Euroboor EDC.355 User manual

Operators manual

V 1.0 | EN | April 2022

Dry Cut-Off Metal Saw

14" / 355 mm

EDC.355

www.euroboor.com

2

Congratulations on the purchase of your EUROBOOR EDC.355 Dry Cut Off Metal Saw. At

EUROBOOR we strive to exceed our customers’ expectations by developing and providing

premium and innovative portable drilling and cutting solutions. We believe that a professional

like you must be able to rely on a professional supplier. Which has led us to become a major

player in the industrial world, with our own factory and several offices worldwide. All because

we have always listened to our customers and to the demands from the market.

Our vision is focused on developing innovative portable tools that add value for our customers

and facilitate them in their daily work. We never lose sight of sustainability, time savings and

cost savings.

Enjoy your new machine!

Before operating your dry cutting machine, please read all instructions first. These include the

Operators Manual and warning label on the unit itself. With proper use, car and maintenance

your model will provide you with years of effective metal cutting performance.

TO REDUCE THE RISK OF INJURY USER MUST READ AND UNDERSTAND ALL INSTRUCTIONS

To view all our offices and their contact information please visit: www.euroboor.com

The original manual has been produced in the English language. If any discrepancies should

occur in translations, reference must be made to the original version for clarification.

www.euroboor.com

3

Table of contents

Table of contents .............................................................................................................. 3

. Safety ........................................................................................................................... 4

1.1 General safety instructions .............................................................................................. 4

1.2 Specific safety information ............................................................................................... 8

2. Description ................................................................................................................. 0

2.1 intended use ................................................................................................................... 10

2.2 Description and features ................................................................................................ 11

2.3 Box contents ................................................................................................................... 12

2.4 Serial number ................................................................................................................. 12

2.5 Technical data ................................................................................................................ 13

2.6 Symbols .......................................................................................................................... 14

2.7 Environmental ................................................................................................................ 15

3. Preparation & adjustment ........................................................................................... 6

3.1 Assembly ........................................................................................................................ 16

3.2 Prior to use ..................................................................................................................... 16

3.3 Fitting the blade ............................................................................................................. 18

3.4 Replacing the blade ........................................................................................................ 19

3.5 Setting cutting angle ....................................................................................................... 21

3.6 Clamping the workpiece ................................................................................................. 22

3.7 Adjusting cutting depth .................................................................................................. 24

4. Using the machine ...................................................................................................... 25

4.1 Turning the motor on and off......................................................................................... 25

4.2 Restart mid cut ............................................................................................................... 26

4.3 Carrying the machine ..................................................................................................... 26

5. Maintenance ............................................................................................................... 27

6. Troubleshooting .......................................................................................................... 29

7. Exploded view & Partslist ............................................................................................ 30

7.1 Exploded view ................................................................................................................ 30

7.2 Spare parts list ................................................................................................................ 32

8. Warranty and service .................................................................................................. 35

9. Certifications............................................................................................................... 36

9.1 CE declaration of conformity.......................................................................................... 36

9.2 Intertek proof of certification ........................................................................................ 37

www.euroboor.com

4

. Safety

. General safety instructions

WARNING: When using the Dry Cut-Off Metal Saw, basic safety precautions should

always be followed to reduce the risk of fire, electric shock and personal injury.

READ AND UNDERSTAND ALL SAFETY INFORMATION AND INSTRUCTIONS. ailure

to follow the warnings and instructions may result in electric shock, fire and/or

serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

This Operator’s Manual including the “General Safety Instructions” should be kept for later

use and enclosed with the power tool, should it be passed on or sold.

The term “power tool” in the warnings refers to your mains operated corded power tool.

Please also observe the relevant national industrial safety regulations. Non observance of the

safety instructions in the said documentation can lead to an electric shock, burns and/or

severe injuries.

www.euroboor.com

5

WORK AREA SAFETY

1. Keep your work area clean and well lit. Cluttered benches and dark areas increase the

chance of accidents;

2. Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks which may ignite the dust

or fumes.

