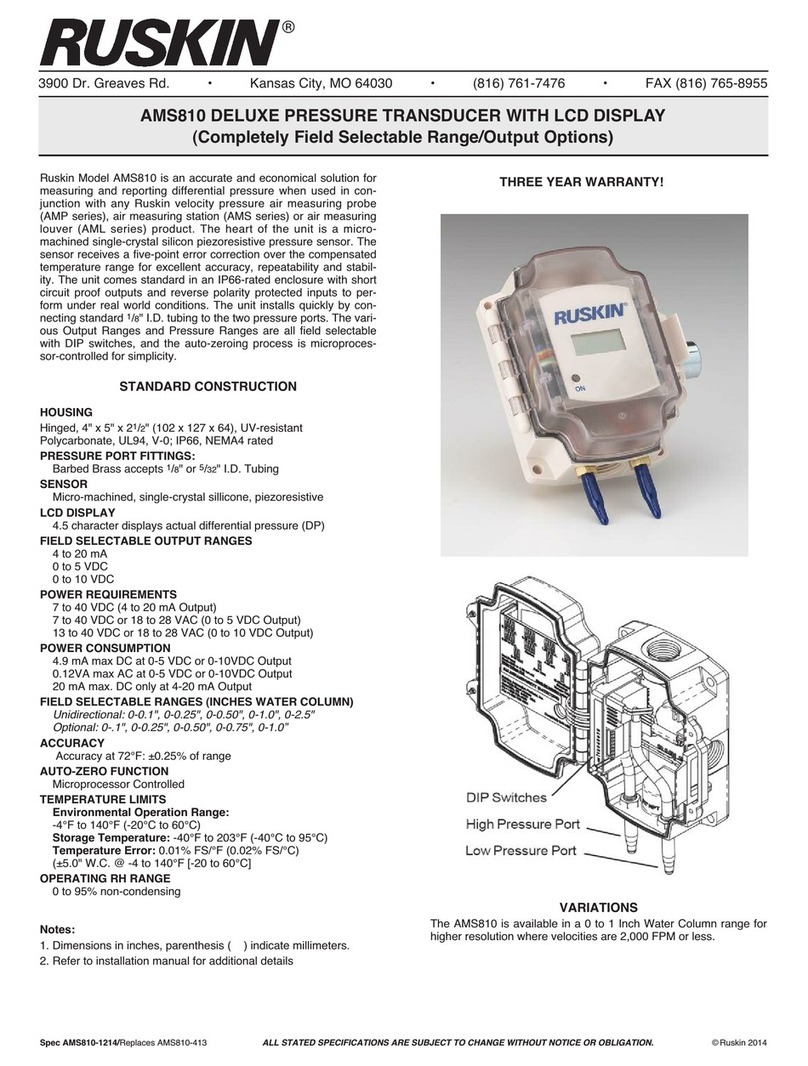

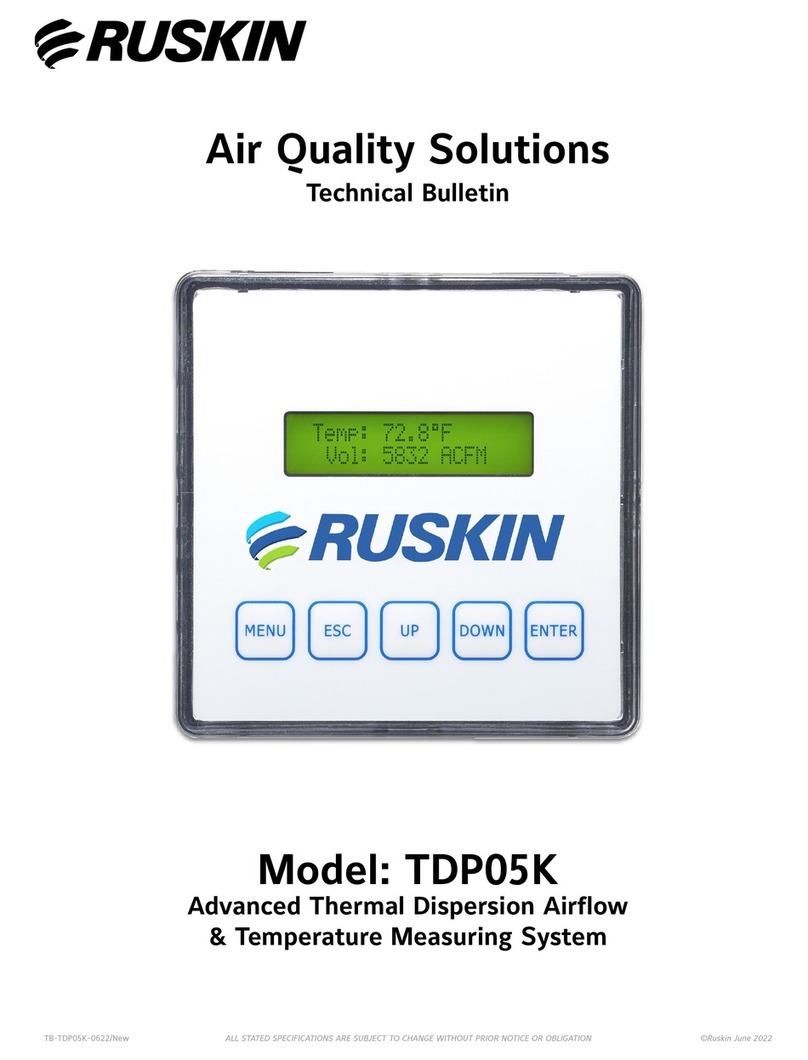

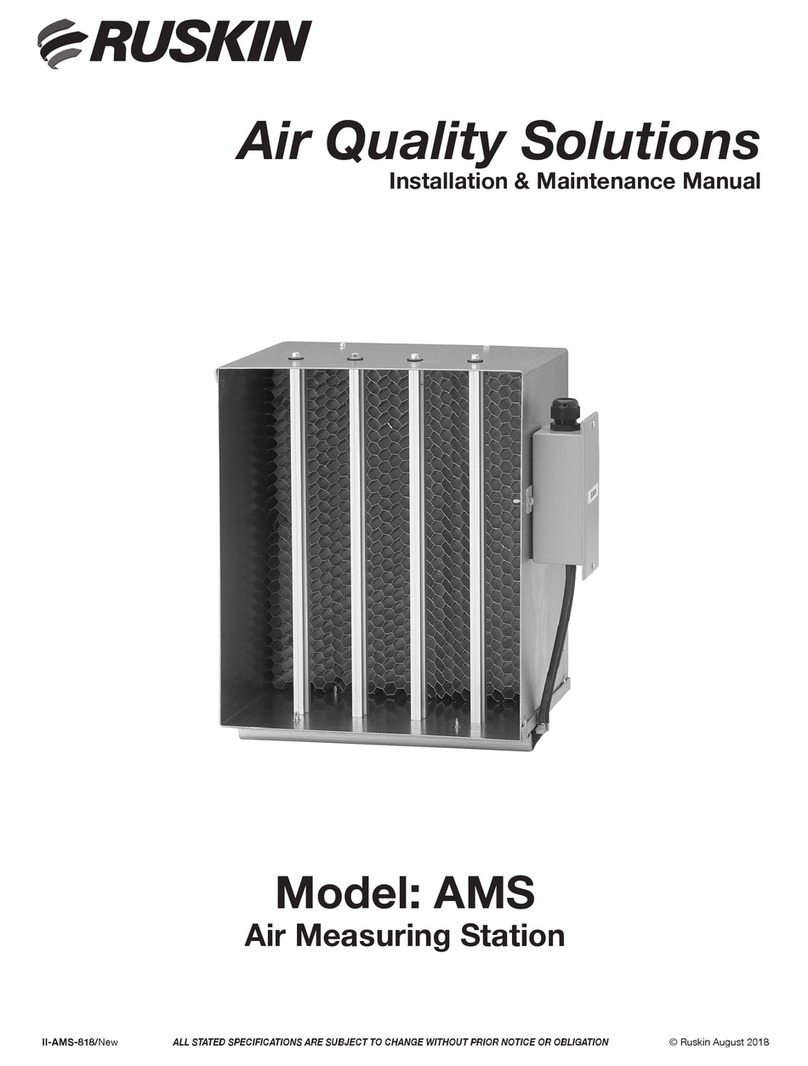

TDP05K Advanced Thermal Dispersion Probe Airow Measuring System Installation Instructions

5

TDP05K Advanced Thermal Dispersion Probe Airow Measuring System Installation Instructions

5

Table 1: Number of Probes/Sensors per Probe for Rectangular Duct Applications

Duct

Height, in.

(mm)

Duct Width, in. (mm)

12

(305)

14

(356)

16

(406)

18

(457)

20

(508)

22

(559)

24

(610)

30

(762)

36

(914)

42

(1,067)

48

(1,219)

54

(1,372)

60

(1,524)

66

(1,676)

72

(1,829)

84

(2,134)

96

(2,438)

108

(2,743)

120

(3,048)

12 (305) 1/2 1/4 1/4 1/4 1/4 1/4 1/4 1/6 1/6 1/6 1/6 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8

14 (356) 1/4 1/4 1/4 1/4 1/4 1/6 1/6 1/6 1/6 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8

16 (406) 2/2 2/2 2/2 2/2 2/3 2/3 2/3 1/6 1/6 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8

18 (457) 2/2 2/2 2/2 2/2 2/3 2/3 2/2 2/2 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8

20 (508) 2/2 2/2 2/3 2/3 2/3 2/3 2/3 2/4 1/8 1/8 1/8 1/8 2/6 2/6 2/6 2/6 2/7 2/8 1/8

22 (559) 2/2 3/2 2/3 2/3 2/3 2/3 2/3 2/4 1/8 1/8 1/8 2/6 2/6 2/6 2/6 2/7 2/8 2/8 2/8

24 (610) 2/2 3/2 2/3 2/3 2/3 2/3 2/3 2/4 2/4 1/8 1/8 2/6 2/6 2/6 2/6 2/7 2/8 2/8 2/8

