Euro Chef Pasta Chef PL6 User manual

2

INDEX

1) WARNINGS Page 2

2) SPECIFICATIONS AND TECHNICAL DATA Page 2

3) INSTALLATION INSTRUCTIONS Page 3

Positioning Page 3

Water connection Page 3

Electrical connection Page 3

4) SETTINGS Page 3

Cooking time settings Page 3

Set points for the electronic board Page 4

5) SELFTEST Page 5

6) SAUCE HEATER (only in the PL6 model) Page 5

7) READING OF THE PORTIONS SUPPLIED Page 5

8) KEYBOARD MESSAGES Page 6

REV.

DATA

MODIFIED PAGES

1

16/06/15

2, 3

2

08/07/15

4

1) WARNINGS

The machines works with boiling water. Take care when opening.

Carry out maintenance work only with the machine disconnected from the mains.

The machine is not waterproof, therefore do not clean with water jets.

Do not switch on the machine without water in the basin and without baskets

Eurochef declines all responsibility where improper use of the machine causes personal injury accidents or damages

to property.

2) SPECIFICATION AND TECHNICAL DATA

Baskets working separately with different time scales.

Basket control with 4 pre-set times for each basket.

PL6 with sauce-heater

PL7 without sauce-heater

Reprogramming times:

Keyboard operated

Basin capacity:

10 litres approx.

Water control:

automatic, with probe for stand level and temperature

Water supply:

by means of 4.5 lt reserve tank

Possibility of connection to the water mains by the same solenoid valve.

Water heating:

immersed heating element

Steam elimination

recirculation extractor

Sauce-heater

Heating thermostate plate, 200 W

Total power

consumption

2,85 Kw

2,6 Kw

Water heating power

consumption

2,5 Kw

2,5 Kw

Power supply

220/400 V - 50/60 Hz

220/400 v –50/60 Hz

Dimensions

width 67 cm

depth 47 cm

height 55 cm

width 57 cm

depth 47 cm

height 55 cm

Empty weight:

Kg 29

Kg 26

3

3) INSTALLATION INSTRUCTIONS

Positioning

The machine must be placed in a proper ambient and with a good ventilation, protected from atmospheric agents.

As the machine does not totally eliminate the produced steam, an efficient extractor may be installed to exchange the

air.

The machine has to be placed ensuring that the top is clear of obstructions, and leaving a clearance of at least 15 cm

on each side for ventilation.

It must be level. If necessary, check the height of the feet by unscrewing or screwing them up having first loosened

the locknut.

Slide the condensation collecting tray into the guides under the machine. This was not mounted for safety during

transport .

Water connection

If mains water is available it is worthwhile having a permanent supply to the machine.

To do this, remove the sauce heater and the right side wall and disconnect the fittings which connect the electro-

valve to the internal water tank.

Connect the electro-valve directly to the water mains using a food-grade plastic tube which must pass through the

hole in the bottom of the plate.

The fittings for the electro-valve are G1/8 in size or G1/4.

Install a ball valve near the machine to cut off the water while maintenance of the electro-valve is taking place.

When it is not possible to connect the machine to the water mains, water is supplied from an internal tank accessible

from the top of the machine, which is filled before using the machine and which is refilled during operation of the

machine.

WHEN FIRST REFILLING THE TANK CHECK THAT THERE ARE NO AIR BUBBLES IN THE CONNECTION

TUBE THAT MIGHT OBSTRUCT THE WATER FLOW. IF NECESSARY, PRESS THE TUBE TO REMOVE THE

AIR.

NB: When heating for the first time the tank will only be refilled when the temperature of the water is higher than

90°C.

Electrical connection

Ensure that the plant is well earthed, according to IEC regulations, and check that the current corresponds with that

stated on the registration plate on the machine.

Finally, check that the plant to which the machine is connected has the power shown on the registration plate.

There must be an automatic, fused or thermally protected switch between the machine and the electric mains supply.

In case of malfunction of the machine, do not try to repair it temporary.

Contact the seller or, if necessary, the manufacturer.

