Metasys NCM 200 Series User manual

Metasys Network Technical Manual 636

Control Modules Section

Technical Bulletin

Issue Date 1297

© 1997 Johnson Controls, Inc. 1

Code No. LIT-636025

Engineering Page 3

•

Description *3

•

Theory of Operation *4

•

Design Considerations *10

•

Components *17

•

NCM Cable Guidelines *20

•

Software Set Up *30

Commissioning Procedures 33

•

Overview *33

•

Setting the N2 End-of-Line Switch 33

•

Installing the Submodules *34

•

NCSETUP *37

Troubleshooting Procedures 39

•

NCM Power Up *39

•

Communications *45

•

Related Commissioning Problems 51

•

Service 53

Specifications and Order Codes *55

•

Specifications *55

•

Ordering Information *56

Network Control Module 200 Series

* Indicates those sections where changes have occurred since the last printing.

2 Control Modules—Network Control Module 200 Series

Control Modules—Network Control Module 200 Series 3

Engineering

The 200 Series Network Control Module (NCM200) is the main

processing module in the Network Control Unit (NCU). Fully

programmable, the NCM200 coordinates and supervises the control

activities for all objects and control loops hardwired to the NCU, as well

as the remote Network Expansion Units (NEUs) and Application Specific

Controllers (ASCs) connected to it over a local bus.

An NCM200, via the N1 Local Area Network (N1 LAN), also has the

ability to control activities for objects located in other NCMs. An example

of exchanged control would be objects shed or restored by the Demand

Limiting/Load Rolling feature.

Different program sets download to an NCM200 to support a variety of

devices on its local buses. The program sets are of two types: Standard

Functionality and Migration Functionality. The Standard Functionality

supports one of the following applications:

•Standard NCM software supports the following: NEUs, Heating,

Ventilating, and Air Conditioning (HVAC) Applications such as Air

Handling Unit (AHU) Controllers, Variable Air Volume (VAV)

Controllers, VAV Modular Assemblies (VMA), Unitary (UNT)

Controllers, Lab and Central Plant (LCP) Controllers, DX-9100/9120,

and Application Specific Controllers (ASCs) on the N2 Bus, plus

C210/C260 controllers on an L2 Bus.

•Fire Management software integrates the fire and safety

IFC-1010/2020 controller to Metasys®, as well as supporting Point

Multiplex Modules (XMs) and HVAC ASCs on the N2 Bus.

•Intelligent Access Controller software integrates the access IAC-600

Controller to Metasys, as well as supporting XMs and HVAC ASCs

on the N2 Bus.

•As an alternative to the Network Terminal (NT), Operator Terminal

(OT) software connects a VT100, or a Personal Computer (PC) with

VT100 emulation software to the NCM200. An NCM with an

Operator Terminal connected supports NEUs, Intelligent Lighting

Controllers (ILCs), and ASCs, including the LCP.

In addition, an Operator Terminal connected to one NCM on the

N1 network can display, schedule, and control Fire, Access, S2, or

L2 Bus applications connected to other NCMs on the network.

Description

4 Control Modules—Network Control Module 200 Series

The Migration Functionality program set builds pathways from the

NCM200 to other systems. While it can support any of the Standard

Functionality program sets described earlier, Migration Functionality can

also connect one of the following applications to Metasys:

•S2 Migration software brings JC/85 field gear, object information, and

control directly into Metasys from the JC/85 trunks.

•JC/85 Gateway allows Metasys object information to integrate with

the JC/85 Central Processing Unit (CPU). In the Gateway application,

the NCM serves as a high-level protocol translator, making Metasys

object information available to a JC/85 headend.

•The Network Port application lets you monitor and control the

Metasys system from a third-party host. The host computer must be

able to communicate with an ALLEN-BRADLEY PLC-5®

(Programmable Logic Controller). The host, in turn, communicates

with the Network Port, which emulates some features of a PLC-5.

Note: For complete information about the Network Port, refer to the

Network Port Technical Bulletin (LIT-6295050) in the Metasys

Connectivity Technical Manual (FAN 629.5).

The NCM200 is a microprocessor-based intelligent node in the Metasys

Network. It integrates three streams of information:

•system and data base information

•application programs

•data and I/O information arriving from the communication ports

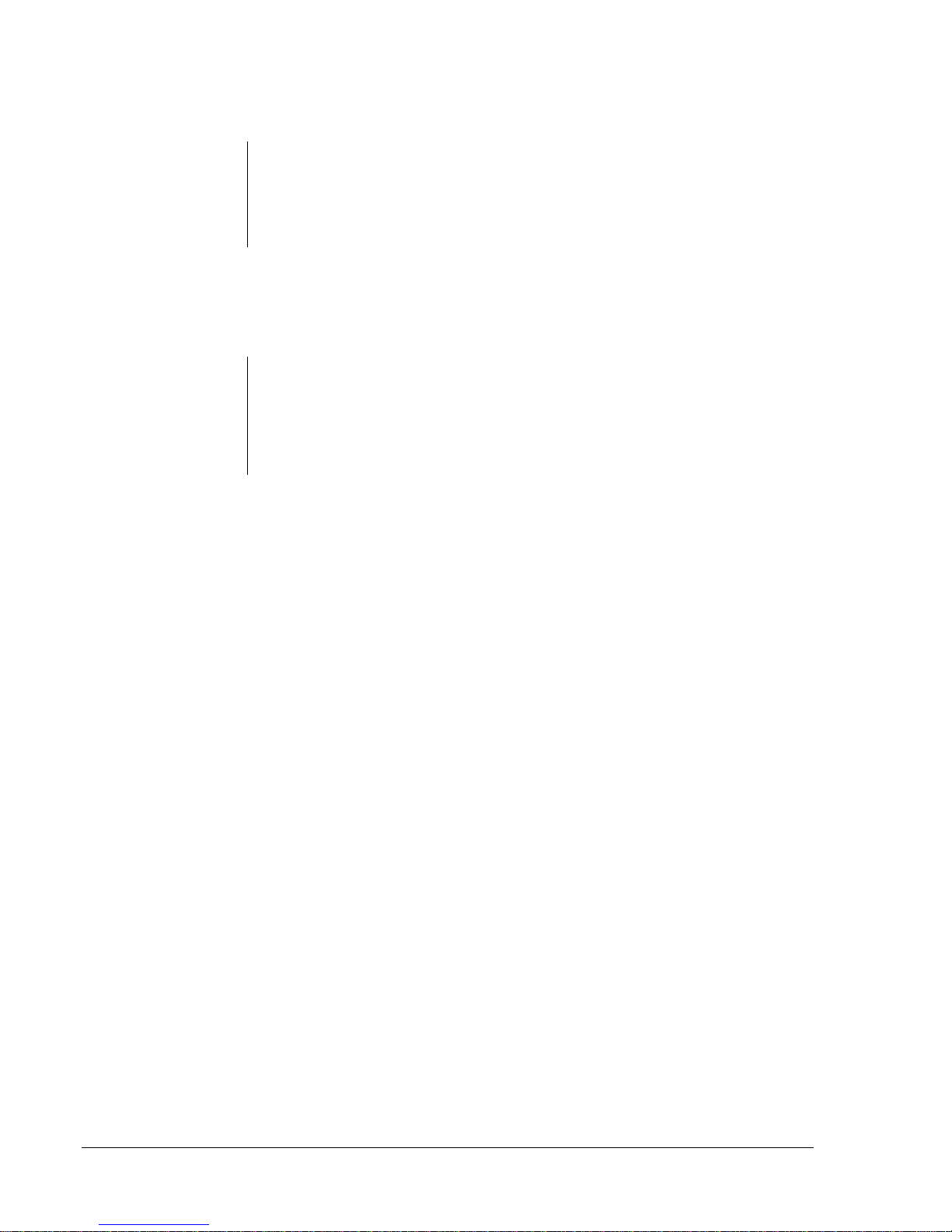

Figure 1 illustrates the basic components and functions of the NCM200.

N1 LAN

N2 Bus Lines Operator

Workstation

TBC

Microprocessor

Clock/Calendar

RS-232 Port

NT Port

Communications

Submodule Slot

Battery

Submodule

Network Identity

Module Slot

Reset Button

Optional L2

Bus Lines

NIM: Memory and

Functionality

N2 Interface

1

5

200TC1

N1 Interface

12

6

3

8

9

10

13

Figure 1: Block Diagram of the NCM200

Theory of

Operation

Control Modules—Network Control Module 200 Series 5

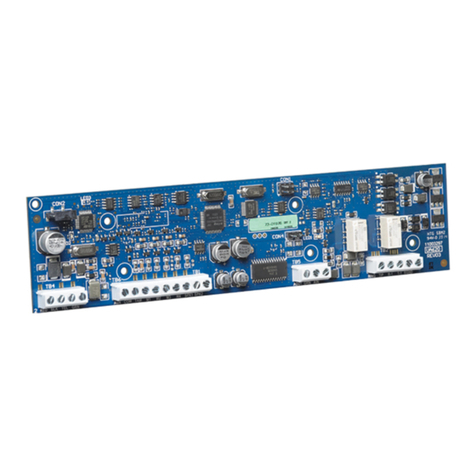

A Network Identity Module (NIM) (Item 1in Figure 1) is a submodule

that configures features and data base capacity for the NCM200.

The NIM206 covers all applications supported by previous NIMs. When

replacing an NIM (for example, an NIM102), use the NIM206. The

NIM206 is factory installed in the NCM201.

200TC02

Figure 2: Network Identity Module (NIM)

The microprocessor (Item 2 in Figure 1) applies the various supervisory

programs to the combined data, and controls the modules and devices that

connect to the NCM via a local bus.

This supervision and control operates in the same manner when any of the

Standard Functionality program sets (standard, fire management,

intelligent access control, or Operator Terminal) are downloaded.

For the Migration Functionality program set, the microprocessor translates

data from the field gear into compatible code for the target system:

•For S2 Migration, the microprocessor integrates the incoming S2 data

into Metasys and extends NCM supervisory and control functions

over the objects on the S2 trunk.

•For JC/85 Gateway, the NCM microprocessor:

- executes commands from the JC/85 headend to objects on the

Metasys side

- provides attribute information for all objects on the Metasys side

- translates and sends Metasys reports to the JC/85 devices

Network Identity

Modules

Microprocessor

6 Control Modules—Network Control Module 200 Series

•In Network Port applications, the microprocessor:

- translates the host-generated requests to Metasys commands

- applies the various supervisory programs to the combined data,

supporting those functions that relate to the mapping of data

objects to the host computer (mapped analog data and binary data

objects)

All the software applications and supervisory routines take place inside the

NCM; data base exceptions and historical files are uploaded to the

Operator Workstation (OWS) (Item 3in Figure 1)for reporting and

archival purposes.

The I/O subsystem supports a multi-user environment consisting of

integrated network connections (N1 and N2), submodule ports, and direct

I/O communication (NT [or Operator Terminal], RS-232).

N1 Local Area Network

N1 LAN communication is provided by the built-in N1 interface (Item 4

in Figure 1) terminating at a BNC connector at the bottom of the NCM200

module.

The N1 LAN is composed of the standard ARCNETchip set and

hardware, allowing communication with both OWSs and other NCMs.

Each NCM and OWS on the system contains a “node manager” task,

whose responsibilities include:

•broadcast once per minute that it is still online

•listen to other node managers to track on and offline trunks

•issue a time stamp for every global data base in its memory

•compare the time stamps of its own data bases to the received time

stamps of other node managers’ data bases, and update the current

data base if necessary

•monitor the printer for online or offline status

The node with the lowest address number on the system issues time and

date information once per day to ensure system synchronization. Time

and date information is backed up by a clock/calendar chip (Item 5in

Figure 1). The node manager also monitors broadcasts and issues

online/offline advisories.

