Et system ELP/DCH Series User manual

1

User’s Manual

ELP/DCH series

PROGRAMMABLE DC ELECTRONIC LOAD

ET System electronic GmbH 2021-06-10 Manual Edition V.2.2

ET System electronic GmbH

2

Content

Contents Introduction.........................................................................................................................................4

Chapter 1 Size and Installation...........................................................................................................................8

1 .1 Dimension ..............................................................................................................................................8

1.2 Installation.............................................................................................................................................10

1.3 Plug in Power Cord ...............................................................................................................................10

Chapter 2 Quick Start.......................................................................................................................................11

2.1 Product Introduction..............................................................................................................................11

2.2 Features .................................................................................................................................................11

2.3 Front Panel ............................................................................................................................................13

2.4 LCD Status Bar Function ......................................................................................................................14

2.5 Rear Panel .............................................................................................................................................16

2.6 First turn-on checkout ...........................................................................................................................16

2.6.1 Self-test Process.....................................................................................................................17

2.6.2 In the Event of a Problem......................................................................................................17

Chapter 3 Functions and Features .......................................................................................................................19

3.1 Basic Operation Modes ......................................................................................................................19

3.1.1 Constant Current Mode (CC)................................................................................................20

3.1.2 Constant Voltage Mode (CV) ................................................................................................21

3.1.3 Constant Resistance Mode (CR)..........................................................................................22

3.1.4 Constant Power Mode (CW) .................................................................................................23

3.2 List Operation........................................................................................................................................24

3.3 OCP Test Function.................................................................................................................................27

3.4 EFFT Function ......................................................................................................................................29

3.5 Auto test function ..................................................................................................................................30

3.6 Dynamic Function .................................................................................................................................35

3.7 Battery test function ..............................................................................................................................39

3.8 Short-circuit Simulation Function .........................................................................................................41

3.9 LED Simulation Function .....................................................................................................................42

3.10 SWEEP dynamic frequency conversion scanning...............................................................................46

3.11 TIMING Time measurement ............................................................................................................48

3.12 DCR DC Resistance Measurement Function ...................................................................................50

3.13 Measurement item ............................................................................................................................52

3.13.1 Voltage, current, resistance and power measurement ...................................................52

3.13.2 Ripple measurement............................................................................................................53

Chapter 4 System settings and Save function......................................................................................................54

4.1 System Settings .....................................................................................................................................54

4.1.1 Von/Voff Function....................................................................................................................55

4.1.2 Source Type Selection Function...........................................................................................56

4.2 Configuration ........................................................................................................................................56

4.2.1 Remote Sense Compensation Mode...................................................................................58

4.2.2 Shortcut Call Mode.................................................................................................................59

4.2.3 Trigger Output Settings..........................................................................................................60

4.3 Save/Recall Function ............................................................................................................................60

Chapter 5 Protection Function.............................................................................................................................62

5. 1 Over-voltage protection (OVP) ............................................................................................................62

5.2 Over-current protection (OCP)..............................................................................................................62

5.3 Over-power protection (OVP)...............................................................................................................63

5.4 Over-temperature protection (OTP) ......................................................................................................63

5.5 Input Voltage Reverse Protection (RV) .................................................................................................64

Chapter 6 I/O Interface........................................................................................................................................65

6.1 I/O Interface .......................................................................................................................................65

6.2 I/O Interface Function ........................................................................................................................65

Chapter 7 Specifications...................................................................................................................................67

7.1 Main Specifications...............................................................................................................................67

Chapter 8 Communication Interfaces..................................................................................................................77

8.1 Communication module ........................................................................................................................77

3

8.2 DB9 .......................................................................................................................................................77

8.3 Protocol .................................................................................................................................................78

8.4 SCPI Communication Instruction .........................................................................................................79

ET System electronic GmbH

4

Contents Introduction

Thank you for purchasing ELP/DCH series DC Electronic Load. To obtain maximum

performance from the product, please read this manual first, and keep it handy for future reference.

We will use the alias E-load of DC Electronic Load in the following.

Registered trademarks

Windows and Excel are registered trademarks of Microsoft Corporation in the United States and/or

other countries.

Checking Package Contents

When you receive the instrument, inspect it carefully to ensure that no damage occurred during

shipping. In particular, check the accessories, panel switches, and connectors. If damage is evident,

or if it fails to operate according to the specifications, contact your authorized Hopetech distributor or

reseller.

When transporting the instrument, use the same packaging materials used for the delivery to you.

Check the package contents as follows

No.

