General Notes

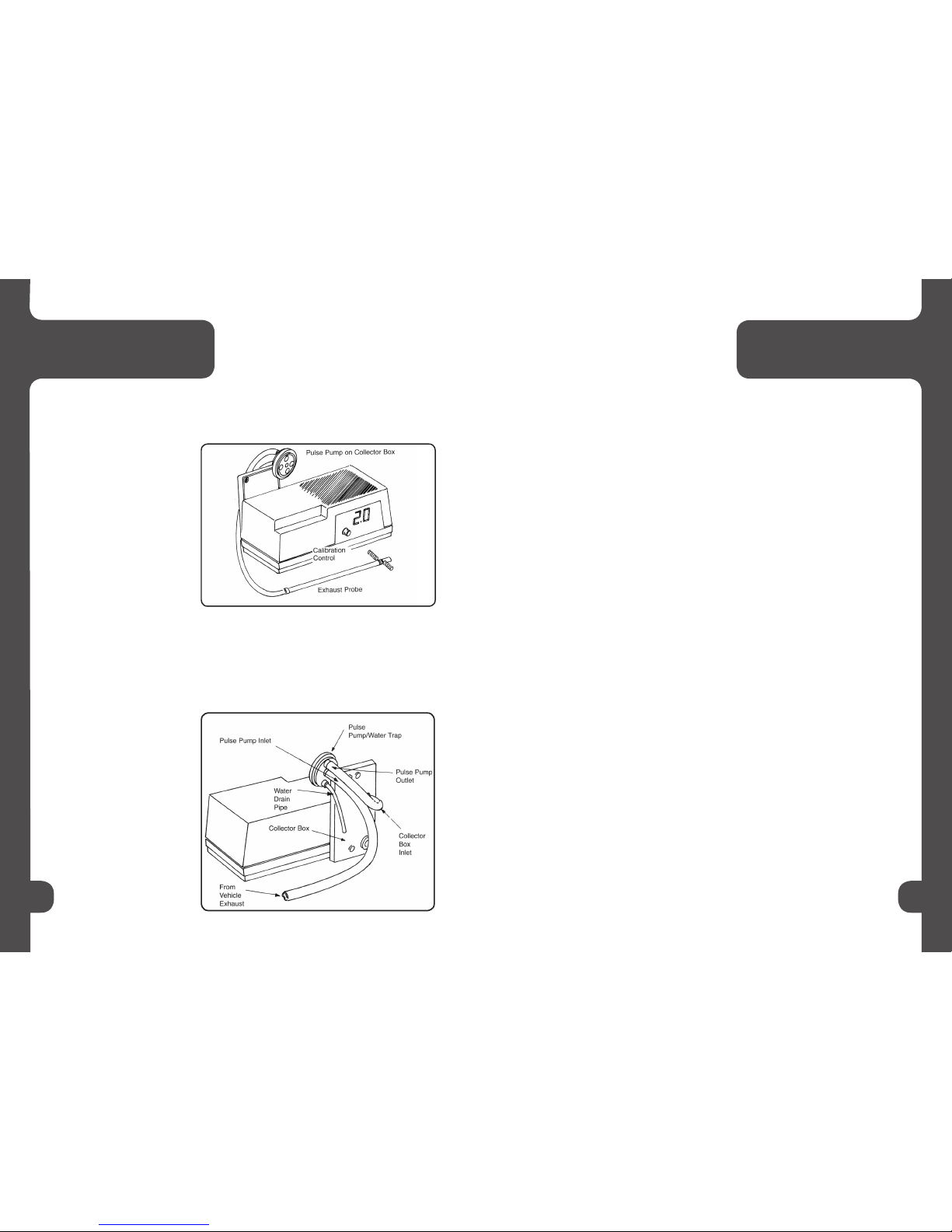

• During testing, check the exhaust sample pipe (from the probe) for any signs of water build

up that will reduce the flow of exhaust gas. Remove any build up of water as soon as it is

seen. If the transparent pipe falls continuously from the exhaust to the pump the automatic

drain should operate and keep the pipe clear of water. Operation of the pulse pump will

usually be audible as the pulsations in the exhaust cause the internal diaphragm to vibrate. If

the instrument ceases to respond to changes in mixture setting or the sound from the pulse

pump becomes irregular, check the sample pipe for collected water.

• It should be noted that engines not fitted with catalytic convertors, even in good overall

condition, will show a fluctuation in idle CO over a period of time, of typically 0.5%. Bearing

in mind this fluctuation, and also errors and drift in the instrument, the user should aim to set

the average CO reading to be midway between the limits set by the manufacturer, or at a

reasonable margin below the prescribed legal limit.

