Et system EAC/AFV User manual

ET System electronic GmbH

Telefon 06205 3948-0

Fax 06205 37560

Hauptstraße 119-121

68804 Altlußheim

www.et-system.de

EAC/AFV

Software version:

January 2015

Table of Contents

Info & Contact Addresses............................................................................................................................................1

Technical Specifications ..............................................................................................................................................1

Ambient Conditions........................................................................................................................................................1

Display............................................................................................................................................................................2

Input Specifications ........................................................................................................................................................2

Output Specifications .....................................................................................................................................................2

Total Power ....................................................................................................................................................................2

Technical Drawing ..........................................................................................................................................................3

Important Safety Instructions .....................................................................................................................................4

Initial Operation .............................................................................................................................................................4

Unpacking.......................................................................................................................................................................4

Setting Up.......................................................................................................................................................................4

Visual Inspection ............................................................................................................................................................4

Mains Operation ............................................................................................................................................................4

Functional Description ................................................................................................................................................5

Block Diagram.................................................................................................................................................................5

Structure of the Main Control Unit ................................................................................................................................6

Description of cable connections ...................................................................................................................................6

Cable Wiring ...................................................................................................................................................................6

General Settings..........................................................................................................................................................7

Initial State & Splash Screen...........................................................................................................................................7

Main Menu .................................................................................................................................................................7

Application.................................................................................................................................................................7

System .......................................................................................................................................................................7

Event..........................................................................................................................................................................7

Menu “APP“ ...................................................................................................................................................................8

Mode “General“ ........................................................................................................................................................8

Mode “Step“..............................................................................................................................................................9

Mode “Gradual“ ......................................................................................................................................................10

Mode “Meas.“ .........................................................................................................................................................11

Error Message..........................................................................................................................................................12

Menu “SYSTEM“ ...........................................................................................................................................................12

Date & Time.............................................................................................................................................................13

System Setting .........................................................................................................................................................13

Language Setting .....................................................................................................................................................13

Menu ”EVENT“ .............................................................................................................................................................13

RS 485 Interface ........................................................................................................................................................14

Command Format ........................................................................................................................................................14

Commands of Functions...............................................................................................................................................14

Answer Commands ......................................................................................................................................................14

Protocol Examples........................................................................................................................................................15

CRC Check Sum.............................................................................................................................................................18

Error Messages..........................................................................................................................................................19

Maintenance.............................................................................................................................................................19

Notes ........................................................................................................................................................................20

Info & Contact Addresses

ET System electronic GmbH 1

INFO & CONTACT ADDRESSES

ET System electronic GmbH was founded in 1986 in the heart of the Rhine-Neckar-Triangle. As a subsidiary of a leading

electricity utility group, the company quickly took on a leading role in the area of laboratory power electronics and

associated electrical measurement. The existing know-how in power technologies in the 90s gave rise to the “Power

Solutions” product division as a strong extension of the historical “Test & Measurement” range.

Since 1997, we have been working successfully as an independent, privately held company with customers in all lines

of business from industry, medical care, railway technology and automotive electronics.

By means of our high vertical range of manufacture and our ever expanding development division we can fast and

flexibly adjust to our customers’ requirements. Necessary approvals such as CSA, UL, VDE, TÜV etc. are flexibly carried

out by qualified personnel. The approval procedures are performed within the scope of development planning and thus

do not negatively impact the start of manufacturing. Permanent manufacturing control through accredited laboratories

and an ISO 9001 compliant quality management system guarantee a constant high-level series-production quality.

We offer repairs and adjustment for units outside of our warranty period. Please contact your local distributor for fur-

ther information:

Place of Business: Altlußheim, Germany

VAT Identification Number: DE 144 285 482

Register Court: Mannheim, Germany

Register Number: HRB 421186

Managing Director: Dipl.-Ing. Eric Keim

Sales Manager: Roland Kosmowski

Development Leader: Hermann Amtsberg

TECHNICAL SPECIFICATIONS

AMBIENT CONDITIONS

Operating Temperature

0 - 45 °C

Operating Height

< 1.500 m

Insulation Resistance

≥ 500 V DC 10 MΩ

Insulation Test Voltage

AC 1.800 V 10 mA/1 min

Cooling

Fan

Humidity

< 90 %

Germany

ET System electronic GmbH

Hauptstraße 119-121

68804 Altlußheim

Germany

Phone: +49 (0) 6205 39480

Fax: +49 (0) 6205 37560

em@il: info@et-system.de

web: www.et-system.de

Technical Specifications

2 ET System electronic GmbH

DISPLAY

Display

Touch screen

Voltage

Display: 0 - 300 V, Resolution: 0.1 V, Accuracy: 0.5 % FS + 4COUNT

Current

Display: 0 - 999,9 A, Resolution: 0.1 A, Accuracy: 0.5 % FS + 4COUNT

Frequency

Display: 0 - 999,9 Hz, Resolution: 0.1 Hz, Accuracy: ± 0.1 Hz

INPUT SPECIFICATIONS

Number of Phases

3

Voltage

230/400 V

Voltage Fluctuation

230/400 V ± 15 %

Frequency Fluctuation

50/60 Hz ± 3 Hz

Power Factor

0.9

Max. permitted current under full load

140.3 A

OUTPUT SPECIFICATIONS

Number of Phases

3

Wave Form

Sine

Low Voltage

0 - 150 V (L - N)