Item

Quantity

1

Electronic Load

1

2

User’s Manual

1

3

RS232 Cable

1

4

Power Cord

1

5

Test Report

1

Safety Notes

The instrument is designed to conform to IEC 61010 Safety Standards, and has been thoroughly

tested for safety prior to shipment. However, using the instrument in a way not described in this

manual may negate the provided safety features.

Before using the instrument, be certain to carefully read the following safety notes.

Note

Mishandling during use could result in injury or death, as well as damage to the instrument. Be certain

that you understand the instructions and precautions in the manual before use.

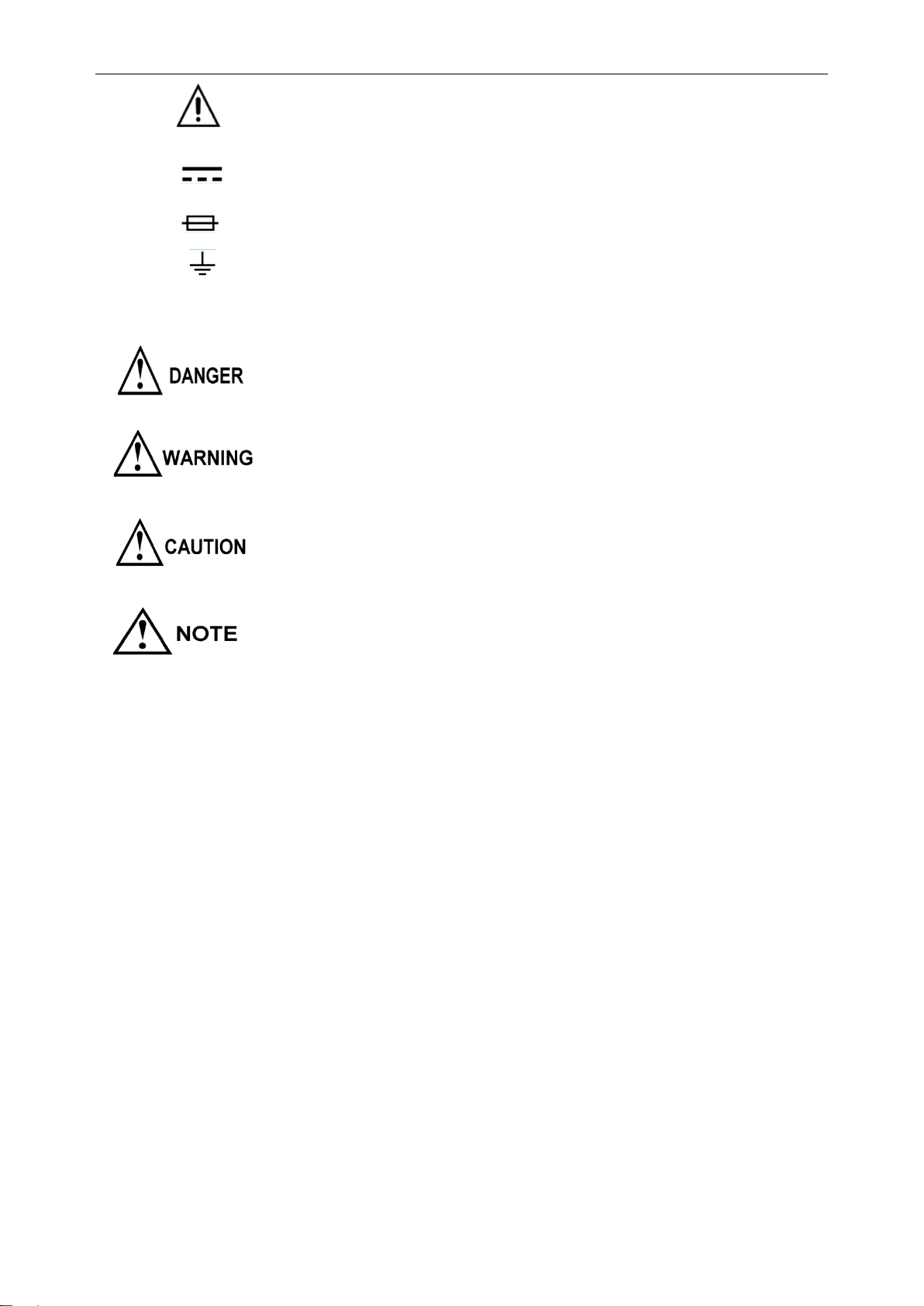

Notation

This manual contains information and warnings essential for safe operation of the instrument and for

maintaining it in safe operating condition. Before using the instrument, be certain to carefully read the

following safety notes.

