spikenzielabs Useless Machine User manual

For the best outcome, follow each step in order.

We recommend reading this guide entirely before you get started.

Tools required:

One phillips screwdriver, and one flat screwdriver, soldering Iron, solder, snips and

supplies to build your own Useless Machine.

The Useless Machine

Parts Only - Build Guide

v0001

TM

Laser cut acrylic, electronics, hardware parts

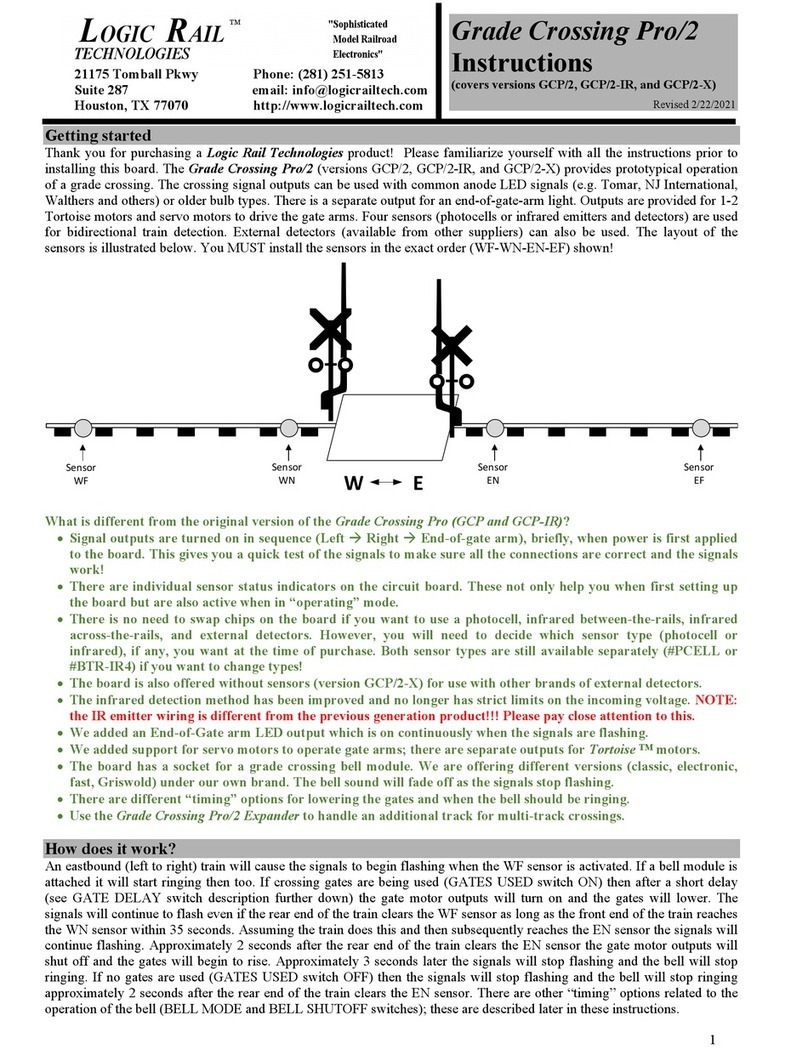

Motor mount - wire side Motor mount - Arm side

2x #4 weld nuts

4x 4-40 nuts

2x #4 washers

4x 3/8” 4-40 screws

2x 1” 4-40 screws

#12 washer Switch nut

and washer

#2 screw and

washer

Battery holder

PCB

220 ohm resistor

100 ohm resistor Switch

Motor

Base washers

Arm

Base

2 Color LED

Snap switch

Screw terminals

Some of the steps in the build of this kit require the snipping component legs. If

you’re building this kit on your own, or with a someone else, we STRONGLY

recommend whoever is present is wearing safety glasses. When the legs are

snipped, the can fly off in unpredictable directions, at a high speed. Also, be sure to

follow the safety instructions that came along with your soldering iron. Wash your

hands after handling solder. Especially before eating. Be safe, and enjoy.