High Voltage

150.1 - 300 V (L - N)

Frequency

45 - 500 Hz

Frequency Stability

±≤ 0.01 %

Max. high voltage current

LO: 83.3 A

Max. low voltage current

HI: 41.7 A

TOTAL POWER

Output Power (kVA)

75

Circuit Mode

IGBT/PWM (pulse width modulation)

Voltage Control

≤ 1 %

Load Control

± 1 %

Wave Form Distortion (THD)

≤ 2 %

Efficiency

≥ 90 %

Reaction Time

≤ 2 ms

Crest Factor

3:1

Protective Devices

Input: fuse switch, Output: overvoltage/undervoltage, overcurrent, overload Input:

overvoltage/undervoltage, countercurrent protection, overtemperature, short circuit protec-

tion, conduct fast protection and lock fault protection , error display

Technical Specifications

ET System electronic GmbH 3

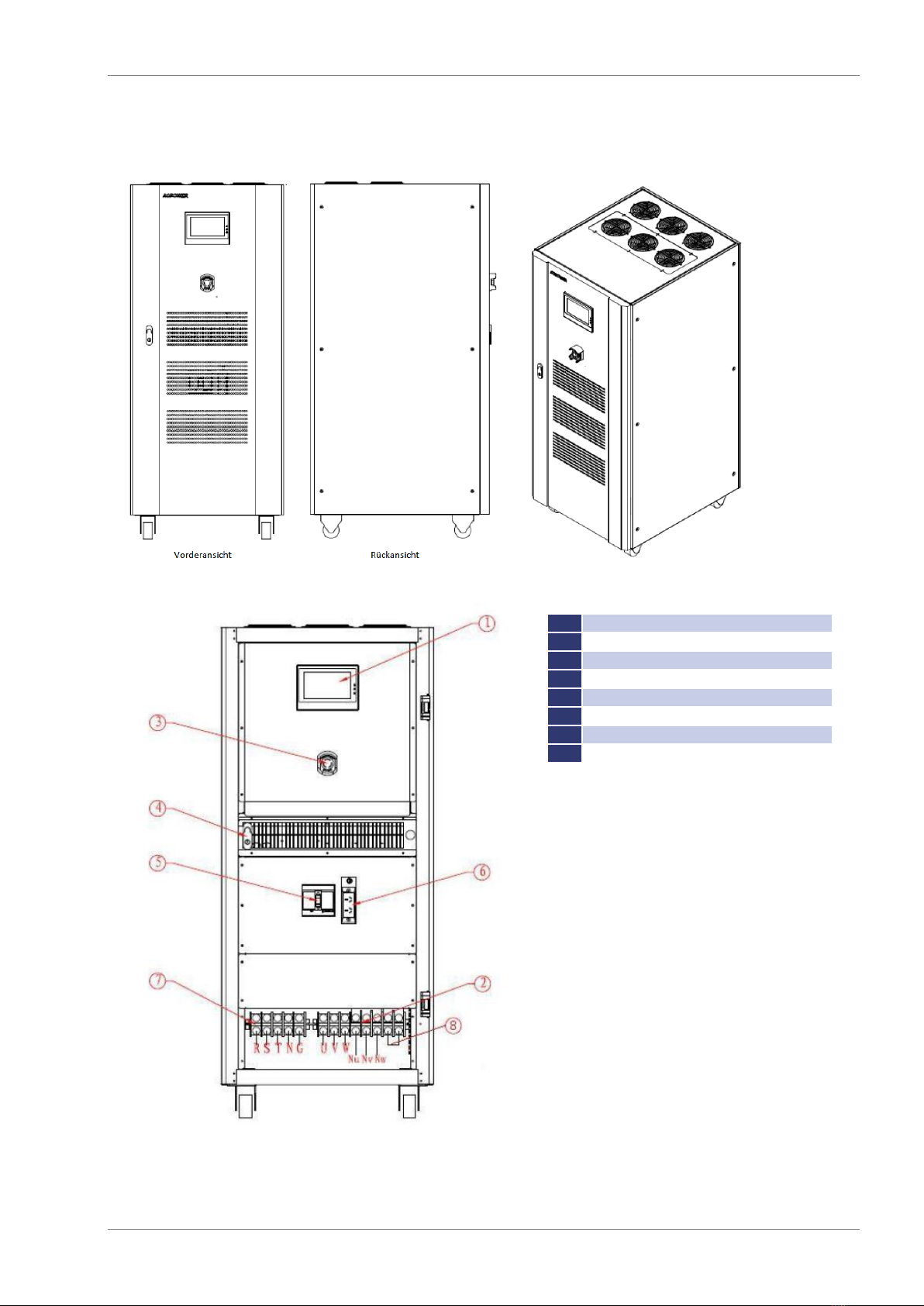

TECHNICAL DRAWING

1

Touchscreen

2

AC Output terminal row: U, V, W, Nu, Nv, Nw

3

Emergency stop button

4

Door handle

5

Input air switch

6

Maintenance socket

7

AC input terminal row: R, S, T, N, G

8

Parallel operation

Important Safety Instructions

4 ET System electronic GmbH

IMPORTANT SAFETY INSTRUCTIONS

Please read this manual thoroughly before putting the device

into operation. Pay regard to the following safety instructions

and keep this manual nearby for future purpose.

This operating manual is based on the state of technology at the time of printing. However, it is possible that despite

regular control and correction, the present document contains printing errors or deficiencies. ET System electronic

GmbH assumes no liability for any technical, printing or translational errors within this manual.

INITIAL OPERATION

UNPACKING

Please make sure that the shipping carton and the packaging is free of damage. If external damage is found, it is im-

portant to record the type of damage. Please keep the original packaging to ensure the device is adequately protected

in case it needs to be transported in the future or claims for compensation need to be asserted.

SETTING UP

To avoid electric shocks and product failure, the device should be installed in a temperature and humidity controlled

indoor environment. The ambient temperature must not exceed 50 °C. The device must never be exposed to liquids or

extreme humidity.

VISUAL INSPECTION

The unit must be examined immediately for defects or damages in transit. Damages caused during transport may be

loose or broken control knobs and bent or broken connectors. Do not use the device if any physical damage is apparent.

Please inform the carriers and a representative of ET System electronic immediately.

MAINS OPERATION

Make sure to verify the model number and voltage stated on the nameplate. Damages due to wrong power feed are

not covered by guarantee conditions.

The unit must only be operated when connected directly to the

mains. To avoid damage, do not connect the unit to

isolating transformers, auto -transformers, magnetic current

limiters or similar devices.

Functional Description

ET System electronic GmbH 5

FUNCTIONAL DESCRIPTION

BLOCK DIAGRAM

The following block diagram gives information about the various adjustment options.