ET System electronic GmbH

5

Indicates very important message in this manual. When the symbol is printed

on the instrument, refer to a corresponding topic in the Instruction Manual.

Indicates DC (direct current)

Indicates a fuse

Indicates earth terminal

In this manual, the risk seriousness and the hazard levels are classified as follows.

Indicates an imminently hazardous situation that will result in death or

serious injury to the operator.

Indicates a potentially hazardous situation that will result in death or serious

injury to the operator.

Indicates a potentially hazardous situation that may result in minor or

moderate injury to the operator or damage to the instrument or malfunction.

Indicates functions of the instrument or relative suggestion of a correct

operation.

Usage Notes

Installation environment

Operating temperature and humidity range

0°C ~ 40°C,< 80%RH(no condensation)

Storage temperature and humidity range

23 ±5°C,< 80%RH (no condensation)

Installing the instrument in inappropriate locations may cause a malfunction of instrument or accident.

Avoid the following locations.

Exposed to direct sunlight or high temperature

Exposed to corrosive or combustible gases

Exposed to water, oil, chemicals, or solvents

Exposed to high humidity or condensation

Exposed to a strong electromagnetic field or electrostatic charge

Exposed to high quantities of dust particles

ET System electronic GmbH

6

Near induction heating systems (such as high-frequency induction heating systems

and IH cooking equipment)

Susceptible to vibration

Checking before use

Before using the instrument at the first time, verify that it operates normally to ensure that no damage

occurred during storage or shipping. If you find any damage, contact your authorized Hopetech

distributor or reseller.

Before using the instrument, check that the coating of the test leads or

cables are neither ripped nor torn and that no metal parts are exposed.

Using the instrument under such conditions could result in electrocution.

Contact your authorized Hopetech distributor or reseller in this case

Handling Precautions

Do not try to modify, disassemble, or repair the instrument. This may result

in fire, electric shock accident, or injury.

Do not place the instrument on an unstable or slanted surface. It may drop

or fall, causing injury or instrument failure.

This equipment is an electric energy conversion to heat equipment,

blocking the ventilation holes of the equipment will lead to serious

consequences.

Be sure to turn the power off after using it.

Measurement precautions

To avoid electric shock accident and short circuit, please operate the

instrument as following:

Do not test the voltage over 150 VDC

Do not test the terminal-to-ground voltage over 160 VDC.

Do not test AC voltage.

ET System electronic GmbH

7

Be sure to connect the test lead correctly.

Wear gloves of rubber or similar materials during measurement.

For achieving the measurement accuracy, it is recommended that the

equipment should be operated half an hour after power-on.