3. Keep bystanders, children, and visitors away while operating a power tool. Distractions

can cause you to lose control.

ELECTRICAL SAFETY

DANGER

1. Power tool plugs must match the outlet. Never modify the plug in any way. Do not use

any adapter plugs. Unmodified plugs and matching outlets will reduced risk of electric

shock.

2. Avoid body contact with grounded surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is earthed or

grounded.

3. Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

4. Do not abuse the cord. Never use the cord to carry the power tool or pull the plug from

an outlet. Keep cord away from heat, oil, sharp edges or moving parts. Replace

damaged cords immediately. Damaged cords increase the risk of electric shock.

5. When operating a power tool outdoors, use an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the risk of electric shock.

6. If operating a power tool in a damp location is unavoidable, use a residual current

device (RCD) protected supply. Use of an RCD reduces the risk of electric shock.

www.euroboor.com

6

PERSONAL SAFETY

WARNING: Wear ear and eye protection when using this power tool.

1. Stay alert, watch what you are doing and use common sense when using a power tool.

Do not use machine while tired or under the influence of drugs, alcohol, or medication.

A moment of inattention while operating power tools may result in serious personal

injury.

2. Use personal protective equipment. Always wear eye protection. Protective equipment

such as dust mask, non skid safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

3. Prevent unintentional starting. Ensure switch is in the off position before connecting

to power source and/or battery pack, picking up or carrying tool. Carrying power tools

with your hand on the switch or energising power tools while pressing the switch,

invites accidents.

4. Remove any adjusting key or wrench before turning the power tool on. A wrench or a

key that is left attached to a rotating part of the tool may result in personal injury.

5. Do not overreach. Keep proper footing and balance at all times. This enables better

control of the power tool in unexpected situations.

6. Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing, and

gloves away from moving parts. Loose clothes, jewellery, or long hair can be caught in

moving parts.

7. If devices are provided for the connection of dust extraction and collection facilities,

ensure these are connected and properly used.

8. Never place hands, fingers, gloves or clothing near cutting area or rotating machine

parts.

POWER TOOL USE AND CARE

1. Secure your workpiece properly. The workpiece should be clamped to avoid possible

movement and pinching as the cut nears completion.

2. Do not force the power tool. Use the correct power tool for your application. The

correct power tool will do the job better and safer at the rate for which it was designed.

3. Do not use the power tool if the switch does not turn it on or off. Any tool that cannot

be controlled with the switch is dangerous and must be repaired.

4. Disconnect the plug from the power source before making any adjustments, changing

accessories, or storing power tools. Such preventive safety measures reduce the risk of

starting the power tool accidentally.

www.euroboor.com

7

5. Store power tools out of the reach of children and do not allow person unfamiliar with

the power tool or these instructions to operate the power tool. Power tools are

dangerous in the hands of untrained users.

6. Maintain power tools. Check for misalignment or binding of moving parts, breakage of

parts, and any other condition that may affect the power tool’s operation. If damaged,

have the tool serviced before use. Many accidents are caused by poorly maintained

tools.

7. Keep cutting tools sharp and clean. Properly maintained tools, with sharp cutting edges

are less likely to bind and are easier to control.

8. Use the power tool, accessories and tool bits, etc. in accordance with these

instructions, taking into account the working conditions and the work to be performed.

Use of the power tool for operations different from those intended could result in a

hazardous situation.

9. Use only accessories that are recommended by EUROBOOR for your power tool.

Accessories that may be suitable for one machine, may become hazardous when used

on another power tool.

SERVICE

1. Power tool service must be performed only by qualified repair personnel. Service or

maintenance performed by unqualified personnel could result in risk of injury.

2. When servicing a power tool, use only identical replacement parts. Follow instructions

in the maintenance section of this manual. Use of unauthorised parts or failure to

follow maintenance instructions may create a risk of electric shock or injury.