30 (762) 3/2 3/2 3/2 3/2 2/4 2/4 2/4 2/4 2/4 2/6 2/6 2/6 2/7 2/7 2/8 2/8 2/8 2/8 2/8

36 (914) 3/2 3/2 3/2 4/2 4/2 4/2 2/4 2/4 2/6 2/6 2/6 2/7 2/8 2/8 2/8 2/8 2/8 2/8 2/8

42 (1,067) 3/2 4/2 4/2 4/2 4/2 4/2 4/2 2/6 2/6 2/7 2/7 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8

48 (1,219) 3/2 4/2 4/2 4/2 4/2 4/2 4/2 3/4 2/6 2/7 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8

54 (1,372) 4/2 4/2 4/2 4/2 4/2 3/4 3/4 3/4 2/7 2/8 2/8 2/8 2/8 2/8 4/4 2/8 2/8 2/8 2/8

60 (1,524) 4/2 4/2 4/2 4/2 3/4 3/4 3/4 4/4 4/4 2/8 2/8 2/8 4/4 4/4 4/4 4/4 2/8 2/8 2/8

66 (1,676) 4/2 4/2 4/2 4/3 3/4 3/4 3/4 4/4 4/4 4/4 2/8 2/8 4/4 4/4 4/4 4/4 4/4 2/8 2/8

72 (1,829) 4/2 4/2 4/2 4/3 3/4 3/4 3/4 4/4 4/4 4/4 2/8 4/4 4/4 4/4 4/4 4/4 4/4 4/4 2/8

84 (2,134) 4/2 4/2 4/2 4/3 3/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4

96 (2,438) 4/2 4/2 4/2 4/3 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4

108 (2,743) 4/2 4/2 4/2 4/3 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4

120 (3,048)4/2 4/2 4/2 4/3 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4

1. The minimum diameter size is 12 x 6.5 inches (304 x 165 mm) for rectangular duct applications. Smaller sizes can be special

ordered. For sizes less than 12 x 6.5 inches (304 x 165 mm), use the same number of probes and sensors as the 12 x 12 in.