ET System electronic GmbH

8

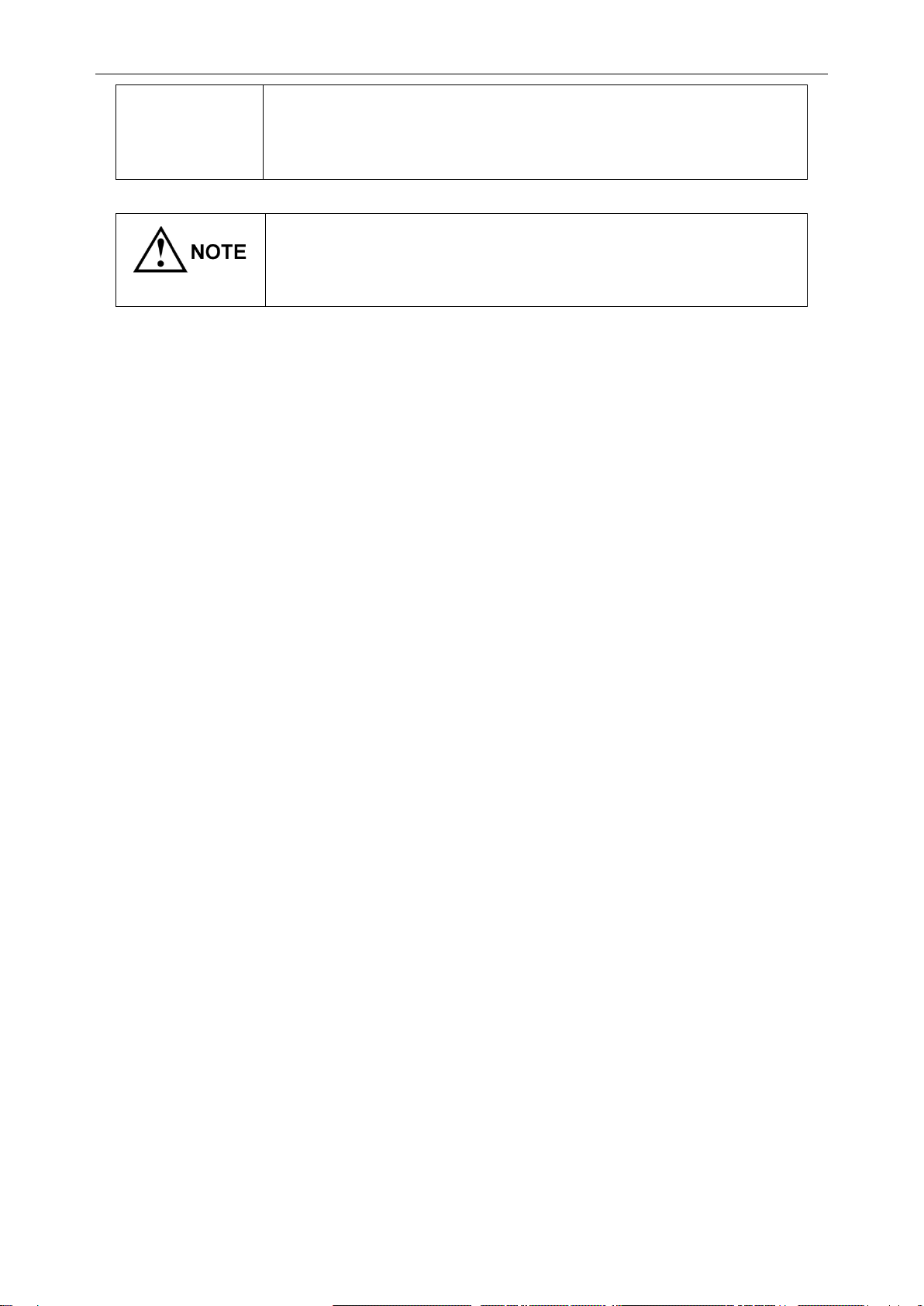

Chapter 1 Size and Installation

1 .1 Dimension

ELP/DCH series electronic load dimension

Figure 1.1 Appearance of instrument

ET System electronic GmbH

9

Figure 1.2 Instrument dimension 1

Figure 1.3 Instrument dimension 2

ET System electronic GmbH

10

1.2 Installation

This instrument is intended for indoor use in a pollution degree 2 environment. Please refer to the

specifications table for the allowable environment operating limits.

Figure 1.6 E-Load outline diagram (unit mm)

There are 2 cabinet mounting holes on the both sides of the E-load. After removing the gap, it can be

used for cabinet installation and positioning.

