Et system MD2010 User manual

MD2010

METAL LOOP DETECTOR

Sensing loop position:

A safety loop should be positioned where the largest amount of metal of the vehicle will be present

when that vehicle is in the path of the moving gate, door or boom pole. Be aware that metal gates,

doors or poles could activate the loop detector if they pass within range of the sensing loop.

A free exit loop should be positioned +/ one and a half car lengths away from the gate, door or

boom pole, on the approach side for traffic exiting.

In cases where more than one loop is installed ensure there is at least 2m between the sensing loops

to prevent cross talk interference between the loops. (Also see Dip switch 1 option and number of

turns around the loop below)

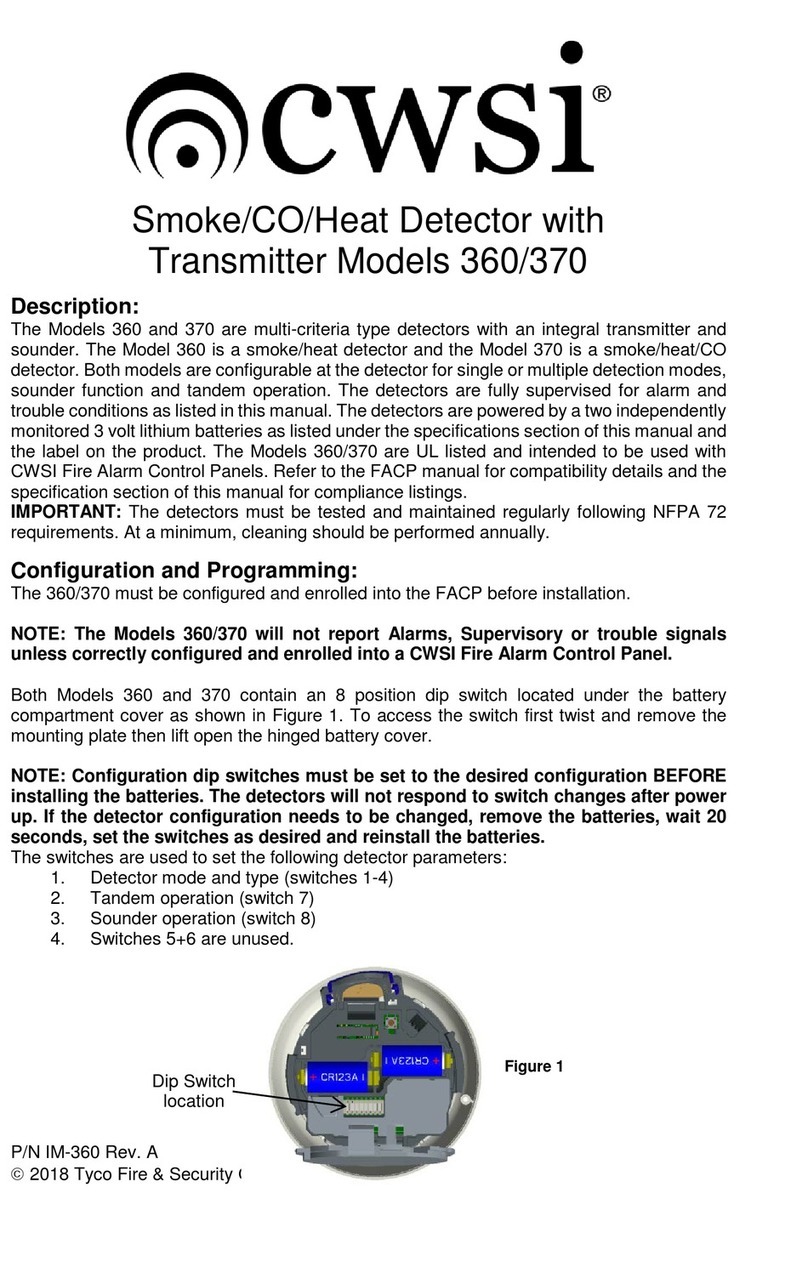

Sensing loop dimensions and shape :( Figure 1)

A square or rectangular slot of +/ 4mm should be cut into the road surface 30 – 50mm deep.

The recommended minimum distance between either of the parallel sides is 1m.

Cross cut the corners by 45º to prevent damage to the cable as it passes around the corners.

The feeder slot will need to be wider to allow for the required twisting of the feeder.

Sensing loop wire:

Single length copper “Panel Flex” (Stove wire)

Silicone insulated

Minimum cross section 1.5mm

2.

Joints in the wire are not recommended. If made they should be soldered and weatherproofed

sufficiently.

Number of turns around the loop:

Loop circumference 7 10m 3 turns

Loop circumference >10m 2 turns

Loop circumference < 7m 4 turns

In cases where 2 loops are adjacent to each other, use 3 turns in one and 4 turns in the other to help

prevent cross talk interference.

Detector position and installation:

Install the detector in a weatherproof housing.

The detector should be as close to the sensing loop as possible.

Installation summary:

Run the single length of wire from the detector, around the loop 3 times (see “Number of turns of loop” above)

and then back to the detector. The 2 ends running to the loop and returning from the loop of the same length

of cable is known as the feeder and must be twisted together 20 – 30 times per meter. The twisting will shorten

the feeder, so allow excess cable when starting out from the detector and on the return from the loop.

MD2010

METAL LOOP DETECTOR

Once complete, seal the loop slots with epoxy compound or bitumen filler. (It is recommended this is only done

after the detector has been connected and tested).

Outline of the Dip-switch setting options:-

Please note: The MD2010 ust be reset (Dip 9 below) every ti e a setting change is ade to the

dip-switches.

On initial power up the detector will also reset.