(304 x 304 mm) size.

Table 1: Number of Probes/Sensors per Probe for Rectangular Duct Applications1

Duct

Height, in.

(mm)

Duct Width, in. (mm)

12

(305)

14

(356)

16

(406)

18

(457)

20

(508)

22

(559)

24

(610)

30

(762)

36

(914)

42

(1,067)

48

(1,219)

54

(1,372)

60

(1,524)

66

(1,676)

72

(1,829)

84

(2,134)

96

(2,438)

108

(2,743)

120

(3,048)

12 (305) 1/2 1/4 1/4 1/4 1/4 1/4 1/4 1/6 1/6 1/6 1/6 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8

14 (356) 1/4 1/4 1/4 1/4 1/4 1/6 1/6 1/6 1/6 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8

16 (406) 2/2 2/2 2/2 2/2 2/3 2/3 2/3 1/6 1/6 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8

18 (457) 2/2 2/2 2/2 2/2 2/3 2/3 2/2 2/2 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8

20 (508) 2/2 2/2 2/3 2/3 2/3 2/3 2/3 2/4 1/8 1/8 1/8 1/8 2/6 2/6 2/6 2/6 2/7 2/8 1/8

22 (559) 2/2 3/2 2/3 2/3 2/3 2/3 2/3 2/4 1/8 1/8 1/8 2/6 2/6 2/6 2/6 2/7 2/8 2/8 2/8

24 (610) 2/2 3/2 2/3 2/3 2/3 2/3 2/3 2/4 2/4 1/8 1/8 2/6 2/6 2/6 2/6 2/7 2/8 2/8 2/8

30 (762) 3/2 3/2 3/2 3/2 2/4 2/4 2/4 2/4 2/4 2/6 2/6 2/6 2/7 2/7 2/8 2/8 2/8 2/8 2/8

36 (914) 3/2 3/2 3/2 4/2 4/2 4/2 2/4 2/4 2/6 2/6 2/6 2/7 2/8 2/8 2/8 2/8 2/8 2/8 2/8

42 (1,067) 3/2 4/2 4/2 4/2 4/2 4/2 4/2 2/6 2/6 2/7 2/7 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8

48 (1,219) 3/2 4/2 4/2 4/2 4/2 4/2 4/2 3/4 2/6 2/7 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8

54 (1,372) 4/2 4/2 4/2 4/2 4/2 3/4 3/4 3/4 2/7 2/8 2/8 2/8 2/8 2/8 4/4 2/8 2/8 2/8 2/8

60 (1,524) 4/2 4/2 4/2 4/2 3/4 3/4 3/4 4/4 4/4 2/8 2/8 2/8 4/4 4/4 4/4 4/4 2/8 2/8 2/8

66 (1,676) 4/2 4/2 4/2 4/3 3/4 3/4 3/4 4/4 4/4 4/4 2/8 2/8 4/4 4/4 4/4 4/4 4/4 2/8 2/8

72 (1,829) 4/2 4/2 4/2 4/3 3/4 3/4 3/4 4/4 4/4 4/4 2/8 4/4 4/4 4/4 4/4 4/4 4/4 4/4 2/8

84 (2,134) 4/2 4/2 4/2 4/3 3/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4

96 (2,438) 4/2 4/2 4/2 4/3 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4

108 (2,743) 4/2 4/2 4/2 4/3 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4

120 (3,048)4/2 4/2 4/2 4/3 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4

1. The minimum diameter size is 12 x 6.5 inches (304 x 165 mm) for rectangular duct applications. Smaller sizes can be special

ordered. For sizes less than 12 x 6.5 inches (304 x 165 mm), use the same number of probes and sensors as the 12 x 12 in.

(304 x 304 mm) size.

HIGHEST SENSOR DENSITY PERSQUAREFOOT INTHEINDUSTRY

DETAILA

Probe/sensor placement for rectangular applications

12" 14" 16" 18" 20" 22" 24" 30" 36" 42" 48" 54" 60" 66" 72" 84" 96" 108" 120"

(305) (356) (406) (457) (508) (559) (610) (762) (914) (1067)(1219)(1372)(1524)(1676)(1829)(2134)(2438)(2743)

(3048)

12" (305)

1/2 1/4 1/4 1/4 1/4 1/4 1/4 1/6 1/6 1/6 1/6 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8

14" (356)

1/4 1/4 1/4 1/4 1/4 1/6 1/6 1/6 1/6 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8

16"(406)

2/2 2/2 2/2 2/2 2/3 2/3 2/3 1/6 1/6 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8

18" (457)

2/2 2/2 2/2 2/3 2/3 2/3 2/3 1/6 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8

20" (508)

2/2 2/2 2/3 2/3 2/3 2/3 2/3 2/4 1/8 1/8 1/8 1/8 2/6 2/6 2/6 2/6 2/7 2/8 1/8

22"(559)

2/2 3/2 2/3 2/3 2/3 2/3 2/3 2/4 1/8 1/8 1/8 2/6 2/6 2/6 2/6 2/7 2/8 2/8 2/8

24" (610)