The guarantee expires if the machine is tampered or in case that non-original spare parts are used.

If the power supply cable is damaged, it has to be changed from the manufacturer or from its technicians, to prevent

any risk.

In any case, the power supply cable must have the designation HO7RN-F with dimension 3 x 1.5 mm2.

4) SETTINGS

Cooking time settings

When the "ON-OFF" green light is on, press the "TIME SET" button to enter the programming mode. "01" appears

on the left display to indicate that you are in programme 1, which corresponds to the time preset for the yellow button

1.

Programming is carried out using the yellow buttons 1, 2 and 3.

Button 1 is used to display preset values and to memorise new values, button 2 to increase the values displayed on

the left display and 3 to decrease them.

Therefore, when the display indicates 01 (the first programme) press button 1 to display the preset time.

To increase it press button 2, to decrease it press button 3. When the desired time is displayed, press button 1 to

memorise it. The number 01, of the programme being worked on, will again appear on the display. To change

programme, use button 2 ( increase) and 3 ( decrease).

Carry on similarly to change the times of the other programmes (see the list in the previous paragraph). Finally, press

the "TIME SET" button again to exit from the programming mode.

4

Set points for the electronic board

The standard default values are shown for use by the service technician. Remember that, with the exception of the

preparation times for the portions, the user is prohibited from changing the programming of the electronic

card, tampering with which could cause irreparable damage.

The manufacturer declines all responsibility in the case of unauthorised intervention on the programming of the card

and any such programming will render null and void the guarantee.

Programme Value checked Value set number

01 immersion time button 1 left 40 seconds

02 immersion time button 2 left 90 seconds

03 immersion time button 3 left 150 seconds

04 immersion time button 4 left 600 seconds

05 immersion time button 1 right 60 seconds

06 immersion time button 2 right 120 seconds

07 immersion time button 3 right 180 seconds

08 immersion time button 4 right 600 seconds

09 water temperature 97°C*

10 hysteresis 00

11 left basket rising time 40 second tenths

12 draining time 30 second tenths

13 fan intervention temperature 40°C

14 left basket descending time 35 second tenths

15 low temperature time-out time 999 seconds

16 max.basket motion time 25 seconds

17 time for level alarm switch on 10 seconds

18 max time for refill 20 minutes

19 motion time to offload left basket 30 second tenths

20 right basket rising time 46 second tenths

21 right basket descending time 35 second tenths

22 motion time to off-load right basket 33 second tenths

23 interval motion baskets 20 seconds

24 part-load heating 01 minute

25 off 00

26 draining pause 0 off 1 on

To change the programming, except for the first 8 programmes, the programme switch on the electronic board must

be operated, or press keys 1 and 4 on the right at the same time, together with the “Time Set” key.

The method of programming is the same as illustrated in the previous paragraph for the portion preparation times.

N.B: If the machine is installed well above sea level, boiling temperature may be lower than the set-point

value. In this case the element is always connected because the set point is never reached. The machine

must therefore be calibrated approximately to a value of 2° C less than the boiling temperature.

WATER BOILING TEMPERATURES

Altitude above the sea-level Temperature °C

200mt 99,3° C

400 mt 98,6° C

600 mt 97,9° C

800 mt 97,2° C

1000 mt 96,5° C

1200 mt 95,8° C

1400 mt 95,1° C

1600 mt 94,4° C

1800 mt 93,7° C

2000 mt 93,0° C

2200 mt 92,3° C

2400 mt 91,6° C

2600 mt 90,9° C

2800 mt 90,2° C

3000 mt 89,4° C

5

5) SELFTEST

In the lower part of the electronic board, at the right side of the microprocessor, there are two small pins (contacts).

To enter in the self-test mode, keep them in short-circuit while switching on the machine. This can be made also

using a screwdriver, paying much attention to avoid touching other alive parts of the electronic board.

Two numbers will appear on the displays: the left one has no meaning, while the one at the right side is the release

number of the software.

The upper and the lower leds remain lit, and this can be helpful to place correctly the sticker of the keyboard if it has

to be changed.

