be displayed either in cubic meters or in liters. The counter can have 9 digits up to 999 million

cubic meters. The resolution is 0.1 liters.

2 different inputs are available for the input signal.

Gas flow meter GD 300 (Ex)/ GD 500 (Ex):

1. Direct connection of the platinum wire sensor

(NON-ATEX)

2. Connection of the HB 300 Ex (ATEX area)

The current output 0(4) - 20 mA indicates the current flow in the form of operating or standard cubic meters.

Two limit values are available for limit value monitoring. Flow rate, device status or error messages can be

passed on to superior PLC system via 2 semiconductor relays.

In addition to a pt100 input, the devices also have mA inputs for pressure and temperature sensors as well as an

integrated barometric sensor for recording the atmospheric pressure.

The standardization can be performed according to the standards DIN 1343, DIN 6358, DIN ISO 2533 or

DIN 102 / ISO 1-1975.

The Modbus RTU bus systems are available as an option for data transmission.

2Technical data

2.1 Input

FLOW RATE

- Input for platinum wire sensor (GD 300/GD 500) (only NON-ATEX) or

FLOW RATE

IMPULSE INPUT

- Impulse input for HB 300 (Ex) (GD 300 (Ex)/GD 500 (Ex))

Definition of minimum threshold to distinguish between gas flow and

standstill possible (creeping quantity suppression).

The following inputs are integrated for connecting external sensors for pressure and temperatures:

TEMPERATURE

- 4 - 20 mA, 2 wire = -100 - 999 °C (17 bit) or

- Pt100, 3 wire (17 bit)

PRESSURE

4 - 20 mA, 2 wire = 0 - 1000 bar (17 bit)

P

=

Speed Pressure Flow Rate Temperature

Rev.-Nr.: IM 326-00 E V0.4-2023-08-11, FW G12.02

Instruction Manual IM 326-00 E

Page 6

Phone: +49 6021- 45 807 - 0

Fax: +49 6021- 45 807 - 20

Esters Elektronik GmbH

Hafenrandstr. 14 · D-63741 Aschaffenburg

Internet: http://www.esters.de

2.2 Output

2.3 Relays

2.4 Electrical values

2.5 Environmental influences

OUTPUT

0 (4) - 20 mA = 0 - (x) Bm³/h, l/h, Bm³/min, l/min,

Nm³/h, NL/h, Nm³/min, NL/min) flow rate

(freely programmable), input resistance 500 Ohm

K1:

Relay (NO) freely programmable

- pulse output (0,1, 1 oder 10 oder 100 m³ per impulse,

freely programmable), counter output quantity or

- limit value or

- device status

K2:

Relay (NO) freely programmable

- pulse output (0,1, 1 oder 10 oder 100 m³ per impulse,

freely programmable), counter output quantity or

- limit value or

- device status

ACCURACY

± 0,05 % EW ± 1 Digit with 23°C

POWER SUPPLY

- 24 V, DC ± 3 V , max. 200 mA (Standard)

- 100 - 240 V, AC, 0,33 - 0,14 A, max. 47 - 63 Hz

(optional, Retrofit kit)

AMBIENT TEMPERATURE

-10 to +55°C

STORAGE TEMPERATURE

-20 to +85°C

TEST VOLTAGE

3 kV

HUMIDITY CLASS

E-DIN 40040

ELECTROMAGNETIC COMPATIBILITY

acc. to EN 50082-2

P

=

Speed Pressure Flow Rate Temperature

Rev.-Nr.: IM 326-00 E V0.4-2023-08-11, FW G12.02

Instruction Manual IM 326-00 E

Page 7

Phone: +49 6021- 45 807 - 0

Fax: +49 6021- 45 807 - 20

Esters Elektronik GmbH

Hafenrandstr. 14 · D-63741 Aschaffenburg

Internet: http://www.esters.de

2.6 Display, housing, weight

2.7 Housing

LCD DISPLAY

4 rows à 20 characters

Size: 66 x 40mm, font size 4.8 mm

Display colour: black on white

DATE

Acc. to ISO8601/EN28601

COUNTER PULSES

Max. 999.999.999.999.999.999 Pulse (1*10^18 - 1 pulse),

resolution 1 pulse

(In the event of a counter overflow, the counter starts at zero.)