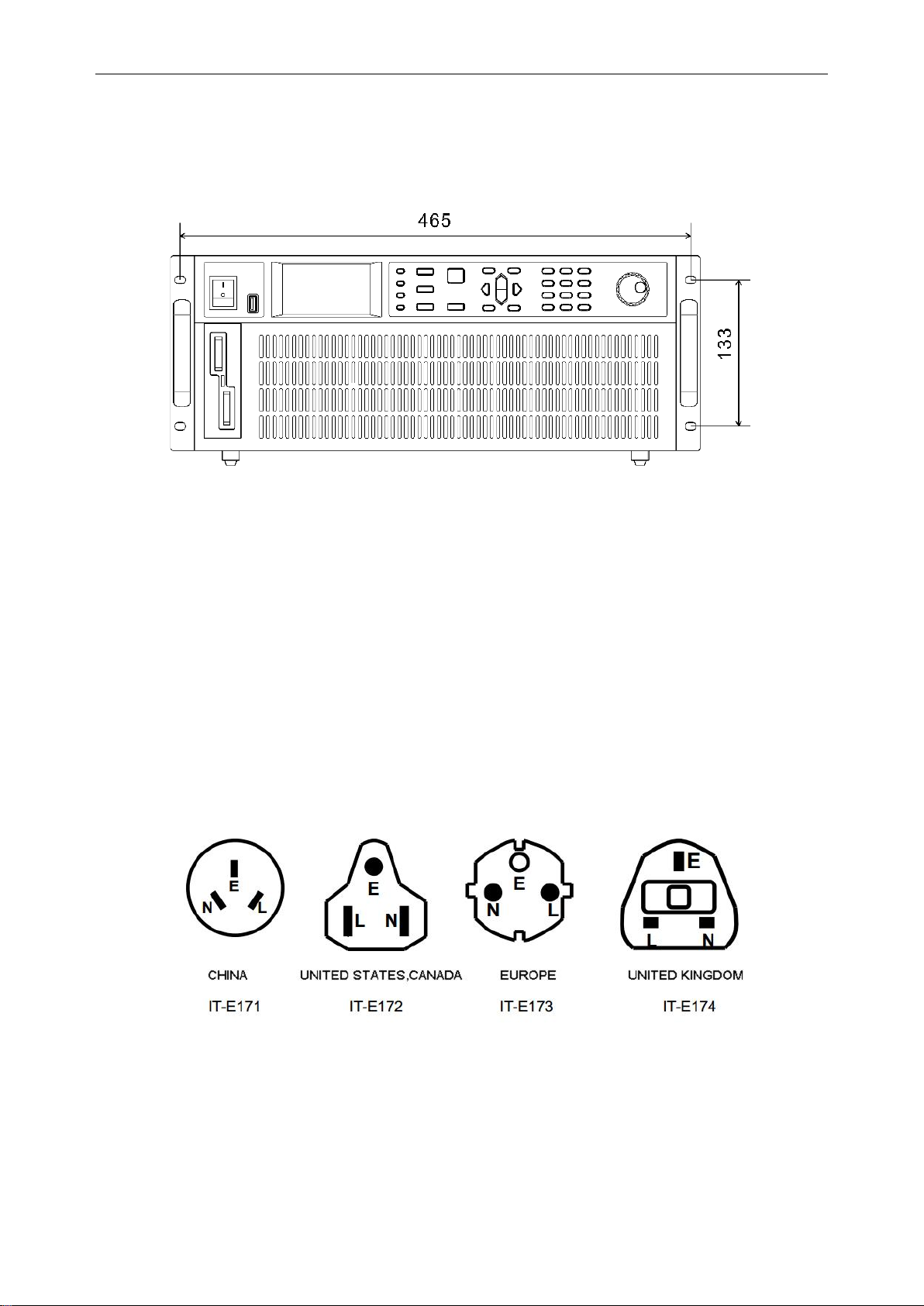

1.3 Plug in Power Cord

Connect an appropriate IEC power cord to the DC Load and plug the power cord into an AC power

outlet. Please find the following power cord type in different countries and areas.

Ensure that the line voltage selector switch on the back panel is set to match your line voltage. Failure

to do so could result in damage to the instrument.

Figure 1.7 4 types of power cord for different countries and area

ET System electronic GmbH

11

Chapter 2 Quick Start

This chapter describes the power-on check procedure for the ELP/DCH Series load to

ensure that the E-load is properly started and used during initialization. It also

introduces the E-load front panel, rear panel, keyboard button functions and LCD

display function to ensure that you can quickly understand the appearance, structure

and button usage of the E-load before operating the E-load.

2.1 Product Introduction

With dynamic, automatic test, LED, List, OCP, EFFECT, battery and short and many other

test functions, ELP/DCH series E-load is mainly used for battery, AC-DC, DC-DC

modules, chargers and electronic components and other product performance testing. It

provides a best solution for design development and production line testing.

ELP/DCH series E-load supports RS232, RS485, and Ethernet communication interfaces

to fit your versatile solution and testing needs.

2.2 Features

1) 24-bit true color LCD display (liquid crystal display), GUI operation interface;

2) 500kHz synchronous sampling, 10Hz, 0.1mV/0.01mA stable resolution output;

3) Four basic function modes:

CV constant voltage mode

CC constant current mode

CW constant power mode

CR constant resistance mode

4)Multiple extended function modes:

LIST mode

ET System electronic GmbH

12

simulate a variety states of load change.

OCP mode

Over current protection point test mode.

EFFECT mode

Load effect test mode.

AUTO mode

5) Actual LED simulation to test LED power.

6) Voltage/current ripple test (Vpp, Ipp );

7) Professional battery test function (BATTERY);

8) Dynamic Test Mode (DYNA);

9) High-speed dynamic frequency conversion scanning function (SWEEP)

10) Short circuit mode (SHORT);

11) Shortcut mode supports 10 sets of global data storage and reading (SHORTCUT);

12) No loading mode (OFF);

13) Support Von and Voff functions;

14) Remote compensation measurement mode (REMOTE);

15) Memory capacity up to 200*8 groups;

16) Intelligent fan system fan automatically initiated activate according based on changing

to the ambient temperatures

17) Built-in Buzzer as an early warning reminder;

ET System electronic GmbH

13

18) Power-off to maintain memory function;

19) USB port upgrade procedure;

20) Electrically isolated communication for I/O interface, RS232/485, NET network port;