In the event of a severed N1 network, each separated LAN forms an

independent network.

Communications

Control Modules—Network Control Module 200 Series 7

Local Bus: N2

The N2 Bus communications are also provided by a built-in interface

(Item 6in Figure 1). Devices on the N2 Bus constitute a local network,

controlled by the NCM. The NCM polls the devices according to a

user-set priority level, which is set at each device’s definition window.

The N2 connects in a daisy chain fashion, and provides the transmission

medium for modules installed within the base frame (e.g., a Digital

Control Module or Point Multiplex Module), as well as the external

devices (application specific controllers--including the IFC-1010/2020

Intelligent Fire Controller and IAC-600 Intelligent Access Controller).

External devices connect to the N2 interface via the Terminal

Communications Board (TBC) (Item 7in Figure 1).

An NCM200 can accept both N2 and L2 communications at the same time

when using the Standard NCM software (not fire management, intelligent

access, or OT software).

Note: Starting with Metasys Release 6.0, a second N2 Bus can be added

using an N2 submodule connected to the NCM’s Communication

Submodule slot (Item 8in Figure 1). For complete information,

see the Dual N2 Bus Application Note (LIT-6363145).

Local Bus: L2

The optional L2 Bus is dedicated to connecting C210A and C260A ASCs

on a local, external trunk, controlled by the NCM. L2 communications are

enabled by installing an L2 submodule in the NCM’s Communication

Submodule slot (Item 8in Figure 1).

The L2 Bus connects in a daisy chain fashion. As is the case with the

N2 Bus, connections from the external lines to the NCM are made at the

Communications Terminal Board. The devices on it are polled with equal

priority.

An NCM200 can accept both N2 and L2 communications at the same time

when using the Standard NCM software (not fire management, intelligent

access, or OT software).

Submodules

Submodule slots (Items 8 and 10 in Figure 1)on the NCM allow users to

plug in submodules to add or change functions to the system.

The Network Identity Module slot (Item 9in Figure 1)is reserved for

NIMs to configure the NCM200. An NIM module must be installed for

the NCM200 to operate.

The Battery Submodule slot (Item 10 in Figure 1)is reserved for the

battery submodule, which allows the NCM to retain code and data base

memory for up to 72 hours in event of a power failure.

8 Control Modules—Network Control Module 200 Series

The Communications Submodule slot (8) allows installation of one of the

following submodules to provide different communications options:

•the L2 submodule, to integrate a C210 or C260 controller to Metasys

•the N2 submodule for connection to a second N2 Bus to integrate N2

devices. See the Dual N2 Bus Application Note (LIT-6363145) for

details.

•an internal modem submodule, to connect to remote operator devices

such as a printer or OWS

•an RS-232C submodule, connecting to a printer, external modem,

S2 Migration Trunk, JC/85 Trunk, Operator Terminal, or directly

connected OWS

The RS-232C submodule is also the means by which you connect

Metasys to a host system in the Network Port application. Refer to

the Network Port Technical Bulletin (LIT-6295050) in the Metasys

Connectivity Technical Manual (FAN 629.5).

RS-232 Submodule: S2 Migration

S2 communications are made via an RS-232 submodule on the NCM200

to a Table Top Modem (TTM). The TTM then interfaces with the JC/85

trunk.

•The S2 parameters are identical to those of the JC/85 trunks.

•S2 Migration connections from the submodule to other devices on the

N1 LAN are identical to those of a Standard Functionality NCM200.

•The S2 Migration NCM does not accept a second submodule for a

local L2 Bus, or other devices via the integrated N2 Bus.

•For S2 Migration applications that require a dial-up port, you must

use the NCM401 instead of the NCM200.

RS-232 Submodule: Gateway to JC/85

The RS-232 connection on the JC/85 headend connects directly into the

RS-232 submodule on the Gateway NCM.

•The Metasys objects on Gateway are connected from throughout the

Metasys Network via the N1 LAN in the same manner as a Standard

Functionality NCM200.

•The Gateway NCM does not accept a second submodule for a local

L2 Bus, or other devices, via the integrated N2 Bus.

Control Modules—Network Control Module 200 Series 9

RS-232 Submodule: Operator Terminal

When using the Operator Terminal (OT) program set, the VT100 (or PC

with VT100 emulation software) connects to the NCM via the RS-232

submodule, replacing the use of the Network Terminal. (Instead of

connecting to the RS-232 port, an OT can connect to the NT Port.

However, only one OT can be connected at a time.)

An Operator Terminal provides a higher level of capability than the

Network Terminal, allowing you to read and write to each attribute of a

Control System (CS) object, as well as define and build data bases for the

Trend and Totalization features. Refer to the Operator Terminal

Technical Bulletin (LIT-636015).

Note: When an Operator Terminal connects to an NCM through either

the submodule (Port 2) or the NT Port (Port 4), the integrated

RS-232 port (Port 3) will also support an unconfigured OWS. An

example of this situation is using a laptop computer to download

software into the NCM.

Additional I/O Support

The Network Terminal Port (Item 11 in Figure 1)supports a connection

from the Network Terminal Unit or Operator Terminal to provide local

operator I/O. The RS-232C Port (Item 12 in Figure 1) provides a

connection to a local workstation or printer.

The NCM powers up in either a cold start condition or a warm start

condition. In the cold-start condition, the NCM automatically requests the

OWS to download the code and data base information into the NCM’s

memory. Refer to the Operator Workstation User’s Manual (FAN 634).

In a warm start condition, the code and data base are stored in memory;

the NCM is immediately and fully operational following the initial

diagnostic tests.

By retaining memory during a power cycle, the battery backup provides a

warm start condition when power returns to the NCM.

A System Reset button (Item 13 in Figure 1) manually resets the NCM

under cold start conditions, which generates a request for code and data

download.