PULSE OUTPUT

0,001 - 1.000.000 m3/pulse, resolution 1l/pulse

Max. 10 pulses/s for Bm3or Nm3

FLOW „OPERATIONAL“

Max. 100 Bm3/s, 360.000 Bm3/h

FLOW „STANDARDIZED“

Max. 1.000 Nm3/s, 3.600.000 Nm3/h

COUNTER

OPERATING QUANTITY

STANDARDIZED QUANTITY

Max. 99.999.999.999.999,9999999 m3(<1*1015)

resolution 0,1cm3

Display: 99.999.999.999.999,9 m3or Nm3

(In the event of a counter overflow, the counter starts at zero.)

STANDARD HOUSING

WALL MOUNTING

Dimensions: 151 mm (W) x 125 mm (H) x 60 mm (D)

Material: polycarbonate UL 94 V0

Protection class: IP 65

Weight: approx. 600 g

HOUSING OPTIONS

- mounting parts for DIN rail mounting

- fixing parts for direct mounting on gas flowmeter GD 300

(only NON ATEX applications)

P

=

Speed Pressure Flow Rate Temperature

Rev.-Nr.: IM 326-00 E V0.4-2023-08-11, FW G12.02

Instruction Manual IM 326-00 E

Page 8

Phone: +49 6021- 45 807 - 0

Fax: +49 6021- 45 807 - 20

Esters Elektronik GmbH

Hafenrandstr. 14 · D-63741 Aschaffenburg

Internet: http://www.esters.de

3Device codes

GDR 1530-0000-0000

Inputs

1: Flow rate: input for platinum wire sensor (GD 300/GD 500) (only NON-ATEX) or

•

1: Flow rate: impulse input for HB 300-R000000 (GD 300/GD 500), HB 300 Ex-R000000

(GD 300 Ex/GD 500 Ex)

•

2: Temperature1): 4 - 20 mA, 2 wire = -100 - 999 °C (17 bit) or

•

2: Temperature (Pt100) 1): 3 wire (17 bit)

•

3: Pressure1): 4 - 20 mA, 2-Leiter = 0 - 1000 bar (17 bit)

•

Output

1: 4 - 20 mA = 0 - (x) Bm³/h, l/h, Bm³/min, l/min, Nm³/h, NL/h, Nm³/min, NL/min)

flow rate (freely programmable), input resistance 500 Ohm

•

Relay

K1 (NO) freely programmable

•

K2 (NO) freely programmable

•

Further Functions

Limit value monitoring (2 limit values)

•

Integrated barometric sensor

•

Optional Functions

Modbus RTU

•

1)virtual input for freely programmable fixed values

Table 1: Device codes

P

=

Speed Pressure Flow Rate Temperature

Rev.-Nr.: IM 326-00 E V0.4-2023-08-11, FW G12.02

Instruction Manual IM 326-00 E

Page 9

Phone: +49 6021- 45 807 - 0

Fax: +49 6021- 45 807 - 20

Esters Elektronik GmbH

Hafenrandstr. 14 · D-63741 Aschaffenburg

Internet: http://www.esters.de

4Operating overview

4.1 Touch keypad

The GDR 1530-0000-0000 is programmed directly on the device using the capacitive touch keyboard.

The menu is guided using the buttons:

4.2 Display: Device start

The start-up screen appears when the device is started. After approx. 10 seconds, the device automatically

switches to the first LIVE screen.

The GDR 1530-0000-0000 differentiates between two screen types, the so-called LIVE screen including error

messages (ERROR screens) and the PARAMETER screen.