Description:

1 Input

connection between power supply endpoint and input terminal disk

2 Input Air Switch

power input control

3 Input Filter

input inductor and capacitor filter

4 Rectifier Filter

converts input alternating current into direct current

5 Soft Start

D.C. capacitor is charged slowly to reduce impulse current

6 Inverter Circuit

converts direct current into PWM waveform

7 Transformer Filter

boosts the output voltage of IGBT and outputs the voltage after LC filter

8 Output

output voltage is transferred to the output terminal disk through the contactor

9 Lightning Protection Device

overvoltage protection, lightning protection, restraining surge current, absorbing spike pulse, etc.

10 Voltage Sampling

input voltage sampling conditioning circuit

11 SCR Drive

drives the control circuit of soft start SCR

12 IGBT Drive

amplifies PWM signals to drive IGBT power components

13 Voltage Feedback

steady output voltage amplitude

14 Voltage/Current Sampling Circuit

samples conditioning circuit of output voltage and current

15 Power Supply

power supply of all PCB

16 Main Control Circuit

processes all input and output signals

17 Display

touch screen display

18 EPO

emergency stop signal

19 Fuse Detection

transmits the fuse power-off signal to the control circuit for trip protection

20 Over-temperature Detection

transmits the over-temperature signal to the control circuit for trip protection

Functional Description

6 ET System electronic GmbH

STRUCTURE OF THE MAIN CONTROL UNIT

The main control unit is divided into three modules: protection sampling, main control, display control.

DESCRIPTION OF CABLE CONNECTIONS

The following picture gives an overview about the cable connections of the main circuit:

Before installing the equipment, all switches need to be disconnected. The circuit cables must be connected according

to the diagram above.

CABLE WIRING

Use the voltmeter to confirm whether there is no voltage output in the distribution lines. Confirm whether all switches

of the variable frequency power supply are in the position “OFF”. The input and output cables can be selected according

to the cables recommended in the following tables.

Input distribution cables:

Input Current (A)

Input live wire (mm²)

Input zero line (mm²)

Input ground wire (mm²)

A

B

C

70.8 A

25 mm²

25 mm²

25 mm²

16 mm²

16 mm²

Output distribution cables:

Output Current (A)

Output live wire (mm²)

Output zero line (mm²)

Output ground wire (mm²)

U

V

W

LO: 83.3 A - HI: 41.7 A

25 mm²

25 mm²

25 mm²

25 mm²

16 mm²

The above recommended reference cables are multi-core flexible copper cables which can be selected by the user ac-

cording to the present input and output current situation. If the length of the input or output lines exceeds 20 meters,

it is recommended that the wire diameter of the cable should be doubled. Successively connect the input distribution

lines to the corresponding wiring terminals at the input and the output distribution lines to the corresponding wiring

terminals at the output.