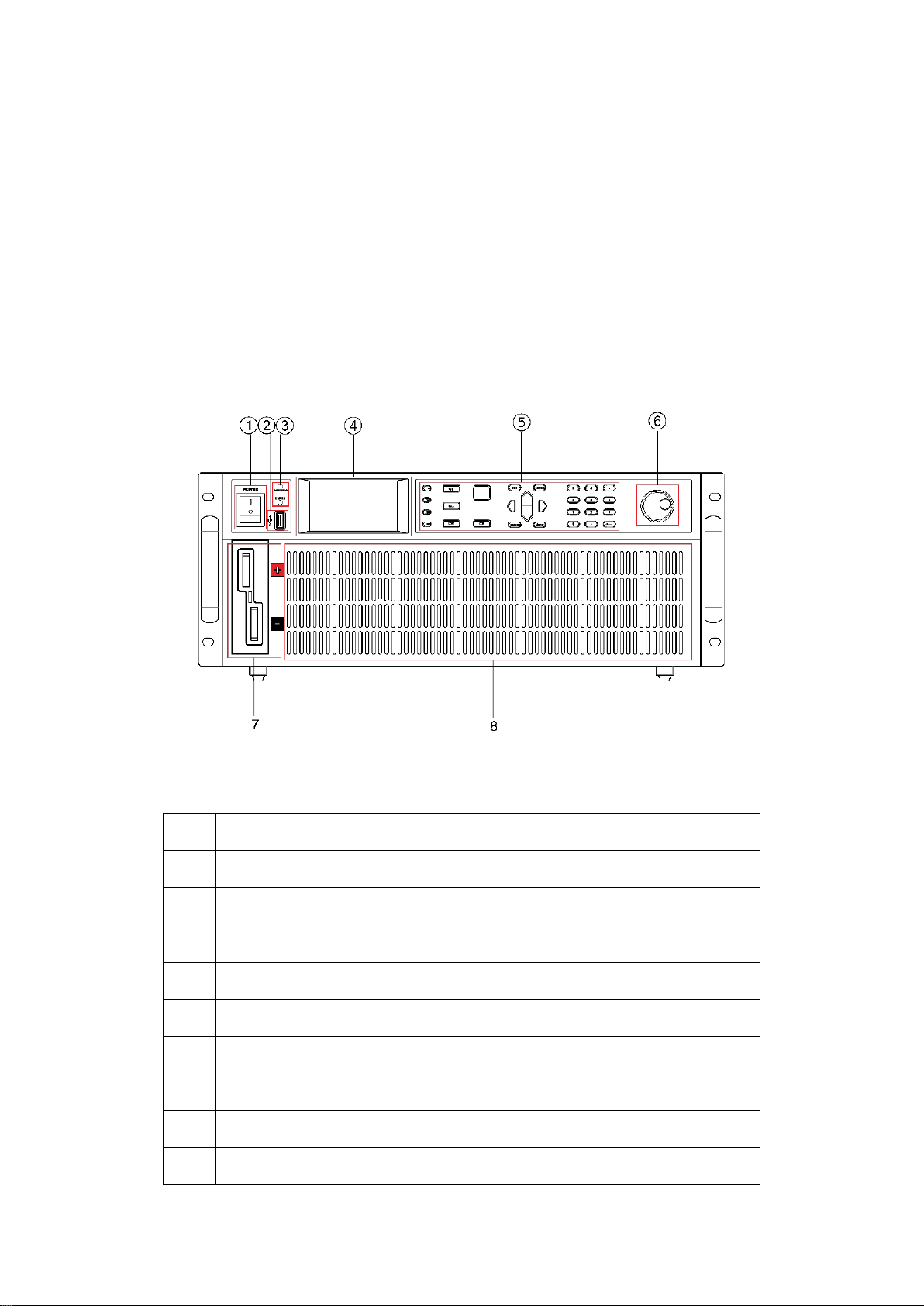

2.3 Front Panel

The following picture is the front panel for the ELP/DCH E-Load. All models have the

same front panel, only the terminal section will vary based on the model.

Figure 2.1 front panel

Item

Description

1

Warning lights for loading failure or other warning states

2

U disk interface

3

Power-up key

4

Function keys

5

E-Load input terminal

6

Operating keys

7

Digital keys

8

Operating keys

9

LCD display panel

ET System electronic GmbH

14

10

SENSE Remote compensation port

Front panel key description

When in the standby state, the panel POWER button light is red,

press the POWER button for 3s, the power is turned on, the screen is

lit, and the panel button light turns green.