In the LIVE screen, you can display the device information (power-on diagram) by briefly pressing the Enter key

(Ok).

left

right

upwards

downwards

cancel, escape

confirm, enter

Figure 1: Touch keypad

Figure 2: Display device start

P

=

Speed Pressure Flow Rate Temperature

Rev.-Nr.: IM 326-00 E V0.4-2023-08-11, FW G12.02

Instruction Manual IM 326-00 E

Page 10

Phone: +49 6021- 45 807 - 0

Fax: +49 6021- 45 807 - 20

Esters Elektronik GmbH

Hafenrandstr. 14 · D-63741 Aschaffenburg

Internet: http://www.esters.de

4.3 Display: LIVE screen

Depending on the device parameterization, corresponding LIVE screens are displayed in relation to the current

measured values and settings relating to the connected sensors. Screens that are not relevant to the operating

mode of the device are hidden accordingly. The display interval can be set by the user.

A setting of 0 prevents the automatic switchover.

Figure 4: Measurement value flow rate

Figure 3: Meter reading

Figure 5: Measurement value temperature

Figure 6: Measurement value pressure

Figure 11: System status

Figure 7: Internal barometric pressure

Figure 8: mA output

Figure 10: Relay

Figure 9: Limit value

P

=

Speed Pressure Flow Rate Temperature

Rev.-Nr.: IM 326-00 E V0.4-2023-08-11, FW G12.02

Instruction Manual IM 326-00 E

Page 11

Phone: +49 6021- 45 807 - 0

Fax: +49 6021- 45 807 - 20

Esters Elektronik GmbH

Hafenrandstr. 14 · D-63741 Aschaffenburg

Internet: http://www.esters.de

4.4 Display: ERROR Screens (Error messages)

In case of an error, an ERROR screen is appended to the LIVE SCREEN for each active error.

If the automatic switching of the LIVE SCREENS is deactivated, the appropriate error screen is automatically

displayed when an error occurs. If the error is gone, the system switches back to the last LIVE SCREEN.

4.5 Display: PARAMETER screen (settings menu) and navigation

The device is parameterized on the PARAMETER screen. Starting from the LIVE screen, you can reach the

PARAMETER screen by holding down the ENTER key (3 seconds).

The settings menu or PARAMETER screen opens on a newly delivered device with the write rights of "Access

rights Level 2". When opening the menu, the display of the access rights level appears for approx. 3 seconds

before switching to the menu.

Within the " Access rights Level 2", the user can make all the necessary system settings for commissioning. A PIN

code (PIN1) can be defined to protect the parameters. The PIN assigned ex works is: 10000. The factory-defined

PIN code results in the device being "open" and thus access to the parameter setting is not protected. The

parameter settings are only protected against unauthorized access after an individual PIN code has been

Navigation in LIVE screen

Switch between the LIVE screens

Within a LIVE screen (e.g. limit value) it is possible to scroll within the screen.

Back to LIVE screen

LONG HOLD/ PRESS (approx. 3 seconds)

Opening the PARAMETER screen or settings menu

Figure 12: Error screen

Figure 13: Main menu

(PARAMETER screen)

Figure 14: Displaying the hierarchy level when

opening the PARAMETER screen

(approx. 3 sec.)

P

=

Speed Pressure Flow Rate Temperature

Rev.-Nr.: IM 326-00 E V0.4-2023-08-11, FW G12.02

Instruction Manual IM 326-00 E

Page 12

Phone: +49 6021- 45 807 - 0

Fax: +49 6021- 45 807 - 20

Esters Elektronik GmbH

Hafenrandstr. 14 · D-63741 Aschaffenburg

Internet: http://www.esters.de

assigned. When the device is restarted or when the user logs off, the device is downgraded to the "Access rights

Level 1”. If the keys on the device are unused within 300 seconds, an automatic logout and thus downgrading to

access level (1) takes place.

In the "Access rights 1 Level", no changes can be made to the settings. The information is only available in read

mode. To change the access rights, logging on to the system is required (see Section ).

All other access levels are only accessible by customer service. In the event of such a support case, the customer

service representative will instruct you accordingly.

4.5.1 Explanations of the menu (PARAMETER screen)

The main menu is shown as a tree structure. Tree nodes can be setting values (PARAMETERS), commands

(COMMANDS) or submenu items. Every parameter and every menu tree node have a unique ID code. A

parameter can be "open" (adjustable) or closed (locked). This is indicated by a symbol (open or closed diamond).