Power Up

Conditions

10 Control Modules—Network Control Module 200 Series

The NCM’s environmental requirements are identical to those of the NCU.

For more information, reference Network Control Unit/Network

Expansion Unit Technical Bulletin (LIT-636020). Power is supplied by an

associated, and separately ordered, Power Supply Module.

Note: For S2 Migration applications that require a dial-up port, you must

use the NCM300/350 instead of the NCM200.

Since Port 1 of the NCM200 is always the built-in N2, the S2 trunk must

be moved from Port 1 on an NCM401 to Port 2 on the NCM200.

1. Remove any configured devices from Port 2 from the Global Data

Definition Language (DDL) file.

2. Move the S2 trunk from Port 1 to Port 2 in both the Global DDL file

and the NC DDL file.

3. After recompiling the NC and Global DDL files, all Graphic

Programming Language (GPL) and JC-BASIC processes must be

translated.

Note: If objects have been added online, these will be lost when you

recompile the NC file. To avoid losing these objects, first perform

a decompile (using UNDDL), and then make the port changes to

the decompiled file.

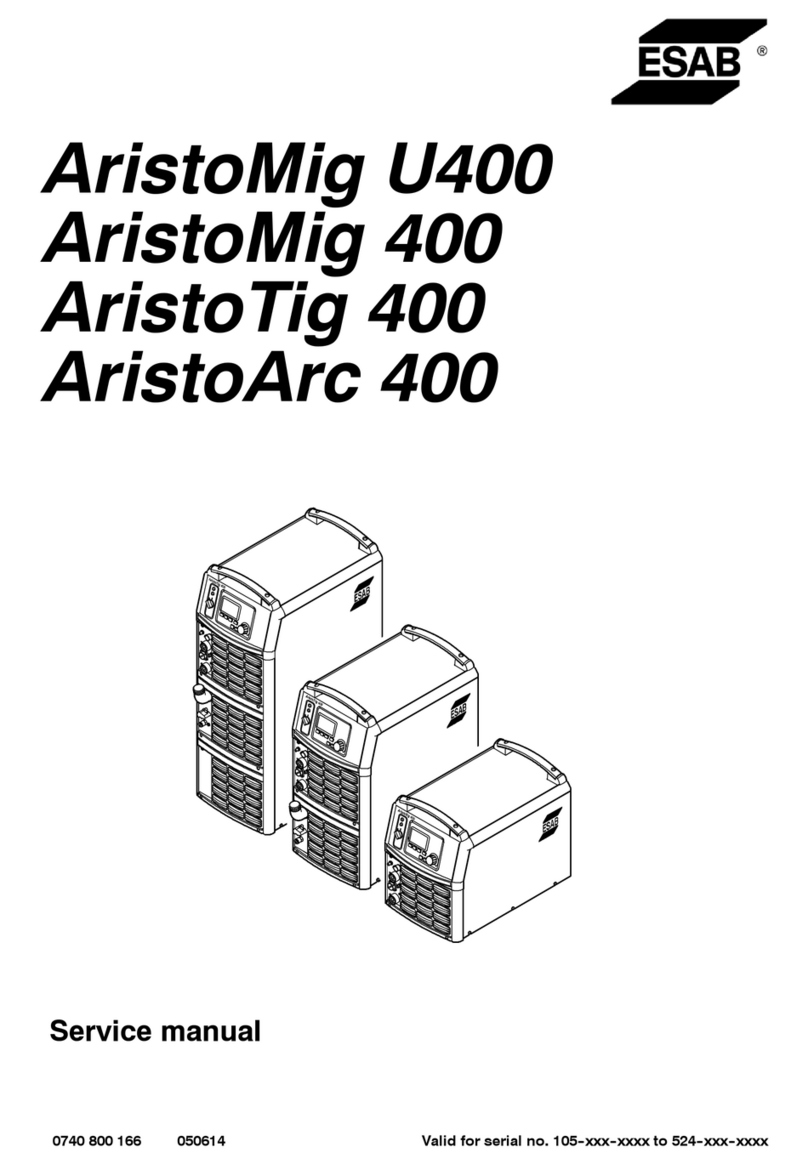

Mount the NCM200 into a standard 1-slot NCU, into Slot 2 of a 2-slot

NCU, or into Slot 3 of a 5-slot NCU (Figure 3). Make sure to terminate

the N1 cable to the BNC connector at the bottom of the NCM200 module.