RESIDUAL RISKS

In spite of the application of the relevant safety regulations and the implementation of safety

devices, certain residual risks cannot be avoided.

•Impairment of hearing

•Risk of personal injury from flying particles

•Risk of burns due to accessories becoming hot during operation

•Risk of personal injury due to prolonged use.

Always try to reduce these risks as much as possible.

www.euroboor.com

8

.2 Specific safety information

WARNING: This tool is intended to function as Dry Cut-Off Metal Saw. Read all safety

warnings, instructions, illustrations and specifications provided with this tool. ailure

to follow all instructions listed below may result in electrical shock, fire and serious

injury.

Safety instructions

1. Fully assemble your metal cutting saw before operation.

2. Secure your workpiece properly. Work should be clamped to avoid possible movement

and pinching as the cut nears completion.

3. Please do the following safety checks before you start using the machine.

a. Always check if all bolts, screws and clamps are fully tightened. Tighten loose

bolts before use. If bolts, screws or clamps are missing, please refer to your

EUROBOOR dealer and have these replaced.

b. Always check if the blade can run freely before you start working with the

machine. Have the Dry Cut Off Metal Saw serviced by qualified repair personnel

at your EUROBOOR dealer, if the blade cannot run freely or vibrates heavily.

c. Check the blade for cracks or other damage before operation. Do not use blade

when it is damaged or deformed.

d. Check if your workpiece is properly secured, using the machine’s clamp.

e. Check if the blade of the machine is not contacting the workpiece before the

machine is turned on.

4. Turn the machine on, but allow the motor to come up to full speed before you start

cutting.

5. Lower the blade onto the material firmly.

6. Wait for the blade to come to a full stop before making adjustments to the machine or

removing / securing the workpiece.

7. Always shut off and unplug machine before servicing or adjusting the machine.

8. Save the instructions manual and warning labels at all times.

www.euroboor.com

9

Safety warnings

1.Do not operate your metal cutting saw until it is completely assembled and installed

according to the instruction.

2. Do not operate your metal cutting saw when bolts, screws and clamps are missing or

not fully tightened.

3. Do not operate the machine if you are not familiar with the operation of a metal cutting

saw. Please obtain advice from a qualified person.

4. Do not use the machine in area’s with flammable liquids or gasses.

5. Do not use the machine in damp area’s or when it is exposed to rain.

6. Do not use the machine if the blade cannot run freely or vibrates heavily.

7. Do not reach behind or over the cutting tool when it is connected to the power source.

8. Do not reach your hands in or near the path of the saw blade.

9. Do not cut any objects that are not clamped, using the clamp of the dry cutting

machine.

10. Do not make any adjustments to the machine, removing or securing the workpiece,

when the blade has not come to a full stop.

11. Do not use a sawing blade with a larger outer diameter than the machines maximum

of 355 mm (14").

12. Do not remove any guards from the machine, as they contribute to the safety level of

the machine.

13. Do not allow the blade to chatter and jump as this may cause increased wear on the

blade, resulting in poor cutting and possible broken blade teeth.

www.euroboor.com

10

2. Description

2. intended use

This EUROBOOR EDC.355 Dry Cut Off Metal Saw is an electrically driven machine for cutting

various types of ferrous and non ferrous metals. The machine is designed to fit a 355 mm (14")

blade. The speed of the machine is 1,450 RPM, with soft start. The machine has an extra safety

button to prevent accidental starts. For cutting, the machine can be adjusted from 0° to 45°

corners. Also the dept can be adjusted using the depth adjustment screw.