Legend

Unique parameter ID or menu node ID

Open/ adjustable parameter

Parameter can be changed.

For better readability, a separator "-" is inserted between

the name and value of the parameter in longer texts of

open parameters.

Closed/ locked parameter

Cannot be changed at the current access level.

For better readability, a "space" separator is inserted

between the name and value of the parameter in longer

texts of locked parameters

Command

Sub menu

P

=

Speed Pressure Flow Rate Temperature

Rev.-Nr.: IM 326-00 E V0.4-2023-08-11, FW G12.02

Instruction Manual IM 326-00 E

Page 13

Phone: +49 6021- 45 807 - 0

Fax: +49 6021- 45 807 - 20

Esters Elektronik GmbH

Hafenrandstr. 14 · D-63741 Aschaffenburg

Internet: http://www.esters.de

4.5.2 Navigation in the menu tree (PARAMETER screen)

4.5.3 Setting parameters

Navigate according to the previous explanations to the desired parameter, which you want to adjust and confirm

with Enter. The editing mode appears.

A distinction is made between enumeration parameters (EP) and numerical parameters (NP).

For the enumeration parameters, the value can be set using the predefined selection. In the case of numerical

parameters, the setting is made by defining the individual digits. Here, the glancing cursor marks the position of

the item to be changed.

1If a parameter cannot be edited due to locking, a parameter info display opens instead.

Navigation in the menu tree (PARAMETER screen)

Switch a menu item down or up

LEFT: Temporarily hide parameter values

Press and hold RIGHT: Load default value for the displayed parameter (if not

locked)

- Opens a submenu item

- Executes a command or

- Edits a parameter 1

- Goes back one menu level

- LONG HOLD/ PRESS

Exits menu and returns to LIVE screen

Figure 15: Enumeration parameter (EP)

Figure 16: Numerical parameter (NP)

P

=

Speed Pressure Flow Rate Temperature

Rev.-Nr.: IM 326-00 E V0.4-2023-08-11, FW G12.02

Instruction Manual IM 326-00 E

Page 14

Phone: +49 6021- 45 807 - 0

Fax: +49 6021- 45 807 - 20

Esters Elektronik GmbH

Hafenrandstr. 14 · D-63741 Aschaffenburg

Internet: http://www.esters.de

After leaving the editing mode by pressing the OK key (Save), you will be returned to the previous position in the

menu tree.

If it was a "chained" parameter, the next following parameter of the chain is opened for editing instead. The

chain is interrupted if a parameter is not saved because the menu item was exited with ESC.

Navigation in editing mode

- Enumeration parameters (EP): adjust option

- Numerical parameters (NP): adjust digits

(The cursor marks the digit to be adjusted, flashes alternately with the

digit located there).

- Enumeration parameters (EP): adjust option

- Numerical parameters (NP): move cursor

Save value and exit editing mode

Do not save value and exit editing mode

P

=

Speed Pressure Flow Rate Temperature

Rev.-Nr.: IM 326-00 E V0.4-2023-08-11, FW G12.02

Instruction Manual IM 326-00 E

Page 15

Phone: +49 6021- 45 807 - 0

Fax: +49 6021- 45 807 - 20

Esters Elektronik GmbH

Hafenrandstr. 14 · D-63741 Aschaffenburg

Internet: http://www.esters.de

5Menu structure and parameter IDs (PARAMETER screen)

5.1 Menu structure: Main menu

ID

MENU STRUCTURE:MAIN MENU

#1001

LANGUAGE

The device software has different languages, which can be set according to customer

requirements.

- - German as factory setting (FS)

#1100

DEVICE INFO

Display of relevant device information, e.g. device family, firmware, serial number, ...

#1500

INPUTS

Settings related to the connected units, such as flow meter, temperature and pressure sensor.

#2400

OUTPUTS

Setting the relay outputs and the current output.

#2900

LIMITS

Defining the limit values A and B

#1200

SYSTEM

Definition of system settings, such as operating mode, display, LED status, error display, ...

#1900

WIZARDS

Selection of wizards, such as quick start via menu ID, restart of the device, reset to factory

settings, ...