5-slot Base Frame 2-slot Base Frame 1-slot Base Frame

200TC03

Figure 3: Mounting the NCM200 into a Standard 1-Slot,

2-Slot, or 5-Slot Base Frame

Design

Considerations

Replacing an

NCM401 with an

NCM200

Mounting

Control Modules—Network Control Module 200 Series 11

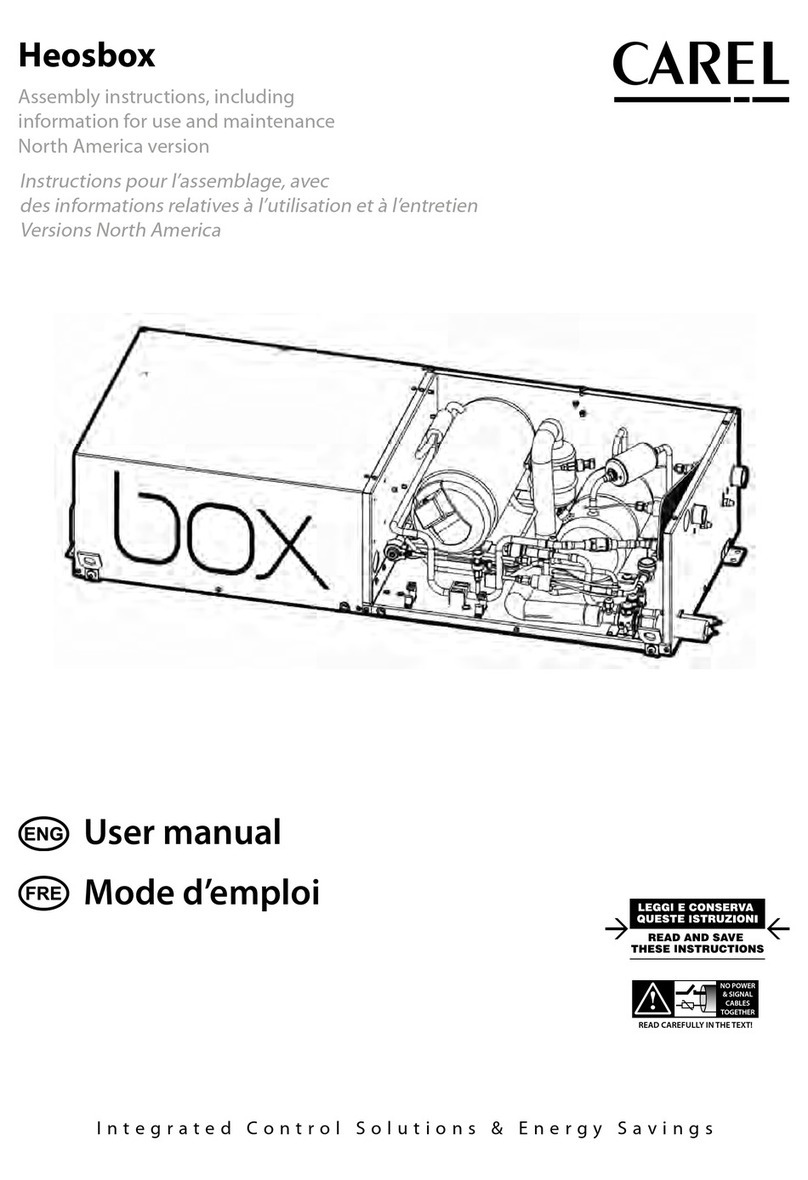

In addition, a simpler, streamlined version of the base frame is available

for the N1 direct-connect NCM (NCM200). This NCM-only base frame

(Figure 4) is for applications that require the NCM200’s supervision and

control over local trunks, but does not require direct wiring to field

devices, or the flexibility of interchanging other electronic modules.

Migration applications, for example, could be installed into the NCM-only

base frame since they are not used to communicate with DCMs or XMs,

and have no field devices connected to the NCU.

Includes Power

Assembly and

Communications

Board

TBC Cover

Opened

to Reveal

N2 and L2 Bus

Connections

Power Supply

NCM200

NCM-Only

Base Frame

N1 LAN Connection

200TC04

5(6(7

Figure 4: Mounting the NCM200 and Power Supply in the

NCM-Only Base Frame (BSF121)

12 Control Modules—Network Control Module 200 Series

The NCM200 requires Release 4.0 or higher of the Metasys software.

S2 Communications Tuning Parameters Modified for Telephone Lines

Due to timing delays over telephone lines, some trunk configurations may

require modification of the following S2 Communications parameters

(using NCSETUP) in order to bring the field gear online:

1. Delay between polls to field devices

2. The polling timeout delay

3. The number of polling retries

See the NCSETUP for Windows Technical Bulletin (LIT-6360251d) for

information on changing these parameters.

Directly Connectable Hardware for Each Software Type of NCM

The NCM Software Options Technical Bulletin (LIT-636023) in the

Control Modules section of the Metasys Network Technical Manual

(FAN 636), describes which Metasys hardware devices function, for each

type of downloadable software, when connected to that NCM. Please

refer to it for the latest software options.

The NIM206 is the only NIM now used. When replacing any NIM, order

the NIM206. For reference when using existing NIMs, the data base

capacity for a NIM102/202 = 300K; NIM104/204 = 600K; and the

NIM106/206 = 1200K.

Standard Functionality: Standard NCM

The load capacity for an NCM depends on the available memory

determined by the installed NIM, in addition to the software configuration

of the connected devices.

Refer to the Network Control Unit/Network Expansion Unit Technical

Bulletin (LIT-636020) for information about the object loading of the

individual electronic modules connected to the NCM via the base frame.

Standard Functionality: Fire Management

Along with the Release 4.0 or higher Metasys software needed for the

NCM200, the fire management software requires the IFC-2020

Release 3.0 or higher firmware. A fire NCM handles one IFC-1010/2020

controller with up to 240 fire zones attached to that controller. Each zone

counts as one object for the purpose of memory sizing.

Software

Configurations

NCM Capacity

Control Modules—Network Control Module 200 Series 13

The following guidelines list other kinds of devices that the fire

management NCM is capable of processing:

•HVAC ASCs (AHUs, VAVs, VMAs, UNTs, PHXs, LCPs,

DX-9100s, etc.)

•Point Multiplex Modules (XM) (Multiplex Binary, Multiplex Relay

Latched, Multiplex Relay Momentary, Multiplex Relay Electrically

Maintained)

The IFC is a building fire management controller, and in most situations it

is alone on the NCM. However, if there are a few remaining ASC or XM

points that do not justify a separate NCM, they can be added to an NCM

supporting the IFC, up to the memory limits of that NCM.

Standard Functionality: Intelligent Access Control

The Intelligent Access Control (IAC) software requires Release 4.0 or

higher Metasys software and IAC-600 Release PS130B firmware. For

Metasys Release 6.0, the IAC NCM handles one or two IAC-600

controllers and up to 16 readers attached to each controller. (Prior to

Release 6.0, the IAC NCM handles one IAC-600 controller and up to

16 readers attached to that controller.)

The following guidelines list other kinds of devices that the intelligent

access control NCM is capable of processing:

•HVAC ASCs (AHUs, VAVs, VMAs, UNTs, PHXs, LCPs,

DX-9100s, etc.)