General Settings

ET System electronic GmbH 7

GENERAL SETTINGS

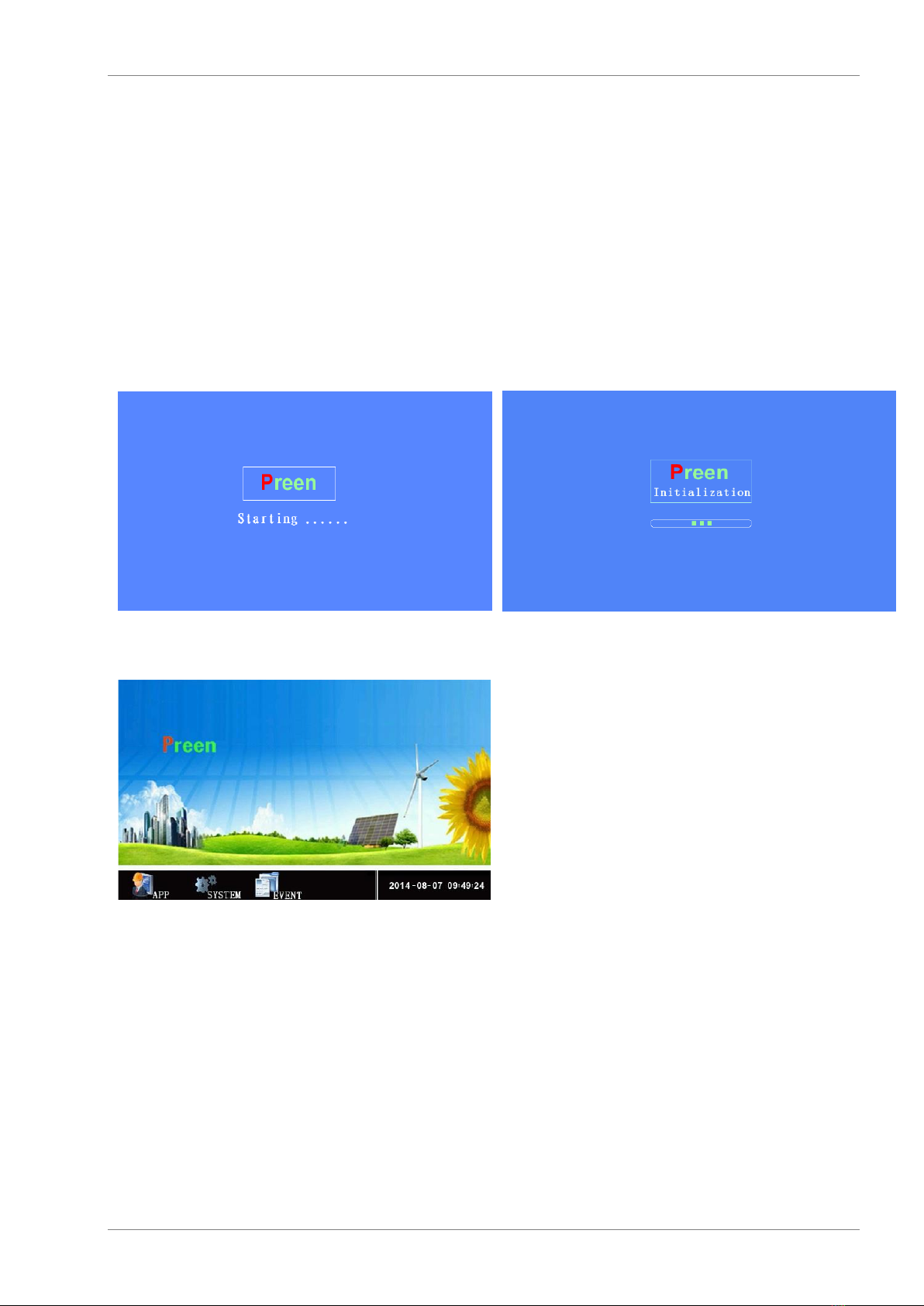

INITIAL STATE &SPLASH SCREEN

The input and output wirings should be connected properly. If the system is started, the main engine fan will start to

operate, the display screen is on and the main interface is entered, indicating that the start-up is normal and the pa-

rameter settings can be entered.

If an external load is connected, the load switch must be disconnected and the input switch connected. Before, the user

should ensure, that no electrical current is flowing at the input terminal row.

When switching on the unit, the splash screen and the initialization graphic will appear on the display.

MAIN MENU

Application

The menu APP displays voltage, current and frequency for each phase of the output terminal. For detailed information,

see chapter →Menu APP.

System

The menu System enables the user to adjust time and other system settings. For detailed information, see chapter →

Menu SYSTEM.

Event

The menu Event records event protocols and information. For detailed information, see chapter →Menu EVENT.