#1950

ACCESS RIGHTS

Functions such as logging in and out of the device in relation to the access levels as well as

setting a separate device pin for the access levels 2.

#1300

COUNTER VALUE

Display of the quantity and pulse counters

P

=

Speed Pressure Flow Rate Temperature

Rev.-Nr.: IM 326-00 E V0.4-2023-08-11, FW G12.02

Instruction Manual IM 326-00 E

Page 16

Phone: +49 6021- 45 807 - 0

Fax: +49 6021- 45 807 - 20

Esters Elektronik GmbH

Hafenrandstr. 14 · D-63741 Aschaffenburg

Internet: http://www.esters.de

5.2 Menu structure: Language

5.2.1 Setting the language: New device

For new devices and devices that have been reset to factory settings, the firmware starts in German. The

LANGUAGE setting parameter is opened automatically. The change is made according to the explanations for

enumeration parameters from section 4.5.3 Setting parameters.

5.2.2 Setting the language: Configured device.

The language can only be changed in the "Access rights 2 Level". If no PIN code (factory setting (FS): 10000) has

been assigned and no previous logout has taken place, it is not necessary to log in to the device again. The device

is therefore open and does not need to be unlocked. The change is made according to the explanations for

enumeration parameters from section 4.5.3 Setting parameters.

Figure 17: Language setting for new devices

P

=

Speed Pressure Flow Rate Temperature

Rev.-Nr.: IM 326-00 E V0.4-2023-08-11, FW G12.02

Instruction Manual IM 326-00 E

Page 17

Phone: +49 6021- 45 807 - 0

Fax: +49 6021- 45 807 - 20

Esters Elektronik GmbH

Hafenrandstr. 14 · D-63741 Aschaffenburg

Internet: http://www.esters.de

5.3 Menu structure: Device info (#1100)2

All parameters within the device info are locked parameters and cannot be changed by the customer.

Only the parameter Measuring point for changing the designation can be changed.

#1100

MENU STRUCTURE:DEVICE INFO

PARA.-TYP

#1101

Device family

Displaying the device family, e.g. GDR-1530

-

#1102

Firmware

Displaying the firmware version, e.g. G12.02

-

#1008

#1011

PcbID

Display of the installed hardware

-

#1965

Modell

Specification of the device type

-

#1103

Serial number

Displaying the serial number of the device

-

#1107

Production year

Display the year of manufacture of the device

-

#1108

Production month

Display the month of manufacture of the device

-

#1104

Operating hours

Displaying the total operating hours of the device

-

#1290

Probe index3

Setting the designation of the measuring point

−Probe index 1 (FS)

−Probe index 2

−Probe index 3

−Probe index 4

EP

#1968

Upgrade-Key

Function not available

NP

2The menu item is not available in previous versions.

3The setting for "Measuring point" can be found in previous versions under the "System" menu item.

P

=

Speed Pressure Flow Rate Temperature

Rev.-Nr.: IM 326-00 E V0.4-2023-08-11, FW G12.02

Instruction Manual IM 326-00 E

Page 18

Phone: +49 6021- 45 807 - 0

Fax: +49 6021- 45 807 - 20

Esters Elektronik GmbH

Hafenrandstr. 14 · D-63741 Aschaffenburg

Internet: http://www.esters.de

5.4 Menu structure: Inputs (#1500)

5.4.1 Input: Flow rate

#1500

MENU STRUCTURE:INPUT FLOW

PARA.-TYP

#1206

Typ-CH-A

Flow rate signal: channel A

Type selection:

−Off

−GD-Sensor direct (FS) (further settings required)

−HB3004/SC300/UNI100 (further settings required)

−Test frequency (further settings required)

NOTE:

GD-Sensor direct:

In the NON-ATEX area, the gas flow meter GD 300/ GD 500 and the

predecessor model GD 100 can be connected directly. If an SC 300 is

installed in the current installation situation, it no longer needs to be

connected.

HB300/SC300/UNI100

−HB 300 Ex-R000000 / UNI-100: In the ATEX area, the gas flow meter GD

300 Ex/ GD 500 Ex is connected via the integrated volume corrector HB

300 Ex-R000000. Older installations with UNI-100 of the predecessor

model GD 100 can be connected.