WARNING: The machine should not be converted or modified, e.g. for any other

form of use, other than as specified in these operating instructions. Warranty will

be voided and the user shall be liable for damages and accidents due to incorrect

use.

www.euroboor.com

11

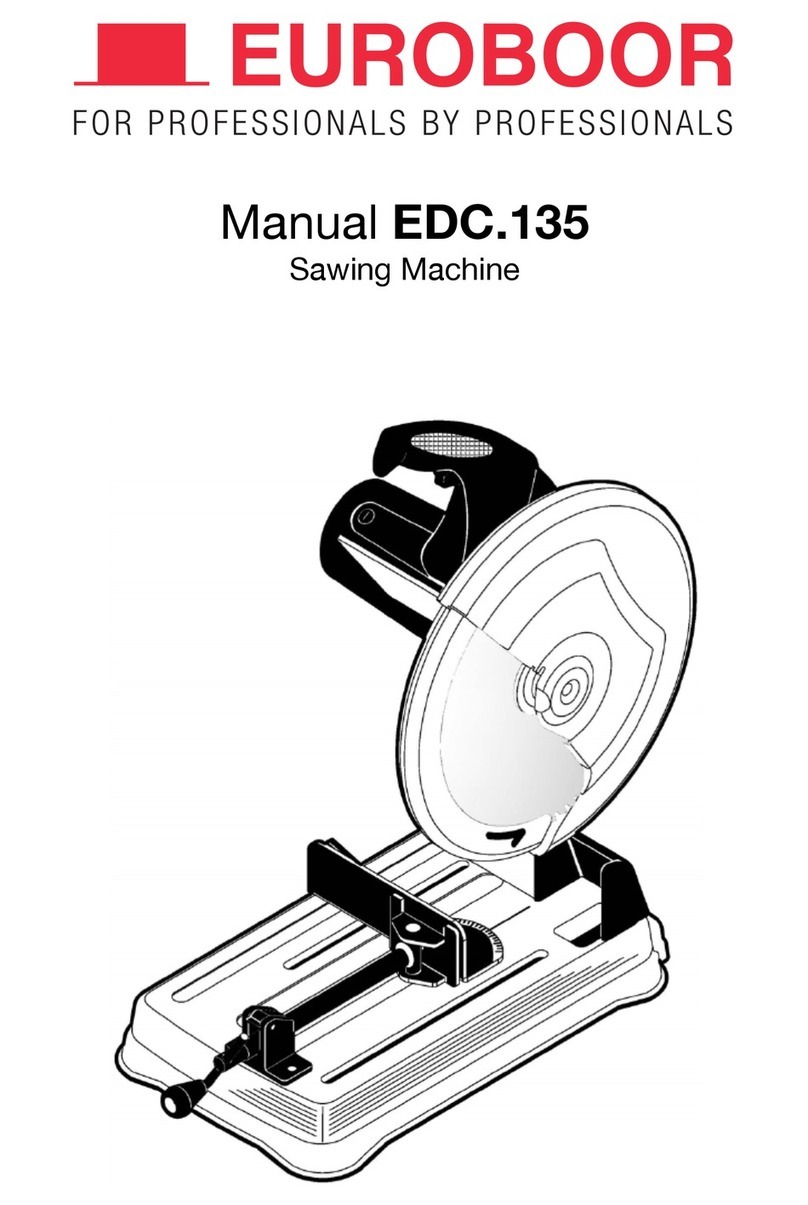

2.2 Description and features

[Image 2 1]

Refer to [Image 2 1 ] for the following features of the machine EDC.355.

1. Safety button 9. Aluminium base with size indication

2. On / off trigger 10. Engine cover / air intake

3. Hand protection shield 11. Arm lock pin

4. Retractable blade cover 12. Depth adjustment screw

5. Clamp knob 13. Angle indication

6. Spindle cover 14. Brand label

7. Dust cover 15. Sawblade

8. Dust collection tray

www.euroboor.com

12

2.3 Box contents

Note: When unpacking, make sure the parts listed below are included. If missing or broken,

please contact distributors as soon as possible.

1x Machine EDC.355

1x Instruction manual

1x Hexagon key M6

1x Hexagon key M10

2x Spare carbon brushes

2.4 Serial number

The serial number is mentioned on the machine twice: on the motor and base. The serial

number will help you and your sales point validate and identify the machine.

