7

it cool at least 2 minutes before

removing the gas cap. Loosen gas cap

slowly to relieve the pressure in the tank.

Fill fuel tank outdoors and never overfill

the tank.

When storing gasoline or equipment

with fuel in tank.

Store away from appliances or

equipment that have a pilot light or other

ignition sources because they can ignite

gasoline vapors.

ENGINE SAFETY PRECAUTIONS

Do not touch hot surfaces. Allow

equipment to fully cool down before

touching.

After the generator has been run, the

engine produces heat. The temperatures

of the muffler and nearby areas can

reach or exceed 1600F. Severe burns

will occur on contact with skin.

Do not modify the generator in any way.

The generator supplies the rated voltage

and rated frequency at its governed

speed.

GENERATOR SAFETY

Never overload your generator as this

can damage your generator or the

electrical devices connected to it.

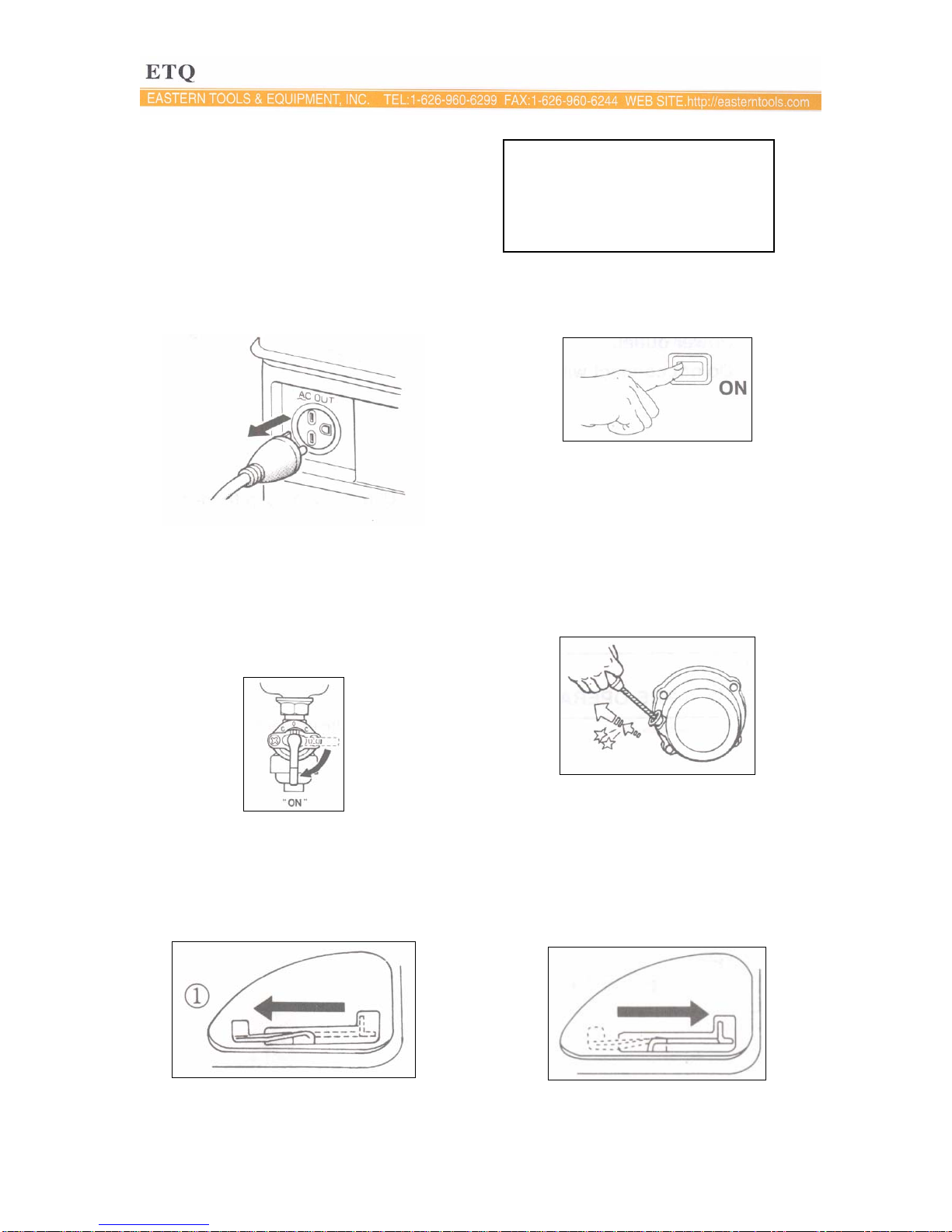

Do not start generator with electrical

devices connected to it. Start the

generator first and after the speed of the

generator stabilizes, electrical loads can

be applied to it.