Main Menu

8 ET System electronic GmbH

MENU “APP“

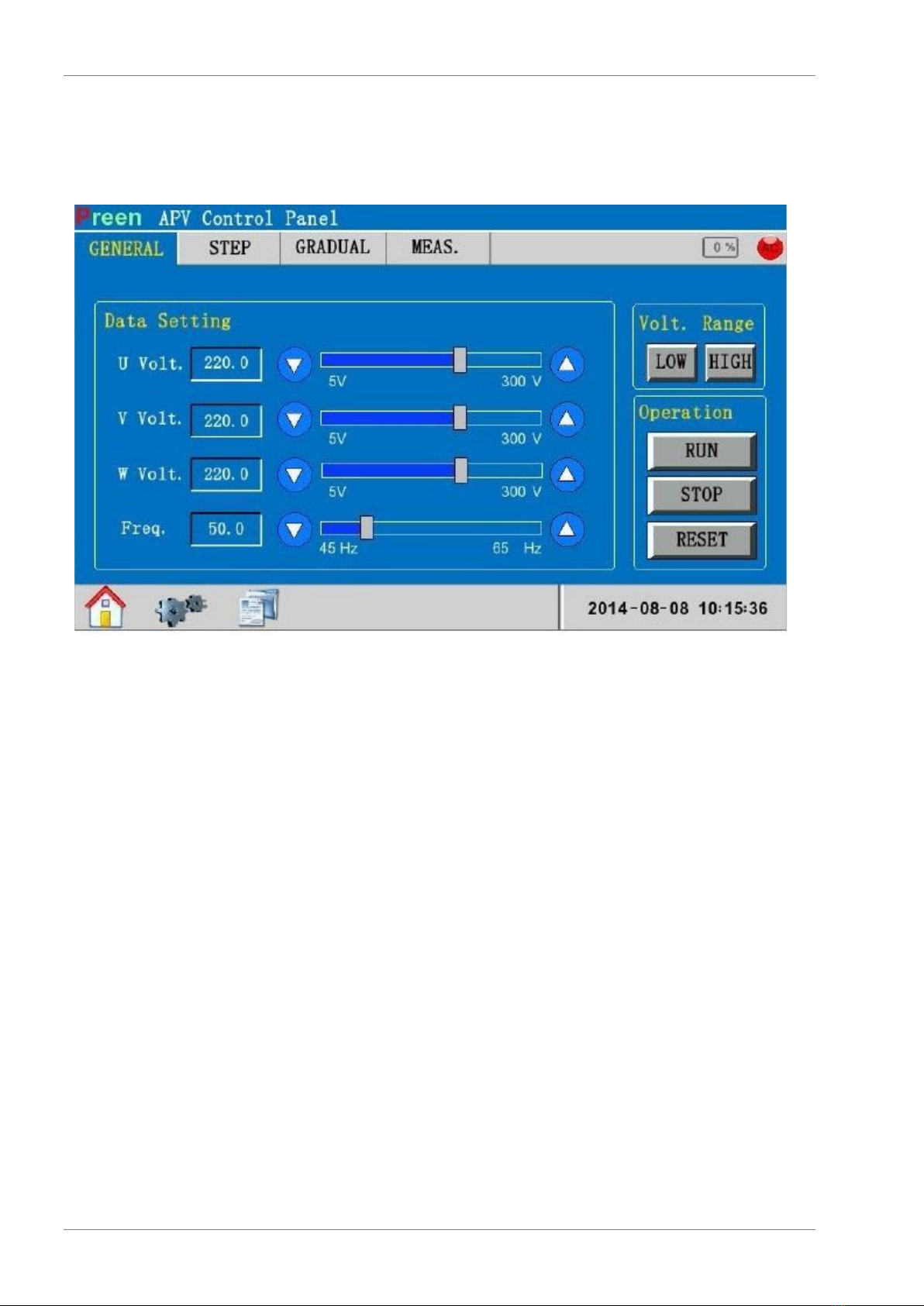

Mode “General“

Data Setting

The adjustment of the values for U Volt., V Volt., W Volt. and Freq. (Frequency) can be adjusted in three ways. A click

on the input field opens the dialog box where the desired value can be entered via keyboard. Alternatively, the value

may be adjusted via slide control and mouse. A third option for entering the values are the arrow buttons besides the

slide control. By clicking these buttons, the value changes by 0.1 interval.

Volt. Range

After clicking the button LOW, the unit is on low voltage. After clicking the button HIGH, the unit is on high voltage.

Operation

The output of the unit is activated when the button RUN is clicked. Deactivate the output by clicking the button STOP.

AC Symbol

The AC symbol in the upper right corner of the display shows the status of the unit output. A red symbol means the

output is inactive, while a green symbol means the output is active.

Main Menu

ET System electronic GmbH 9

Mode “Step“

Download Parameter

Starts the download of the adjusted parameters.

Operation

Mode ”Step“ is activated after button RUN was clicked, and deactivated after button STOP was clicked. RESET sets

the unit back to its initial state.