−HB 300 -R000000 / SC 300 / SC 310: In the NON-ATEX area the gas flow

meter GD 300/ GD 500 can be connected via the integrated volume

corrector HB 300-R000000 or via the external signal conditioners

SC 3005and SC 310.

EP

#2500

- Test frequency (Display only when selected: Test frequency)

Type selection:

−0,1 Hz

−0,2 Hz

−0,5 Hz

−1 Hz

−2 Hz

−5 Hz (FS)

−….

−1 kHz

EP

4Only the HB300 integrated volume correctors with type code HB 300-R0000 / HB 300 Ex-R0000 can be

connected.

5Signal conditioners SC 300 and SC 310 can be connected, but it is possible to connect the gas flow meter GD 100

/ GD 300 / GD 500 also directly via the platinum wire.

P

=

Speed Pressure Flow Rate Temperature

Rev.-Nr.: IM 326-00 E V0.4-2023-08-11, FW G12.02

Instruction Manual IM 326-00 E

Page 19

Phone: +49 6021- 45 807 - 0

Fax: +49 6021- 45 807 - 20

Esters Elektronik GmbH

Hafenrandstr. 14 · D-63741 Aschaffenburg

Internet: http://www.esters.de

#1500

MENU STRUCTURE: INPUT FLOW

PARA.-TYP

#2110

Sensor curve CH-A (Display only when selected: GD-300 Sensor direct,

HB300/SC300/UNI100)

#2101 Valid Points

- 02 (FS)

NOTE:

The definition of the number of interpolation points can take place as

follows:

- Transfer of the resolution/ native pulses (liters/pulse), specification from

the nameplate of the gas flow meter.

- (Examples see section Error! Reference source not found. Error!

Reference source not found.)

This applies to connections with HB 300 (Ex)-R000000 or direct connection

of the gas flow meter GD 300/ GD 500 and if no calibration protocol is

available.

Number of points: 2

- Take over of values from factory calibration protocol

Number of points: n+1

n+1 = number of measuring points of the calibration protocol plus 1

(For details see section 7.2 Factory calibration certificate for gas flow meter

#2111 Justierung

- 00 (FS)

NP

NP

P

=

Speed Pressure Flow Rate Temperature

Rev.-Nr.: IM 326-00 E V0.4-2023-08-11, FW G12.02

Instruction Manual IM 326-00 E

Page 20

Phone: +49 6021- 45 807 - 0

Fax: +49 6021- 45 807 - 20

Esters Elektronik GmbH

Hafenrandstr. 14 · D-63741 Aschaffenburg

Internet: http://www.esters.de

#1500

MENU STRUCTURE:INPUT DURCHFLUSS

PARA.-TYP

Continuation: Sensor curve CH-A (Display only when selected: GD-300

Sensor direct, HB300/SC300/UNI100)

#220x Charline

Number depending on the number of specified measuring points in #2101,

where the first measuring point is always 0

# 2201 Frequency 1 (NP): 0 Hz (FS)

# 2202 Volume1 (NP): 0 l (FS)

# 2203 Frequency 2 (NP): x.x Hz (FS)

# 2204 Volume 2 (NP): x.x l (FS)

…

# 220x Frequency n (NP): x.x Hz

# 220y Volume n (NP): x.x l

NOTE:

−Adoption of the resolution (liter/pulse) data from the nameplate of the

gas flow meter.

Example acc. to Error! Reference source not found. Error! Reference

source not found.

# 2201 Frequency 1 (NP): 0.0 Hz

# 2202 Volume 1 (NP): 0

# 2203 Frequency 2 (NP): 1 Hz

# 2204 Volume 2 (NP): 0,5002 l (Example)

−Transfer of values from factory calibration record

Number of points: n+1,

corresponding to number of measuring points in the protocol plus 1

Example acc. to 7.2 Factory calibration certificate for gas flow meter

# 2201 Frequency 1 (NP): 0.0 Hz

# 2202 Volume 1 (NP): 0

# 2203 Frequency 2 (NP): 3.16 Hz

# 2204 Volume 2 (NP): 2.1982 l

# 2205 Frequency 3 (NP): 17.27 Hz

# 2206 Volume 3 (NP): 2.1974 l

….