Dip-switch 1 – Freq. (Frequency):-

This setting is used in cases where two or more loop detectors and sensing loops have been installed. (The

sensing loops and detectors should be positioned at least 2m apart). Set one detector to HI frequency and the

other set to LO frequency to minimize the effects of crosstalk between the two systems.

OFF = Low frequency

ON = High frequency

Dip-switch 2 and 3 – Sensitivity:-

This setting determines the necessary change to the loop frequency to trigger the detector, as

metal passes across the sensing loop area.

2 OFF and 3 OFF = Low sensitivity 1% of loop frequency

2 ON and 3 OFF = Low to Mediu sensitivity 0.5% of loop frequency

2 OFF and 3 ON = Mediu to High sensitivity 0.1% of loop frequency

2 ON and 3 ON = High sensitivity 0.02% of loop frequency

Dip-switch 4 - Boost ode:-

If boost mode is ON the detector will immediately switch to high sensitivity once activated.

As soon as the vehicle is no longer being detected the sensitivity reverts back to what has been set on

dipswitch 2 and 3.

This mode is used when the height of the undercarriage of a vehicle increases as it passes over the sensing

loop.

OFF = No boost active

ON = Boost ode active

Dip-switch 5 – Per anent presence or li ited presence ode:- (When presence ode selected.

See dip-switch 8)

MD2010

METAL LOOP DETECTOR

This setting determines how long the relay remains active when a vehicle is stopped within the sensing loop

area.

ON = Per anent presence ode. The relay will remain active for as long as a vehicle is detected within the

sensing loop area. When the vehicle clears the sensing loop area, the relay will deactivate.

OFF = Li ited presence ode. With li ited presence mode on the detector will only activate the relay for 30

in.

If the vehicle has not moved out of the loop area after 25 in, the buzzer will sound to alert the user that the

relay will deactivate after another 5 min. Moving the vehicle across the sensing loop area again, after the relay

has deactivated, will re activate the detector for 30 min.

Dip-switch 6 – Relay Response (when):- (Pulse ode only. See dip-switch 8)

This setting determines when the relay will activate.

OFF = PULSE ON DETECT. Relay activates immediately the vehicle is detected in the sensing loop area.

ON = PULSE ON UNDETECT. Relay activates immediately the vehicle leaves the sensing loop area.

Dip-switch 7 – Filter:-

This setting provides a 2 sec delay between when the metal object is detected and when the relays activate.

This option is used to prevent false activations when small or fast moving objects pass through the loop area.

This option can be used where an electric fence nearby is the cause of false activations.

If the object does not remain in the area for 2 sec the detector will not activate the relays.

Dip-switch 8 – Pulse ode or Presence ode:-

This setting determines how the relay responds to a vehicle standing still within the sensing loop

area.

ON = Presence ode. Relay will remain active, as per dip switch 5 selection, for as

long as a vehicle is within the loop sensing area.

OFF = Pulse ode. Relay will activate for 1 sec only on entry or exit of sensing loop

area as set by dip switch 6. To re activate the vehicle must leave the sensing area

and re enter.

Dip-switch 9 – Reset:-

Please note: The MD2010 ust be reset every ti e a setting change is ade to the Dip-switches!

To reset, switch Dip switch 9 on for approximately 2 seconds and then off again. The detector then completes

the loop test routine.

Relay status:

Relay Vehicle Present No vehicle present Loop faulty No Power

N/O Closed Open Closed Closed

Presence

mode N/C Open Closed Open Open

N/O Pulses closed 1

sec. Open Open Open

Pulse mode

N/C Pulses open 1 sec.

Closed Closed Closed

On power up or reset the following will occur:

Ensure the sensing loop area has been cleared of all loose pieces of etal, tools and vehicles

before powering up or resetting the detector!

Detector auto tests the sensing loops:

MD2010

METAL LOOP DETECTOR

Faulty loop – Open loop or loop frequency below 20Khz:

Fault LED - 3 flashes, 3 sec pause, 3 flashes, 3 sec pause.........this continues until the faulty loop is

corrected and the detector is reset.

Buzzer - 3 beeps, 3 sec pause, 3 beeps, 3 sec pause.......repeats five times and then silences.

■

If the loop circuit is continuous (measure with continuity meter) then increase the loop

frequency by adding more turns of wire.

Faulty loop – Short circuited or loop frequency above 120Khz:

Fault LED – 6 flashes, 3 sec pause, 6 flashes, 3 sec pause ..........this continues until the faulty loop is

corrected and the detector is reset.

Buzzer – 6 Beeps, 3 sec pause, 6 beeps, 3 sec pause..........repeats 5 times and then silences.

■

If there is no short circuit in the loop circuit then reduce the number wire turns around the

loop to reduce the loop frequency.

Good loop:

All three the Detect LED, Fault LED and the buzzer will beep/flash (count) between 2 and 11

times to indicate the loop frequency.

■

1 Count = 10Khz

For example; 3 counts x 10Khz = Loop frequency of 30 – 40 KHz.

Buzzer and LED indications after initial power up/reset:

1 sec flashes 1 sec apart No vehicle (metal) detected in loop area.

On permanently Vehicle (metal) detected in loop area.

3 flashes 3 sec apart

Loop w ire is open circuit. Use Dip sw itch 9 after

any corection is made

6 flashes 3 sec apart Loop w ire is short circuited. Use Dip sw itch 9 after

any corection is made

Tone as long as vehicle

is in loop area Buzzer sounds to confirm the first ten detections

Continuous tone w ith no

vehicle in the loop area

Loose w iring in loop or pow er terminals.

Use Dip sw itch 9 after any correction is made.

Detect LED -

Fault LED -

Buzzer -

0860 109 238

Table of contents