•Point Multiplex Modules (XM) (Multiplex Binary, Multiplex Relay

Latched, Multiplex Relay Momentary, Multiplex Relay Electrically

Maintained)

The IAC-600 is a building access controller, and in most situations it is

alone on the NCM. However, if there are a few remaining ASC or

expansion module points that do not justify a separate NCM, they can be

added to an NCM supporting the IAC-600, up to the memory limits of that

NCM.

Standard Functionality: Operator Terminal

The Operator Terminal NCM has a load capacity similar to that of the

standard NCM, including support of the Intelligent Lighting Controller

(ILCs) and Lab and Central Plant Controller.

It differs from the standard NCM in that it replaces the Network Terminal,

and does not support the DSC-1000 family of controllers (i.e., C210A,

C260A, C260X, C500X) connected to the same NCM.

An Operator Terminal NCM may, however, interact with DSC-1000

controllers if they are connected to another NCM on the N1 LAN.

14 Control Modules—Network Control Module 200 Series

Migration Functionality: Gateway

An NCM200 with a 200 series NIM and Gateway software can connect

one gateway trunk (via the RS-232 submodule) and map up to 1400 JC/85

Level 3 points. This trunk requires a dedicated RS-232 port on the JC/85

headend. An NIM206 handles the largest JC/85 data base allowed.

Migration Functionality: Network Port Application

See the Network Port Technical Bulletin (LIT-6295050).

Migration Functionality: S2 Migration

An NCM200 with a 200 series NIM and S2 software can connect

one JC/85 trunk through one Table Top Modem (for example, if

four trunks were originally connected to the JC/85 headend, four NCMs

are required unless the trunks can be reconfigured). The data base size of

each trunk can be calculated with the NCM Memory Estimator.

The following are countable JC/85 objects:

•FPU device

•FPU hardware points (the SST101 counts as two objects)

•DSC-8500 device

•DSC-8500 hardware points

•DSC-8500 data points

•DSC-8500 status variables

In addition to the memory required by the object count and Metasys

standard features, also calculate additional memory used for written

programs of GPL equivalents to JC/85 features. See How to Use the

Metasys GPL HVAC Library (LIT-636121), under the App. Notes: GPL

HVAC Library tab of the Metasys Network Technical Manual (FAN 636).

Applications of interest to JC/85 users are:

•interlocks

•computed points

•chiller sequencing

Application notes exist for each of these processes in Volume IV of the

Metasys Network Technical Manual (FAN 636).

Among the considerations about adapting JC/85 code to Metasys, here are

a few that may adjust the memory requirements:

•Auto Shutdown

When converting JC/85’s Auto Shutdown feature to Metasys, write an

equivalent GPL process for Metasys and add the file object size to the

NCM’s memory usage.

Control Modules—Network Control Module 200 Series 15

•ESO (Enthalpy Switch Over)

When converting the JC/85 ESO feature to Metasys, you must choose

one of the four economizer features utilized in Metasys. Details and

specifications about each of these programs are listed in How to Use

the Metasys GPL HVAC Library (LIT-636121).

- ECONEN Comparison Enthalpy Economizer

- ECONOE Outdoor Air Enthalpy Economizer

- ECONDB Outdoor Air Dry Bulb Economizer

- ECONRA Differential Temperature Economizer

Table 1 shows applications and port restrictions when installing

submodules into an NCM200 with a Standard Functionality software set

downloaded (standard, fire management, intelligent access control, OT).

Table 1 : Standard Functionality NCM200 Serial Port Configuration

Connection

Maximum

Concurrent

Connections5

Port 1

(RS-485)

Port 2

(Dial) 6, 9

Port 3

(Laptop)2

Port 4

(NT) 11, 12

N2

2

✓

✓

L2 1

1

✓

S2

1

✓

JC-85 Gateway

1

✓

Network Port

1

✓

OWS-Direct (configured 8)

2

✓

✓

OWS-Dial 7

1

✓

✓, 3

OWS (unconfigured 10 )

1

✓

NT

1

✓

NT-Emulator

1

✓

OT 4

1

✓

✓

✓

OT-Dial 4, 7

1

✓

✓

NC Printer

2

✓

✓

NC Printer-Dial 7

1

✓

✓

N1 – ARCNET

Ethernet

Maximum Speed

--

19.2K

19.2K

19.2K

19.2K

Notes:

1 The L2 Bus connection requires an L2 submodule.

2 Direct connection is recommended on Port 3 for the OWS. This allows connection to

systems locally.

3 Download from remote OWS is only available on the NCM350/361.

4 Use of the Operator Terminal replaces the Network Terminal and disables the NT port.

Continued on next page . . .

Configuring the

NCM

Submodules:

Standard

Functionality

16 Control Modules—Network Control Module 200 Series

Notes: (Cont.)

5 The maximum number of connections of that type on the NCM. For example, there can

be two N2 connections on the NCM, on Ports 1 and/or 2. There can be one OWS Dial

connection on the NCM, on Port 2, 3, 5, or 6.

6 Use RS-232 cable to connect devices to the integrated RS-232 port. Connections at the

integrated ports are independent of each other; for example, a printer can be connected

to both ports at the same time. An RS-232 submodule is required for these connections.

7 Dial-up printer, OWS, or OT connected to phone line via a modem.

8 A configured OWS is an OWS that is defined in the data base.

9 N2 Bus can connect to this port via an RS-232 to RS-485 converter.

10 An unconfigured OWS is not defined in the data base (for example, a laptop computer).

It can be used to run logs and summaries, or to download a data base. They cannot be

connected directly to the Ethernet LAN.

11 Either an NT or an OT directly connects to the RJ-12 port via the NT Emulator cable.

12 An OT, or a PC with NT Emulator software, connects directly to the RS-232 port via

RS-232 cable.

Table 2 illustrates applications and port restrictions when installing

submodules into an NCM200 with one of the Migration Functionality

software sets downloaded (for the Network Port Application, see the

Network Port Technical Bulletin, LIT-6295050).

Note: When installing a Migration NIM, you have the option of loading

any of the Standard Functionality software sets instead of a

Migration software set.