For example:

3552204001

Breaks down to:

355 22 04 001

Machine Year Month Identification number

Maintain labels, name plates and other machine identification. These carry important

information. Obtain replacements when unreadable or missing.

www.euroboor.com

13

2.5 Technical data

EDC.355 Metric Imperial

Folded dimensions (L x W x H) 530 x 350 x 420 mm 20 7/8 x 13 3/4 x 16 9/16"

Unfolded dimensions (L x W x H) 620 x 350 x 630 mm 24 7/16 x 13 3/4 x 24 13/16"

Weight 18.6 kg 41 lb

Motor power 2,480 W 11 A

Speed 1,450 rpm

Max. blade diameter 355 mm 14"

Bore diameter 25.4 mm 1"

Max. cutting angle 45°

Voltage 230 V 50/60 Hz 120 V 60 Hz

2.5. Cutting capacities

EDC.355 Metric Imperial

Cutting capacity 0° 105 x 105 mm 4 1/8 x 4 1/8"

Cutting capacity 0° 90 x 145 mm 3 9/16 x 5 11/16"

Cutting capacity 0° 120 mm 4 3/4"

Cutting capacity 45° 80 x 80 mm 3 1/8 x 3 1/8"

Cutting capacity 45° 90 x 80 mm 3 9/16 x 3 1/8"

Cutting capacity 45° 90 mm 3 9/16"

www.euroboor.com

14

2.6 Symbols

Symbol Term, meaning Explanation

Read documentation

Be absolutely sure to read the enclosed documentation

such as the Instruction Manual and the General Safety

Instructions

Wear ear protection Use ear protection during operation

Wear eye protection Use eye protection during operation

Dangerous electrical voltage Be sure the machine is safe for use, without any open

and/or protruding wires

Danger/warning/caution Observe the information in the adjacent text!

European conformity symbol Confirms the conformity of the power tool with the

directives of the European Community

ISO9001 Certified in accordance with ISO9001:2015 quality

management system.

Class of protection II

Product with double layered insulation. In case of

failure of the main layer of insulation the product

remains safe due to a second layer of insulation.

Intertek Licensed testing laboratory for CE certification

cETLus listed mark The product is approved for selling on the Canadian

and US markets.

mm Millimetre Unit of measure for the dimensions

" Inch Unit of measure for the dimensions

www.euroboor.com

15

Symbol Term, meaning Explanation

kg Kilogram Unit of measure for the mass

lb Pound Unit of measure for the mass

V Volt Unit of measure for the electric voltage

A Ampere Unit of measure for the electric current intensity

W Watt Unit of measure for the output

rpm Revolutions per minute Unit of measure for the motor speed

2.7 Environmental

Separate collection. This product must not be disposed of with normal household

waste.

Separate collection of used products and packaging allows materials to be recycled

and used again. Re use of recycled materials helps prevent environmental pollution

and reduces the demand for raw materials.

Local regulations may provide for separate collection of electrical products from the

household, at municipal waste sites or by the retailer when you purchase a new product.

www.euroboor.com

16

3. Preparation & adjustment

3. Assembly

The EUROBOOR EDC.355 machine comes pre assembled, but without blade attached. Fitting

the blade to the machine is necessary before operating the machine. Please refer to “3.3 fitting

the blade” for instructions on how to fit the blade. Further to this it is advised to check the

machine is complete and all standard accessories are included before proceeding in any way.

WARNING: Before undertaking any type of preparation or adjustment, make sure

the machine is switched off and the power supply is disconnected.

3.2 Prior to use

Prior to any use, check the machine and all of its components for damage and check that all

moving parts are in perfect working order and do not jam.

All parts must be correctly installed and must fulfil all conditions necessary to ensure perfect

operation of the machine.

A damaged and/or incorrectly functioning machine must be repaired or replaced according

the original specifications by EUROBOOR or any authorised EUROBOOR dealer or service

point.

DO NOT use under wet conditions or in presence of flammable liquids or gases.