Main Menu

10 ET System electronic GmbH

The button in the upper right field of the display switches between adjustment function and graphical display of the

mode “Step”.

Mode “Gradual“

Download Parameter

Starts the download of the adjusted parameters.

Main Menu

ET System electronic GmbH 11

Operation

Mode ”Gradual“ is activated after button RUN was clicked, and deactivated after button STOP was clicked. RESET

sets the unit back to its initial state.

The button in the upper right field of the display switches between adjustment function and graphical display of the

mode “Gradual”.

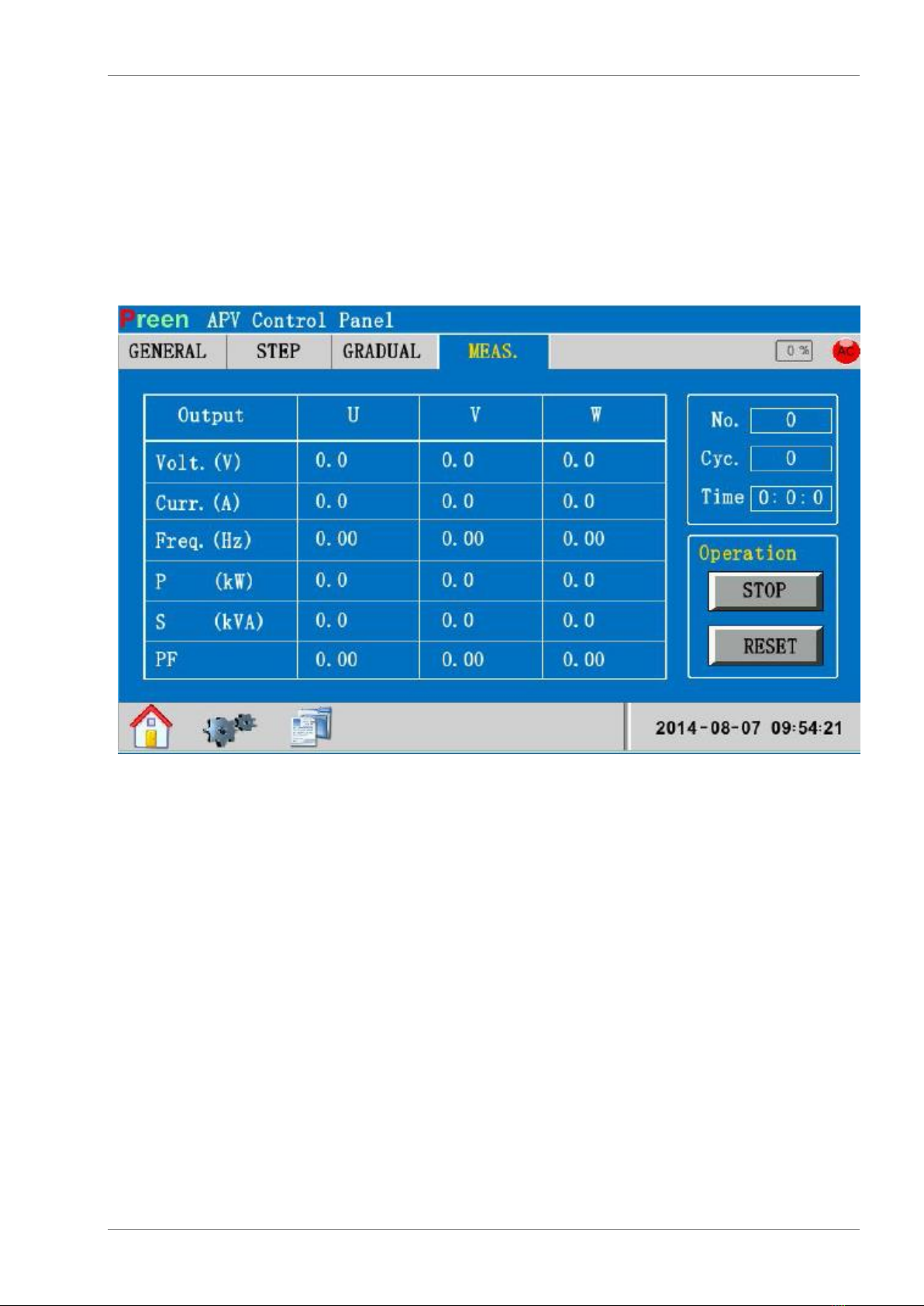

Mode “Meas.“

Operation

The mode “Meas.“ (realtime sampling) is paused after the button STOP was clicked. A click on the button RESET sets

the unit back to its initial state.