!

Assembling the PCB

Switch Installation:

Make sure that the switch

is being installed on the

top side of PCB. There is

no orientation to the

switch. Refer to these

photos.

Switch Soldering:

The switch needs to be standing perfectly

vertical on the PCB. We use a ‘Helping

Hands’ tool to hold the solder.

This way, your fingers hold the switch,

and the other hand is free to solder.

Solder one tab, and see if the switch is

90˚ to the PCB.

Resistor Preparation:

There are 2 resistors in the kit. One

100 Ohm (brown black brown), gets

installed into [R1]. The 220 Ohm (red-

red-red) gets installed in [R2].

Bend the legs like in the photos here,

with the leg as close as possible to the

body of the resistor.

Resistor placement and soldering:

1- Place the resistors in place as

the photo above.

2- Flare the legs

to hold the

resistors in place

3- Solder the 4

legs on the

bottom side of the

PCB.

4- While wearing

safety glasses,

Trim the excess.

Screw terminal placement and soldering:

1- Slide the 2 screw

terminals together joining them

into one single 4 pin strip.

2- The holes in

the screw

terminals need to

be aiming away

from the switch.

3- Solder all 4 pins.

Aligning and soldering the LED:

1- Notice the different lengths of

the legs on the LED. Leg #2 is

the longest. #1 is the second

longest, and #3 is the shortest.

The LED gets installed with leg

#1 closest to the edge of the

PCB.

Important to note:

The LED gets installed on the

bottom side of the PCB.

123

2- Slide the 3 LED legs down

through the holes in the PCB.

3- Leaving about

.25” of leg bend the LED so that it

can bend like the photo in step #4.

4- Bend the led like in this photo,

and hold it in place.

5- Solder the three legs of the LED,

and snip the excess.

Placing and installing the snap switch:

1- The snap switch gets installed

on the bottom side of the PCB.

The hinge side of the snap

switch goes on the indicated

side on the PCB.

2- Line up the 3 pins with the

three holes on the PCB.

3- Press firmly on the snap switch,

making sure it is flush with the

surface of the PCB.

4- Solder one pin, and check to

make sure the snap switch is flush

with the PCB.

5- Solder the other two pins.

Hinge

Peel the protective film

All of the acrylic parts have a cling film that protects the pieces during manufacturing

and transport. The film or tape may be blue, brown or white. Start at a corner, and

remove the film from both sides of each piece.

Ready the motor, motor mount, and fasteners

Line up the 2 long screws, 2 small washers, 2 motor mount acrylic pieces, and weld

nuts as you see below.

Motor mount arm side

2x 1” 4-40 screws

2x #4 weld nuts

2x #4 washers

Motor mount wire side

Motor

Wire

Side

Nub

Attaching the motor to the mount

Hold the motor with the wires on the

left and away from you. The ‘nub’

facing you.

Place the arm side motor mount acrylic

piece over the motor, making sure that

the ‘nub’ fits in the hole in the mount.

Nub

Hold the other motor mount as

above. Place against the wire

side of the motor

Place the weld nuts into the holes on the

arm side of motor mount.

The weld nuts

Hold the weld nuts in place

with tape or your fingers. In

the next step we will be

screwing them in place.

Nub

Place a washer on each

of the long screws While holding the weld nuts in place, slide both screws

through the washers, motor mount, motor and screw into

the weld nut. For the moment, leave the screws loose

enough so that the motor mount plastic can wiggle a little.

With the screws a little loose, press

down against a flat surface, so that

the both bottoms of the motor

mount are flat.

Keeping the bottoms of the motor

mount flat against the surface,

tighten both screws. Do not over-

tighten, you may crush the motor.

Attaching the PCB assembly

Take the PCB that you’ve previously

assembled.

Place the PCB assembly over the

motor assembly.

Note how the acrylic tabs fit

through the holes in the PCB.

You will be using these nuts and screws to hold

secure the PCB to the motor mount.