DO NOT let children come into contact with the machine. Supervision is required when

inexperienced operators use this machine.

www.euroboor.com

17

ELECTRICAL SAFETY

The machine electronics have been designed for one voltage only. Always check that the

power supply corresponds to the voltage on the rating label.

EUROBOOR EDC.355 is designed in class II (double isolated). Earth grounding is not required.

If the power supply cord is damaged, it must be replaced by a specially prepared cord available

through the EUROBOOR service organisation.

EXTENSION CABLE

If an extension cable is required, use an approved extension cable suitable for the power input

of this tool (see technical data). The minimum conductor size is 1.5 mm²; the maximum length

is 30 meter. When using a cable reel, always unwind the cable completely.

www.euroboor.com

18

3.3 Fitting the blade

WARNING: Before undertaking any type of preparation or adjustment, make sure

the machine is switched off and the power supply is disconnected.

1. Remove the spindle cover by loosening the two bolts

using the M6 hexagon key.

2. Put on the spindle lock by using the spindle lock lever.

Carefully rotate the spindle, by hand, until the spindle

lock locks in place.

After the spindle is locked, keep the lock on and at the

same time, loosen the spindle bolt using the M10

hexagon key.

3. When the spindle bolt is loosened: remove the small flange and the front flange from

the driveshaft.

Note: Keep the back-flange in place.

4. Raise the retractable blade cover to its highest position.

While remaining in that position, the sawing blade can be

placed onto the spindle.

Note: Check the blade for cracks or other damage before

operation. Do not use blade when it is damaged or

deformed. Also check if the blade can run freely and

without vibrating.

www.euroboor.com

19

5. Lower the retractable blade cover and put the front flange and small flange back into

place.

6. Tighten the spindle bolt using the M10 hexagon key. Make sure the spindle is locked

using the spindle lock while tightening the spindle bolt.

7. Put the spindle cover back in place and tighten the bolts using the M6 hexagon key.

3.4 Replacing the blade

WARNING: Before undertaking any type of preparation or adjustment, make sure the

machine is switched off and the power supply is disconnected.

1. Remove the spindle cover by loosening the two bolts

using the M6 hexagon key.

2. Put on the spindle lock by using the spindle lock lever.

Carefully rotate the blade, by hand, until the spindle

lock locks in place.

After the spindle is locked, keep the lock on and at the

same time, loosen the spindle bolt using the M10

hexagon key.

www.euroboor.com

20

3. When the spindle bolt is loosened: remove the small flange and the front flange from

the driveshaft.

Note: Keep the back-flange in place

4. Raise the retractable blade cover and take out the current

blade.

WARNING: Be careful for sharp edges.

5. With the retractable blade cover still held in raised position, the new sawing blade can

be placed onto the spindle.

Note: Check the blade for cracks or other damage before operation. Do not use blade

when it is damaged or deformed. Also check if the blade can run freely and without

vibrating.

6. Lower the retractable blade cover and put the front flange and small flange back into

place.

7. Tighten the spindle bolt using the M10 hexagon key. Make sure the spindle is locked

using the spindle lock while tightening the spindle bolt.

8. Put the spindle cover back in place and tighten the bolts using the M6 hexagon key.

Table of contents

Other Euroboor Saw manuals

Popular Saw manuals by other brands

Makita

Makita XPS01 instruction manual

XTline

XTline XT106305 user manual

ABACO MACHINES

ABACO MACHINES S1 Instruction manual and safety instructions

MK Diamond Products

MK Diamond Products MK-170 SERIES Owner's manual & operating instructions

Logan Graphic Products

Logan Graphic Products F100-5 instruction manual

MasterCraft

MasterCraft 054-8151-4 instruction manual

Hitachi

Hitachi C 7SB2 Handling instructions

Dimas

Dimas Dimas WS 460 operating instructions

Evolution

Evolution S355CPSL Original instructions

MK Diamond Products

MK Diamond Products MK-2000 PRO Series Owner's manual operating instruction & parts list

Skil

Skil CR541801 owner's manual

Parkside

Parkside 282495 Translation of the original instructions