Main Menu

12 ET System electronic GmbH

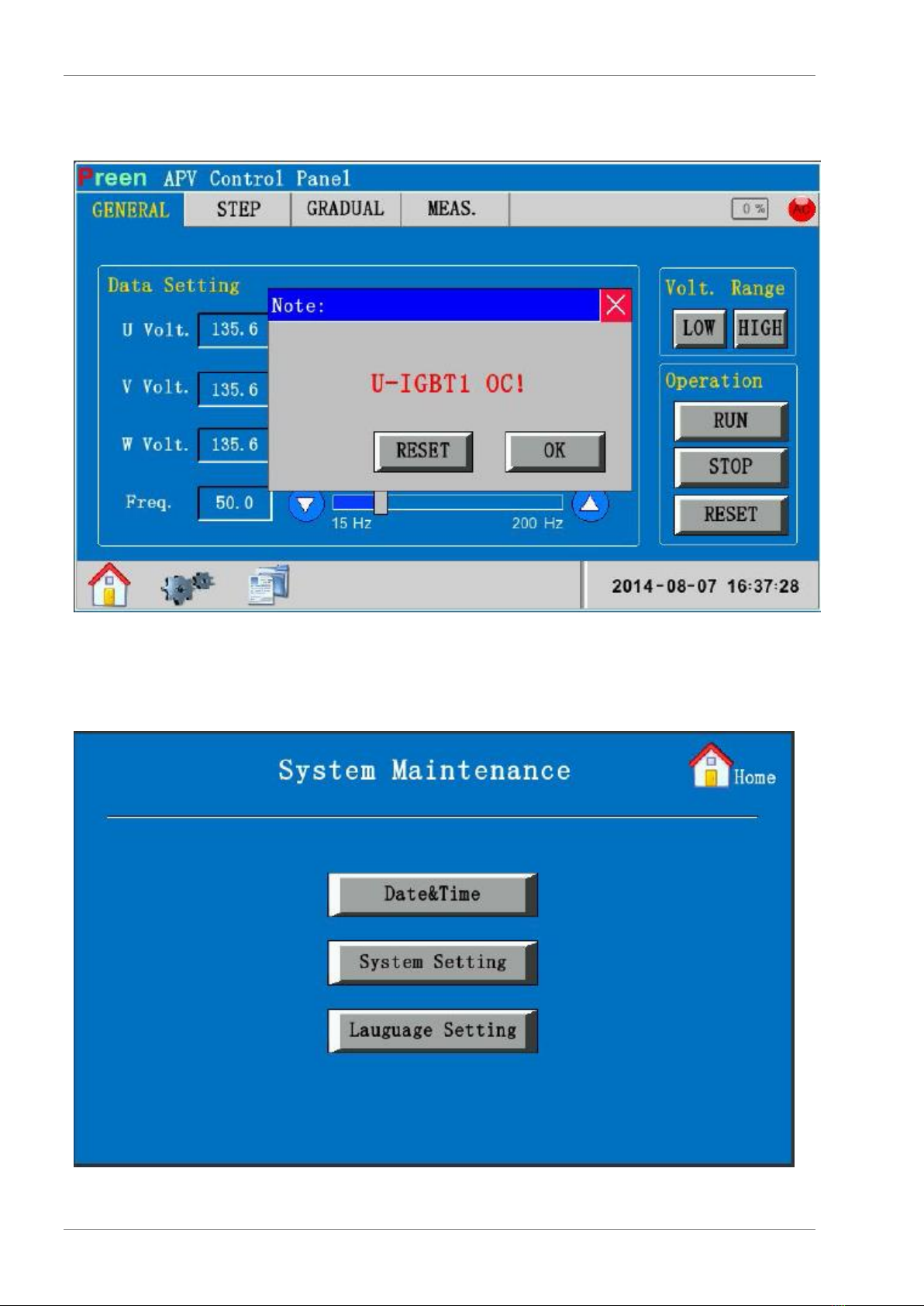

Error Message

Operation

A click on the button RESET resets the error meassage. Clicking OK switches to the previous display.

MENU “SYSTEM“

Main Menu

ET System electronic GmbH 13

Date & Time

Date and time can be entered via keyboard. The button Back saves these settings and switches to the previous menu.

System Setting

System settings may be read but cannot be changed by the user. In case, that adjustments shall be made, please contact

our service.

Language Setting

Adjusts the menu language. The button Back saves these settings and switches to the previous menu.

MENU ”EVENT“

Operation

Clicking on the button Previous/Next browses the unit log. The button Clear deletes all saved protocols. The button

Back saves settings and opens the previous menu.