In the working mode, press the key SET to set the parameters

corresponding to the mode.

Long press to open/close the keyboard lock;

when the status bar icon is , all other keys are invalid.

When the E-load is in the working mode, press this key to select the

expected load modes.

Press this key to switch the interface between load, system

configuration, system parameter setting and loading the setting files.

In the working mode interface, adjust the cursor position and adjust

the loading value. Move the status bar position on another interface.

Trigger the E-load in specific working mode

Confirm the selected value or enter the setting menu.

Cancellation of operation or moving back to the top menu.

Loading or unloading the load.

4 basic working modes(CV/CC/CW/CR) shortcut keys.

11 digital keys and is backspace key

2.4 LCD Status Bar Function

The following screen is ELP/DCH series E-oad LCD display interface.The status bar is

the top line icons. There are several icons on the status bar in the top line.

ET System electronic GmbH

15

Figure 2.2 LCD interface

Item

Description

1

Instrument operating mode and status bar (described in the below table);

2

Readback value display

3

Present loading value edit box

4

E-load protection limit setting

5

E-load conversion parameter value display

Status bar icon description

The remote compensation function is turned on.

Through the SENSE port at the rear panel of E-load, the output

voltage of the power supply under test is collected.

Using remote sensing, you can sense the voltage at the power

supply's terminals, effectively removing the effect of the voltage drop

in the connection wire.

Loading automatically while start setup voltage > VON voltage

Stop loading while shutdown voltage < Voff voltage

Shortcut mode is on

Keyboard lock.

Icon is , keyboard locks, long press to unlock.

ET System electronic GmbH

16

means E-load connecting to the PC, it is allowed to Send

commands on the PC to perform related operations on the E-load.

2.5 Rear Panel

The following picture is the rear panel for the ELP/DCH E-load.

Figure2.3 Rear panel

Item

Description

1

Cooling holes

2

0 to full-scale current, corresponding to 0-10V output, can be connected

to the oscilloscope

3

Hardware Power button

4

Power inlet ( AC 100~240V input)

5

LAN communication port

6

SENSE port for voltage sense compensation

7

DB9 communication interface, RS232/485

8

I/O interface connector, this I/O interface need to be powered by external

power

2.6 First turn-on checkout

The successful self-test process indicates that the E-load meets the factory standards and

ET System electronic GmbH

17

can be used by the user normally. Before operating the E-load, make sure you understand

the safety instructions.

Ensure that the line voltage selector switch on the back panel is

set to match your line voltage. Failure to do so could result in

damage to the instrument.

Connect an appropriate power cord to the E-Load and plug the

power cord into an AC power outlet. Ensure that nothing is

connected to the INPUT terminals.

Before operating the E-load, ensure it is well grounded.

To prevent damaging the E-load, please pay special attention to

positive and negative polarities of E-load during connection!

2.6.1 Self-test Process

The standard E-load self-test process is as follows:

1) Connect an appropriate IEC power cord to the E-load and plug the power cord into an

AC power outlet. Press the hardware power button at the back panel. At this time, soft

power switch button lights up red in the front panel, long press the soft power switch to

power on the instrument.(if the E-load using soft power switch button)

2) After the E-load initialization completed, the LCD display shows the working mode

information.

Figure 2.4 CV Work mode interface

2.6.2 In the Event of a Problem

If the E-load fails to power up, the following troubleshooting steps will help you to solve the

ET System electronic GmbH

18

problem.

1. Make sure the power cord is connected properly and the power switch has been

pushed in to ON.

Go to step 2 ---- when the power cord is well connected

Back to step 1----- when the power cord is wrongly connected

2. Check the hardware Power button at the back panel in ON state and the soft Power

Switch at the front panel is lit red.( if the E-load using soft power switch button )

Go to step 3--- YES

Press the Power button to turn on the instrument and to see if the exception is

cleared------NO.

3. Check whether the voltage of power supply is larger than the rated voltage of the

equipment.