2/2 3/2 2/3 2/3 2/3 2/3 2/3 2/4 2/4 1/8 1/8 2/6 2/6 2/6 2/6 2/7 2/8 2/8 2/8

30" (762)

3/2 3/2 3/2 3/2 2/4 2/4 2/4 2/4 2/4 2/6 2/6 2/6 2/7 2/7 2/8 2/8 2/8 2/8 2/8

36" (914)

3/2 3/2 3/2 4/2 4/2 4/2 2/4 2/4 2/6 2/6 2/6 2/7 2/8 2/8 2/8 2/8 2/8 2/8 2/8

42" (1067)

3/2 4/2 4/2 4/2 4/2 4/2 4/2 2/6 2/6 2/7 2/7 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8

48" (1219)

3/2 4/2 4/2 4/2 4/2 4/2 4/2 3/4 2/6 2/7 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8

54" (1372)

4/2 4/2 4/2 4/2 4/2 3/4 3/4 3/4 2/7 2/8 2/8 2/8 2/8 2/8 4/4 2/8 2/8 2/8 2/8

60" (1524)

4/2 4/2 4/2 4/2 3/4 3/4 3/4 4/4 4/4 2/8 2/8 2/8 4/4 4/4 4/4 4/4 2/8 2/8 2/8

66" (1676)

4/2 4/2 4/2 4/3 3/4 3/4 3/4 4/4 4/4 4/4 2/8 2/8 4/4 4/4 4/4 4/4 4/4 2/8 2/8

72" (1829)

4/2 4/2 4/2 4/3 3/4 3/4 3/4 4/4 4/4 4/4 2/8 4/4 4/4 4/4 4/4 4/4 4/4 4/4 2/8

84" (2134)

4/2 4/2 4/2 4/3 3/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4

96" (2438)

4/2 4/2 4/2 4/3 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4

108" (2743)

4/2 4/2 4/2 4/3 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4

120" (3048)

4/2 4/2 4/2 4/3 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4

Duct Height

"B"

Duct Width A - Probe Length

The model TDP05K probe assembly may be installed in square,

round, or oval ducts and plenums. Hardware required for the insertion

style mounting configuration (as depicted in the DETAILS shown

below) is provided as standard with the TDP05K. Stand-off mounting

hardware is available as an option for applications that require probes

mounted onto the upstream side of a Ruskin model CD50, CD60 or

insulated TED50 control damper (damper sold separately). For

specific installation and operation details, and for round or oval

applications, refer to the Installation and Maintenance Instructions.

The information on this data sheet is for general reference and is

subject to correction or modification.

DETAIL 3

DETAIL 2

DETAIL 4

Primary

Probe

Ancillary

Probe

Duct Height

Height / 2

Height / 4

Duct Height

Height / 2

Duct Width

Duct Width

Primary

Probe

Ancillary

Probe

Ancillary

Probe

Ancillary

Probe

Primary

Probe

Ancillary

Probe

Ancillary

Probe

Duct

Height

Height / 3

Height / 3

Height / 6

Duct

Height

Height / 4

Height / 4

Height / 4

Height / 8

Duct Width

Duct Width

DETAIL 1

Round Duct Mounting

Attach Round Duct Hinge Plate to Round Duct Mounting Plate.

5

Rectangular Duct Internal Mounting

Each Internal Mount Air Measurement System consists of one or more ancillary probes to be mounted inside existing

ductwork or opening to be wired to an externally located REMOTE WIRED PRIMARY or junction box. The REMOTE

WIRED PRIMARY receives air and temperature measurement data via the probe network’s twisted shielded pair. The

REMOTE WIRED PRIMARY is the user interface as well as the interface point for power and connection to the Building

Automation System. Spacing of Internal mount probes is the same as Insertion mount probes.

FRONTVIEW

Install with sensors on bottom of probe when installed horizontally.

6.52

REF.

ACTUAL DUCT SIZE MINUS 1/2”

14", 18", 24", 30" or 36"

Sensing Points

3.80

REF.

DIMENSION

14

18

24

30

36

Probe/Sensor Count per Duct Size

#Probes / #Sensors per Probe

Example: HTDP-S ordered for a 24"w x 24"h

duct will consist of two (2) 24" long probes

with each probe having 4 sensors (2/4)

Typical HTDP-S Installation Configuration

(HTDP-S shown with 3 duct-mounted ancillary probes wired to

wall-mounted Remote Primary Controller with Display)

Model HTDP-S

AVAILABLE FOR

NEXT-DAY OR SAME-DAY

SHIPPING!

TDP05K Advanced Thermal Dispersion Probe Airow Measuring System Installation Instructions

5

Table 1: Number of Probes/Sensors per Probe for Rectangular Duct Applications1

Duct

Height, in.

(mm)

Duct Width, in. (mm)

12

(305)

14

(356)

16

(406)

18

(457)

20

(508)

22

(559)

24

(610)

30

(762)

36

(914)

42

(1,067)

48

(1,219)

54

(1,372)

60

(1,524)

66

(1,676)

72

(1,829)

84

(2,134)

96

(2,438)

108

(2,743)

120

(3,048)

12 (305) 1/2 1/4 1/4 1/4 1/4 1/4 1/4 1/6 1/6 1/6 1/6 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8

14 (356) 1/4 1/4 1/4 1/4 1/4 1/6 1/6 1/6 1/6 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8

16 (406) 2/2 2/2 2/2 2/2 2/3 2/3 2/3 1/6 1/6 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8

18 (457) 2/2 2/2 2/2 2/2 2/3 2/3 2/2 2/2 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8

20 (508) 2/2 2/2 2/3 2/3 2/3 2/3 2/3 2/4 1/8 1/8 1/8 1/8 2/6 2/6 2/6 2/6 2/7 2/8 1/8