RS 485 Interface

14 ET System electronic GmbH

RS 485 INTERFACE

COMMAND FORMAT

Ad-

dress

Function

Length

Data Range

CRC Check

Addr

Func

Len

{data}

CRC_H CRC_L

COMMANDS OF FUNCTIONS

Control

0x00~0x0F

Adjustment

0x10~0x1F

Adjustment Data Functions

0x20~0x2F

Data Enquiry

0x30/0x31

Application parameter

0x16~0x17

Command for standard address

0x02

ANSWER COMMANDS

0 x 02

Address

0 x 50

Function

0 x 01

Command length

0 x 00

Status:

00 –Communication on

01 - Timeout Error

02 - Parity Error

0 x 00

CRC Checksumme high byte

0 x 1D

CRC Checksumme low byte

RS 485 Interface

ET System electronic GmbH 15

PROTOCOL EXAMPLES

Command

Function

Command example

Control examples

Operation

0x01

Send command:

0x02 address

0x01 function code

0x02 command length

0x00 0x01 Operation type:

0x01—general mode function operation

0x02—step mode function operation

0x03—gradual mode function operation

0x04—Three-phase voltage independent setting function

0x05/0x06—reserved

0x07—Voltage disturbances run

0x08—Frequency disturbances run

0x09—Voltage and Frequency disturbances run

0x3C CRC Checksum high byte

0x3C CRC Checksum low byte

Answer from unit:

0x02 0x50 0x01 0x00 0x00 0x1D

Stop

0x02

Send command:

0x02 address

0x02 function code

0x00 command length

0xD1 CRC Checksum high byte

Answer from unit:

0x02 0x50 0x01 0x00 0x00 0x1D

Reset

0x03

Send command:

0x02 address

0x03 function code

0x00 command length

0xD0 CRC Checksum high byte

0xF0 CRC Checksum low byte

Answer from unit:

0x02 0x50 0x01 0x00 0x00 0x1D

Remote Control

0x04

Send command:

0x02 address

0x04 function code

0x04 command length

0x00 0x01 Remote control connection: 0-disconnect, 1-connect

0x00 0x01 reserved

0x58 CRC Checksum high byte

0x84 CRC Checksum low byte

Answer from unit:

0x02 address

0x04 function code

0x0A command length

0x00 0x01 operation status: 0-stop, 1-run

0x08 0x98 current output voltage

0x01 0xF4 current output frequency

Output voltage

0x07

Send command:

0x02 address

0x07 function code

0x02 command length

0x00 0x00 Output voltage in high or low segment

0x00—Output voltage in low segment

0x01—Output voltage in high segment

0x3C CRC Checksum high byte

0xB4 CRC Checksum low byte

Answer from unit:

0x02 0x50 0x01 0x00 0x00 0x1D

RS 485 Interface

16 ET System electronic GmbH

Command

Function

Command example

Application Settings

General information (AC)

0x20

Send command:

0x02 address

0x20 function code

0x04 command length

0x08 0x98 current output voltage (220 V x 10)

0x01 0xF4 current output frequency (50 Hz x 10)

0x40 CRC Checksum high byte

0xb9 CRC Checksum low byte

Answer from unit:

0x02 0x50 0x01 0x00 0x00 0x1D

Note: The command RUN has to be send again if voltage or current were

adjusted before.

Adjustment mode “STEP“

0x21

Send command:

0x02 address

0x21 function code

0x0A command length

0x00 0x01 Group number(1-24)

0x08 0x98 output voltage of this group(220V×10)

0x01 0xF4 output frequency of this group(50Hz×10)

0x00 0x00 0x00 0x0A execution time of this group(10second)

0x7C CRC Checksum high byte

0xF1 CRC Checksum low byte

Answer from unit:

0x02 0x50 0x01 0x00 0x00 0x1D

Adjustment mode “GRADUAL“

0x22

Send command:

0x02 address

0x22 function code

0x0E command length

0x00 0x01 Group number (1-12)

0x04 0x4C output voltage of this group (110 V x 10)

0x01 0xF4 output frequency of this group (50 Hz x 10)

0x08 0x98 output voltage of this group (220 V x 10)

0x02 0x58 output frequency of this group (60 Hz x 10)

0x00 0x00 0x00 0x0A execution time of this group (10 Sekunden)

Answer from unit:

0x02 0x50 0x01 0x00 0x00 0x1D

Voltage adjustment 3phase (AC)

0x23

Send command:

0x02 address

0x23 function code

0x08 command length

0x08 0x98 current R-phase output voltage (220 V x 10)

0x08 0x98 current S-phase output voltage (220 V x 10)

0x04 0x4C current T-phase output voltage (110 V x 10)

0x01 0xF4 current output frequency (50 Hz x 10)

0x63 CRC Checksum high byte

0xF2 CRC Checks

Answer from unit:

0x02 0x50 0x01 0x00 0x00 0x1D

Adjustment of application parameters

Mode “STEP“ Loop adjustment

0x16

Send command:

0x02 address

0x16 function code

0x06 command length

0x00 0x01 starting group number of step-mode loop

0x00 0x18 ending group number of step-mode loop

0x00 0xFF loop number

0x09 CRC Checksum high byte

0x31 CRC Checksum low byte

Answer from unit:

0x02 0x50 0x01 0x00 0x00 0x1D

Mode “GRADUAL“ Loop adjustment

0x17

Send command:

0x02 address

0x17 function code

0x06 command length

0x00 0x01 starting group number of Gradual-mode loop

This manual suits for next models

1

Table of contents

Other Et system Power Supply manuals