Table 2: Migration Functionality NCM200 Serial Port Configuration

Port Application

(Ports must be configured via system software for

appropriate application.)

NT Port Network Terminal directly connects via the NT cable.

Integrated RS-232 Port

(Port 3)

All devices connect to the integrated RS-232 port via an

RS-232 cable.

Configured OWS (i.e., defined in the data base)

Printer

Unconfigured OWS (i.e., not defined in the data base): An

example would be a laptop computer. May be used to run logs

and summaries, or to download a data base.

Communications

Submodule Port

(Port 2)

S2 Migration, connected via RS-232 submodule to JC/85 trunk

via Table Top Modem.

JC/85 Gateway, connected via RS-232 submodule to JC/85

headend. (Connection may alternately be via a high-speed

modem over a dedicated phone line.)

Note: JC/85 Gateway: To send the NCM print file to the JC/85 printer, define the printer as

“Port 2” (the communications submodule slot--the same port definition as you assign

to Gateway). To print to a printer connected directly to the NCM200, connect the

printer into the RS-232 port (Port 3--the integrated port).

Configuring the

NCM

Submodules:

Migration

Functionality

Control Modules—Network Control Module 200 Series 17

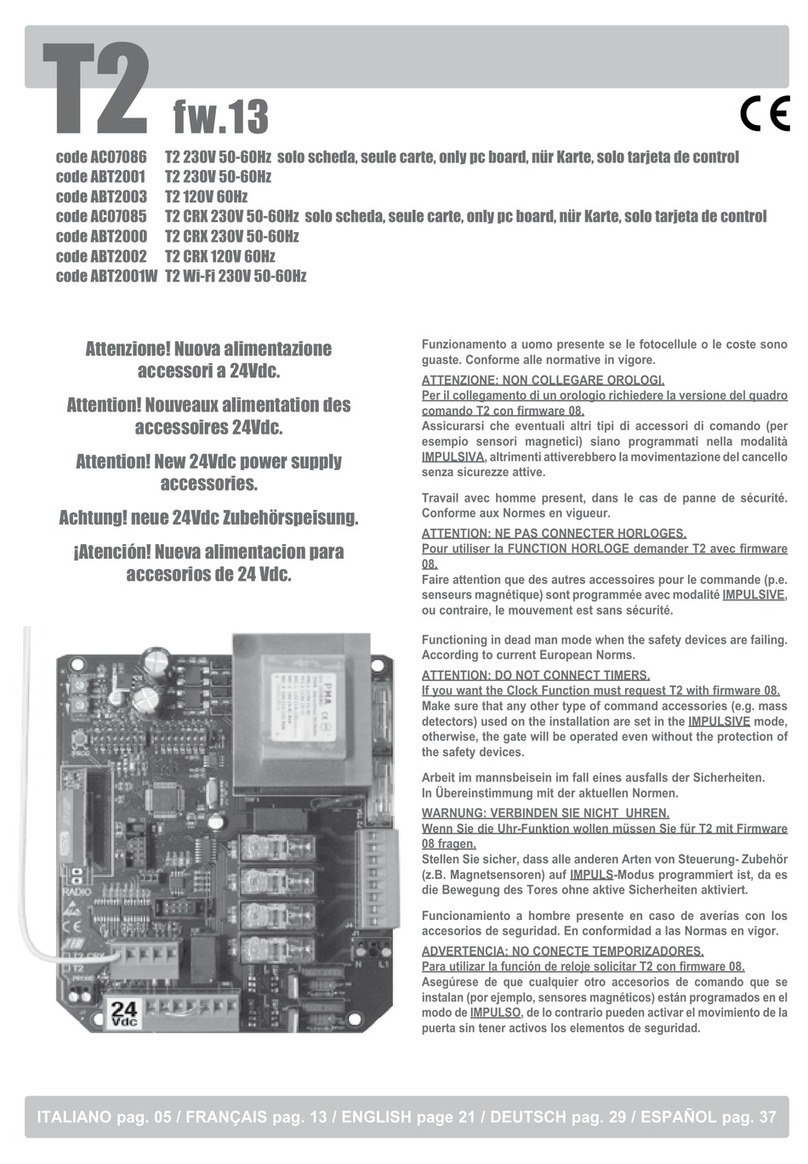

Figure 5 illustrates the ports and submodule positions on the NCM.

5(6(7

RS-232 Port - Port 3

(Laptop Operator Workstation or Printer)

NTU Port (6-pin Telephone Plug)

Slot for Communications

Submodule - Port 2

Battery Submodule (Included)

Reset Button

LED

Board N2 End-of-Line Switch

Slot for Network Identity Module

N1 LAN Connection

200TC05

Note: The integrated

N2 Bus is Port 1.

Figure 5: Port and Submodule Positions on the NCM

The L2 submodule provides compatible signals for a DSC-1000 L2 Bus

(C210 and C260 controllers). The L2 submodule inserts in only

one orientation. There is one switch to set on the L2 submodule:

Channel A/B Switch: Indicates which terminal blocks the L2 connects to

on the communication panel. Set to Channel B, corresponding with the

TB2 terminals on the TBC.

For applications requiring a second N2 Bus, use the N2 submodule, which

provides compatible signals for N2 devices. For complete information,

see the Dual N2 Bus Application Note (LIT-6363145) in this manual.

The N2 submodule inserts in only one orientation. There are two switches

to set on the N2 submodule:

Channel A/B Switch: Indicates which terminal blocks the N2 connects to

on the communication panel. Set to Channel B, corresponding to the TB2

terminals on the TBC.

End-of-Line (EOL) Switch: Indicates whether the NCM is one of the

two EOL devices on the N2 bus. Setting the N2 EOL to In means the

NCM is EOL. Out means that other modules are daisy-chained (in the

backplane) both upline and downline of the NCM.

The RS-232 submodule provides input/output at standard RS-232C levels.

The RS-232 submodule inserts in only one orientation.

