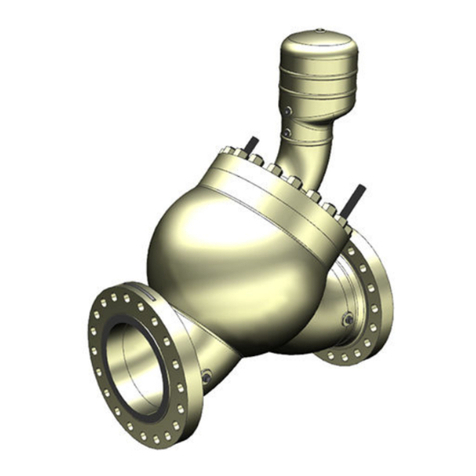

ETP 904-2

ETP HYDRO-GRIP TYPE GEW2

diameter 40 mm and length -135, -170, -240 mm

diameter 50 mm and length -55, -135, -170 mm

Assembly instructions

1. The tool and the ETP HYDRO-GRIP GEW2 must be thoroughly cleaned, removing all traces

of grease and other impurities. Coat the ETP HYDRO-GRIP GEW2 lightly with an anti-

moisture spray.

2. Place the pre-balanced cutter and spacers onto the HYDRO-GRIP GEW2.

3. Place the safety ring (A) onto the GEW2 arbor. Tighten the ring nut (B) by hand very lightly

until the nut, safety ring and the tool are in contact with each other. DO NOT tighten the allen

screws (D) at this stage.

4. Remove the dust cap (C) and then pressurize the hydraulic arbour until you feel that the tools

are centred.

5. Tighten the allen screws (D) in the ring nut and make sure that they are tightened evenly one

turn at a time and to 8Nm (6 lbs).

6. Tighten the pressurizing screw max 7 Nm (5.2 lbs) by using an allen T-wrench. DO NOT

OVER TIGHTEN the pressurizing mechanism. Any further turns will not increase the pressure

but may result in a damage mechanism.

7. Place and tighten the dust cover cap (C), making sure that the sealing is not damaged.

8. The complete tool set is now ready for grinding and balancing. Check the balance of the

complete unit i.e. cutterhead with GEW2 arbor. The balance grade is Q2,5 as per EN 847-1.

9. The complete unit, tool with GEW2 arbor is now ready to be installed in a Powermat machine.

Disassembly instruction

1. To disassemble the tool and GEW2 unit you simply remove the dust cover cap and release

the pressure by using the allen T-wrench. Loosen the three locking screws and remove the

ring nut and the safety ring. The tool and spacers can be removed from the GEW2 arbor.

Safety instruction

Pay special attention: that the mounting handle (an additional accessory item) is removed from the

GEW2 before starting the machine.

Note: Always check that all screws are tightened between either sharpening/ usage of the complete

tool set. Always check the balance each time you have changed tools on the arbor.

Publ. 2021-03