ET System electronic GmbH

19

Chapter 3 Functions and Features

This chapter will introduce functions and features of ELP/DCH E-load in the following

sections:

Basic operation modes

LIST function

OCP over current test function

EFFT load effect test function

AUTO automatic test function

DYNA dynamic test function

BATT battery test function

SHORT short-circuit simulation function

LED load simulation function

SWEEP dynamic frequency conversion scanning function

TIMEING time measurement function

DCR DC resistance measurement function;

Measurement items

3.1 Basic Operation Modes

The E-load has four basic modes:

1) Constant current mode (CC)

2) Constant voltage mode (CV)

3) constant resistance mode (CR)

4) Constant power mode (CW)

ET System electronic GmbH

20

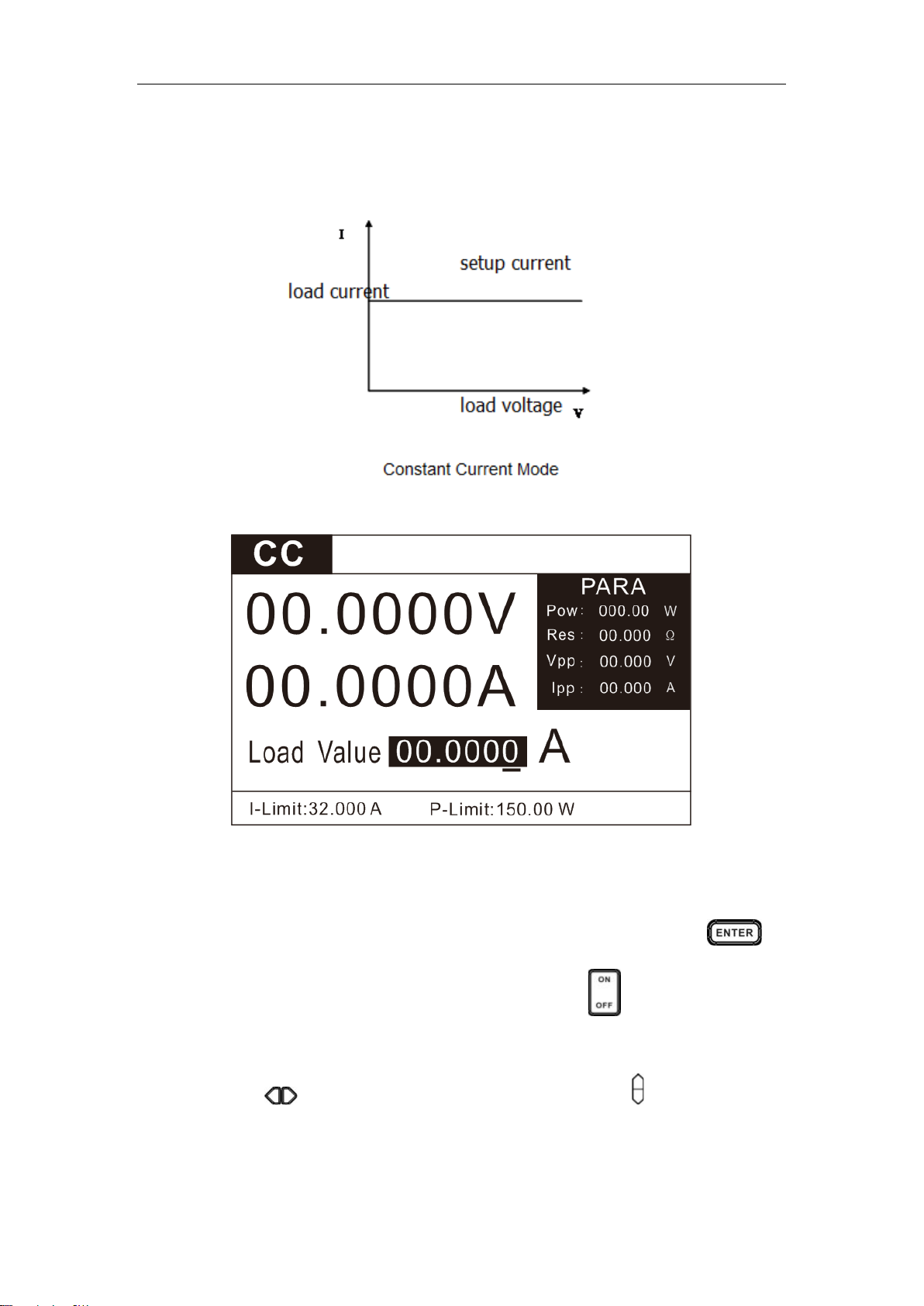

3.1.1 Constant Current Mode (CC)

In constant current mode, the DC E-load will sink a constant current, regardless of the

voltage of the source. See the figure below.

Figure 3.1 CC mode

In CC mode, the E-load provides two methods to set the constant current value.

1) In CC mode, use the numeric keys to input the current value, press the key to

confirm the setup constant current value, and press the key to load or unload the

source.

2) Press the key to move the cursor position and press the key to adjust the value

at the corresponding position.

ET System electronic GmbH

This manual suits for next models

18

Table of contents

Other Et system Power Supply manuals