3/8” 4-40 screws

4-40 nuts

Slide the nut into the

slotted area in the mount,

and start sliding the

screw through the hole in

the PCB.

Using your fingers,

tighten the screw.

Make sure the nut

does not slide out.

Finish tightening the

screw using a

screwdriver.

In the same way, slide in the other nut, on the other side, and attach the other screw.

!In order to attach the arm, the motor spindle should be in

the 12 o’clock position (or close to it). Check yours.

✘Bad ✘Bad

12 o’clock position

✔Good

If your motor happens to be in the correct 12 o’clock position,

skip to: Attaching the arm

Adjusting the motor shaft position

!Skip this step if your motor shaft is already in a

12 o’clock position - from the previous step

Load 2x AA batteries into

the battery holder.

Do not try to twist the motor spindle

by hand, or using the arm. We will

show you how to use the battery

pack to rotate the motor.

Touch the red and black wires to the wires

connected to the motor. Pull one of the

wires away and check the position of the

motor shaft. Repeat until you have the

motor shaft at a 12 o’clock position.

Really close is good too.

Once done, remove the batteries from the

holder and set it aside.

Attaching the arm

Locate these parts:

#2 screw #12 washer

#2 washer

The arm

Place the large washer over the motor spindle.

Note: The washer and arm get attached to the

LED / Switch side.

The large washer in place.

Align the arm piece so that the laser cut hole will fit the motor spindle. Press the arm

over the spindle until the top of the spindle and the arm plastic are flush. The arm

does not get pushed all the way down to the washer. Make sure not to bend the level

on the snap switch with the arm, as you are attaching the arm to the motor spindle.

Do not try to move the arm with your hand.

You will break the gears in the motor

!

Put the #2 washer on

the #2 screw.

Using a screwdriver, screw in the screw and washer to

secure the arm.

Installing completed motor assembly

Line up the 2 slots, and place the

motor assembly in place.

Next, we will be attaching

the base.

Set up the bottom panel, and

the motor assembly in this

orientation in front of you.

Note, the arm side of the base

has the slot closer to the slot.

Slide the screw through the base, and

side the nut in so it rests in the slot.

Tighten with a screwdriver, do not over

tighten.

Do the same on the other side of the

assembly. Slip the nut in the slot, and

slide the screw up from the bottom

Tighten with a screwdriver, do not over

tighten.

You will be using these nuts and screws to hold secure

the motor mount assembly to the bottom plate.

3/8” 4-40 screws

4-40 nuts

Attaching the wires

To attach the wires, you will need a

small flat blade screwdriver. Start by

sliding the black wire from the battery

pack in to the screw terminal marked

-BLACK on the PCB.

The red wire from the battery pack goes

to the +RED screw terminal. Screw both

in place.

Note: Make sure to tighten the screw terminals onto the bare wire, and not the colored

plastic casing. You may have to loosen the screw terminal in order to get the wire in.

The bottom wire coming off the motor

goes beside the black wire. Handle

these wires carefully, the terminals on

the motor are not very robust.

Slide in and screw down the wire.

The top wire from the motor connects to

the last screw terminal. Slide it in place,

and screw it down.

Motor and wiring testing flowchart

Flip switch - away from arm

Install batteries

Arm should move down

(If not already in

the down position)

Flip switch - towards arm

Works well?

Continue to next step

No

Yes

Troubleshooting

No movement at all:

- Check batteries.

- Verify black goes to (-) and red to

(+) on the PCB assembly.

- Make sure bare wire is making

contact in each of the screw

terminals, and not the plastic

covering.

Arm moves the wrong way:

- Switch the position of the two wires

from the motor going to the screw

terminals on the PCB assembly

After troubleshooting, test with this

flowchart once again.

No

There are four mounting holes on the base to

mount the mechanism into the box you create.

We included four 1/8” washers so that if

required, the base can be bolted down inside

your box .

Arm does not toggle the switch:

- Loosen the 2x 1” screws that go

through the motor and mount a little.

Table of contents

Other spikenzielabs Control Unit manuals