22 (559) 2/2 3/2 2/3 2/3 2/3 2/3 2/3 2/4 1/8 1/8 1/8 2/6 2/6 2/6 2/6 2/7 2/8 2/8 2/8

24 (610) 2/2 3/2 2/3 2/3 2/3 2/3 2/3 2/4 2/4 1/8 1/8 2/6 2/6 2/6 2/6 2/7 2/8 2/8 2/8

30 (762) 3/2 3/2 3/2 3/2 2/4 2/4 2/4 2/4 2/4 2/6 2/6 2/6 2/7 2/7 2/8 2/8 2/8 2/8 2/8

36 (914) 3/2 3/2 3/2 4/2 4/2 4/2 2/4 2/4 2/6 2/6 2/6 2/7 2/8 2/8 2/8 2/8 2/8 2/8 2/8

42 (1,067) 3/2 4/2 4/2 4/2 4/2 4/2 4/2 2/6 2/6 2/7 2/7 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8

48 (1,219) 3/2 4/2 4/2 4/2 4/2 4/2 4/2 3/4 2/6 2/7 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8

54 (1,372) 4/2 4/2 4/2 4/2 4/2 3/4 3/4 3/4 2/7 2/8 2/8 2/8 2/8 2/8 4/4 2/8 2/8 2/8 2/8

60 (1,524) 4/2 4/2 4/2 4/2 3/4 3/4 3/4 4/4 4/4 2/8 2/8 2/8 4/4 4/4 4/4 4/4 2/8 2/8 2/8

66 (1,676) 4/2 4/2 4/2 4/3 3/4 3/4 3/4 4/4 4/4 4/4 2/8 2/8 4/4 4/4 4/4 4/4 4/4 2/8 2/8

72 (1,829) 4/2 4/2 4/2 4/3 3/4 3/4 3/4 4/4 4/4 4/4 2/8 4/4 4/4 4/4 4/4 4/4 4/4 4/4 2/8

84 (2,134) 4/2 4/2 4/2 4/3 3/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4

96 (2,438) 4/2 4/2 4/2 4/3 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4

108 (2,743) 4/2 4/2 4/2 4/3 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4

120 (3,048)4/2 4/2 4/2 4/3 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4

1. The minimum diameter size is 12 x 6.5 inches (304 x 165 mm) for rectangular duct applications. Smaller sizes can be special

ordered. For sizes less than 12 x 6.5 inches (304 x 165 mm), use the same number of probes and sensors as the 12 x 12 in.

(304 x 304 mm) size.

TDP05K Advanced Thermal Dispersion Probe Airow Measuring System Installation Instructions

5

Table 1: Number of Probes/Sensors per Probe for Rectangular Duct Applications

Duct

Height, in.

(mm)

Duct Width, in. (mm)

12

(305)

14

(356)

16

(406)

18

(457)

20

(508)

22

(559)

24

(610)

30

(762)

36

(914)

42

(1,067)

48

(1,219)

54

(1,372)

60

(1,524)

66

(1,676)

72

(1,829)

84

(2,134)

96

(2,438)

108

(2,743)

120

(3,048)

12 (305) 1/2 1/4 1/4 1/4 1/4 1/4 1/4 1/6 1/6 1/6 1/6 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8

14 (356) 1/4 1/4 1/4 1/4 1/4 1/6 1/6 1/6 1/6 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8

16 (406) 2/2 2/2 2/2 2/2 2/3 2/3 2/3 1/6 1/6 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8

18 (457) 2/2 2/2 2/2 2/2 2/3 2/3 2/2 2/2 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8

20 (508) 2/2 2/2 2/3 2/3 2/3 2/3 2/3 2/4 1/8 1/8 1/8 1/8 2/6 2/6 2/6 2/6 2/7 2/8 1/8

22 (559) 2/2 3/2 2/3 2/3 2/3 2/3 2/3 2/4 1/8 1/8 1/8 2/6 2/6 2/6 2/6 2/7 2/8 2/8 2/8

24 (610) 2/2 3/2 2/3 2/3 2/3 2/3 2/3 2/4 2/4 1/8 1/8 2/6 2/6 2/6 2/6 2/7 2/8 2/8 2/8

30 (762) 3/2 3/2 3/2 3/2 2/4 2/4 2/4 2/4 2/4 2/6 2/6 2/6 2/7 2/7 2/8 2/8 2/8 2/8 2/8

36 (914) 3/2 3/2 3/2 4/2 4/2 4/2 2/4 2/4 2/6 2/6 2/6 2/7 2/8 2/8 2/8 2/8 2/8 2/8 2/8

42 (1,067) 3/2 4/2 4/2 4/2 4/2 4/2 4/2 2/6 2/6 2/7 2/7 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8

48 (1,219) 3/2 4/2 4/2 4/2 4/2 4/2 4/2 3/4 2/6 2/7 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8

54 (1,372) 4/2 4/2 4/2 4/2 4/2 3/4 3/4 3/4 2/7 2/8 2/8 2/8 2/8 2/8 4/4 2/8 2/8 2/8 2/8

60 (1,524) 4/2 4/2 4/2 4/2 3/4 3/4 3/4 4/4 4/4 2/8 2/8 2/8 4/4 4/4 4/4 4/4 2/8 2/8 2/8

66 (1,676) 4/2 4/2 4/2 4/3 3/4 3/4 3/4 4/4 4/4 4/4 2/8 2/8 4/4 4/4 4/4 4/4 4/4 2/8 2/8

72 (1,829) 4/2 4/2 4/2 4/3 3/4 3/4 3/4 4/4 4/4 4/4 2/8 4/4 4/4 4/4 4/4 4/4 4/4 4/4 2/8

84 (2,134) 4/2 4/2 4/2 4/3 3/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4

96 (2,438) 4/2 4/2 4/2 4/3 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4

108 (2,743) 4/2 4/2 4/2 4/3 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4

120 (3,048)4/2 4/2 4/2 4/3 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4

1. The minimum diameter size is 12 x 6.5 inches (304 x 165 mm) for rectangular duct applications. Smaller sizes can be special

ordered. For sizes less than 12 x 6.5 inches (304 x 165 mm), use the same number of probes and sensors as the 12 x 12 in.