# 2212 Frequency 7 (NP): 82.69 Hz

# 2213 Volume 7 (NP): 2.18994 l

A maximum of 32 measuring points can be defined.

NP

Table of contents

Other ESTERS ELEKTRONIK Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Metrohm

Metrohm Mira M-1 manual

YOKOGAWA

YOKOGAWA Power Series Plus instruction manual

Dwyer Instruments

Dwyer Instruments RVM Specifications-installation and operating instructions

ALAT UJI

ALAT UJI TG-101 Operating instructions manual

Omron

Omron K6CM series user manual

Chauvin Arnoux

Chauvin Arnoux C.A 1725 Quick start manual

Agilent Technologies

Agilent Technologies E8363BU-014 Installation note

Toa

Toa ZM-104 Specifications

PCE Health and Fitness

PCE Health and Fitness CTT Series user manual

Underground Magnetics

Underground Magnetics Mag 9 manual

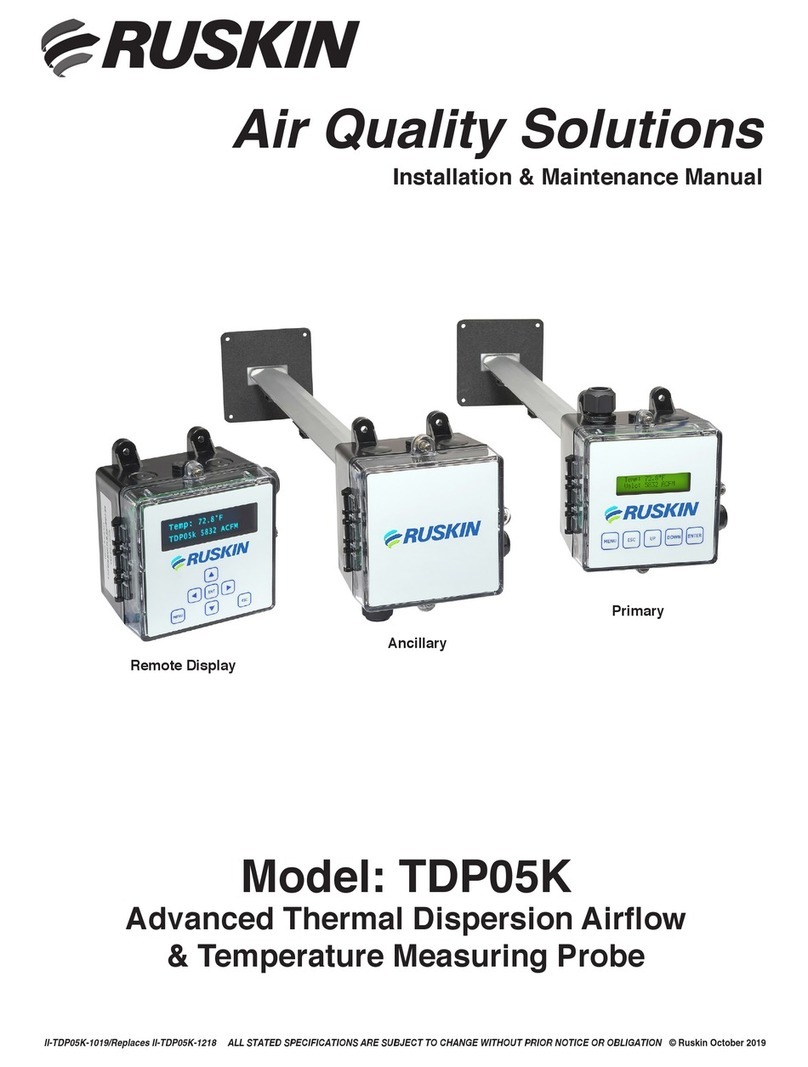

Ruskin

Ruskin TDP05K Installation & maintenance manual

KROHNE

KROHNE OPTIMASS 1000 Series Guidelines for use