There are no switches to set. However, because of the recessed connector

on the NCM, a special right-angle cable with a narrow profile shell is

required to attach to the RS-232 submodule. One end of this cable

(NU-CBL101-0) arrives pigtailed.

Components

L2 Submodule

N2 Submodule

RS-232

Submodule

18 Control Modules—Network Control Module 200 Series

The user connects the pigtailed wires into a separately ordered hood, either

male (MHK101) or female (FHK101), according to the pinout

requirements.

The internal modem is Hayes® compatible, with the baud rate

automatically configuring to either 300 bps or 1200 bps. The module

inserts in only one orientation. This modem is compatible with the

Metasys Network and resides within the NCM. An external modem

(Hayes compatible) may be preferred if faster communication rates or

different performance characteristics are needed. Connecting an external

modem requires the use of the RS-232 submodule.

There are no switches to set on the internal modem. Two phone jacks are

evident on the module face. The phone line connects to the upper jack

marked Line. A telephone handset can be connected into the lower jack

marked Handset.

The Network Terminal plugs into this 6-pin telephone jack, which

supports Transmit, Receive, and Data Terminal Ready lines. There are no

switches to set on this built-in port.

This port is non-functional when the Operator Terminal software set is

downloaded. The NT port does not support the Zone Bus Terminal.

!

CAUTION: Do not plug a phone line into the NT port. Plugging a

phone line into the RJ-12 port may damage the port

and render it unusable.

There are no switches to set on the built-in RS-232C port (Port 3), which

is used to support a local OWS or local printer. All RS-232 connections to

third-party equipment must be made with shielded cable. A typical

application may utilize the built-in RS-232 port in addition to the RS-232

submodule, for a total of two RS-232 connections.

The battery submodule automatically recharges from the NCM, and

maintains Random Access Memory (RAM) programs and data bases for

up to a 72-hour power failure. The module installs in the field and inserts

in only one orientation. There are no switches to set.

The TTM-10n Table Top Modem provides an interface between the

RS-232 submodule on the S2 Migration NCM and one JC/85

communications trunk. A TTM-10n modem consists of an external power

supply, a circuit board with enclosure, and one master modem card.

Three models (and one alternative) of the TTM-10n are available:

Internal Modem

Submodule

RJ-12 Network

Terminal Port

RS-232C Port

Battery

Submodule

Table Top

Modem

Control Modules—Network Control Module 200 Series 19

TTM-101 Provides the interface necessary to communicate to a

18 AWG proprietary, shielded, twisted-pair trunk.

A TRM-101 comes mounted to the printed circuit card, and

is available for single-trunk applications only.

TTM-102 Provides the interface necessary to communicate to a

dedicated leased type 3002 phone line. A DPM-101 comes

mounted to the printed circuit card.

TTM-103 Provides the interface necessary to communicate on a

JC/LINK Generic Bridge. The Rolm bridge version is not

available.

MDM-101 An alternative modem to interface between an RS-232

(UDS-202) submodule from the S2 NCM and a remote MDM-101

(outside vendor modem would be the UDS-202) over a

voice-grade type 3002 leased phone line.

The printers are not a component of the NCM200. However, the specific

printer models approved for the NCM200 are the IBMProprinter III

and the LexmarkModel 2380 (set to emulate an IBM Proprinter III).

Notes: Smoke control applications require a printer connection to the

NCM. If the Fire OWS is not being used, a UL Listed PRN-3/-4

printer must be connected directly to at least one UL Listed

NCM200/201-0 or NCM300/350-2 running the smoke control

algorithm and the NCM must be configured as “NC Direct.”

Figure 19 illustrates the pinout connections to the NCM’s

integrated RS-232 port or RS-232 submodule.

To properly configure the printer for the NCM200, use the individual

printer instructions as a guide to set the mode and DIP switches to the

following configurations:

Card: Serial Interface

Mode: RS-232

Polarity: No reverse polarity (typically--this setting could change,

depending on the individual computer system and cabling.)

Baud Rate: Set to the rate established in DDL. Default is 9600.

Data Bits: 8

Parity: No

Stop Bits: 1

Protocol: XON/XOFF

Operation: Normal

Cable connections are illustrated in the following section, NCM Cable

Guidelines.

Printers

20 Control Modules—Network Control Module 200 Series

This section starts by illustrating the N1 LAN connections for new and

retrofit applications. N2 cabling to the communications terminal board is

described in the Network Control Unit/Network Expansion Unit Technical

Bulletin (LIT-636020), and the N2 Communications Bus Technical

Bulletin (LIT-636018).

This section then organizes cable connections by device (such as by OWS,

printer, etc.) and finally by migration type (Gateway or S2). Devices

connecting to both the RS-232 submodule and the integrated RS-232 port

show two cables, since the pinouts for those connections are different.

Using the NCM-Only Base Frame

Connect the N1 cable via a T-connector to the bottom of the NCM200

module, as shown in Figure 6. Ensure that no metal part of the connection

(EOL cap, T-connector, or exposed metal part of the cable) is touching a

case or any metal on the base frame. Black tape, or a clip-on plastic

shroud, will protect the metal from inadvertent contact.

Power Supply

NCM200

TC200_6

N1 LAN Connection

Add terminal cap or

continue N1 LAN at

left side of "T."

Apply black tape or

plastic shroud around

metal connections.

1.

2.

Figure 6: Making N1 LAN Connections Using

NCM-Only Base Frame

NCM Cable

Guidelines

NCM200 N1 LAN

Connection

Other Metasys Control Unit manuals

Popular Control Unit manuals by other brands

Moeller

Moeller EMR4-RDC-1-A installation instructions

Dickey-John

Dickey-John Land Manager SE manual

Wöhner

Wöhner CRITO CrossBoard Mounting instructions

Meinberg

Meinberg IMS-GNS181-UC Setup guide

Wilo

Wilo PLR Installation and operating instructions

Gemu

Gemu 707 Installation, operating and maintenance instructions