(304 x 304 mm) size.

Table 1: Number of Probes/Sensors per Probe for Rectangular Duct Applications1

Duct

Height, in.

(mm)

Duct Width, in. (mm)

12

(305)

14

(356)

16

(406)

18

(457)

20

(508)

22

(559)

24

(610)

30

(762)

36

(914)

42

(1,067)

48

(1,219)

54

(1,372)

60

(1,524)

66

(1,676)

72

(1,829)

84

(2,134)

96

(2,438)

108

(2,743)

120

(3,048)

12 (305) 1/2 1/4 1/4 1/4 1/4 1/4 1/4 1/6 1/6 1/6 1/6 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8

14 (356) 1/4 1/4 1/4 1/4 1/4 1/6 1/6 1/6 1/6 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8

16 (406) 2/2 2/2 2/2 2/2 2/3 2/3 2/3 1/6 1/6 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8

18 (457) 2/2 2/2 2/2 2/2 2/3 2/3 2/2 2/2 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8

20 (508) 2/2 2/2 2/3 2/3 2/3 2/3 2/3 2/4 1/8 1/8 1/8 1/8 2/6 2/6 2/6 2/6 2/7 2/8 1/8

22 (559) 2/2 3/2 2/3 2/3 2/3 2/3 2/3 2/4 1/8 1/8 1/8 2/6 2/6 2/6 2/6 2/7 2/8 2/8 2/8

24 (610) 2/2 3/2 2/3 2/3 2/3 2/3 2/3 2/4 2/4 1/8 1/8 2/6 2/6 2/6 2/6 2/7 2/8 2/8 2/8

30 (762) 3/2 3/2 3/2 3/2 2/4 2/4 2/4 2/4 2/4 2/6 2/6 2/6 2/7 2/7 2/8 2/8 2/8 2/8 2/8

36 (914) 3/2 3/2 3/2 4/2 4/2 4/2 2/4 2/4 2/6 2/6 2/6 2/7 2/8 2/8 2/8 2/8 2/8 2/8 2/8

42 (1,067) 3/2 4/2 4/2 4/2 4/2 4/2 4/2 2/6 2/6 2/7 2/7 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8

48 (1,219) 3/2 4/2 4/2 4/2 4/2 4/2 4/2 3/4 2/6 2/7 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8

54 (1,372) 4/2 4/2 4/2 4/2 4/2 3/4 3/4 3/4 2/7 2/8 2/8 2/8 2/8 2/8 4/4 2/8 2/8 2/8 2/8

60 (1,524) 4/2 4/2 4/2 4/2 3/4 3/4 3/4 4/4 4/4 2/8 2/8 2/8 4/4 4/4 4/4 4/4 2/8 2/8 2/8

66 (1,676) 4/2 4/2 4/2 4/3 3/4 3/4 3/4 4/4 4/4 4/4 2/8 2/8 4/4 4/4 4/4 4/4 4/4 2/8 2/8

72 (1,829) 4/2 4/2 4/2 4/3 3/4 3/4 3/4 4/4 4/4 4/4 2/8 4/4 4/4 4/4 4/4 4/4 4/4 4/4 2/8

84 (2,134) 4/2 4/2 4/2 4/3 3/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4

96 (2,438) 4/2 4/2 4/2 4/3 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4

108 (2,743) 4/2 4/2 4/2 4/3 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4

120 (3,048)4/2 4/2 4/2 4/3 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4

1. The minimum diameter size is 12 x 6.5 inches (304 x 165 mm) for rectangular duct applications. Smaller sizes can be special

ordered. For sizes less than 12 x 6.5 inches (304 x 165 mm), use the same number of probes and sensors as the 12 x 12 in.

(304 x 304 mm) size.

HIGHEST SENSOR DENSITY PERSQUAREFOOT INTHEINDUSTRY

DETAILA

Probe/sensor placement for rectangular applications

12" 14" 16" 18" 20" 22" 24" 30" 36" 42" 48" 54" 60" 66" 72" 84" 96" 108" 120"

(305) (356) (406) (457) (508) (559) (610) (762) (914) (1067)(1219)(1372)(1524)(1676)(1829)(2134)(2438)(2743)

(3048)

12" (305)

1/2 1/4 1/4 1/4 1/4 1/4 1/4 1/6 1/6 1/6 1/6 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8

14" (356)

1/4 1/4 1/4 1/4 1/4 1/6 1/6 1/6 1/6 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8

16"(406)

2/2 2/2 2/2 2/2 2/3 2/3 2/3 1/6 1/6 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8

18" (457)

2/2 2/2 2/2 2/3 2/3 2/3 2/3 1/6 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8 1/8

20" (508)

2/2 2/2 2/3 2/3 2/3 2/3 2/3 2/4 1/8 1/8 1/8 1/8 2/6 2/6 2/6 2/6 2/7 2/8 1/8

22"(559)

2/2 3/2 2/3 2/3 2/3 2/3 2/3 2/4 1/8 1/8 1/8 2/6 2/6 2/6 2/6 2/7 2/8 2/8 2/8

24" (610)

2/2 3/2 2/3 2/3 2/3 2/3 2/3 2/4 2/4 1/8 1/8 2/6 2/6 2/6 2/6 2/7 2/8 2/8 2/8

30" (762)