• Calibration of the instrument may be checked at any time. Simply remove the exhaust probe

and wait at least ten minutes in fresh air, for the exhaust gas to disperse from the collector

box. If necessary, the calibration may then be adjusted using the calibration control knob.

• It is advised to periodically check the calibration of the instrument during particularly

extended tests.

• Some older engines will not readily tick over at idle speeds for long periods. The speed may

become erratic, and engine misfiring may occur. With the prolonged testing of such engines,

it may be necessary to occasionally purge the engine by, for instance, increasing the speed

to 2000 rpm - 3000 rpm for 15 seconds. This may be done at any time during the tests but

the exhaust probe should be removed beforehand.

• For engines fitted with a catalytic convertor if the catalyst is in good working order and fully

up to temperature the reading should be less then 0.5% if it is higher than this then either

the catalyst is not up to temperature, internally fouled, has failed or the engine is running

excessively rich.

• If the exhaust pipe has a curved inlet it may be necessary to slightly bend the metal exhaust

probe to give better fit. Avoid kinking the pipe and restricting the flow. Full insertion of the

exhaust probe is essential for accurate readings.

• Use only a 12 volt car battery in good condition as power supply. A faulty or flat car battery

may not be able to supply adequate current to the instrument (Gastester draws about 0.8

amps), resulting in errors in use and difficulty in calibration.

Q. The car does not drive well with the correct idle mixture setting.

A. This is a common complaint. On older vehicles the cause is likely to be a fuel system fault

which creates a weak mixture just above idle speed. Clean the idle jet and idle air bleed jet

on fixed choke carburettors. Check for needle/jet wear on variable choke carburettors (above

40,000 miles). These are available as spare parts. Check acceleration enrichment device.

Q. The correct mixture setting cannot be achieved/setting is continually too rich.

A. Clean the idle air bleed jet and air passage on fixed choke carburettors. Check for severe

needle jet wear on variable choke carburettors. Check for high fuel level in the float chamber.

Check cold start device.

Q. Setting is continually too weak.

A. Clean the idle jet on fixed choke carburettors. Check needle and jet for disengagement from

adjusting device or sticking on variable choke carburettors. Check for air leaks.

Q. The engine misfires or is unstable at idle with the correct mixture setting.

A. Misfire/engine instability causes increase in HC reading and potential emission test failure

even with correct CO level. Check for general engine condition – compression pressures,

sparking plugs etc. Check for air leaks, these may cause severe variation in mixture between

cylinders. Investigate mixture quality i.e. fuel air mixture may not be finely atomized due to

partially blocked air jets or prematurely feeding main jet system caused by high float chamber

level etc. Check for advanced ignition timing, tight valve clearances, slow idle speed

Q. The mixture setting drifts

A. Check for leaking float chamber needle valve if CO level steadily increases with prolonged

idle. Check for high float chamber level. Check Gastester CALIBRATION in air, slight drift

will occur during extended operation. Good stability should be obtained over a period of five

minutes or more. A variation of, for example 0.5% CO at ¬ CO is not uncommon on an engine

which is in good working order.

Q. Gastester gives errors or slow/no response to mixture changes.

A. Check for water in the probe pipe and adequate probe insertion; minimum 8 inches/20 cm. If

a baffled silencer with no tailpipe is fitted, as on some motorcycles, temporary restriction of

the exhaust outlet or temporary fitting of a tailpipe extension may be the only way to achieve

acceptable results.

Note: In use the pipe from the exhaust probe should preferably slope down continuously

to the Pulse Pump/Water Trap so that water runs down and may be automatically

expelled from the drain pipe. Operation of the pulse pump is clearly audible as the internal

diaphragm vibrates with pulsations from the exhaust, if response is obtained at higher

than idle speeds only, Pulse Pump may need replacement. (Alternatively twist the pump

cap on the body to re-seat the diaphragm). If the pump is working, the vehicle mixture

adjustment may be ineffective.

Q. Gastester Professional cannot be set to the Calibration Condition in air after warm-up.

A. First check that the unit is switched correctly to CO range and is used in a horizontal position

(the unit will not operate correctly if instrument is significantly inclined or if the instrument

angle is changed after calibration). Ensure that the unit is connected to a car battery

(NB: a 12v dry cell battery or a faulty car battery can not provide enough current and are

unsatisfactory). Ensure that the unit is correctly warmed up (allow at least 10 minutes).

8 9

6. Further Information 7. Common Problems