When connecting electrical loads, make

sure the devices are “OFF” first before

connecting them. Keep the same

concept when disconnecting electrical

devices, make sure all devices are in the

“OFF” position before disconnecting.

Operate the generator on level surfaces

only. Inclined surfaces reduce the

effective lubrication of the engine.

Do not expose the generator to excessive

moisture, dust, dirt, or corrosive vapors.

PREPARATION BEFORE

OPERATION

Before starting the generator, verify the

following conditions.

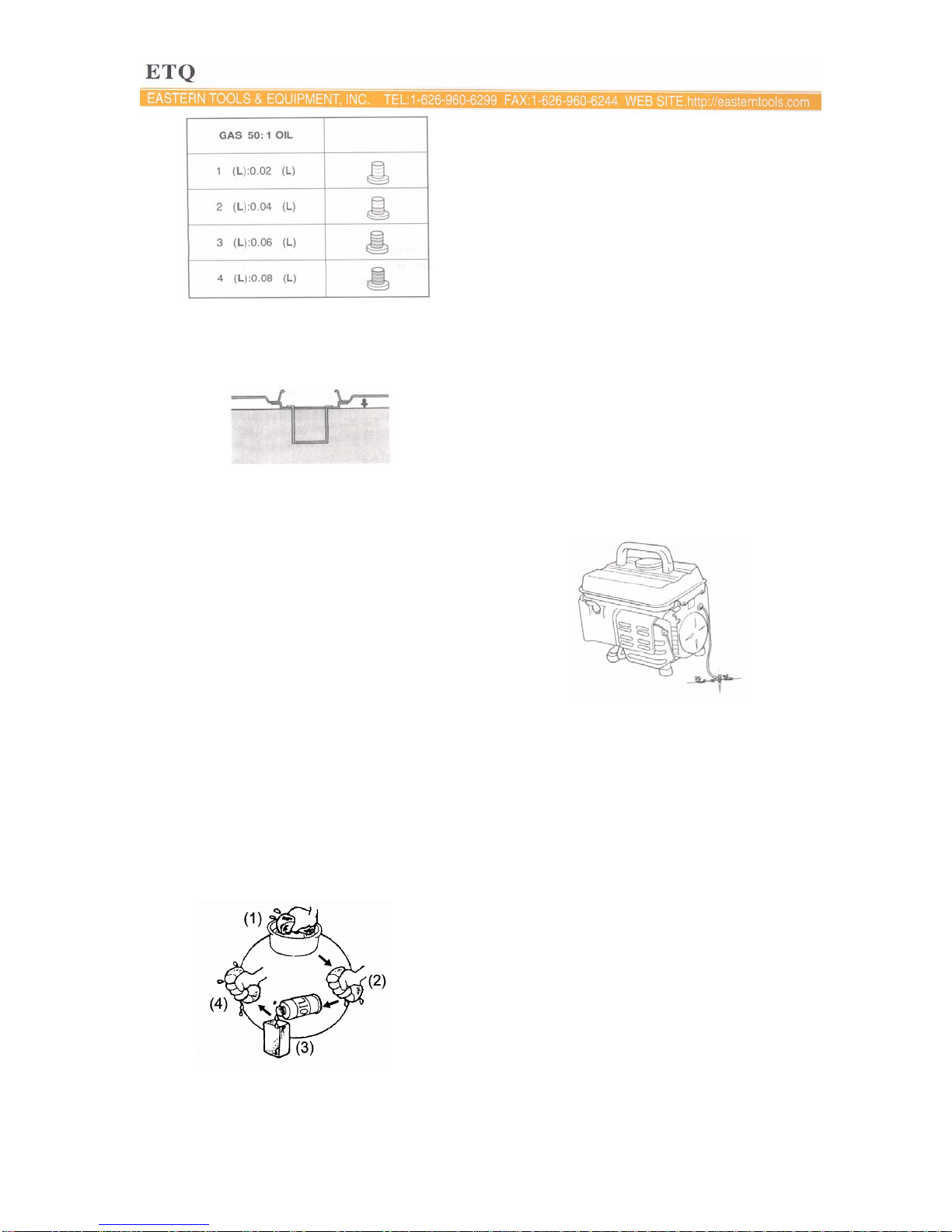

GASOLINE

•Add premixed oil and gasoline

and never fill the fuel tank

indoors. Also, be sure to install

the fuel tank cap on tight after

filling. Premix ratio should be

50 parts gasoline and 1 part 2

stroke oil. Use fuel tank cap to

measure oil.