Press ON/OFF push- button to test the displays: letters UAO appear at the left side, then at the right side, then 888

appears on both the displays.

When the left-hand display shows letters I O, the push buttons, including “TIME SET” and “ON/OFF”, can be tested.

Pushing one button, its number is shown on the display and the relevant led turns on. “TIME SET” is nr. 9 “ON/OFF”

is nr. 10.

Pressing ON/OFF, the test of the buttons ends and the temperature probes are checked. The left hand display shows

the temperature read by the lower probe and the right-hand display shows the one read by the level probe. Toughing

the probes it is possible to see the temperatures changing.

Pressing TIME SET, the outputs of the electronic board are checked.

Push-button 1 is used to make the test. When an output is ON, led WAIT is on, when the output is OFF, the led

READY is on.

Push-button 2 is used to go to the following output and button 3 to go back to the previous one.

Initially the left-hand display shows U 1, i.e. output 1, which is the one of the control switch of the water heater.

Pressing 1 the output is activated, the control switch makes and the element becomes hot.

Pressing 2 the display shows U 2, which is the output of the air blower.

U 3 is the left-hand motor when it lifts the basket and U 4 the same motor when it lowers the basket.

In order to test also the microswitch of the motor, it is better to remove the baskets before making the test.

In this way the motor shaft can turn freely and the lever of the microswitch can enter and exit from the slot of its cam.

When the left-hand microswitch feels the slot, the led of the left-hand push-button 1 turns on, while when testing the

right-hand microswitch, the led of the right-hand push-button 1 turns on.

U 5 is the right-hand motor lifting the basket.

U 6 is the right-hand motor lowering the basket.

U 7 is the sauces element.

U 8 is the water solenoid-valve.

U 9 e U A are not in use.

Pressing TIME SET the program exits from the self-test.

6) SAUCE HEATER (only in PL6 model)

The sauce-heater basins are placed on a thermostatically-controlled heating plate.

The working temperature of this plate should be left fixed, but should regulation be needed, turn the knob of the

thermostat placed under the electronic card on the left side of the machine, remembering that before removing the

hatch enclosing the electrical parts, it is very important to switch off the current to the machine.

Temperatures advisable for sauces vary from about 65 to 80 degrees Centigrade.

Lower temperatures favour the growth of bacteria, while at higher temperatures the sauces cook and stick to the

bottom of the basin.

7) READING OF THE PORTIONS SUPPLIED

To read the number of portions supplied, press yellow buttons 1 and 4 at the same time.

The figure shown on the display on the left indicates values up to 999, while each LED alight on the yellow and white

buttons indicate a thousand.

For example, if the display indicates 452 and two LEDs are alight, then 2,452 portions have been supplied.

The count goes as far as 8,999 portions, and then is zeroed.

6

8) KEYBOARD MESSAGES

Some possible malfunctions are shown by an error code which appears on the left display together with an

alternating acoustic signal.

In this case the machine remains blocked until conditions return to normal.

Before asking for technical assistance carry out a reset test by turning the machine off and then on using the master

switch.

Malfunction messages are as follows

A01 No heating

The card does not show the increase in temperature with the heating ON. The probe may be broken or the

heating relay may be defective.

A02 Probe not connected or temperature too high

The cause of the signal may be malfunctioning of the probe.

A03 Non-control of the left motor

The signal indicates that the motor does not stop at the preset time which might be because

1) the cam on the motor itself has shifted or 2) the relevant microswitch is broken or 3) a total motion time of the

basket was preset which is higher than the limit (normally 25 seconds) foreseen for programme 16.

A04 Non-control of the right motor

As above

A05 Heating not working properly

During the heating phase the temperature does not increase within the time foreseen in programme 15.

A06 Non-control of the level

The probe does not read the level or shows a temperature under zero.

A07 Level probe short circuited

A08 The heating is turned off after a long period without water.

This message can appears also when water in the basin is at a temperature of about 0° C.

