4

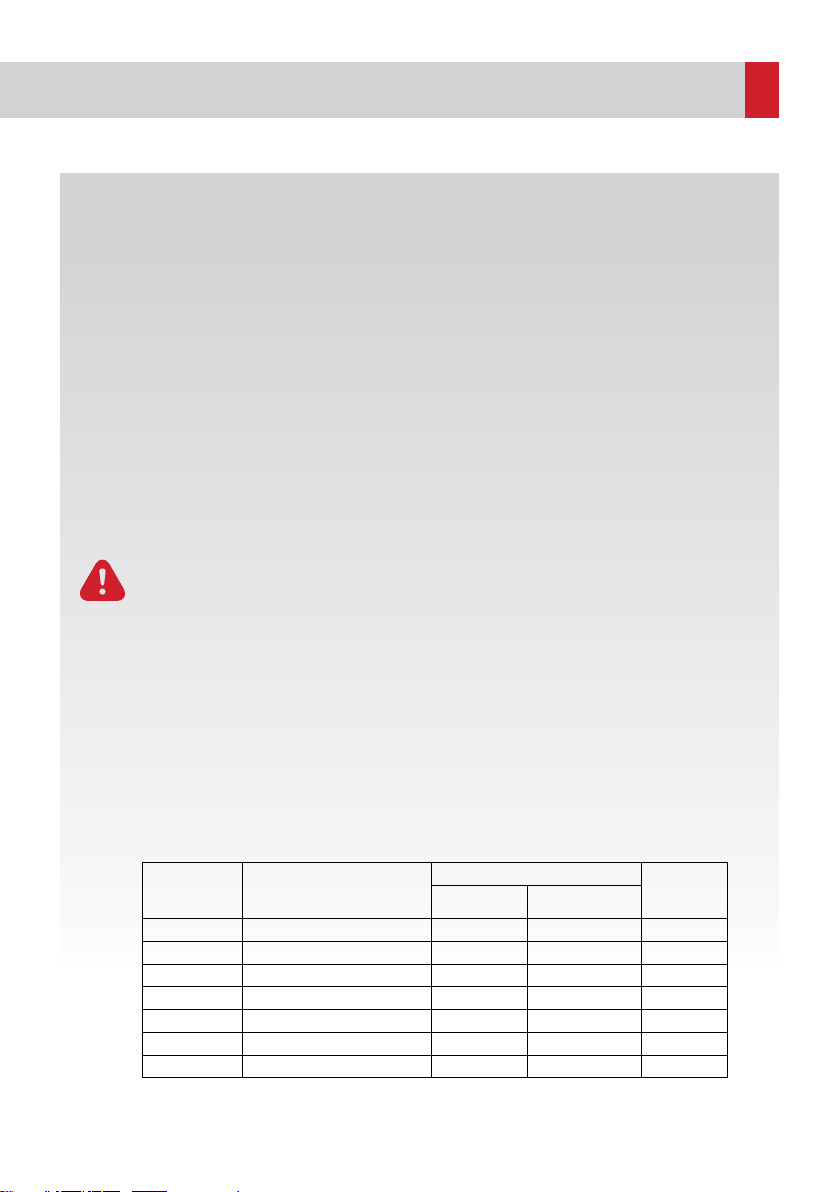

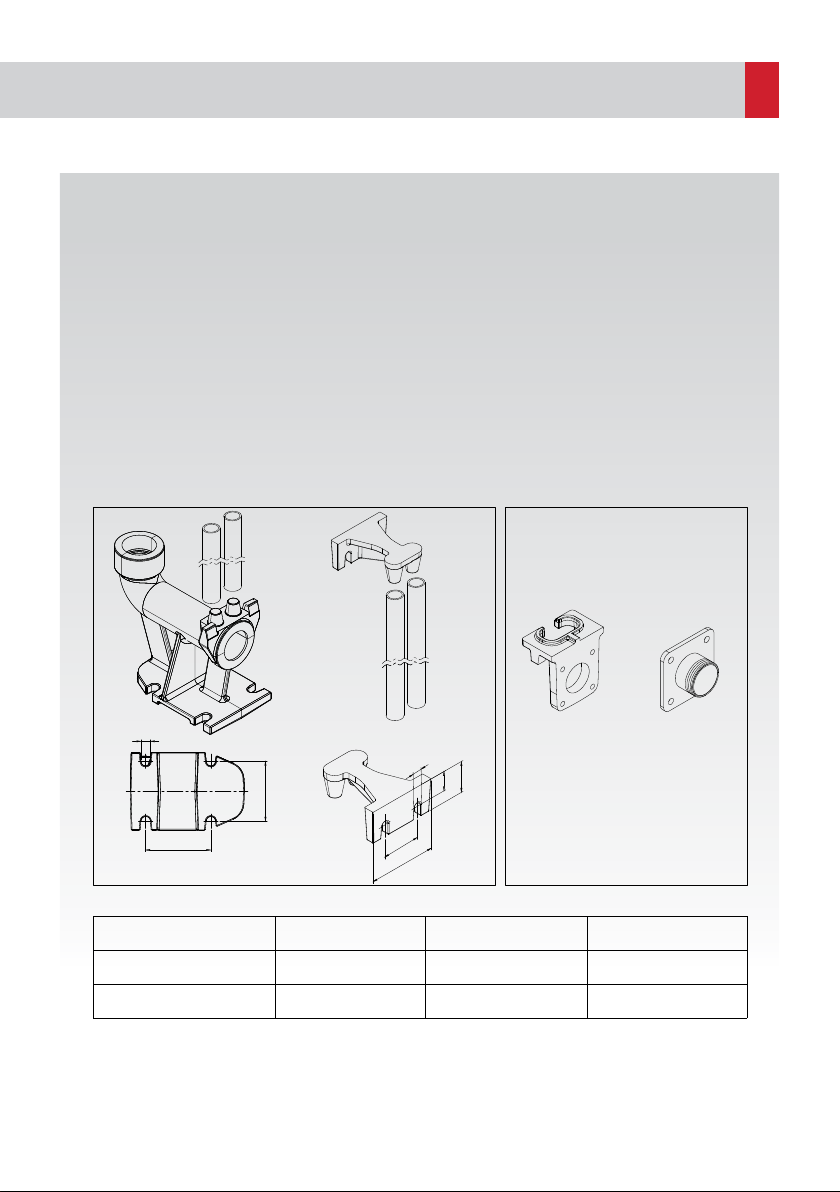

Fxed Installaton wth Sledge (Fgure 2)

• Fx the bottom secton of the sledge to the tank base as shown.

• Cut two 3/4" stanless ppes accordng to the dstance between the top secton of the

sledge and the fxed secton of the sledge and nstall (Fgure 4, Fgure 5).

• Mount the pump sledge flange and the connecton parts (Fgure 6). Attach a chan or a

rope to the handlng rng of the pump, slde the pump downwards from the sledge and

place t on the bottom part of the sledge.

• Connect the check valve and the valve to the horzontal secton n order to facltate access

to the dscharge ppe.

• Ths wll enable pump mantenance whle keepng the dscharge ppe connected to the

nstallaton

8. Troubleshootng

The motor starts runnng but the pump does not transfer: Make sure that water level s not

very low and the sucton nozzle or the dscharge ppe s not clogged.

If the transfer of the pump s reduced: Check for blockages and check the accuracy of the

rotaton drecton on the three-phase models.

If the pump runs ntermttently:

- The floater swtch adjusted wrong.

- The contaner of the pump s very small.

- The current wthdrawn from the electrcal panel s hgh.

- The pump or the ppes are clogged.

9. Nose

If the pump runs partally under water, the nose level should be less than 70 db(A), but ths

value s not applcable when the pump runs completely under water.

10. Installaton

The nner dameters and the szes of the ppes should allow flow. The water speed should be

hgher than 0.8-1m/sec n horzontal ppes, 1.6.m/sec n case of sand and floatng substances

and hgher than 2.5m/sec n vertcal ppes to prevent any possble blockage. The dscharge

ppe should never be smaller than the pump dscharge dameter. The vertcal ppe sectons

should be lmted and the horzontal ppe sectons should be slghtly nclned n the drecton

of the flow to prevent any depost that may cause the pump to stop.

The pump should be held from ts handlng rng whle beng lfted or moved, and never be

lfted from ts cables snce ths may damage the pump. (Fgure 1) The maxmum mmerson

dept (ncludng the cable) should be 5m for EFP 11 and 10m for EFP 22 and EFP26.