3/2 3/2 3/2 3/2 2/4 2/4 2/4 2/4 2/4 2/6 2/6 2/6 2/7 2/7 2/8 2/8 2/8 2/8 2/8

36" (914)

3/2 3/2 3/2 4/2 4/2 4/2 2/4 2/4 2/6 2/6 2/6 2/7 2/8 2/8 2/8 2/8 2/8 2/8 2/8

42" (1067)

3/2 4/2 4/2 4/2 4/2 4/2 4/2 2/6 2/6 2/7 2/7 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8

48" (1219)

3/2 4/2 4/2 4/2 4/2 4/2 4/2 3/4 2/6 2/7 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8 2/8

54" (1372)

4/2 4/2 4/2 4/2 4/2 3/4 3/4 3/4 2/7 2/8 2/8 2/8 2/8 2/8 4/4 2/8 2/8 2/8 2/8

60" (1524)

4/2 4/2 4/2 4/2 3/4 3/4 3/4 4/4 4/4 2/8 2/8 2/8 4/4 4/4 4/4 4/4 2/8 2/8 2/8

66" (1676)

4/2 4/2 4/2 4/3 3/4 3/4 3/4 4/4 4/4 4/4 2/8 2/8 4/4 4/4 4/4 4/4 4/4 2/8 2/8

72" (1829)

4/2 4/2 4/2 4/3 3/4 3/4 3/4 4/4 4/4 4/4 2/8 4/4 4/4 4/4 4/4 4/4 4/4 4/4 2/8

84" (2134)

4/2 4/2 4/2 4/3 3/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4

96" (2438)

4/2 4/2 4/2 4/3 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4

108" (2743)

4/2 4/2 4/2 4/3 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4

120" (3048)

4/2 4/2 4/2 4/3 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4 4/4

Duct Height

"B"

Duct Width A - Probe Length

The model TDP05K probe assembly may be installed in square,

round, or oval ducts and plenums. Hardware required for the insertion

style mounting configuration (as depicted in the DETAILS shown

below) is provided as standard with the TDP05K. Stand-off mounting

hardware is available as an option for applications that require probes

mounted onto the upstream side of a Ruskin model CD50, CD60 or

insulated TED50 control damper (damper sold separately). For

specific installation and operation details, and for round or oval

applications, refer to the Installation and Maintenance Instructions.

The information on this data sheet is for general reference and is

subject to correction or modification.

DETAIL 3

DETAIL 2

DETAIL 4

Primary

Probe

Ancillary

Probe

Duct Height

Height / 2

Height / 4

Duct Height

Height / 2

Duct Width

Duct Width

Primary

Probe

Ancillary

Probe

Ancillary

Probe

Ancillary

Probe

Primary

Probe

Ancillary

Probe

Ancillary

Probe

Duct

Height

Height / 3

Height / 3

Height / 6

Duct

Height

Height / 4

Height / 4

Height / 4

Height / 8

Duct Width

Duct Width

DETAIL 1

Round Duct Mounting

Attach Round Duct Hinge Plate to Round Duct Mounting Plate.

5

Round Duct Mounting

Attach Round Duct Hinge Plate to Round Duct Mounting Plate.

Table 1: Number of Probes / Sensors per Probe for Rectangular Duct Applications

Table 1: Number of Probes / Sensors per Probe for Rectangular Duct Applications

Table 1: Number of Probes / Sensors per Probe for Rectangular Duct Applications

Table 1: Number of Probes / Sensors per Probe for Rectangular Duct Applications

Table 1: Number of Probes / Sensors per Probe for Rectangular Duct Applications

Table 1: Number of Probes / Sensors per Probe for Rectangular Duct Applications

Table 1: Number of Probes / Sensors per Probe for Rectangular Duct Applications

Table 1: Number of Probes / Sensors per Probe for Rectangular Duct Applications

Table 1: Number of Probes / Sensors per Probe for Rectangular Duct Applications

Table 1: Number of Probes / Sensors per Probe for Rectangular Duct Applications

Table 1: Number of Probes / Sensors per Probe for Rectangular Duct Applications

Table 1: Number of Probes / Sensors per Probe for Rectangular Duct Applications

Table 1: Number of Probes / Sensors per Probe for Rectangular Duct Applications

Table 1: Number of Probes / Sensors per Probe for Rectangular Duct Applications

Table 1: Number of Probes / Sensors per Probe for Rectangular Duct Applications

Table 1: Number of Probes / Sensors per Probe for Rectangular Duct Applications

Table 1: Number of Probes / Sensors per Probe for Rectangular Duct Applications

Table 1: Number of Probes / Sensors per Probe for Rectangular Duct Applications

Table 1: Number of Probes / Sensors per Probe for Rectangular Duct Applications

Table 1: Number of Probes / Sensors per Probe for Rectangular Duct Applications

Table 1: Number of Probes / Sensors per Probe for Rectangular Duct Applications

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

8"

12"

14"

16"

18"

20"

22"

24"

30"

36"

42"

48"

54"

60"

66"

72"

84"

96"

108"

120"

Rectangular Duct Internal Mounting

Each Internal Mount Air Measurement System consists of one or more ancillary probes to be mounted inside existing

ductwork or opening to be wired to an externally located REMOTE WIRED PRIMARY or junction box. The REMOTE

WIRED PRIMARY receives air and temperature measurement data via the probe network’s twisted shielded pair. The

REMOTE WIRED PRIMARY is the user interface as well as the interface point for power and connection to the Building

Automation System. Spacing of Internal mount probes is the same as Insertion mount probes.