7

PICTURE A

MAIN SWITCH HEATING ELEMENT CONNECTOR

KEYBOARD TEMPERATURE LEVEL WATER

PROBE PROBE JUNCTION

8

PICTURE B

HEATING RELAY TRANSFORMER BLOWER

ELECTRONIC BOARD SAUCES MICROSWITCH MOTOR OF THE

THERMOSTAT LEFT BASKET

9

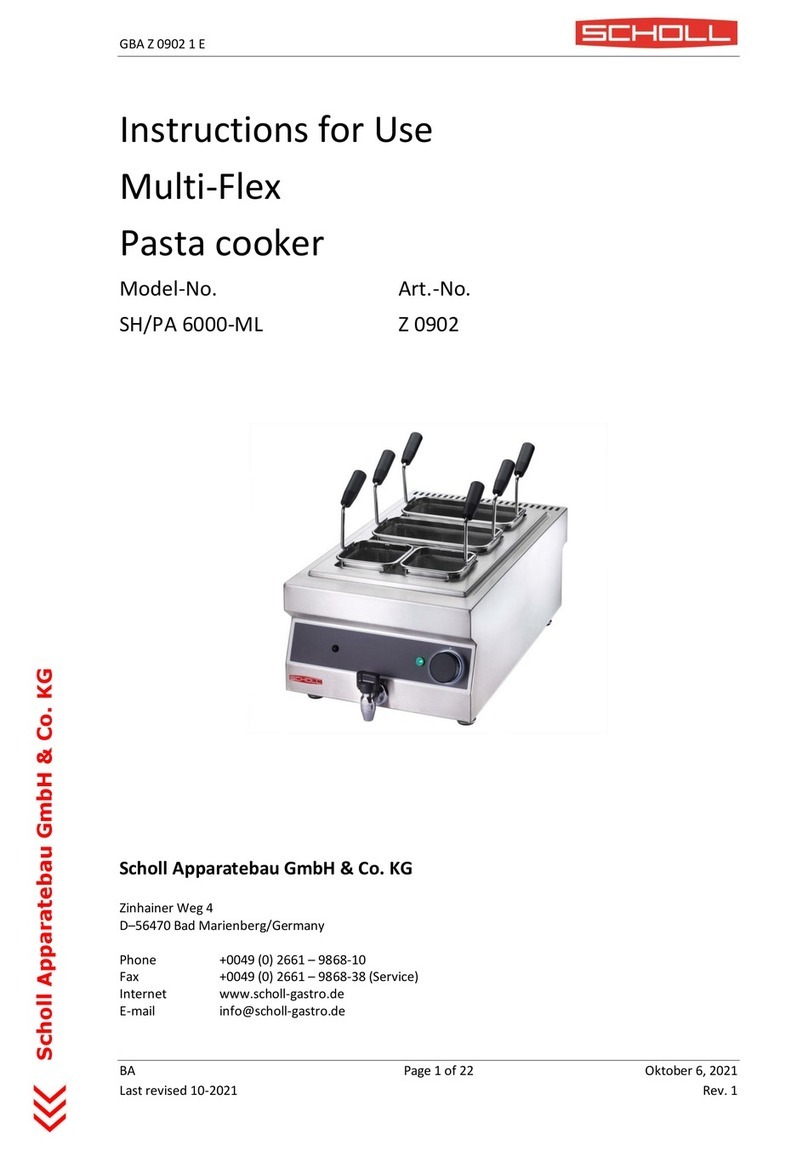

PICTURE C

SAUCE WARMER WATER TANK

MICROSWITCH MOTOR OF THE RIGHT BASKET SOLENOID VALVE

10

This manual suits for next models

1

Table of contents

Popular Pasta Maker manuals by other brands

Whirlpool

Whirlpool AGB 448/WP Installation, Operating and Maintenance Instructions for the Installer and the User

Ernesto

Ernesto HG00385 Operation and safety notes

Andrew James

Andrew James Pasta Maker manual

Philips

Philips HR2375 user manual

Kuppersbusch

Kuppersbusch EFS 4710.0 Directions for use

Philips

Philips HR2355/09 user manual