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

Rectangular Duct Width "A" = Probe Length

8"

(203)

12"

(305)

14"

(356)

16"

(406)

18"

(457)

20"

(508)

22"

(559)

24"

(610)

30"

(762)

36"

(914)

42"

(1067)

48"

(1219)

54"

(1372)

60"

(1524)

66"

(1676)

72"

(1829)

84"

(2134)

96"

(2438)

108"

(2743)

120"

(3048)

FRONT VIEW

GREATER THAN 60" AND UP TO 120"

3 PROBES WITH 8 SENSORS

SEE TABLE FOR EK MEAN DISTRIBUTION

AUTHOR BJC

CHECKED ENK

APPROVED

10/7/2015

10/20/2015

PRODUCT

SIZE

D

SCALE

DWG NO REV

C

SHEET 2 OF 2INVENTOR

MATERIAL

ECN

TITLE

3900 Doctor Greaves Rd,

Grandview, MO 64030

PROPRIETARY AND

CONFIDENTIAL

TDP05K

87-020155-00D

ROUND PROBE CONFIGURATIONS

NONE6347 8/15/2018

APPROVED

SLEEVE LENGTH

(12" MINIMUM)

PRIMARY PROBE

87-020162-03D

NOTES:

1. EQUAL AREA DISTRIBUTION SHOWN.

2. USE THIS LAYOUT FOR EK MEAN DISTRIBUTION ALSO.

3. SEE ORDER FOR DISTRIBUTION TYPE.

4. ALL DIMENSIONS GIVEN IN INCHES.

ANCILLARY PROBE

87-020162-04D

EK MEAN DISTRIBUTION

DIAMETER PROBES/SENSORS

GREATER THAN 32" & LESS THAN 48" 3/4

GREATER THAN OR EQUAL TO 48" & LESS THAN 56" 3/6

GREATER THAN OR EQUAL TO 56" 3/8

DREVISED NOTE UNDER FRONT VIEW

TO SHOW UPDATED SIZES DPM ABH 8/15/2018

C REMOVED OBSOLETE PROBE NUMBERS BJC 7/31/2017

B SEE SHEET 1 BJC LEH JDW 2/1/2017

REV DESCRIPTION BY CHK APV APVD DATE

UNLESS OTHERWISE SPECIFIED, USE STD.

ENGINEERING TOLERANCES PER WIQ-008

DRAWING NUMBER DESCRIPTION

87-020156-00D OVAL DUCT CONFIGURATION

87-020157-00D RECTANGULAR EA DUCT CONFIGURATION

87-020181-00D RECTANGULAR LOG C DUCT CONFIGURATION

10-24 x .75

SELF DRILLING SCREW

(4 REQUIRED PER CONTROL BOX)

C

C

D

SLEEVE LENGTH / 2 - 2.125

SLEEVE LENGTH / 2

SLEEVE LENGTH / 2 + 2.125

FRONT VIEW

GREATER THAN 60" AND UP TO 120"

3 PROBES WITH 8 SENSORS

SEE TABLE FOR EK MEAN DISTRIBUTION

ANCILLARY VIEW

AUTHOR BJC

CHECKED ENK

APPROVED

10/7/2015

10/20/2015

PRODUCT

SIZE

D

SCALE

DWG NO REV

C

SHEET 2 OF 2INVENTOR

MATERIAL

ECN

TITLE

3900 Doctor Greaves Rd,

Grandview, MO 64030

PROPRIETARY AND

CONFIDENTIAL

TDP05K

87-020155-00D

ROUND PROBE CONFIGURATIONS

NONE6347 8/15/2018

APPROVED

SLEEVE LENGTH

(12" MINIMUM)

60°

60°

PRIMARY PROBE

PRIMARY PROBE

87-020162-03D

NOTES:

1. EQUAL AREA DISTRIBUTION SHOWN.

2. USE THIS LAYOUT FOR EK MEAN DISTRIBUTION ALSO.

3. SEE ORDER FOR DISTRIBUTION TYPE.

4. ALL DIMENSIONS GIVEN IN INCHES.

ANCILLARY PROBE

87-020162-04D

EK MEAN DISTRIBUTION

DIAMETER PROBES/SENSORS

GREATER THAN 32" & LESS THAN 48" 3/4

GREATER THAN OR EQUAL TO 48" & LESS THAN 56" 3/6

GREATER THAN OR EQUAL TO 56" 3/8

DREVISED NOTE UNDER FRONT VIEW

TO SHOW UPDATED SIZES DPM ABH 8/15/2018

C REMOVED OBSOLETE PROBE NUMBERS BJC 7/31/2017

B SEE SHEET 1 BJC LEH JDW 2/1/2017

REV DESCRIPTION BY CHK APV APVD DATE

UNLESS OTHERWISE SPECIFIED, USE STD.

ENGINEERING TOLERANCES PER WIQ-008

DRAWING NUMBER DESCRIPTION

87-020156-00D OVAL DUCT CONFIGURATION

87-020157-00D RECTANGULAR EA DUCT CONFIGURATION

87-020181-00D RECTANGULAR LOG C DUCT CONFIGURATION

10-24 x .75

SELF DRILLING SCREW

(4 REQUIRED PER CONTROL BOX)

C

C

D

SLEEVE LENGTH / 2 - 2.125

SLEEVE LENGTH / 2

SLEEVE LENGTH / 2 + 2.125

AIR

FLOW

Round Duct Mounting Offset When mounting 2 or more probes in a round duct, they must be oset

from each other by at least 2 1/8 inches, in the direction of air ow to

avoid mechanical interference.

Ruskin model HTDP-S oers the

advanced technology available with

the model TDP05K and makes it

available in these probe lengths for

Same-Day or Next-Day shipping to

meet critical project scheduling!

DETAIL A

TDP05K probe/sensor placement for rectangular applications

HTDP-S Probe/Sensor Count per Duct Size

#Probes / #Sensors per Probe